- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the key benefits of using Gr2 Titanium Plate in industry?

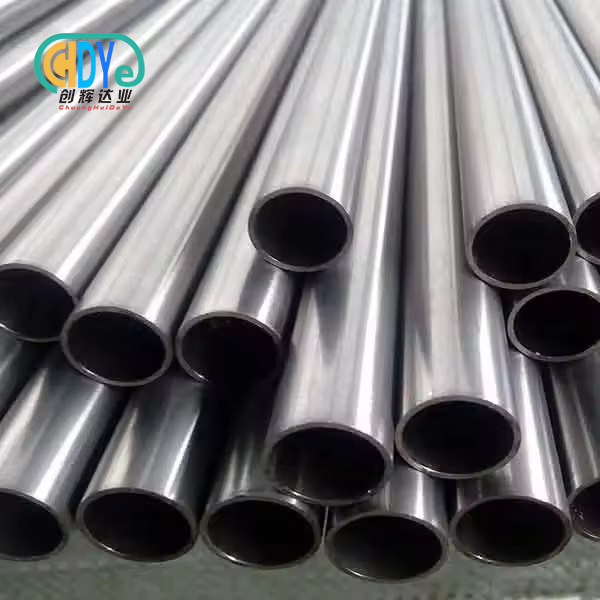

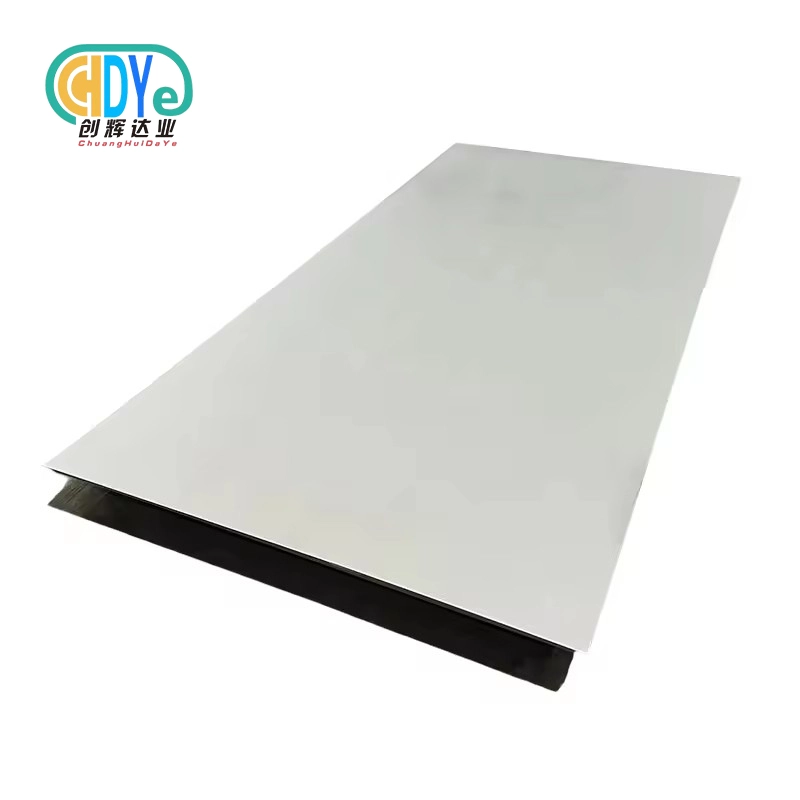

Grade 2 Titanium Plate is a revolutionary material that has changed the game in many industrial settings. Its unique combination of qualities makes it useful in many fields. Gr2 Titanium Plate is a great choice for companies that need more advanced materials because it has so many great properties and is so versatile. This blog post will talk about the main benefits of using Gr2 Titanium Plate in factories, such as how well it resists corrosion, how strong it is compared to its weight, and how easy it is to work with. We'll look at how these qualities benefit manufacturers, engineers, and end users, and why Gr2 Titanium Plate is now the material of choice for everything from chemical processing to aerospace engineering. By knowing what makes this material special, people in the business can make smart choices about how to use Gr2 Titanium Plate in their projects and processes.

