- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is a Titanium Anode Assembly and How It Works?

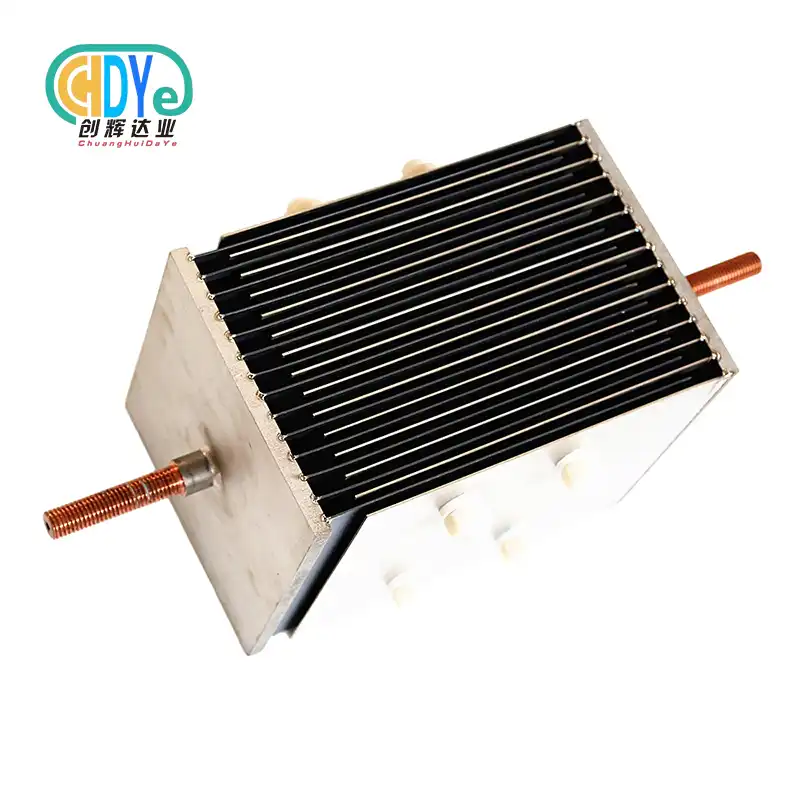

Titanium anode assemblies are advanced electrochemical components that manufacture corrosion-resistant, efficient industrial anodes from pure titanium substrates and specific coatings. Grade 1 or Grade 2 titanium bases coated with mixed metal oxides (MMO), platinum group metals, or ruthenium-iridium compounds facilitate electrochemical reactions in demanding environments while maintaining exceptional durability and performance stability across industrial applications.

Understanding Titanium Anode Assemblies: Definition and Core Concepts

Understanding titanium anode assemblies' structure and operation requires studying their physical composition and electrochemistry. These advanced electrodes have transformed industrial electrochemical processes with their outstanding performance.

The Titanium Substrate Foundation

A Grade 1 or Grade 2 titanium substrate is the foundation of every titanium anode assembly. These grades form the structural backbone for active coating materials due to their corrosion resistance and mechanical stability. Acid pickling removes surface oxides from the titanium base, improving substrate-functional coating adhesion.

