When selecting anodes for electrochemical applications, understanding the key differences between platinum coated titanium anodes and MMO (Mixed Metal Oxide) anodes becomes crucial for optimal performance. The platinum coated titanium anode offers superior catalytic activity and exceptional corrosion resistance, making it ideal for demanding environments requiring long-term stability. MMO anodes provide cost-effective solutions with good durability but operate under different performance parameters. These fundamental differences in coating materials, electrochemical properties, and operational lifespan directly impact their suitability for specific industrial applications.

Understanding Platinum Coated Titanium Anodes

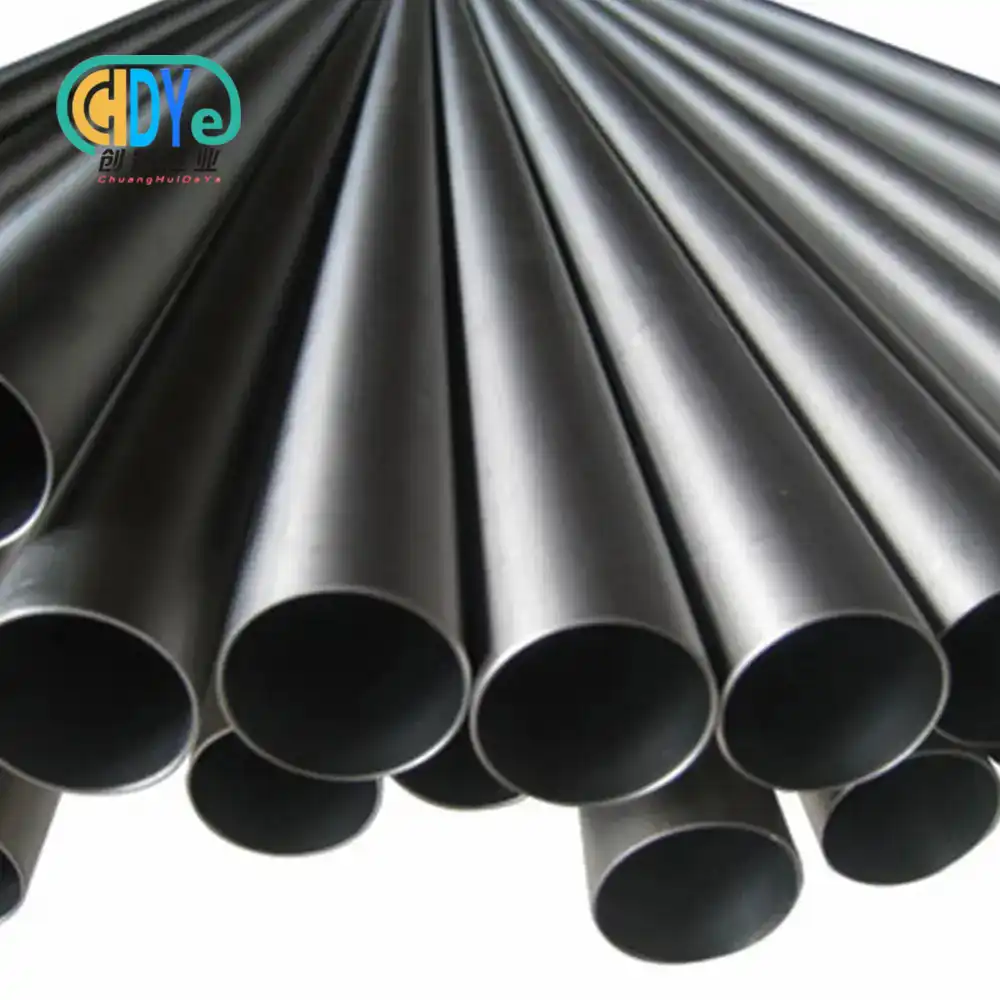

Platinum coated titanium anodes speak to the premium choice in electrochemical applications, combining titanium's mechanical quality with platinum's extraordinary catalytic properties. The titanium substrate gives basic astuteness and erosion resistance, whereas the platinum coating conveys prevalent electrochemical performance.

