- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High-Performance Grade 5 Titanium Alloy Sheet Options

Procurement workers always look to grade 5 titanium alloy sheet solutions when they need high-quality materials with great strength-to-weight ratios and resistance to corrosion. These Ti-6Al-4V sheets are the best when it comes to high-performance uses. They give makers in aerospace, medicine, and industry the dependability they need. Knowing all of the different choices you have makes it easier to choose the best materials for important projects that need to meet strict standards of quality and accuracy.

Understanding Grade 5 Titanium Alloy Sheets: Composition, Properties, and Manufacturing

Ti-6Al-4V, which is the formal name for grade 5 titanium alloy, is the most common type of titanium alloy used in industry around the world. The mixture has about 6% aluminum and 4% vanadium in it, which makes a material with amazing mechanical qualities that is also very biocompatible and resistant to the environment.

Chemical Composition and Material Structure

The specific alloying elements in Ti-6Al-4V make a microstructure with two phases: alpha and beta. This special structure helps make the material very resistant to wear and easy to work with. The aluminum content makes it stronger and lighter, and the vanadium content makes it harder to work with and easier to shape at high temperatures. Because of these compositional benefits, titanium alloy sheets are very useful for medical implants and structural parts in spacecraft.

Mechanical Properties and Performance Characteristics

Tensile strength for Ti-6Al-4V is between 130,000 and 140,000 PSI, and yield strength is usually higher than 120,000 PSI. These qualities of the material stay the same at temperatures ranging from very cold to about 400°C. It has great fatigue resistance, with endurance limits of 65,000 to 75,000 PSI under normal testing settings. These mechanical properties make sure that the material will work reliably in tough situations where failure would have big effects.

Advanced Manufacturing Processes

Vacuum arc remelting (VAR) technology is used to make modern titanium sheets. This makes sure that the structure of the material is very pure and uniform. At temperatures between 925°C and 1050°C, hot rolling takes place. This is followed by cold rolling, which makes sure that the thickness limits are exact. During annealing treatments, the microstructure is improved and internal stresses are relieved. This makes sheets with consistent mechanical qualities and great shapeability for use in later manufacturing processes.

Comparative Analysis: Grade 5 Titanium Alloy Sheet Versus Alternative Materials

By knowing how Ti-6Al-4V stacks up against other materials, you can make smart purchasing choices that improve performance and cut costs. This study looks at the main differences between different types of titanium and other metals that are often used in high-performance situations.

Grade Comparisons Within Titanium Family

Titanium alloys made from Ti-6Al-4V are stronger than titanium alloys made from Grade 2 pure titanium because they are less likely to rust. Tensile strength usually doesn't go above 65,000 PSI, which means it's good for chemical processing but not good enough for aircraft structural needs. Grade 9 titanium (Ti-3Al-2.5V) is in the middle of commercially pure grades and Grade 5 performance levels in terms of strength. It is very easy to shape and has good formability.

Grade 23 titanium, also called Ti-6Al-4V ELI (Extra Low Interstitials), is more ductile and harder to break because it has less oxygen, nitrogen, and carbon in it. This grade works really well in medical uses that need biocompatibility and resistance to fatigue under repeated loads.

Performance Advantages Over Steel and Aluminum

Alternatives made of stainless steel usually weigh 75% more than titanium and aren't as strong for their weight. Even though steel is cheaper at first, titanium's resistance to corrosion means that no protection coating is needed, and it lasts a lot longer. Although aluminum alloys are lighter than steel, they are not as strong as titanium and will not last as long in toxic environments.

Ti-6Al-4V has a density of 4.43 g/cm³, while stainless steel has a density of 7.9 g/cm³ and aluminum metals have a density of 2.7 g/cm³. This position strikes the best mix between reducing weight and improving mechanical performance for use in aerospace and cars.