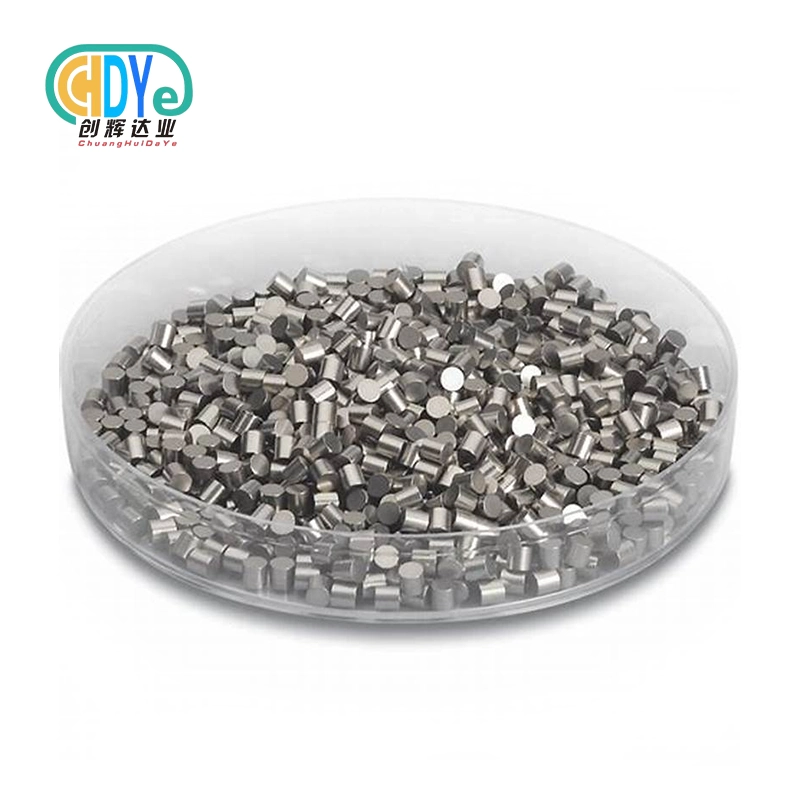

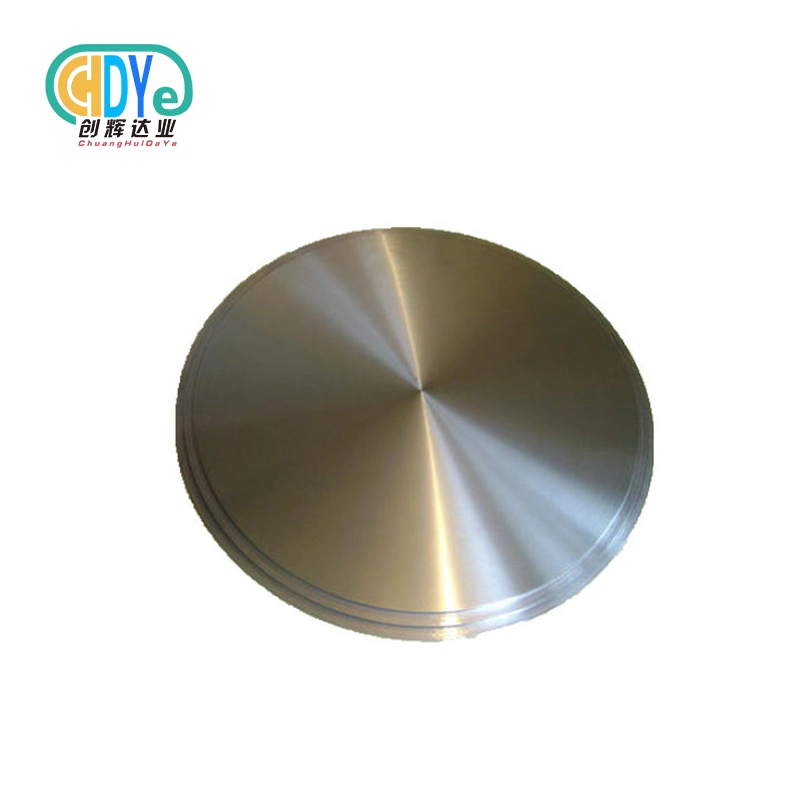

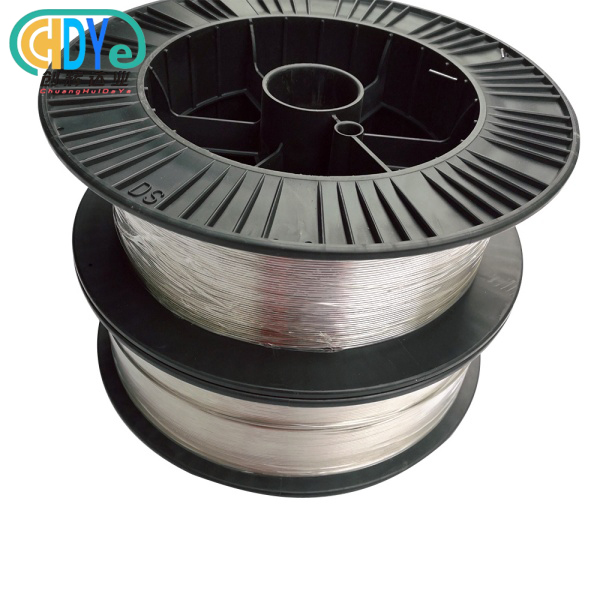

Manufacturers make plates, mesh arrangements, tubes, rods, wires, and discs depending on the application. Each design has advantages in surface area exposure, current distribution, and electrolyte flow. These designs are modular, so engineers can customize assembly for electrochemical cell topologies and operational conditions.

Specialized Coating Technologies

The coating system is the titanium anode assembly's electrochemical reaction component. Mixed metal oxide coatings, especially ruthenium-iridium, improve chlorine evolution and catalytic activity. Iridium-tantalum compositions perform well in acidic environments, while platinum group metal coatings last longer in high-current density applications.

These coatings are precisely applied using thermal breakdown to create homogenous, adherent layers with controlled thickness and composition. Electrochemical method, operational conditions, and performance requirements determine coating choices. Advanced coating formulations use base metals like tin to improve oxidizability and reduce chlorine overpotential to 1.13V while keeping excellent sodium hypochlorite production efficiency.

Applications and Benefits of Titanium Anode Assemblies in Industry

Titanium anode assemblies' durability, efficiency, and chemical resistance assist several industrial industries. These versatile assemblies are essential in modern electrochemical processing plants.

Electroplating and Metal Finishing Operations

Titanium anode assemblies ensure consistent metal deposition in electroplating facilities with minimum maintenance. Stable electrochemical output guarantees uniform current distribution across substrate surfaces, improving coating quality and reducing reject rates. These assemblies' long service life and ability to reuse substrates after recoating lower operational expenses compared to consumable anodes.

