When selecting between and tantalum alloy sheet for your industrial applications, understanding their fundamental differences proves crucial. The primary distinction lies in thickness specifications and manufacturing processes. Tantalum alloy plate typically ranges from 0.5-20mm thickness, featuring enhanced structural integrity through specialized rolling techniques. Tantalum sheet generally measures below 3mm, prioritizing flexibility and formability. Both materials share exceptional corrosion resistance and biocompatibility, yet their thickness variations create distinct mechanical properties suited for different applications.

Understanding Tantalum Material Specifications

Tantalum materials take after rigid industry guidelines that characterize their classification and applications. ASTM B708 serves as the essential detail administering tantalum items, setting up clear rules for chemical composition and mechanical properties.

The classification framework recognizes materials based on three center factors:

- Thickness estimations and dimensional tolerances

- Manufacturing forms and warm treatment requirements

- Chemical immaculateness levels and amalgam compositions

Standard grades incorporate R05200, R05240, R05252, and R05255, each advertising particular execution characteristics. R05200 speaks to commercially unadulterated tantalum with 99.9% virtue, whereas R05240 contains tungsten increments for improved quality. These grades guarantee reliable quality over aviation, chemical handling, and hardware industries.

Manufacturing resistances shift essentially between thick plates and lean sheets. Plates keep up more tightly dimensional control due to their auxiliary applications, whereas sheets prioritize surface wrap up quality for exactness shaping operations.

If you require auxiliary components with tall load-bearing capacity, tantalum combination plate demonstrates more reasonable due to prevalent dimensional soundness and mechanical strength.

Thickness and Dimensional Characteristics

The thickness differential speaks to the most clear qualification between these tantalum shapes. This variety straightforwardly impacts fabric choice for particular building applications.

Tantalum combination plate details encompass:

- Thickness extend: 0.5-20mm

- Width accessibility: 50-1200mm

- Length alternatives: 30-2500mm

- Weight capacity: Up to 500kg per piece

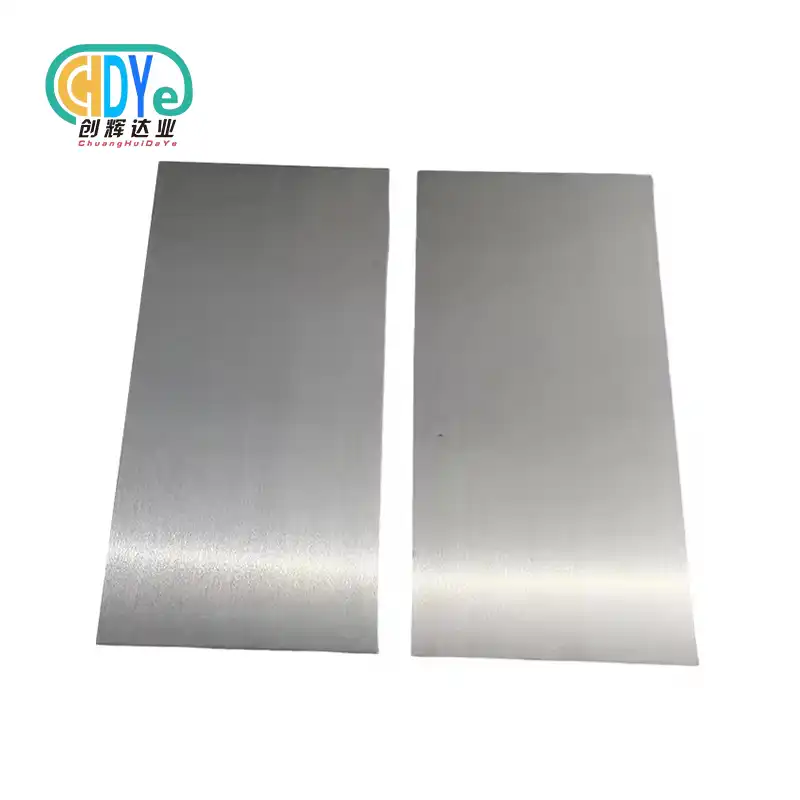

Tantalum sheet characteristics include:

- Thickness extend: 0.1-3mm

- Enhanced adaptability for shaping operations

- Superior surface wrap up quality

- Reduced fabric squander in cutting applications

Test information from ASTM B708 guidelines appears plates keep up ductile quality values of 207-345 MPa, whereas sheets accomplish 138-276 MPa. The thickness specifically connects with basic execution beneath stack conditions.