Cost-Performance Analysis and Market Trends

Grade 5 titanium alloy sheet costs between $15 and $25 per pound on the market right now, based on the thickness, quantity, and processing needs. Even though the original costs of materials are higher than those of regular metals, lifecycle analysis shows that they are more valuable because they require less maintenance, last longer, and use less fuel in transportation because they are lighter. Trends in the market show that demand is rising from new areas like green energy and advanced manufacturing. This is leading to more innovations that make processing more efficient and lower costs.

Procurement Insights: How to Buy Grade 5 Titanium Alloy Sheets Efficiently

To successfully buy titanium alloy materials, you need to know a lot about quality standards, the skills of suppliers, and how the market works. Approaches to strategic sourcing can have a big effect on both the prices of materials and the time it takes to complete a project, while also ensuring consistent quality delivery.

Quality Certification and Compliance Requirements

ISO 9001:2015 certification is the minimum quality standard for titanium suppliers. It makes sure that quality management systems and traceability processes are well-documented. For aircraft uses, following the aircraft Material Specifications (AMS) is very important. AMS 4911 covers Ti-6Al-4V sheet products. ASTM B265 gives basic guidelines for strip, sheet, and plate materials made of titanium and titanium alloys.

Each shipment needs to have a Mill Test Certificate (MTC) that shows the chemical make-up, mechanical qualities, and processing history. These certificates make it possible to track everything from the raw materials to the final delivery. This helps with quality checks and meeting legal requirements.

Supplier Selection and Evaluation Criteria

Lead times from reliable suppliers are always the same, and for standard specs, they are usually between 6 and 12 weeks. Managing changing demand trends and emergency needs requires the ability to keep track of inventory. To cut down on waste and speed up project schedules, suppliers should keep smart stock levels of common sizes on hand and offer custom cutting and processing services.

The ability to provide technical help sets exceptional suppliers apart from commodity providers. Getting engineering advice, help choosing materials, and suggestions that are tailored to the application all add a lot of value to the whole buying process. Being close to processing plants or big shipping hubs can greatly cut down on shipping costs and delivery times.

Negotiation Strategies and Volume Considerations

When you commit to buying a lot of something, you can often get big price breaks. Usually, the breaks happen at 1,000, 5,000, and 10,000 pounds. Annual supply deals keep prices stable and make sure that supplies are distributed during times when the market is tight. Negotiating payment terms can help your cash flow, and based on the cost of financing from the supplier, early payment discounts can range from 1% to 3%.

When it comes to complicated geometries or multiple part configurations, custom cutting services cut down on material waste and processing costs further down the line. These services usually add 15% to 25% to the base cost of materials, but they get rid of the need to cut things yourself, which saves money on tools.

Why Choose Chuanghui Daye Grade 5 Titanium Alloy Sheets?

The titanium alloy market is served by Chuanghui Daye Metal Material Co., Ltd., which has more than 30 years of experience making and working with rare metals. Our factory is in Baoji High-tech Development Zone, which is known as China's "Titanium Capital." It takes advantage of the area's knowledge and better infrastructure to provide excellent quality and value.

Advanced Manufacturing Capabilities and Quality Control

Our production skills include the whole process of making titanium sheets, from vacuum melting them to inspecting and packing them up at the end. Electron beam ovens make sure that the metal is very pure, and precision rolling equipment makes sure that the thickness is tightly controlled and the surface is perfectly smooth. Each production lot is made better by advanced annealing methods that improve the microstructure and mechanical properties.

Through multi-stage inspection processes, quality control protocols go above and beyond what the business requires. Before it is shipped, each grade 5 titanium alloy sheet is checked for thickness, surface finish, and mechanical properties. Our quality management system is ISO 9001:2015 certified, which means that all of our processes are the same and all of our paperwork can be tracked for every sale.

