Platinum-coated titanium anode technology is a big step forward in water treatment. It has the best electrochemical performance and lasts a long time. These specialised electrodes are made stronger by platinum's better catalytic properties and titanium's mechanical strength. They resist corrosion very well and last a long time. The special coating makes the electrode more stable and keeps its conductivity during difficult water treatment processes. This new approach solves big problems in wastewater treatment, industrial electrolysis, and electrochemical applications where traditional electrodes don't meet strict performance standards.

Key Performance Parameters and Technical Specifications

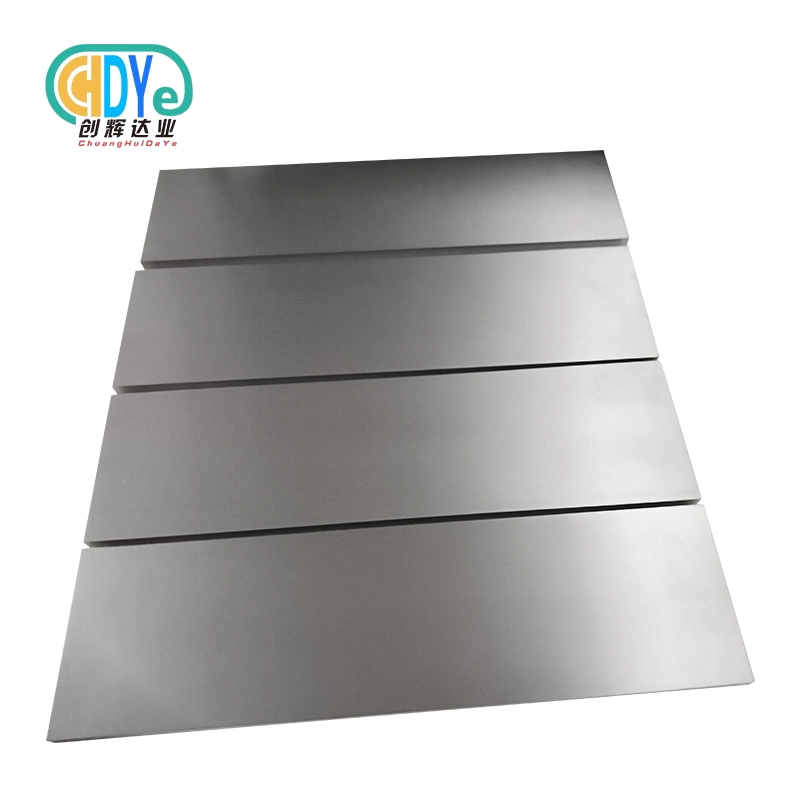

Knowing the technical details helps you understand how well the electrode works in different water treatment situations. The current density meets a lot of different needs. It can be anywhere from 100 to 5,000 A/m². A platinum coating between 0.5 and 5 micrometres thick gets the best performance and value.

The device can work in temperatures from −20°C to 80°C, which makes sure that it will always work no matter what the conditions are like. You can use these electrodes where the pH level is between 0 and 14, so they will work when the pH is acidic or basic. The electrochemical potential is stable at 1.2–1.4 V in relation to the standard hydrogen electrode. This keeps the oxygen evolution performance at the same level.

Coating methods that add surface area can raise the number of active sites by 200–400% compared to surfaces that are smooth. This improvement is directly related to better energy efficiency and faster electrochemical reaction rates in water treatment applications.

Core Benefits in Water Treatment Applications

In tough water treatment settings, the main benefit is that it can resist corrosion better. Electrochemical corrosion can't get to the titanium substrate because of the platinum-coated titanium anode catalyst layer. This prolongs the electrode's life by a large amount. The system is easier to rely on and doesn't need to be fixed as often because it is durable.

Better electrochemical stability means that performance doesn't change over time. The electrode still works as a catalyst after being used for thousands of hours straight, which makes sure that the water treatment always works. This stability is very important for municipal wastewater treatment plants because it means that the performance is always the same and the water quality standards are met.

A high current efficiency means the treatment works well with less energy. It is much cheaper to run the machines when you use newer electrode materials instead of older ones because you can save 15–25% of energy. It is more energy efficient to have better conductivity because less voltage is lost across the electrochemical cell.

