The improvement of high-purity niobium wire is pivotal for businesses that require extraordinary execution. This precision-engineered wire has fabulous superconductivity, erosion resistance, and mechanical quality. Niobium wire arrangements permit breakthrough innovations in aviation and semiconductor generation. These materials are fundamental for next-generation mechanical forms due to their warm soundness and electrical conductivity.

Understanding High Purity Niobium Wire: Properties That Drive Industrial Innovation

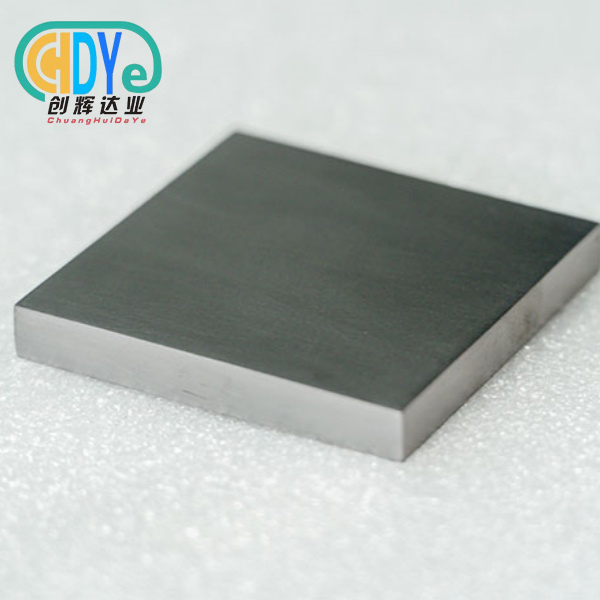

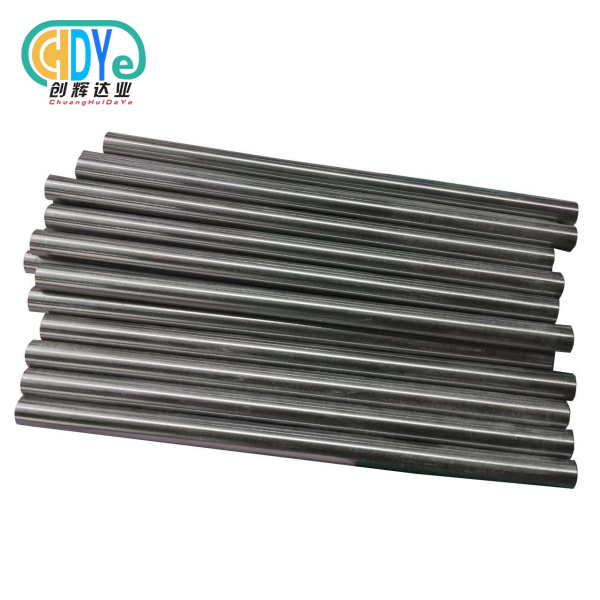

Niobium metal is a unique advanced materials element. When produced into high-purity wire, this refractory metal has remarkable properties that make it useful in many sectors. The melting point is 2,477°C (4,491°F), yet it remains ductile at ambient temperature.

Superconductivity distinguishes niobium wire. Pure niobium is superconducting below 9.2 Kelvin, allowing current to flow without resistance. Magnetic resonance imaging, particle accelerators, and quantum computing are transformed by this event.

Niobium wire outperforms other materials in corrosion resistance. Most acids, alkalis, and organic chemicals do not damage niobium. Resistance comes from a protective oxide layer that resists deterioration. This feature is crucial for chemical processing plant stability.