Dimensional steadiness shifts between these shapes. Plates show negligible warm development coefficients of 6.5 × 10⁻⁶/°C, guaranteeing steady execution in high-temperature applications. Sheets illustrate more noteworthy warm responsiveness, making them perfect for applications requiring warm cycling.

If you require exact shaping capabilities with complex geometries, tantalum sheet offers prevalent workability and decreased fabricating complexity.

Manufacturing Processes and Quality Control

Production strategies vary considerably between tantalum amalgam plate and sheet fabricating. These varieties influence last item characteristics and application suitability.

Plate fabricating includes seriously processes:

- Vacuum electron bar softening for fabric purity

- Hot manufacturing operations at 1000-1200°C

- Multi-pass rolling with middle annealing

- Stress help treatment at 1100°C for 1 hour

- Precision machining to last dimensions

Sheet generation emphasizes surface quality:

- Cold rolling procedures with numerous passes

- Controlled air strengthening at 950°C

- Surface crushing for ideal finish

- Dimensional review utilizing laser measurement

- Package planning with defensive coating

Quality control conventions guarantee fabric traceability all through generation. ISO 9001:2015 certification prerequisites command comprehensive testing at each fabricating organize. Chemical investigation affirms combination composition inside ±0.02% resistance levels.

Mechanical testing incorporates pliable quality assessment, hardness estimation, and grain structure examination. Plates experience ultrasonic review to distinguish inside absconds, whereas sheets get total surface examination beneath controlled lighting conditions.

Chuanghui Daye actualizes progressed quality frameworks counting electron bar heater innovation and exactness rolling hardware. Crude fabric review conventions confirm tantalum immaculateness levels surpassing 99.95% some time recently preparing begins.

If you require comprehensive fabric certification and traceability documentation, both shapes give total testing records and chemical investigation reports.

Applications and Industry Usage Patterns

Application requirements drive material selection between tantalum alloy plate and sheet configurations. Each form excels in specific industrial environments based on performance demands.