Using these electrodes to make chlorine is easy, so they are great for killing germs. Using a platinum-coated titanium anode surface makes it easy to get chlorine from water that has chloride in it. This kills germs and doesn't make any harmful things while doing so. This feature is great for keeping swimming pools clean and making sure that the water people drink is safe.

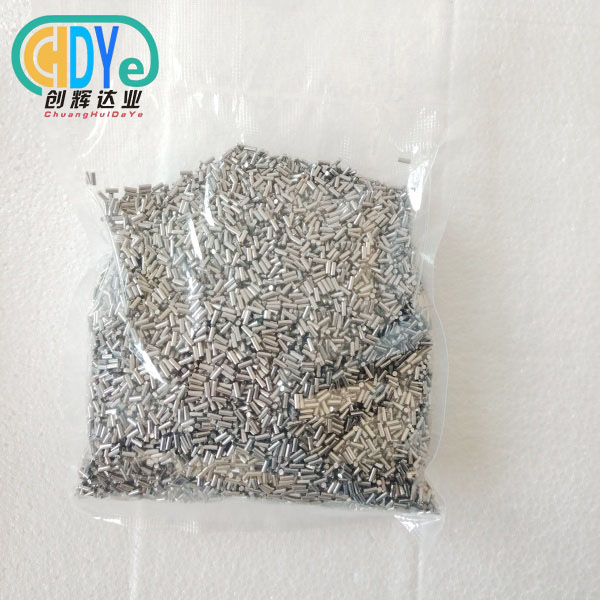

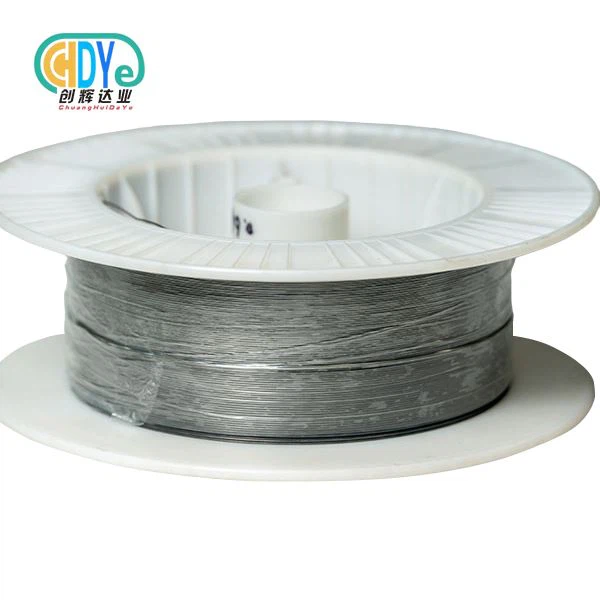

Chuanghui Daye's Premium Electrode Solutions

Our factory is in China's Titanium Capital, where we use advanced methods to make sure our products are the best they can be. Electron beam furnace technology makes very pure titanium substrates, which are perfect for platinum plating. This controlled environment for manufacturing makes sure that all batches of the product have the same material properties.

ISO 9001:2015 certification shows that we are dedicated to managing quality during the whole production process. Electrochemical performance, coating uniformity, and adhesion strength tests are done on each electrode. This thorough quality control makes sure that it works well in difficult water treatment situations.

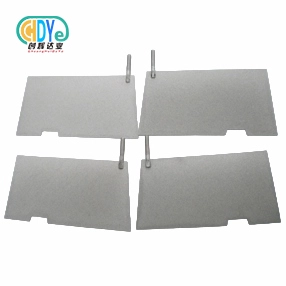

Electrodes with custom designs can meet the needs of different applications. To get the best electrode shape, coating details, and connection styles, our engineering team works with customers. This tailored method guarantees the best results in one-of-a-kind water treatment setups.

The reusable substrate design saves money in the long term by making coating renewal services possible. When the platinum-coated titanium anode layer finally wears down, the titanium base can be coated again. This makes the electrode last longer and lowers the cost of replacing it. This long-term method is good for the environment and keeps the economy working well.