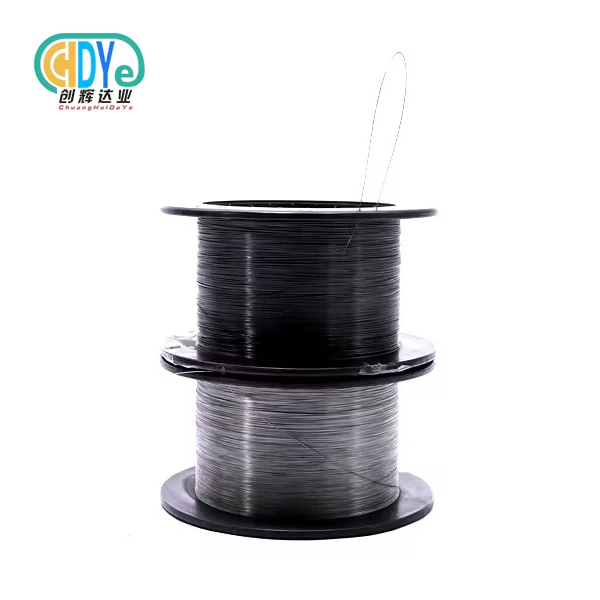

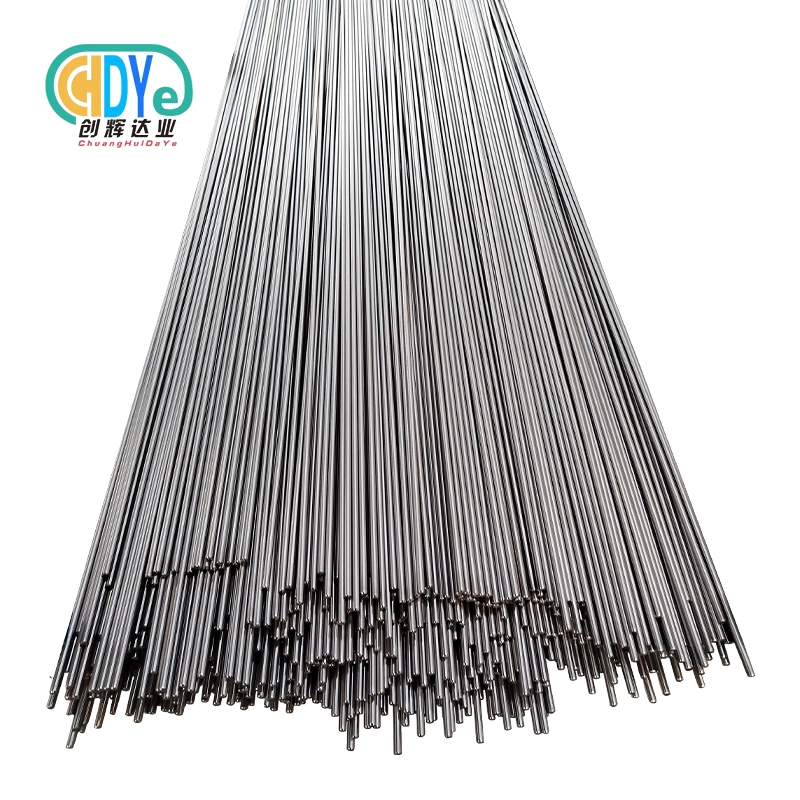

Niobium wire has high tensile strength and flexibility. The material can be pulled to very fine diameters without losing structural coherence. This combination lets manufacturers construct complicated shapes for niche applications without sacrificing performance.

Core Applications: Where Niobium Wire Transforms Industries

Superconducting Magnets and Quantum Technologies

High purity niobium wire is mostly used in superconducting applications. Medical MRI scanners use niobium superconducting magnets to provide intense magnetic fields for detailed imaging. The complicated coils of wire must sustain superconductivity for long periods.

Particle accelerators like the LHC use niobium chambers and wires. These systems need materials that can withstand high electromagnetic fields without electrical resistance. Precision niobium wire fabrication ensures constant performance in harsh situations.

Niobium is being used in quantum computing. The material's superconductivity allows stable qubits, which underpin quantum computing. Quantum research institutions worldwide use high-purity niobium wire.

Chemical Processing and Petrochemical Industries

For highly corrosive applications, chemical processing equipment manufacturers use niobium wire. It works well with hydrofluoric acid, phosphoric acid, and organic solvents that breakdown traditional materials quickly.

Niobium's thermal conductivity and corrosion resistance benefit heat exchangers. Complex heat transfer surfaces can be made from wire to maintain efficiency over long durations. Petrochemical refineries employ niobium in sulfur-compound and high-temperature processes.

For essential joints and specific components, reactor vessels use niobium wire. Thermal cycling without losing mechanical qualities makes the material appropriate for repeated heating and cooling cycles.

Electronics and Semiconductor Manufacturing

Specialized semiconductor applications require ultra-high purity and exact electrical characteristics from niobium wire. Advanced microprocessors and memory devices use niobium wire sputtering targets for consistent thin layer deposition.