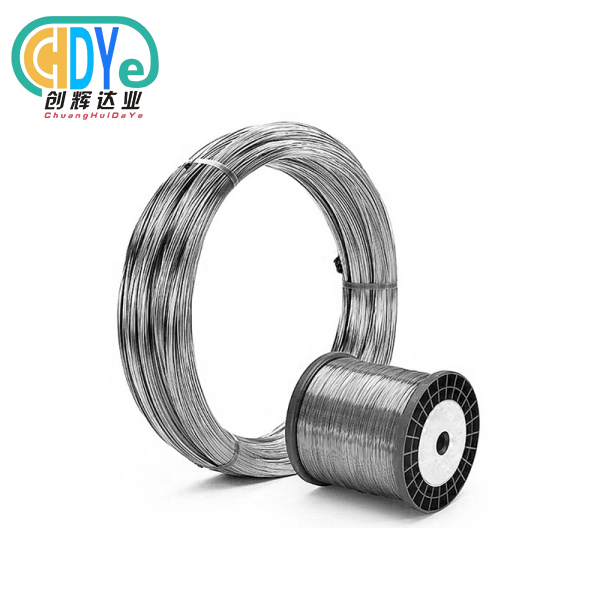

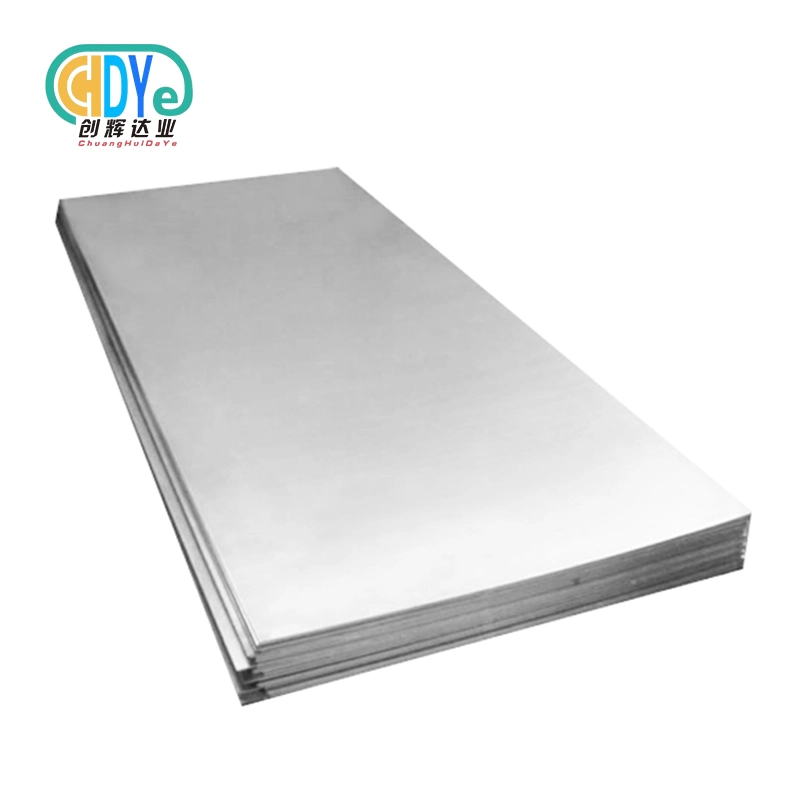

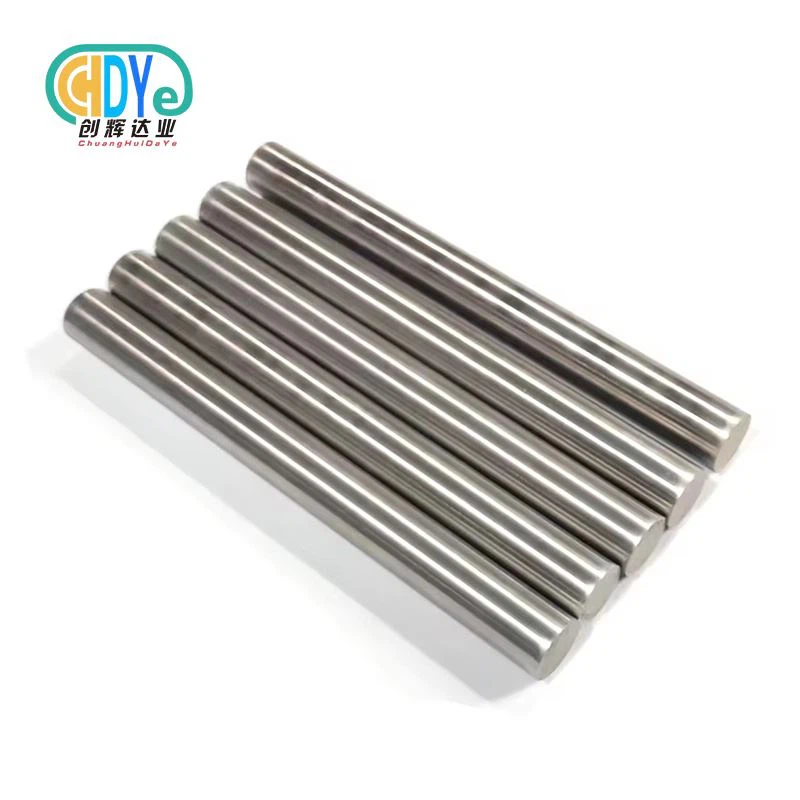

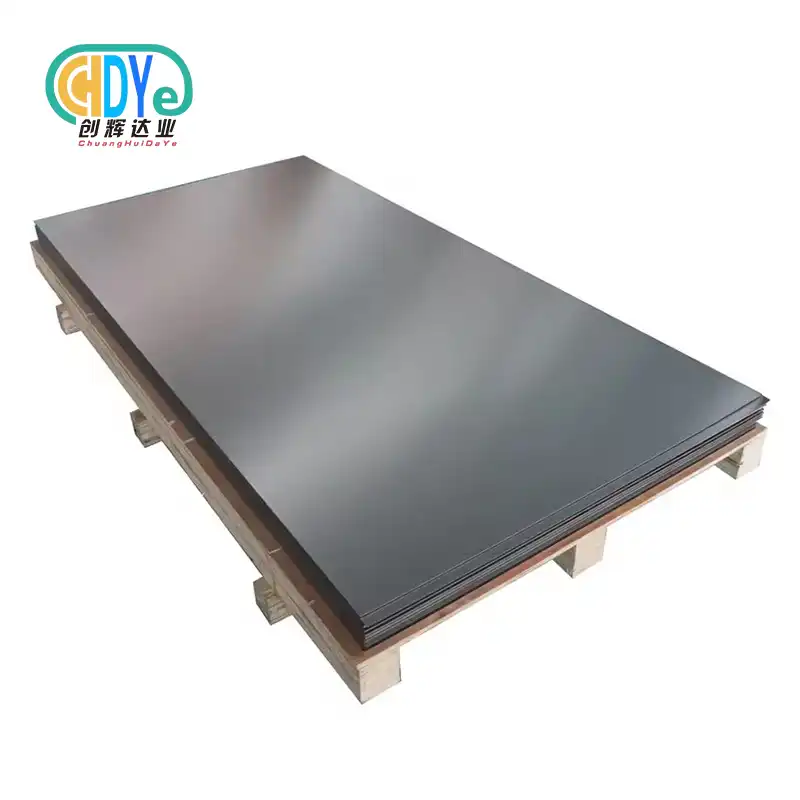

Comprehensive Product Range and Custom Services

Titanium alloy sheets that we make come in thicknesses from 0.5 mm to 50 mm and normal widths up to 2,500 mm. If you need a different size, just let us know. There are different types of surface finishes, such as mill finish, pickled, and polished, so that the right one can be used for the job. Precision cutting, forming, and machining are some of the processing services we offer. These services cut down on customer wait times and inventory needs.