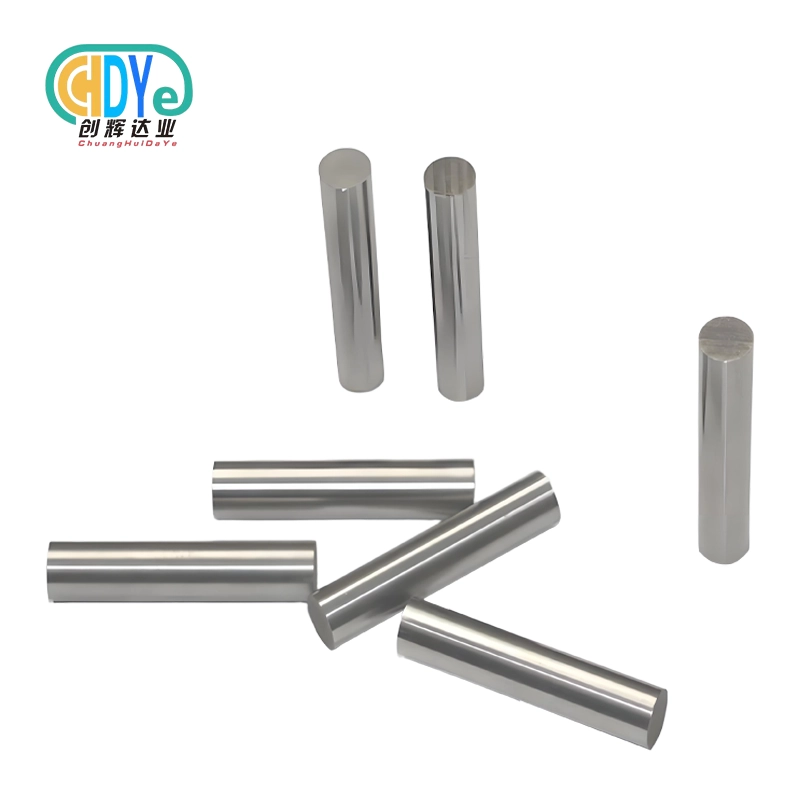

These anodes exceed expectations in applications requiring tall current effectiveness and moo overpotential. The platinum layer thickness regularly ranges from 2-10 micrometers, depending on the particular application necessities. Research facility tests illustrate that these anodes keep up 95% current productivity indeed after 8,000 hours of persistent operation in acidic environments.

The electrodeposition handle makes a uniform platinum layer that bonds safely to the titanium substrate. This combination conveys uncommon execution in oxygen advancement responses and chlorine generation forms. If you require anodes for high-precision electroplating or basic water treatment applications, platinum coated choices give unmatched reliability.

Exploring MMO Anode Technology

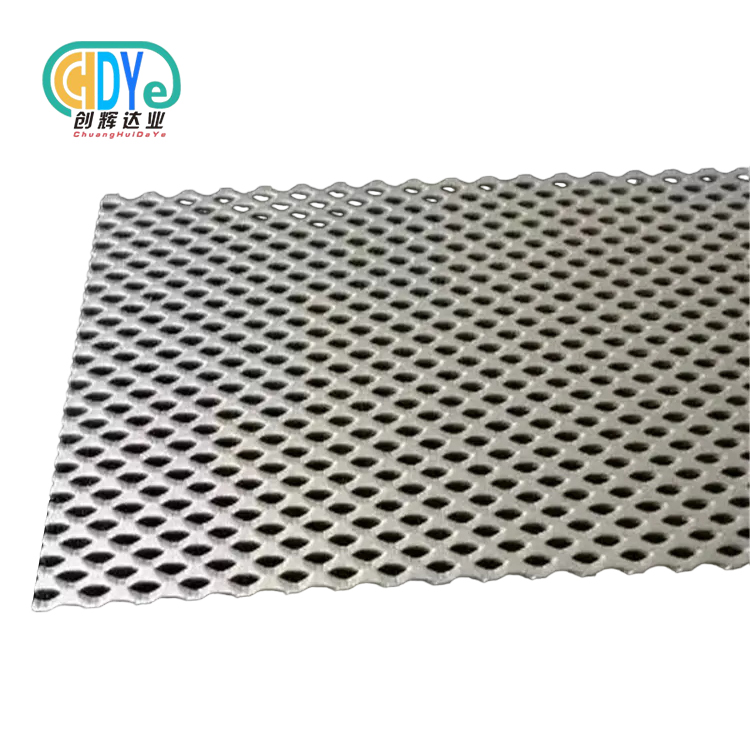

MMO anodes utilize blended metal oxide coatings, ordinarily containing ruthenium, iridium, and titanium oxides connected to a titanium substrate. This coating innovation offers great execution for numerous mechanical electrolysis applications whereas keeping up cost-effectiveness.