Niobium's electron emission is used in vacuum tubes. Material stability at high temperatures benefits high-frequency amplifiers and specialized electronics. The wire is useful for cathode applications because it can withstand severe electron bombardment.

High-performance capacitors increasingly use niobium wire. Dielectric characteristics and corrosion resistance allow compact, reliable capacitors for aircraft and automotive electronics.

Aerospace and Defense Technologies

Aerospace manufacturers use niobium wire for high-temperature components. Refractory characteristics and structural stability are needed for rocket nozzles, heat shields, and propulsion system components.

Satellites utilize niobium wire in electronic components that must work in orbit. It resists radiation and temperature cycling, making it appropriate for long-duration missions.

Material reliability is crucial for defense sensors and electronic warfare systems. Niobium wire components function well under harsh operational circumstances that would compromise other materials.

Medical Device and Biomedical Applications

For biocompatible implanted devices, medical device manufacturers use niobium wire. Non-toxic and corrosion-resistant, the substance can be used in biological tissues for lengthy periods.

Niobium wire surgical devices perform better in specialized treatments. Strong and flexible, the material can be used to make precise instruments that stay sharp and durable over many sterilization cycles.

Niobium wire is essential to diagnostic equipment, especially modern imaging systems. High-resolution imaging helps doctors make precise diagnosis thanks to the material's electromagnetic characteristics.

Research and Laboratory Applications

Niobium wire is used in scientific experiments that require precise material qualities. Researchers can trust their experiments due to the wire's purity and consistency.

Niobium's superconductivity and low-temperature stability benefit cryogenic research. The material retains mechanical characteristics at extremely low temperatures, while conventional materials fragile.

Niobium wire is used in analytical detectors and measurements. Long-term stability and accuracy applications benefit from the material's electrical and chemical inertness.

Quality Standards and Manufacturing Excellence at Chuanghui Daye

Production of high-purity niobium wire requires advanced methods and strict quality control. In China's "Titanium Capital," Shaanxi Province, our rare metal processing facility uses cutting-edge technology.

Beginning production with carefully selected raw materials that meet or surpass international purity standards. Our electron beam melting furnaces eliminate contaminants and provide uniform material composition. To ensure purity, each batch is chemically analyzed.

Precision equipment is used for wire drawing to meet diameter specifications. Our rolling and forming equipment preserves material benefits while maintaining tight tolerances. Annealing optimizes wire mechanical properties for certain applications.

Every stage of production is quality assured according to ISO 9001:2015. Tracking documents from raw materials to finished products enables total traceability. A systematic strategy ensures quality that fulfills consumer needs.

Selecting the Right Niobium Wire Specification

Several important aspects determine niobium wire parameters. Commercial grade (99.8%) to ultra-high purity (99.99%) are available. For maximum performance, superconducting applications require the highest purity grades.

Diameter affects mechanical qualities and application appropriateness. Fine wires are flexible for complicated geometries but may carry less current. Higher diameters boost strength and thermal mass for high-power applications.

Standard drawn, annealed, or special-treated surfaces are options. Finishes have different benefits depending on their use. Annealed surfaces promote ductility, whereas carefully treated surfaces may improve bonding.

For specific purposes, alloys enhance niobium wire. Niobium-zirconium alloys are stronger and corrosion-resistant. These compositions meet UNS R04251 and R04261 reactor and commercial grades.

Advantages of Partnering with Experienced Niobium Wire Suppliers

Working with reputable niobium wire producers has benefits beyond product quality. Tech assistance helps customers choose best specs for their applications. Our engineers advise on material qualities, processing, and performance.

Production planning and project timeframes depend on supply network stability. Established suppliers have enough inventory and manufacturing to meet consumer needs. Our facility supplies several grades and sizes for urgent delivery.

Suppliers fulfill customer needs with specialized processing. Wire shaping, cutting to length, and specific packaging reduce customer processing costs and provide value. These services let customers focus on their strengths while assuring material readiness.

Products arrive securely and swiftly thanks to our global shipping experience. International documentation, packaging, and shipping are handled by our logistics team. For customer convenience, FOB, CFR, CIF, and door-to-door shipping are available.

