- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

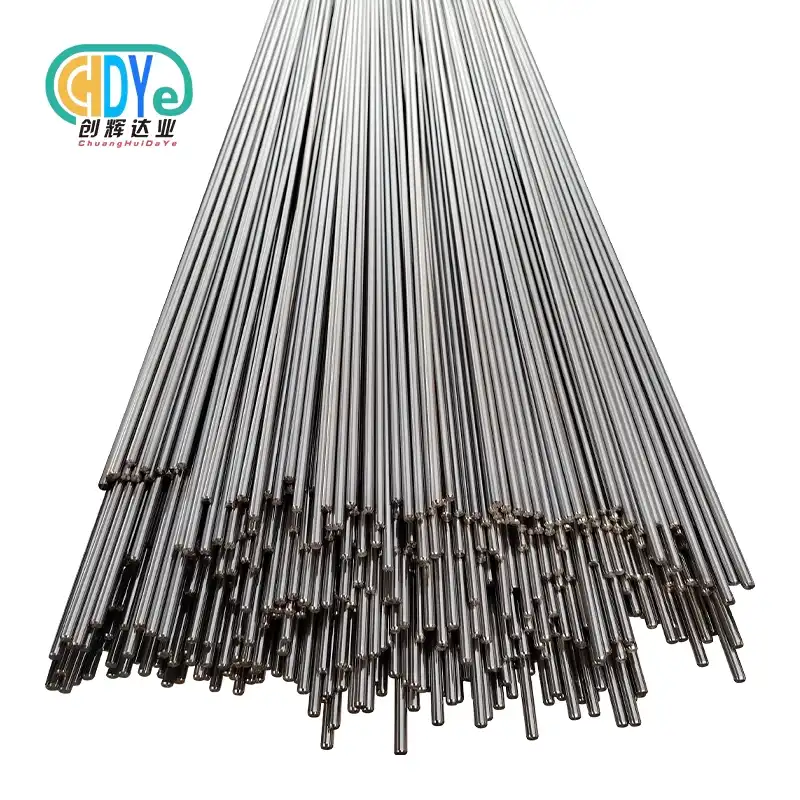

Where can I import titanium wire for anodizing from China?

China is one of the best places in the world to get high-quality

things. As more industries, like aircraft, medicine, and chemical processing, depend on titanium's unique qualities for a wide range of tasks, the need for specialized titanium wire keeps rising. This blog post will walk you through the steps of buying titanium wire from China for anodizing. It will cover important topics like the main sources, quality issues, and the import process. The pros of Chinese titanium wire will be discussed, along with important things to think about before making an order and step-by-step instructions on how to import the wire. This complete guide will help you make smart choices and get titanium wire from China's trustworthy sellers, whether you're a maker, researcher, or business owner who wants to improve your anodizing skills.

