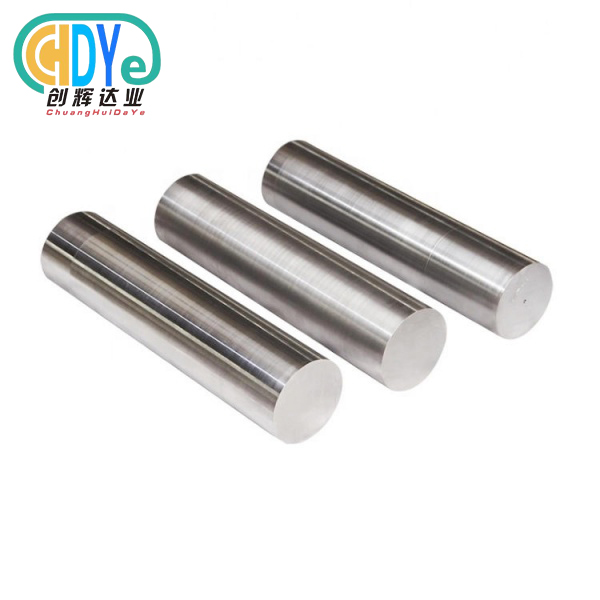

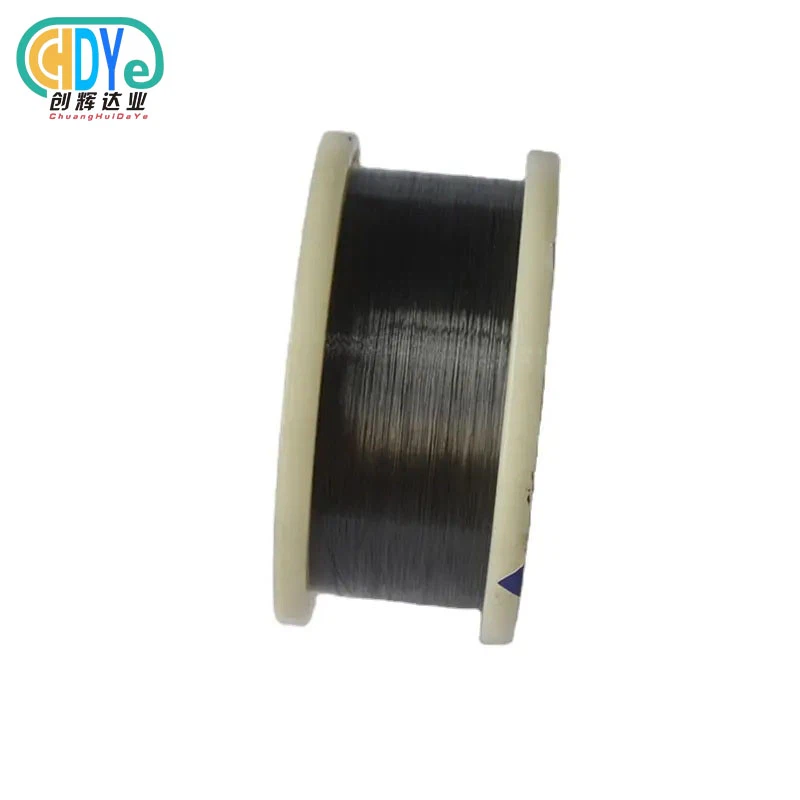

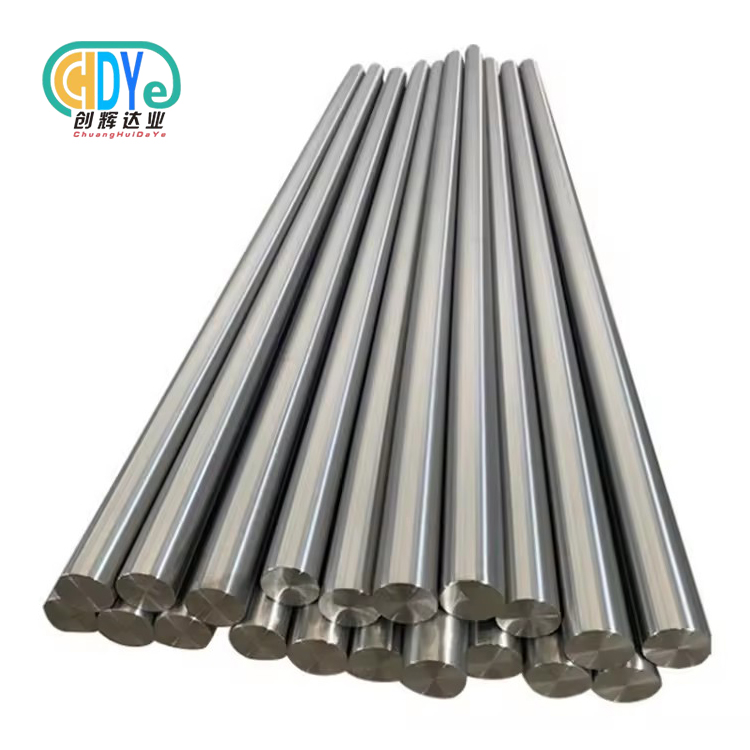

There aren't many sellers of certified titanium seamless tubes that can send orders to any country who can be trusted to do so. You should think about the standards for quality, the knowledge and experience needed to make things, and the ability to plan and carry out an operation's specifics. The titanium tubes that come from Shaanxi Chuanghui Daye Metal Material Co., Ltd. meet ASTM standards B338, B337, B861, and B862. The company is ISO 9001:2015 certified and ships packages globally. The company is in Baoji, which is known as China's "Titanium Capital." For over thirty years, they've been offering Grade 1, 2, 7, 9, and 12. For aerospace, chemical, medical, and industrial uses, they offer sizes from OD10–300 × WT0.5–10 × L100–18,000 mm.

Why Global Sourcing of Titanium Seamless Tubes Matters

Because some areas have specialised manufacturing skills, the titanium tubing market has become more global. Suppliers who can deliver high-purity materials with steady quality levels are sought after by businesses around the world.

International Procurement's Strategic Benefits

Global sourcing makes it possible to get to know specialised manufacturing hubs where experts have spent decades learning how to process titanium. For example, there are many companies in the Baoji region of China that make titanium and have very good melting, forging, and rolling capabilities. Because of this concentration of expertise, they often offer better prices, shorter lead times, and better technical support than local distributors.

Making Sure Quality in Global Supply Chains

Today, companies that make titanium tubes use strict quality management systems that include checking the materials, electron beam melting, and full testing protocols. To make sure that the dimensions and material properties meet global standards, the advanced facilities use automated inspection tools, precision lathes, and annealing furnaces.

Understanding Titanium Seamless Tube Applications and Specifications

Titanium pipes are strong, rust-resistant, and safe, making them useful in many ways.

Defence and Aerospace Applications

Aerospace companies need titanium alloy tubes for fuel lines, hydraulic systems, and structural parts. Grade 9 titanium tubing (Ti-3Al-2.5V) is strong and weldable for aeroplanes. Defence contractors make missile parts and naval systems for harsh marine environments using these materials.

Petroleum and chemical applications

In harsh chemical environments, titanium hollow pipes are essential for condensers, heat exchangers, and pipelines. Titanium is better than stainless steel in seawater, acid, and chlorinated compound environments because it corrodes less.

Medical Tool Production

Medical device companies make diagnostic, implanted, and surgical tools from titanium tubing. Titanium is non-toxic and harmless. The material is also suitable for harsh medical applications.