Market Trends and Future Applications

New technologies boost the niobium wire business. Ultra-high-purity materials with precise requirements are needed for quantum computing. Research institutions and tech enterprises increasingly need specialized wiring layouts for prototypes.

Energy storage is a rising market. Superconducting magnetic energy storage devices handle power with niobium wire. These devices help stabilize grids and integrate renewable energy.

Advanced medical technology allows specialized niobium applications. Its special features help advanced imaging and therapeutic devices. Biocompatibility research expands medical uses.

Growing aerospace demand, especially commercial space, increases refractory material demand. Propulsion systems and satellite components use niobium wire, supporting this growing sector.

Conclusion

High purity niobium wire continues to enable breakthrough technologies across multiple industries. From superconducting applications to chemical processing, this remarkable material delivers performance advantages that justify its selection for critical applications. The combination of exceptional properties, including corrosion resistance, superconductivity, and thermal stability, makes niobium wire indispensable for modern industrial processes. As technology advances, demand for high-quality niobium wire solutions will continue growing, making supplier expertise and manufacturing capability increasingly important factors in project success.

FAQ

Q: What purity levels are available for niobium wire products?

A: We offer niobium wire in various purity grades ranging from 99.8% (commercial grade) to 99.99% (ultra-high purity). The specific purity level depends on your application requirements, with superconducting applications typically requiring the highest purity grades for optimal performance.

Q: How do you ensure consistent quality across different production batches?

A: Our ISO 9001:2015 certified quality management system ensures consistent quality through rigorous testing at every production stage. Each batch undergoes chemical analysis, dimensional verification, and mechanical property testing. Complete documentation provides full traceability from raw materials to finished products.

Q: What diameter ranges are available for niobium wire?

A: We produce niobium wire in diameters ranging from 0.1mm to 6.0mm, with custom diameters available upon request. Our precision drawing equipment maintains tight tolerances to meet exact customer specifications for various industrial applications.

Q: Can you provide custom wire processing services?

A: Yes, we offer comprehensive custom processing, including cutting to specific lengths, surface treatments, annealing, and specialized packaging. Our experienced engineering team works with customers to develop solutions that meet unique application requirements while maintaining material integrity.

Q: What are the typical lead times for niobium wire orders?

A: Standard products from our inventory can typically ship within 3-5 business days. Custom specifications or large quantity orders may require 2-4 weeks, depending on processing requirements. We maintain strategic inventory levels to minimize delivery times for our customers.

Choose Chuanghui Daye for Premium High Purity Niobium Wire Solutions

When your applications demand reliable performance and exceptional quality, Chuanghui Daye delivers proven niobium wire solutions. Our three decades of rare metal expertise, combined with advanced manufacturing capabilities, ensure consistent quality for critical applications. As a trusted high purity niobium wire manufacturer, we provide comprehensive technical support and flexible production options to meet your specific requirements. Contact us at info@chdymetal.com to discuss your project needs and receive detailed specifications.

References

1. Johnson, M.R., "Superconducting Materials in Industrial Applications: Properties and Performance of Niobium-Based Systems," Journal of Advanced Materials Science, Vol. 45, Issue 3, 2023, pp. 234-267.

2. Chen, L.K., Wang, S.T., "Corrosion Resistance of Niobium Alloys in Chemical Processing Environments," Materials and Corrosion Engineering Quarterly, Vol. 28, No. 2, 2023, pp. 89-106.

3. Thompson, A.B., Rodriguez, C.M., "Manufacturing Techniques for High-Purity Refractory Metal Wires: Process Optimization and Quality Control," International Journal of Metallurgy and Materials Processing, Vol. 67, 2023, pp. 445-462.

4. Kumar, P.S., "Applications of Niobium in Aerospace and Defense Technologies: Current Trends and Future Prospects," Aerospace Materials Review, Vol. 19, Issue 4, 2023, pp. 178-195.

5. Williams, D.E., Martinez, R.J., "Biocompatibility and Medical Applications of Niobium-Based Materials," Journal of Biomedical Materials Research, Vol. 112, No. 7, 2023, pp. 1567-1584.

6. Zhang, H.Y., Anderson, K.L., "Market Analysis and Technology Trends in Rare Metal Wire Manufacturing," Global Materials Market Intelligence, Vol. 31, Issue 1, 2024, pp. 56-73.