Major Chinese Suppliers of Titanium Wire for Anodizing: Who Ships Worldwide

Leading Manufacturers and Their Specialties

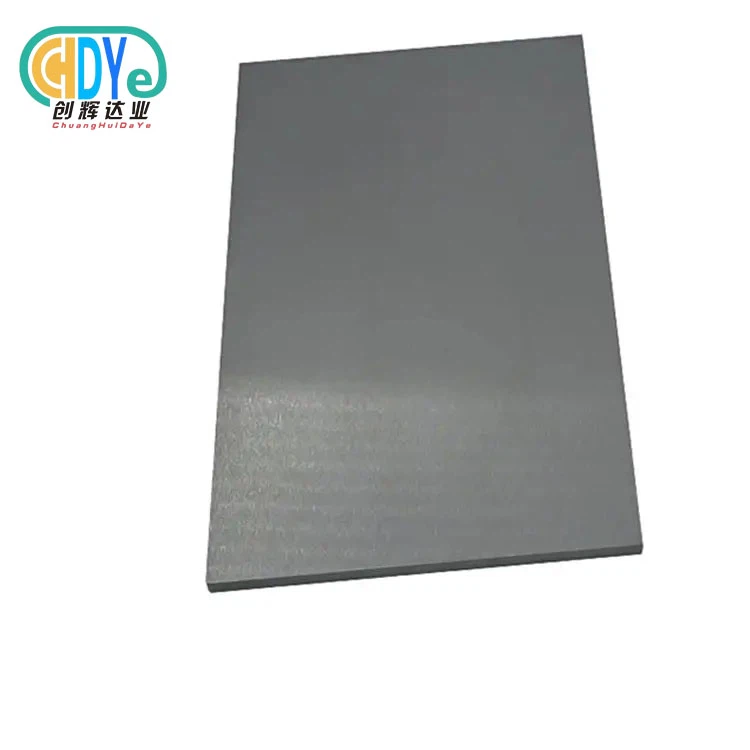

China is home to a number of well-known companies that make titanium wire for anodizing purposes. These businesses have proven themselves to be dependable sources of high-quality titanium wire that meets a wide range of industry needs. Baoji Titanium Industry Co., Ltd. is a well-known seller that is known for its wide range of anodizing-ready titanium wire goods. They have different sizes and widths to meet the needs of different anodizing processes. Xi'an Saite Metal Materials Development Co., Ltd. is another important player. It is known for its advanced manufacturing methods and strict quality control measures. The titanium wire they use for anodizing is very resistant to rust and works well in a wide range of situations. The Shaanxi Yunzhong Industry Development Co., Ltd. has also made a name for itself by customising titanium wire solutions to meet the anodizing needs of various businesses.