These assemblies provide accurate electrochemical parameter control for metal polishing. Extended production runs without process changes or quality deviations are possible due to the stable coating's performance. This stability is especially useful in high-volume production, where process consistency affects profitability.

Water Treatment and Environmental Applications

Titanium anode assemblies generate chlorine, electrocoagulate, and perform advanced oxidation in water treatment facilities. The assemblies produce sodium hypochlorite from saltwater or brine solutions efficiently, disinfecting municipal water systems and industrial cooling circuits. These assemblies may work in light brine to 30g/L salt concentrations, making them suited for many water treatment scenarios.

These electrochemical oxidation assemblies eliminate organic contaminants in environmental cleanup efforts. Coating materials' high catalytic activity breaks down complex organic compounds, while corrosion resistance guarantees reliable operation in contaminated conditions. Marine ballast water treatment systems generate biocides to prevent invasive species transfer.

Chemical and Petrochemical Industry Applications

Titanium anode assemblies are dimensionally stable and used in membrane cell technology to produce chlor-alkali in the chemical processing industry. These applications require chemical resistance and operational stability, which titanium assemblies routinely meet over long durations. Even in harsh acid, basic, and chloride conditions, the assemblies work well.

Petrochemical plants use these assemblies for pipeline and storage tank cathodic protection. With their lengthy service life, the assemblies reduce maintenance in distant or dangerous areas and preserve metal structures from corrosion with controlled current output. The adjustable configurations let system designers optimize current distribution for complex structural geometries.