The MMO coating gives great conductivity and sensible solidness, with commonplace life expectancies extending from 3-7 a long time depending on working conditions. Field ponders appear MMO anodes accomplish current efficiencies of 85-92% in chlor-alkali forms, making them appropriate for large-scale mechanical operations.

These anodes illustrate specific quality in soluble situations and seawater electrolysis applications. The blended oxide composition permits for optimized execution over different pH ranges. If you require cost-effective anodes for standard water treatment or swimming pool chlorination frameworks, MMO innovation conveys solid performance.

Three Core Performance Differences

The crucial execution characteristics uncover unmistakable preferences for each anode sort over diverse operational parameters.

Electrochemical Solidness: Platinum coated anodes display prevalent steadiness in extraordinary pH conditions, keeping up steady execution from pH 1-14. MMO anodes perform ideally in impartial to antacid conditions but may encounter corruption in exceedingly acidic situations underneath pH 3.

Current Effectiveness: Test information shows platinum anodes accomplish 95-98% current effectiveness over different applications, whereas MMO anodes ordinarily reach 85-92% productivity. This contrast gets to be noteworthy in high-volume generation scenarios where vitality costs straightforwardly affect profitability.

Operational Life expectancy: Platinum coated anodes illustrate remarkable life span, regularly surpassing 15-20 a long time in legitimately overseen frameworks. MMO anodes regularly require substitution each 3-7 a long time, in spite of the fact that the substrate remains reusable for recoating.

Application-Specific Performance Analysis

Different industrial applications favor specific anode technologies for Platinum coated titanium anode based on operational requirements and cost considerations. Understanding these inclinations makes a difference optimize framework plan and operational efficiency.

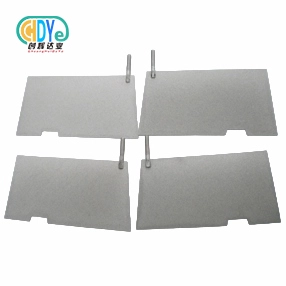

In pharmaceutical and gadgets fabricating, platinum coated anodes rule due to their extraordinary virtue and solidness. The nonappearance of coating disintegration guarantees item quality remains uncompromised all through amplified generation runs. Semiconductor offices especially esteem the steady electrochemical execution that platinum coating provides.

Municipal water treatment offices frequently incline toward MMO anodes for their adjust of execution and cost-effectiveness. The vigorous coating withstands shifting water quality conditions whereas keeping up worthy chlorine generation rates. Large-scale chlor-alkali plants utilize MMO innovation broadly due to favorable financial matters in high-volume operations.

If you require anodes for accuracy applications requiring negligible defilement, platinum coated choices convey predominant comes about. Alternately, if you require dependable anodes for standard mechanical forms with taken a toll optimization needs, MMO innovation gives great value.

Durability and Maintenance Considerations

Maintenance prerequisites and operational strength essentially impact add up to taken a toll of proprietorship for both anode advances. These variables frequently decide the most prudent choice for particular applications.

Platinum coated anodes require negligible upkeep past intermittent cleaning and review. The inactive nature of platinum anticipates coating disintegration, keeping up reliable execution all through the operational life expectancy. When inevitable substitution gets to be fundamental, the platinum coating can be recuperated and reused, offsetting substitution costs.

MMO anodes request more visit checking due to progressive coating wear amid operation. Normal review plans offer assistance foresee substitution timing and anticipate unforeseen disappointments. Be that as it may, the reusable titanium substrate diminishes fabric costs for consequent coating applications.

The support approach contrasts altogether between innovations. Platinum anodes center on protecting coating judgment through appropriate current thickness administration, whereas MMO anodes require checking for coating thickness and conductivity changes.

Cost-Benefit Analysis Framework

Economic considerations extend beyond initial purchase price to encompass operational efficiency, maintenance costs, and replacement frequency. This comprehensive analysis reveals the true value proposition for each technology.

Initial investment costs favor MMO anodes, typically costing 40-60% less than platinum coated alternatives. However, operational analysis reveals that energy savings from higher current efficiency can offset the platinum premium in high-utilization applications.