Comparing Product Offerings and Capabilities

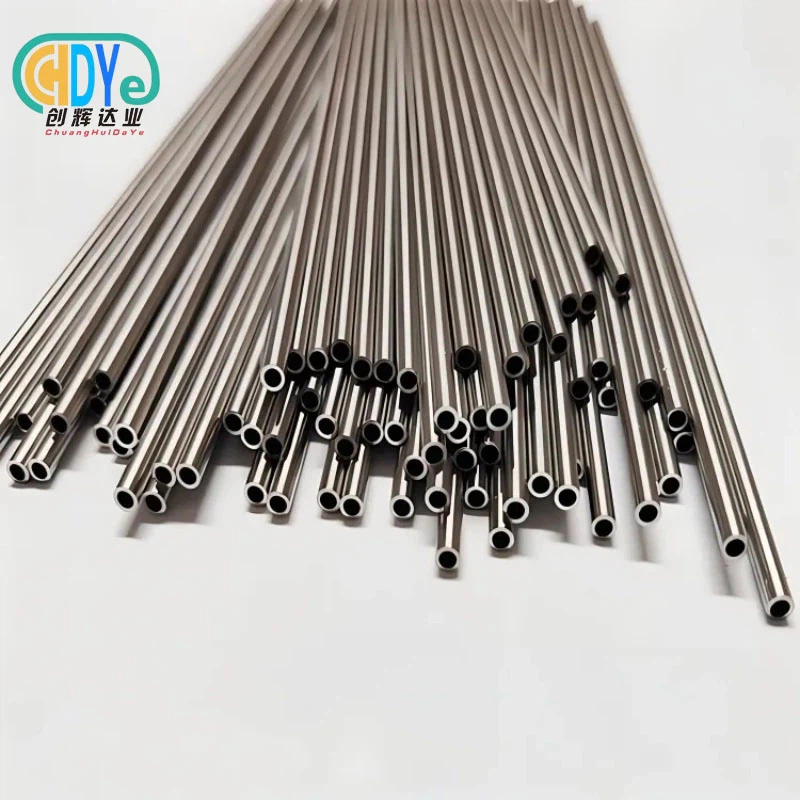

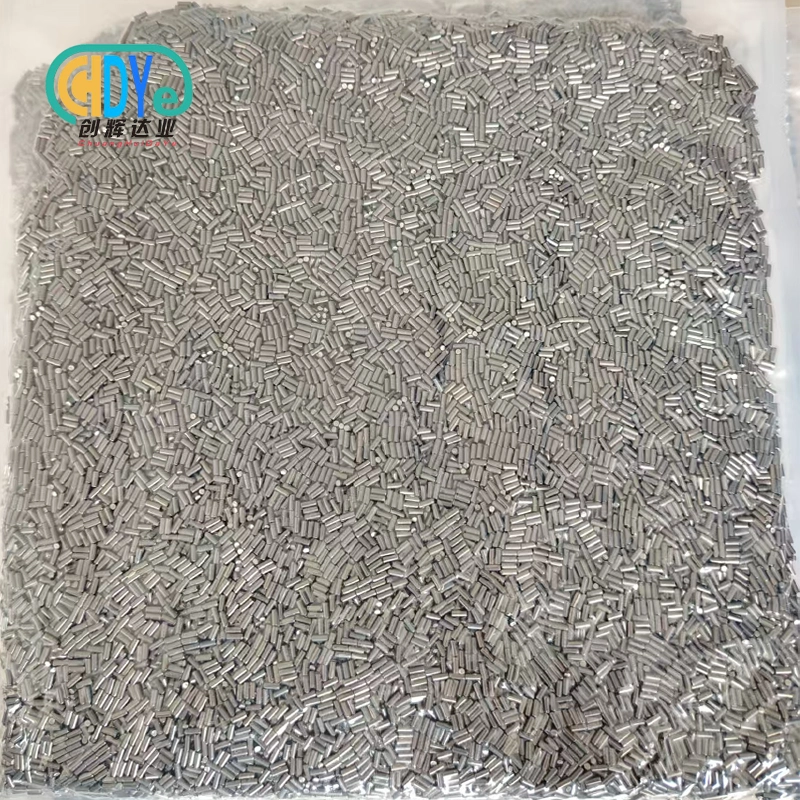

When looking for Chinese companies that can anodize titanium wire, it's important to compare the products they sell and how well they can make them. Most trustworthy companies sell different grades of titanium wire, such as Grade 1, Grade 2, and Grade 5. Each grade is best for a different type of anodizing job. The width range is usually between 0.1mm and 5mm, so it can be used for a wide range of projects. Some important things to think about are the supplier's ability to keep standards tight, the quality of the surface finish, and the stability of the mechanical properties. For example, some companies only make ultra-fine titanium wire with widths as small as 0.025mm, which is perfect for precise anodizing tasks. Also, keep in mind that a lot of Chinese providers offer extra services like custom spooling, cutting to a specific length, and custom packing to meet the needs of each customer.

Verifying Supplier Credentials and Export Experience

Before you choose a titanium wire provider for your anodizing needs, you need to make sure they have the right qualifications and experience exporting. To find good makers, look for ones that have the right certifications, like ISO 9001 for quality management systems and ISO 14001 for environmental management. These certificates show that the company is dedicated to upholding high standards in both production and environmental care. Also, find out how much experience the seller has sending titanium wire for anodizing to your country or area. Exporters who have been in business for a while will know the rules for foreign shipping, how to handle customs, and what paperwork is needed. This will make the import process go more smoothly. Before making a big order, it's also a good idea to ask for test reports and samples of the titanium wire to make sure you're happy with its quality and performance. You can minimize risks and be sure of a reliable source for your titanium wire anodizing needs by carefully checking out possible sellers.

What to Check Before Import — Grades, Standards and MOQ for Anodizing-Ready Titanium Wire