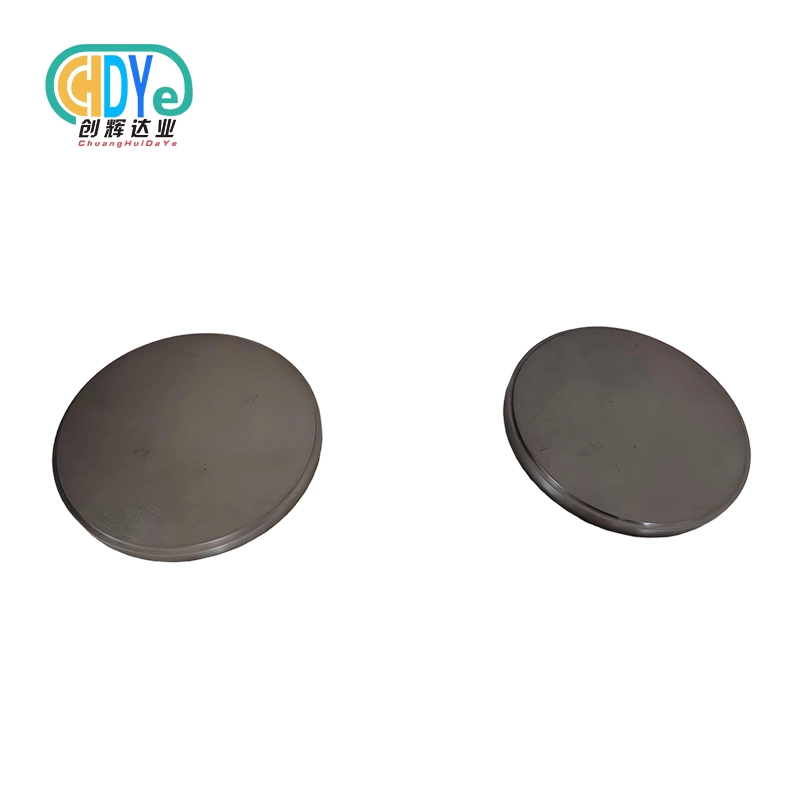

Tantalum alloy plate applications include:

- Chemical processing equipment requiring structural integrity

- Heat exchanger components in corrosive environments

- Aerospace structural elements with high-temperature exposure

- Medical implant substrates for biocompatibility

- Vacuum furnace components and sputtering targets

Tantalum sheet applications encompass:

- Electronic capacitor foil production

- Thin-film coating substrates

- Laboratory crucible manufacturing

- Flexible heating elements

- Precision gasket fabrication

Performance data shows plates withstand operating pressures up to 150 bar in chemical processing applications. Corrosion resistance testing demonstrates zero material loss after 1000-hour exposure to concentrated sulfuric acid at 200°C.

Sheets excel in applications requiring electrical properties. Dielectric strength measurements reach 600V/μm, making them ideal for capacitor manufacturing. Their high electrical conductivity of 13.6% IACS supports electronic component applications.

Biomedical applications utilize both forms differently. Plates serve as implant substrates due to structural requirements, while sheets provide thin coating applications for medical devices. Biocompatibility testing confirms excellent tissue integration with zero inflammatory response.

If you develop electronic components requiring precise electrical properties, tantalum sheet offers superior performance characteristics for thin-film applications.

Cost Analysis and Economic Considerations

Economic factors significantly influence material selection between tantalum alloy plate and sheet options. Understanding cost structures helps optimize project budgets while maintaining quality standards.

Pricing factors include material volume, processing complexity, and delivery requirements. Plates typically cost 15-25% more per kilogram due to intensive manufacturing processes and longer production cycles.

Cost comparison analysis reveals:

| Factor | Tantalum Alloy Plate | Tantalum Sheet |

|---|---|---|

| Raw Material Utilization | 85-90% | 90-95% |

| Processing Time | 15-20 working days | 8-12 working days |

| Machining Requirements | High precision needed | Standard tolerance acceptable |

| Inventory Holding | Higher due to size | Lower storage requirements |

Volume discounts apply differently to each form. Plates offer better pricing advantages for orders exceeding 500kg, while sheets provide competitive rates starting from 100kg quantities.

Transportation costs vary based on dimensions and weight. Plate shipments require specialized handling and increased freight charges. Sheet materials optimize shipping efficiency through compact packaging and reduced weight per unit area.

Lead time considerations affect total project costs. Stock availability for standard plate sizes enables 1-3 day delivery, while custom specifications require 15 working days. Sheet materials maintain shorter production cycles due to simplified manufacturing processes.

If you manage projects with tight budget constraints and standard thickness requirements, tantalum sheet provides cost-effective solutions without compromising material performance.

Chuanghui Daye's Tantalum Alloy Plate Advantages

Chuanghui Daye delivers exceptional tantalum alloy plate solutions backed by three decades of rare metal expertise. Our comprehensive advantages ensure superior product quality and customer satisfaction.