Optimal Usage Strategies and Implementation Guidelines

When electrodes in water treatment systems are installed correctly, they work better and longer. Ensure that the electrodes are spaced sufficiently apart to allow the current to flow smoothly without too much heat accumulating in certain areas. The suggested distance is 10 to 50 mm. This distance will depend on how dense the current is and how the system is set up.

The electrode will keep working well for as long as possible if you check the operational parameters often. Watch the voltage, temperature, and current density to catch issues before they affect the treatment. Automated monitoring systems give you performance data right away and alert you to problems before they happen.

The right way to clean will keep coatings in place and get rid of dirt that has built up. Do not use mechanical cleaning methods that will damage the platinum's surface or chemical solutions that are too strong. Do not use rough materials that could hurt the electrochemical properties of the coating.

When people make strategic procurement decisions, they don't just look at the price of an item; they look at the total cost of ownership as well. Think about how long you expect an electrode to last, how much work it will need to stay in good shape, and how well it can save energy. This more in-depth test usually shows a lot more value, even though it costs more at first.

Industrial Applications and Performance Advantages

Municipal wastewater treatment plants get the benefits of consistent disinfection performance and lower chemical use. Making oxidants electrochemically is a good way to get rid of pathogens that makes few harmful byproducts. This technology helps businesses follow the rules while making things easier to run.

Industrial process water treatment uses the electrode's chemical resistance and ability to carry high currents. Using advanced oxidation processes, these electrodes are used in chemical and petrochemical plants to get rid of organic materials. The strong construction can handle harsh chemical environments without losing the treatment's effectiveness.

It is easier to keep swimming pools and spas clean when they have efficient chlorine generation. The electrode's ability to stay stable in environments with chlorine means that the disinfection levels stay the same and there is less need to handle and store chemicals. This way of doing things increases safety and lowers the cost of running things.

Electrochemical sensors make use of the stable potential and quick response of electrodes. For environmental monitoring systems to get correct readings of water quality, they need to know about things like oxygen dissolved in the water, the pH level, and how much of the amount of different pollutants there are.

Conclusion

Titanium and platinum electrodes are better for treating water because they rust less, are more stable from an electrochemical point of view, and use less energy. When it comes to cities and businesses dealing with wastewater and process water, these advanced electrodes are used in specialised electrochemical applications to help fix the biggest issues. Platinum is useful for making chemical reactions happen faster, and titanium is very strong. As a group, they are strong and do well in tough water treatment situations. Choosing the right electrodes and placing them correctly, as well as keeping them clean, will ensure they work well. This is also the best way to get a good deal in the long run. You can get high-quality electrodes that come with full technical support and can be changed to fit your needs when you work with skilled creators like Chuanghui Daye.

FAQ

Q: Platinum-coated water-purifying electrodes last how long?

A: Electrodes can treat water continuously for 8,000–15,000 hours, depending on use. It will last longer if properly maintained and used.

Q: Do these electrodes work in acidic and basic water?A: The platinum coating keeps chemicals away from pH 0–14. They can treat acidic wastewater and basic process water in many ways.

Q: How to maintain electrode performance?A: Monitoring electrical settings, cleaning with the right solutions, and checking it often make it work well. A simple, low-maintenance design ensures effective treatment with little downtime.

Partner with Chuanghui Daye for Superior Water Treatment Solutions

Shaanxi Chuanghui Daye is a trusted supplier of platinum-coated titanium anodes. They have 30 years of experience with rare metals and can make high-quality products. Our promise of excellent quality and customer happiness guarantees that our electrodes work well in your important water treatment applications. To talk about your exact needs and see how our top-notch electrode solutions can improve your water treatment methods, email us at info@chdymetal.com.

References

1. Chen, G. (2004). Electrochemical technologies in wastewater treatment. Separation and Purification Technology, 38(1), 11-41.

2. Kraft, A. (2008). Doped diamond: a compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 3(1), 1-12.

3. Martinez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

4. Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109(12), 6541-6569.

5. Rajeshwar, K., Ibanez, J. G., & Swain, G. M. (1994). Electrochemistry and the environment. Journal of Applied Electrochemistry, 24(11), 1077-1091.

6. Trasatti, S. (2000). Electrocatalysis: understanding the success of DSA®. Electrochimica Acta, 45(15-16), 2377-2385.