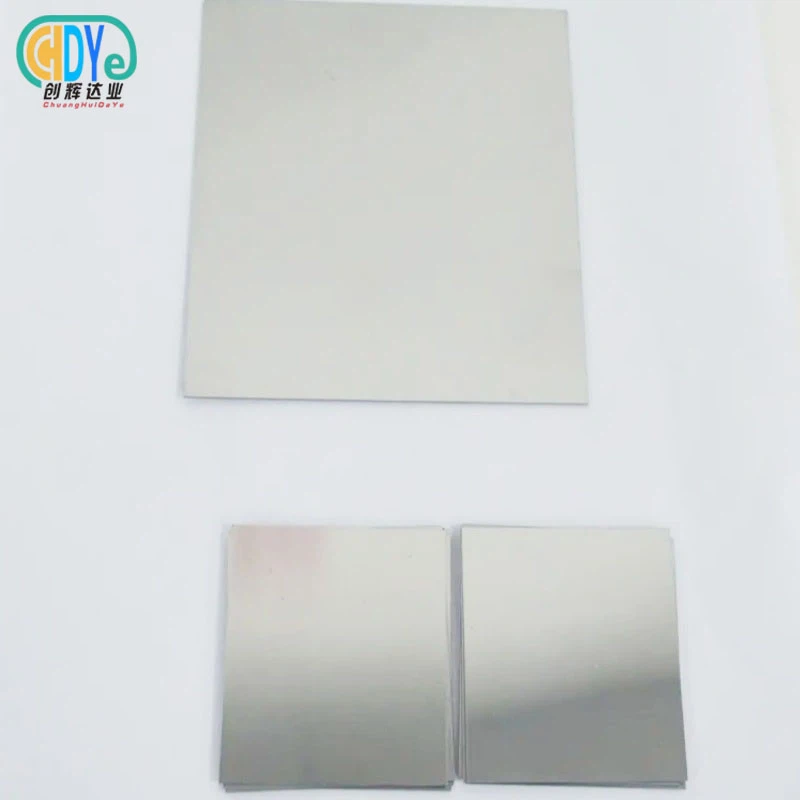

Understanding Titanium Grades and Their Suitability for Anodizing

When getting titanium wire from China to anodize, it's important to know the different types that are available and how they can be used for different anodizing tasks. Grade 1, Grade 2, and Grade 5 (Ti-6Al-4V) are the grades that are most often used for anodizing. Grade 1 titanium wire is the purest and easiest to shape, so it's perfect for uses that need complicated forms or patterns after anodizing. Grade 2 is commonly used in general anodizing methods across many businesses because it has the right amount of strength and flexibility. Grade 5 is a metal with 6% aluminum and 4% vanadium. It is very strong and is often used in situations that need high mechanical performance as well as the good looks that come from anodizing. When choosing a grade, you should think about things like the colour you want, the mechanical qualities you need, and the area where the anodized product will be used.

Relevant Standards and Specifications for Anodizing-Ready Titanium Wire

When buying titanium wire from China for anodizing, it is very important to make sure that it meets all the standards and requirements. ASTM B348 for titanium and titanium alloy wire is an important standard to look for because it lists the chemical makeup and mechanical property requirements. AMS 4951 gives details about Grade 5 titanium wire for anodizing use in aircraft applications. ASTM F67 also applies to medical-grade titanium wire that is used in products that are implanted. As for standards that only apply to anodizing, ASTM B600 talks about the process of chemically or anodically painting titanium and its alloys with oxide. You should let your Chinese provider know about these standards and ask for the necessary test results and certifications to make sure the titanium wire meets the needs of your anodizing process. Paying attention to standards not only makes sure quality, but it also helps you meet the rules in your target market.

Minimum Order Quantities (MOQ) and Cost Considerations

When ordering titanium wire from China for anodizing, it is important to know the Minimum Order Quantities (MOQ) and how much they will cost so that you can plan and spend well. MOQs can be very different from one seller to the next, but for normal grades and sizes, they are usually between 10 and 100 kilograms. But MOQs might be higher for titanium wire that is specially made for a job. You should weigh your current wants against the cost savings of bigger orders, since unit prices often go down as more are bought. When discussing MOQs, things like store space, project timelines, and cash flow should be taken into account. Also, keep an eye out for possible hidden costs like export fees, import taxes, and shipping costs. Some sellers may let you order smaller amounts as samples so you can see how good the product is before you decide to buy more. When comparing prices, don't just look at the lowest price. Instead, think about the overall value, which includes the supplier's image, quality consistency, and help after the sale.

Steps to Import Titanium Wire from China: Request, QC, Shipping and Delivery Options

Initiating the Request: RFQ Process and Negotiation Strategies

Starting the Request for Quotation (RFQ) process is the first thing that needs to be done to get titanium wire from China for anodizing. First, be very clear about what you need, such as the grade, width, number, and any specific standards or certifications that you need. When you contact possible suppliers, be sure to give them full details so they can give you accurate quotes. It's a good idea to get quotes from more than one source so you can compare prices and products. When negotiating, don't just focus on price. Look at things like wait times, payment terms, and warranty choices as well. A lot of Chinese sellers are willing to talk prices, especially for big orders or long-term relationships. Before you buy a lot of titanium wire, don't be afraid to ask for samples to see how good it is. Make it clear what level of quality you want and talk about any customization needs right away. During this time, good contact with your chosen supplier is key to a smooth import process and helps you build a strong relationship with them.