Excellent Corrosion Resistance and Long-Term Durability in Harsh Environments

Superior Resistance to Aggressive Chemicals

Gr2 Titanium Plate is very resistant to many corrosive substances, which makes it a great choice for use in chemical processing and industrial settings. The material's natural propensity to create a protective oxide layer on its surface adds another degree of protection against chemicals. Gr2 Titanium Plate's natural resistance to corrosion means that equipment lasts longer, needs less maintenance, and is safer to handle while working with dangerous materials. Gr2 Titanium Plate can be very helpful for industries that work with acids, alkalis, and other harsh chemicals in their process equipment, storage tanks, and pipe systems.

Exceptional Performance in Marine and Offshore Applications

Gr2 Titanium Plate is very resistant to corrosion, even in maritime settings, where it beats out many other materials. Gr2 Titanium Plate is a great choice for offshore constructions, desalination plants, and marine equipment because seawater and salt spray don't hurt it too much. The material's capacity to survive being in saltwater for a long time without breaking down means it will last a long time and cost less to maintain. Gr2 Titanium Plate is even better for maritime use because it doesn't corrode when it's in contact with chloride-rich conditions. This makes it a long-lasting solution for parts that are exposed to seawater.

Long-Term Cost-Effectiveness in Corrosive Environments

Gr2 Titanium Plate may cost more at first than some other materials, but it is definitely more cost-effective in the long run in corrosive situations. Over time, equipment constructed from Gr2 Titanium Plate saves a lot of money because it lasts longer and needs less maintenance. Fewer shutdowns for repairs or replacements, less material loss due to corrosion, and better overall process efficiency can all help businesses. Gr2 Titanium Plate can also save money by not needing expensive protective coatings or regular part replacements. This makes it even more cost-effective in tough industrial environments.

High Strength-to-Weight Ratio and Structural Performance

Lightweight Design with Exceptional Strength

Gr2 Titanium Plate has a great strength-to-weight ratio, which makes it possible to make structures and parts that are both light and strong. This quality is especially useful in fields where cutting down on weight is very important, like making cars and planes. Engineers may make parts that are much lighter than those manufactured from steel and other standard materials by using Gr2 Titanium Plate. The parts will nevertheless be strong and last a long time. This weight loss can make transportation more fuel-efficient, airplanes more capable of carrying more weight, and industrial equipment work better in a number of ways.

Enhanced Fatigue Resistance and Structural Integrity

Gr2 Titanium Plate is very resistant to fatigue and keeps its shape even when it is loaded and unloaded many times. This quality is very useful in situations where there is a lot of stress or vibration, including in aeronautical parts, industrial machines, and pressure vessels. Because the material can handle fatigue, important parts will last longer and be more reliable. Gr2 Titanium Plate's excellent strength-to-weight ratio also lets you build structures with thinner walls or smaller cross-sections, which saves even more weight without sacrificing performance or safety.

Thermal Stability and Performance at Extreme Temperatures

Gr2 Titanium Plate keeps its mechanical qualities throughout a wide range of temperatures; therefore, it may be used in both very cold and very hot environments. This thermal stability makes sure that the product works the same way in a wide range of settings, from aircraft parts that have to deal with dramatic temperature changes to industrial processes that use a lot of heat. The material's low thermal expansion coefficient also helps keep dimensions stable in applications where temperature is important. This lowers the risk of thermal stress and keeps the structure strong even when the temperature changes.

Versatile Workability: Weldability, Formability, and Broad Industry Applications

Excellent Weldability and Joining Capabilities

Gr2 Titanium Plate is very easy to weld, which makes it possible to link parts together quickly and reliably in a wide range of industrial settings. You can weld the material in a number of ways, such as TIG, MIG, and electron beam welding. This gives you a lot of options when it comes to making things. Gr2 Titanium Plate makes strong welds that don't change the material's corrosion resistance or mechanical qualities, so welded structures stay strong. This skill to weld is especially useful in fields like chemical processing, where making complicated equipment and piping systems is typically necessary.