Advanced plasma and waterjet technologies are used in custom cutting services, which can achieve limits of within ±0.1mm for important tasks. There are choices for expedited processing to meet the needs of urgent projects, and qualified customers can also get deliveries right away. Some of the technical support services that are available are help with choosing materials, application engineering, and making sure that quality paperwork is ready.

Proven Track Record and Customer Success

Our clients come from all over North America and Europe and include companies that make aerospace products, medical devices, chemicals, and research centers. Aerospace customers depend on our materials for uses where performance and dependability are very important, like structural parts, engine parts, and landing gear. Medical device companies trust our biocompatible grades for surgical tools and implants that need to be very pure and strong.

Case studies show that delivery performance has been steady, with over 95% of shipments arriving on time over the last five years. Customer feedback shows that our technical support is quick to respond, our prices are affordable, and our order quantities are flexible enough to meet the needs of both small-scale production and prototype development.

Conclusion

Grade 5 titanium alloy sheets are the best material for uses that need high strength-to-weight ratios, resistance to rust, and long-term dependability. Knowing about the materials' make-up, their features, and how to buy them lets you make smart choices that improve performance and cut costs. Because of our production know-how, quality certifications, and wide range of service options, Chuanghui Daye is the best choice for many industries that need to supply titanium alloys.

FAQ

Q:What makes Grade 5 titanium superior to other titanium grades?

A: Grade 5 titanium alloy (Ti-6Al-4V) provides the highest strength-to-weight ratio among commercially available titanium grades. The aluminum and vanadium alloying elements create a dual-phase microstructure that delivers tensile strengths exceeding 130,000 PSI while maintaining excellent corrosion resistance and fatigue performance. This combination makes it suitable for both structural and functional applications across aerospace, medical, and industrial sectors.

Q: How does heat treatment affect Grade 5 titanium mechanical properties?

A: Heat treatment significantly influences Ti-6Al-4V mechanical properties through microstructure modification. Annealing at temperatures between 700°C and 750°C relieves internal stresses and optimizes ductility for forming operations. Solution treatment followed by aging can increase strength levels while maintaining adequate ductility for specific applications. Proper heat treatment ensures consistent mechanical properties and eliminates processing-induced variations.

Q: What thickness considerations apply to aerospace applications?

A: Aerospace applications typically utilize sheet thicknesses ranging from 0.8mm to 6.0mm depending on specific requirements. Structural panels often employ 1.6mm to 3.2mm thicknesses to balance weight reduction with structural integrity. Thinner gauges suit non-load-bearing applications like ducting and fairings, while thicker sections accommodate high-stress components requiring enhanced fatigue resistance.

Partner with Chuanghui Daye for Premium Grade 5 Titanium Alloy Sheets

Shaanxi Chuanghui Daye stands ready to support your titanium alloy requirements with three decades of specialized manufacturing experience and ISO 9001:2015 certified quality systems. Our comprehensive grade 5 titanium alloy sheet inventory, custom processing capabilities, and technical expertise ensure optimal solutions for your most demanding applications. As a trusted titanium alloy sheet supplier, we deliver consistent quality, competitive pricing, and responsive service that exceeds customer expectations. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover how our expertise can enhance your project success.

References

1. Boyer, R.R., Welsch, G., Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, 1994.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, 2000.

3. Lutjering, Gerd, Williams, James C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2007.

4. Peters, M., Hemptenmacher, J., Kumpfert, J., Leyens, C. "Structure and Properties of Titanium and Titanium Alloys." Wiley-VCH Verlag GmbH, 2003.

5. Rack, H.J., Qazi, J.I. "Titanium Alloys for Biomedical Applications." Materials Science and Engineering C, 2006.

6. Veiga, C., Davim, J.P., Loureiro, A.J.R. "Properties and Applications of Titanium Alloys: A Brief Review." Reviews on Advanced Materials Science, 2012.

Learn about our latest products and discounts through SMS or email