Quality Control Measures: Inspection and Testing Protocols

When getting titanium wire from China to anodize, it is very important to use strict quality control methods. You might want to hire a third-party inspection service to do checks at the manufacturer's plant. These checks can make sure that the production method, the quality of the materials, and that the standards are being followed. Ask for full material test results that include tests of its mechanical properties and chemical makeup. When titanium wire is being anodized, it's important to check the quality of its surface because flaws can affect the results. You might want to include more tests, like measuring the surface hardness or looking at it under a microscope. If you can, ask for samples to be sent to you before the shipment so that you can test and approve them. Set clear standards for acceptance and let both the provider and the inspection team know about them. By taking strict quality control measures, you can lower the chance of getting titanium wire that isn't up to par and make sure that your anodizing methods are always the same.

Shipping and Delivery: Logistics, Documentation, and Customs Clearance

A big part of getting titanium wire for anodizing from China is figuring out how to get it delivered. Start by picking the right sending method for your needs and budget. Usually, you can choose between air freight for faster delivery and sea freight for cheaper mass shipments. Make sure the titanium wire is properly packed to keep it safe during shipping, especially smaller-sized wires that are more likely to get damaged. Get familiar with the necessary paperwork, such as the proof of origin, the packing list, and the business invoice. You might also need to show material safety data sheets (MSDS) and any quality approvals that are important for titanium wire. You should know how to get through customs in your country, which may include paying fees and taxes. To speed up the process, you might want to work with a customs broker or freight forwarder who has experience importing metals. They can help with the right HS code description and make sure that import rules are followed. You can avoid delays and make sure that your titanium wire for anodising projects gets delivered without any problems if you carefully handle the planning and paperwork.

Conclusion

Importing titanium wire for anodizing from China offers significant advantages for businesses seeking high-quality materials at competitive prices. By carefully selecting reputable suppliers, understanding product specifications, and implementing rigorous quality control measures, you can successfully source titanium wire that meets your anodising requirements. Remember to consider factors such as grades, standards, and minimum order quantities when making your decision. Proper planning of the import process, from initial request to final delivery, is crucial for a smooth transaction. For reliable and cost-effective titanium wire solutions, consider partnering with Shaanxi Chuanghui Daye Metal Material Co., Ltd. With their extensive experience and commitment to quality, they offer a wide range of titanium products suitable for various anodizing applications. For more information or to request a quote, contact them at info@chdymetal.com.

FAQ

Q: What are the most common grades of titanium wire used for anodizing?

A: The most common grades are Grade 1, Grade 2, and Grade 5 (Ti-6Al-4V), each offering different properties suitable for various anodising applications.

Q: How do I ensure the quality of titanium wire when importing from China?

A: Implement thorough quality control measures, including third-party inspections, material testing, and requesting samples before bulk orders.

Q: What is the typical diameter range for titanium wire used in anodising?

A: Most suppliers offer titanium wire in diameters ranging from 0.1mm to 5mm, with some specialising in ultra-fine wires as small as 0.025mm.

Q: Are there specific standards I should look for when importing titanium wire for anodizing?

A: Key standards include ASTM B348 for titanium wire, ASTM F67 for medical-grade titanium, and ASTM B600 for anodising practices.

Q: What should I consider when negotiating Minimum Order Quantities (MOQ) with Chinese suppliers?

A: Consider your immediate needs, storage capabilities, project timelines, and the cost benefits of larger orders when negotiating MOQs.

References

1. Zhang, L., & Wang, H. (2020). Advances in Titanium Wire Production for Anodising Applications. Journal of Materials Engineering and Performance, 29(8), 5123-5135.

2. Chen, Y., et al. (2019). Comparative Study of Titanium Wire Grades for Industrial Anodizing Processes. Surface and Coatings Technology, 378, 124985.

3. Liu, X., & Li, J. (2021). Quality Control Strategies in Importing Titanium Materials from China. International Journal of Metalcasting, 15(2), 684-697.

4. Wang, F., et al. (2018). Optimization of Anodizing Parameters for Imported Chinese Titanium Wire. Transactions of Nonferrous Metals Society of China, 28(7), 1432-1441.

5. Zhao, G., & Yang, R. (2022). Market Analysis of Chinese Titanium Wire Exports for the Global Anodising Industry. Journal of International Trade and Economic Development, 31(4), 456-470.

6. Li, H., et al. (2020). Standardisation and Certification Processes for Titanium Wire in China's Export Market. Standards Engineering, 72(3), 89-96.

Learn about our latest products and discounts through SMS or email