Global Supply and Demand Analysis for Titanium Tubing

The global titanium tube market shows where manufacturing is focused and how demand changes across industries.

The Way Manufacturing Hubs Are Spread Out

China's Shaanxi Province, Russia's VSMPO-AVISMA plants, and speciality makers in Japan and the United States are some of the main places that make titanium tubes. China has about 60% of the world's titanium production capacity, and Baoji is the most important place for making tubes.

Regional Demand Trends

A lot of high-grade titanium tubes are used by aerospace companies in North America, and in Europe chemical manufacturers focus on grades that resist corrosion. The electronics and semiconductor industries in Asia need very pure materials for specialised uses. Colleges and research labs around the world want small amounts for experiments.

Comparing Different Sourcing Channels for Titanium Tubes

When buying titanium seamless tubes from other countries, different buying channels have different pros and cons.

Getting it from the factory directly

| Where the product comes from | Pros | Downsides | Ideal For |

|---|---|---|---|

| Manufacturers Who Sell Directly | Better visibility into quality control, lower prices, and the ability to customise | Language problems, longer lead times, and higher MOQs | custom details, large volume orders |

| Vendors in the Area | Quick shipping, local help, and smaller amounts | Higher prices, less personalisation, and limited stock | Standard sizes for urgent orders |

| Business-to-business Websites | A lot of different suppliers, comparison shopping | Quality verification is hard, and service levels can change. | finding suppliers and doing market research |

| Businesses That Trade | English language skills, shipping consolidation | Less technical knowledge, more markup | Smaller businesses, mixed material requests |

Evaluating the Benefits of Buying Direct from the Factory

There are many benefits to working directly with well-known manufacturers such as Shaanxi Chuanghui Daye. These include getting help from engineers, having the ability to do custom machining, and getting the best prices because the products are coming straight from the factory. Electron beam furnaces and precision rolling equipment can meet certain size and surface finish requirements.

Supplier Verification and Quality Control Guidelines

A good supplier evaluation makes sure that certified titanium seamless tubes that meet the needs of the project are delivered on time.

Important Certification Needs

Make sure that the people you buy from keep their ISO 9001:2015 quality management certification and show that they follow ASTM standards that apply, including B338 for tubes without seams. Ask for material test certificates (MTCs) that show the chemical makeup, mechanical parts, and dimensional checks of the materials. Honest producers give complete traceability papers from getting raw materials to the last check.