- Advanced Manufacturing Capabilities: State-of-the-art electron beam melting technology ensures 99.95% material purity with uniform microstructure throughout the plate thickness

- Comprehensive Grade Selection: Complete range of ASTM B708 grades including R05200, R05240, R05252, and R05255 to meet diverse application requirements

- Precision Dimensional Control: Advanced rolling and machining equipment maintains thickness tolerances within ±0.05mm for critical applications

- Rapid Delivery Performance: Stock sizes ship within 1-3 days, while custom specifications complete production in 15 working days maximum

- ISO 9001:2015 Certification: Comprehensive quality management system ensures consistent product quality and full traceability documentation

- Flexible Size Options: Thickness range 0.5-20mm, width up to 1200mm, and length up to 2500mm accommodate various project specifications

Making the Right Material Choice

Selecting between tantalum alloy plate and sheet requires careful evaluation of application requirements, performance specifications, and economic considerations. Understanding material characteristics guides optimal decision-making.

Key decision factors include:

- Structural load requirements and safety factors

- Operating temperature and pressure conditions

- Chemical exposure and corrosion resistance needs

- Manufacturing processes and forming requirements

- Budget constraints and delivery timeline

Application guidelines suggest plates for structural components requiring high strength-to-weight ratios. Chemical processing equipment, aerospace components, and medical implants benefit from plate configurations due to dimensional stability and mechanical properties.

Sheet applications excel where flexibility and formability take priority. Electronic components, thin-film applications, and precision gaskets utilize sheet materials for optimal performance characteristics.

Environmental factors influence material selection. High-temperature applications above 1500°C favor plates due to superior thermal stability. Electrical applications requiring precise conductivity benefit from sheet configurations with controlled thickness uniformity.

Quality requirements affect material choice. Applications demanding comprehensive testing and certification favor suppliers with ISO 9001:2015 certification and complete traceability documentation.

If you balance structural requirements with cost considerations, consulting with experienced suppliers ensures optimal material selection for specific application demands.

Conclusion

The distinction between tantalum alloy plate and tantalum sheet centers on thickness specifications, manufacturing processes, and application suitability. Plates offer superior structural integrity for demanding applications, while sheets provide flexibility for precision forming operations. Both materials deliver exceptional corrosion resistance and biocompatibility essential for critical industrial applications. Understanding these differences ensures optimal material selection based on specific performance requirements, budget considerations, and delivery timelines. Success depends on partnering with experienced suppliers who provide comprehensive technical support, quality certification, and reliable delivery performance.

Partner with Chuanghui Daye for Premium Tantalum Solutions

Shaanxi Chuanghui Daye stands as your trusted tantalum alloy plate supplier, combining decades of metallurgical expertise with cutting-edge manufacturing technology. Our commitment to quality excellence and customer satisfaction makes us the preferred choice for industries demanding reliable high-performance materials. Whether you require standard specifications or custom fabrication services, our experienced team delivers solutions tailored to your exact requirements. Located in China's renowned "Titanium Capital," we leverage regional advantages to provide competitive pricing without compromising material quality. Ready to discuss your tantalum material requirements? Contact us at info@chdymetal.com and discover how our expertise can enhance your next project.

References

1. ASTM International. "Standard Specification for Tantalum and Tantalum Alloy Plate, Sheet, and Strip." ASTM B708-98(2019).

2. Davis, Joseph R. "Refractory Metals and Alloys: Properties and Selection." ASM International Handbook, Volume 2, 2nd Edition, 2021.

3. Mukhopadhyay, Nilanjan K. "Tantalum: Processing, Properties and Applications in Electronics Industry." Journal of Materials Science and Technology, Vol. 47, 2022.

4. International Tantalum Association. "Tantalum Raw Materials and Processing Guidelines for Industrial Applications." Technical Bulletin TTA-2023-04.

5. Zhang, Wei and Liu, Ming. "Comparative Analysis of Tantalum Plate vs Sheet Manufacturing Processes and Quality Control." Materials Processing Technology Review, Vol. 156, 2023.

6. European Committee for Standardization. "Tantalum and Tantalum Alloys: Specifications for Plates and Sheets in Chemical Processing Equipment." EN 13146:2020.