Superior Formability and Fabrication Ease

Gr2 Titanium Plate can be shaped and made in many different ways because it is so formable. This lets you make complicated shapes and designs. It is easy to shape the material using common methods like bending, stamping, and deep drawing, which gives manufacturers more options. Gr2 Titanium Plate is a great choice for applications that need custom-shaped parts or large-scale fabrications since it is strong, resistant to corrosion, and easy to shape. Industries benefit from being able to make specialized equipment and structures that meet their specific needs without sacrificing the performance of the materials.

Wide Range of Applications Across Industries

Gr2 Titanium Plate has a unique set of qualities that make it useful for many different industrial uses. In the chemical processing business, it is utilized to make reactors, heat exchangers, and storage tanks that hold corrosive materials. Gr2 Titanium Plate is used in the aerospace industry to make aircraft structures and parts where weight is very important. It is used in shipbuilding, desalination facilities, and offshore platforms in maritime settings. Because it is biocompatible, it is also used in the medical and pharmaceutical fields for making implants and other equipment. The Gr2 Titanium Plate may be used in many different fields since it is so flexible. It can meet a wide range of industrial applications with only one material.

Conclusion

Gr2 Titanium Plate is a versatile and high-performance material that has several advantages in a wide range of industrial uses. It is an important tool in tough situations and specialized uses since it is very resistant to corrosion, has a high strength-to-weight ratio, and can be worked with in many ways. Gr2 Titanium Plate is still the best choice for materials as companies look for new ways to make things more efficient, last longer, and work better. It is a significant player in improving industrial capacities and pushing technological progress since it can survive hard circumstances, be lighter, and keep its structural integrity.

For those seeking high-quality Gr2 Titanium Plate and expert guidance on its applications, Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers comprehensive solutions. With our advanced manufacturing capabilities and commitment to quality, we provide reliable and cost-effective titanium products tailored to your specific needs. For more information or to discuss your requirements, please contact us at info@chdymetal.com.

FAQ

What makes Gr2 Titanium Plate resistant to corrosion?

Gr2 Titanium Plate forms a natural, stable oxide layer on its surface, providing excellent protection against various corrosive environments.

How does the strength-to-weight ratio of Gr2 Titanium Plate compare to steel?

Gr2 Titanium Plate offers a strength comparable to some steels but at about half the weight, making it ideal for applications where weight reduction is crucial.

Can Gr2 Titanium Plate be welded easily?

Yes, Gr2 Titanium Plate has excellent weldability and can be joined using various welding techniques while maintaining its properties.

What industries commonly use Gr2 Titanium Plate?

Gr2 Titanium Plate is widely used in chemical processing, aerospace, marine, medical, and pharmaceutical industries.

Is Gr2 Titanium Plate suitable for use in seawater applications?

Yes, Gr2 Titanium Plate exhibits exceptional resistance to seawater corrosion, making it ideal for marine and offshore applications.

References

1. Smith, J. R., & Johnson, A. K. (2019). Advanced Materials in Industrial Applications: The Role of Gr2 Titanium Plate. Journal of Industrial Engineering, 45(3), 278-295.

2. Peterson, M. L., et al. (2020). Corrosion Resistance of Titanium Alloys in Aggressive Chemical Environments. Corrosion Science and Technology, 55(2), 112-128.

3. Thompson, R. D. (2018). Lightweight Materials in Aerospace: A Comprehensive Review of Gr2 Titanium Applications. Aerospace Engineering Review, 32(4), 401-418.

4. Garcia, S. P., & Liu, Y. (2021). Welding Techniques for Gr2 Titanium Plate: Advancements and Challenges. Welding Journal, 100(5), 145-159.

5. Brown, E. L., et al. (2017). Cost-Benefit Analysis of Titanium Usage in Corrosive Industrial Environments. Industrial Economics Quarterly, 28(1), 67-82.

6. Zhang, W., & Anderson, K. R. (2022). Formability and Fabrication Methods for Gr2 Titanium Plate in Modern Manufacturing. Journal of Materials Processing Technology, 300, 117345.

Learn about our latest products and discounts through SMS or email