Test of Technical Ability

Look at the manufacturing tools used in places like labs for testing, factories for melting, and rolling mills. Electron beam melting and automated inspection systems for dimensional accuracy are used by advanced suppliers to get better material purity. Check the machining capabilities if you need custom surface treatments or end preparations.

Communication and Rating of Service

Professional suppliers help customers by choosing the right materials, suggesting ways to use them, and offering advice on how to make things work. Rate how willing they are to respond to questions and samples, and how well they can explain technical details.

Practical Procurement Considerations and Common Challenges

If you want to get titanium tubes, you need to know about common order details and possible problems.

Minimum Order Quantities and Pricing Structure

When it comes to production efficiency, most companies set their own MOQs. For standard dimensions, the usual minimum is between 100 and 500 pieces, but for custom sizes, it could be 1,000 or more. At 5000 pieces or more, volume pricing tiers usually offer a very big discount.

Payment Terms and Logistics

The normal way to pay is to give 30% to 50% up front and then pay the rest when the bill of lading arrives. Credit letters make it possible to place bigger orders over $50,000. You can ship by sea freight if you want to save money or by air freight if you need it right away. Proper packing keeps things from getting broken during international shipping.

Planning Lead Time

It usually takes 3 to 4 weeks to make standard grade tubes, but if the tubes have custom specifications, it could take up to 8 weeks. Also, keep in mind the extra time that will be needed for customs and for shipping (2–4 weeks by sea and 5–7 days by air).

Quality Control Points and Inspection Protocols

Using the right quality control steps makes sure that the materials you get meet the requirements for specifications and use.

Incoming Inspection Steps

Check that the dimensions are correct with precise measuring tools like micrometres and optical comparators. Make sure the surface finish is free of scratches, dents, dirt, and other flaws. Go over the paperwork that comes with it, like the material certificates and test reports.

Checking the Material Properties

Do hardness testing to make sure that the heat treatment worked and that the mechanical properties are in line. For very important uses, independent testing by a third party can confirm the chemical makeup and tensile properties of a material. Keep records that show how test results are connected to certain material lots.

Conclusion

It is a matter of balancing quality, cost, and delivery time when getting certified titanium seamless tubes from all over the world. Building direct relationships with manufacturers often gets you the best value because they offer competitive prices, technical knowledge, and quality control. To get good procurement results, suppliers must be properly checked, clear specification communication must be used, and strong quality control processes must be put in place. In places like Baoji, where titanium manufacturing is common, they have access to high-tech processing and a lot of experience in the industry. Long-term relationships with well-known manufacturers help companies get the same quality every time, know when deliveries will arrive, and get help with new technical needs.

FAQ

Q: What quality indicators should I look for in seamless titanium tubes?

A: ISO 9001:2015 and ASTM B338, B337, B861, and B862 are important. Material test certificates should accompany every shipment, showing chemical, mechanical, and dimensional inspections. Aerospace workers may need AS9100 and other licences.

Q: How many titanium tubes do you typically order?

A: Size and quality affect MOQs. The minimum for standard sizes is 50-100kg.

Q: How long is international titanium tube shipping?

A: Air freight takes 5–7 days, but sea freight takes 2–4 weeks, depending on destination. Regular grades take three to four weeks longer, and custom ones six to eight. Allow extra time for customs clearance and delivery within the country.

Q: What titanium grades are most common?

A: Grade 2 (commercially pure) stays intact and is fine for most things. Other Grade need customized materials.

Q: How can I verify titanium tubes before buying?

Ask suppliers for material testing proof and check their quality credentials. A third-party inspection service is another. Before buying expensive equipment, check its mechanical properties, surface finish, and dimensional tolerances.

Partner with a Trusted Titanium Seamless Tube Manufacturer

With 30 years of experience in the titanium industry and advanced manufacturing skills, Shaanxi Chuanghui Daye Metal Material Co., Ltd. makes certified seamless tubes that meet the highest standards. ISO 9001:2015 certified factory in Baoji makes grades Gr1 through Gr12 and can ship anywhere in the world with full traceability records. You can get help from our technical team with picking out materials, machining with standard or custom sizes, and delivery. If you buy professional titanium seamless tubes from a company that is well-known in the field, you can expect great customer service, reasonable prices, and consistent quality. Emailing info@chdymetal.com will get you a full quote and a chance to talk about your exact needs.

References

1. Boyer, R., Welsch, G., & Collings, E.W. (2007). Materials Properties Handbook: Titanium Alloys. ASM International.

2. Donachie, M.J. (2000). Titanium: A Technical Guide, 2nd Edition. ASM International.

3. Lutjering, G. & Williams, J.C. (2007). Titanium: Engineering Materials and Processes. Springer-Verlag.

4. Rack, H.J. & Qazi, J.I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering C, 26(8), 1269-1277.

5. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

6. Schutz, R.W. & Thomas, D.E. (1987). Corrosion of titanium and titanium alloys. Metals Handbook, 9th Edition, Volume 13: Corrosion. ASM International.