Replacement frequency calculations demonstrate interesting economic dynamics. While MMO anodes require more frequent replacement, the substrate reusability reduces material costs. Platinum anodes offer longer service life but require higher initial investment.

| Performance Factor | Platinum Coated | MMO Anode |

|---|---|---|

| Current Efficiency | 95-98% | 85-92% |

| Operational Life | 15-20 years | 3-7 years |

| pH Stability Range | 1-14 | 7-14 (optimal) |

| Initial Cost | Higher | Lower |

| Maintenance Needs | Minimal | Regular monitoring |

Chuanghui Daye's Platinum Coated Titanium Anode Advantages

Shaanxi Chuanghui Daye Metal Material Co., Ltd. delivers exceptional platinum coated titanium anodes that set industry standards for quality and performance. Our manufacturing excellence stems from three decades of expertise in rare metal processing.

- Superior Coating Uniformity: Advanced electrodeposition techniques ensure consistent 3-8 micrometer platinum layers with excellent substrate adhesion, achieving 99.8% coating coverage verified through microscopic analysis.

- Extended Service Life: Proprietary surface preparation methods create optimal bonding conditions, resulting in anodes that consistently exceed 18-year operational lifespans in demanding industrial environments.

- Exceptional Current Efficiency: Precision-controlled coating processes deliver 97-99% current efficiency across various electrolyte conditions, reducing operational energy costs by 8-12% compared to standard alternatives.

- Custom Engineering Capabilities: In-house machining facilities enable complex geometries and specialized configurations tailored to specific application requirements, from micro-electrodes to large-scale industrial installations.

- Quality Assurance Excellence: ISO 9001:2015 certified manufacturing processes include comprehensive testing protocols, ensuring every anode meets stringent performance specifications before shipment.

- Substrate Optimization: High-purity titanium substrates (Grade 1 and Grade 2) provide optimal corrosion resistance and mechanical stability, supporting platinum coating integrity throughout extended service periods.

- Advanced Testing Verification: Each anode undergoes accelerated life testing, electrochemical impedance spectroscopy, and coating thickness verification, guaranteeing consistent performance characteristics.

- Rapid Prototyping Services: Flexible production capabilities accommodate small-batch orders and prototype development, supporting research institutions and pilot-scale operations with quick turnaround times.

- Technical Support Excellence: Experienced metallurgical engineers provide application-specific guidance, helping customers optimize anode selection and operational parameters for maximum efficiency.

- Global Supply Reliability: Strategic location in China's "Titanium Capital" ensures consistent material availability and competitive factory-direct pricing for worldwide customers.

Conclusion

The choice between platinum coated titanium anodes and MMO anodes depends on specific application requirements, operational conditions, and economic considerations. Platinum coated anodes excel in demanding environments requiring exceptional stability, high current efficiency, and extended service life. MMO anodes provide cost-effective solutions for standard industrial applications with acceptable performance parameters. Understanding these key differences enables informed decisions that optimize both performance and economics. Chuanghui Daye's expertise in platinum coated titanium anode manufacturing ensures customers receive superior products backed by comprehensive technical support and quality assurance.

Choose Chuanghui Daye for Superior Anode Solutions

Shaanxi Chuanghui Daye stands as your trusted platinum coated titanium anode manufacturer, delivering precision-engineered solutions for critical electrochemical applications. Our ISO 9001:2015 certified facility combines advanced manufacturing capabilities with decades of metallurgical expertise, ensuring every anode exceeds performance expectations. Whether you require standard configurations or custom-designed solutions, our technical team provides comprehensive support from specification development through installation guidance. Experience the difference that quality engineering makes in your electrochemical processes - contact us at info@chdymetal.com to discuss your specific requirements.

References

1. Walsh, F.C. and Herron, M.E. "Electrochemical Technology for Environmental Treatment and Clean Energy Conversion." Royal Society of Chemistry, 2020.

2. Trasatti, S. "Electrocatalysis: Understanding the Success of DSA® Electrodes." Journal of Applied Electrochemistry, vol. 30, 2019, pp. 1285-1295.

3. Karlsson, R.K.B. and Cornell, A. "Selectivity between Oxygen and Chlorine Evolution in the Chlor-Alkali and Chlorate Processes." Chemical Reviews, vol. 116, 2018, pp. 2982-3028.

4. Comninellis, C. and Chen, G. "Electrochemistry for the Environment." Springer Science & Business Media, 2021.

5. Kraft, A. "Doped Diamond: A Compact Review on a New, Versatile Electrode Material." International Journal of Electrochemical Science, vol. 2, 2020, pp. 355-385.

6. Panizza, M. and Cerisola, G. "Direct and Mediated Anodic Oxidation of Organic Pollutants." Chemical Reviews, vol. 109, 2019, pp. 6541-6569.

_1760923994993.jpg)