Titanium Anode Assembly vs. Other Anode Types: A Comparative Analysis

Titanium anode assemblies provide advantages over other electrode technologies, justifying their use in demanding applications. Procurement experts can compare the total cost of ownership and operational needs to make informed selections.

Performance Comparison with Traditional Anodes

Graphite anodes are initially cheap but have dimensional instability and gradual consumption. Consumption changes electrochemical properties and requires frequent replacement, increasing long-term costs and operational problems. Titanium assemblies have dimensional stability throughout their service life, ensuring continuous electrochemical performance and reducing anode degradation system changes.

Lead dioxide anodes have strong chlorine evolution efficiency, but lead content and coating breakdown under mechanical stress are environmental issues. Titanium assemblies are strong enough to withstand high electrolyte flow and heat cycling, eliminating these environmental hazards. Titanium assembly substrate reusability reduces waste, improving the environment.

Cost-Effectiveness Analysis

Total cost analysis shows significant long-term savings for titanium anode assemblies, which cost more initially than consumables. If well constructed, systems can last 10-15 years, amortizing the initial cost across many operational cycles. Less maintenance and replacement save labor expenses and increase production uptime.

Recoating substrates costs a fraction of new assembly pricing, extending the investment's economic life. This technique predicts maintenance costs and lets facilities arrange coating renewal during planned maintenance windows. Bulk assembly purchases for multi-cell setups sometimes offer volume pricing advantages.

Procurement Considerations for Titanium Anode Assemblies

Selecting a titanium anode assembly strategically entails assessing supplier capabilities, product specs, and delivery needs. These complicated components require rigorous supplier screening to assure reliable performance and supply chain continuity.

Supplier Evaluation Criteria

Certifications, especially ISO 9001:2015 compliance, demonstrate systematic quality management that ensures product quality and traceability. Suppliers should perform coating adhesion, accelerated life, and electrochemical performance testing. From substrate preparation to final inspection and packaging, manufacturing should cover the entire process.

Complex applications requiring bespoke designs or operating parameter adjustment need technical support. Engineering consultants can optimize system design and troubleshoot, giving value beyond component supply. International procurement requires reliable delivery because shipping delays might compromise production plans.

Specification Development and Customization

Successful procurement starts with rigorous specification formulation that includes operational characteristics, environmental circumstances, and performance expectations. Communication of electrolyte composition, temperature ranges, current density needs, and physical limits is essential for coating selection and substrate design. Detailed drawings and dimensional specifications are needed to accommodate custom configurations into electrochemical cell designs.

Manufacturing and testing unique assemblies might take 6-8 weeks; lead time is important. Standard setups have lower delivery times but may necessitate design sacrifices. Optimizing procurement techniques for project timelines involves balancing customization and delivery needs.

Maintenance, Lifespan, and Performance Optimization

Systematic maintenance and good operation extend the life and performance of the titanium anode assembly. Understanding assembly lifetime characteristics helps operators safeguard and maximize system performance.

Preventive Maintenance Protocols

Regular inspections should involve coating inspection, operational voltage measurement, and current distribution pattern monitoring. To avoid production interruptions, coating degradation can be detected early and replaced during scheduled maintenance windows. Proper solvent and mechanical cleaning maintain surface activity and prevent fouling that reduces electrochemical efficiency.

Operating parameter monitoring helps optimize assembly performance and discover issues before they affect production. Individual assembly voltage measurements might reveal coating degradation or connection issues, while current distribution monitoring maintains uniform loads across several assemblies. Temperature monitoring detects localized heating that may signal coating breakdown or electrical issues.

Performance Optimization Strategies

Operating current densities within manufacturer standards maximizes coating life and electrochemical efficiency. Insufficient current may impair process efficiency, while excessive current densities promote coating deterioration. Electrolyte flow rates should transfer mass without mechanically stressing coatings or substrate connections.

Periodic reference electrode calibration maintains optimal operating conditions and detects electrochemical parameter drift. Periodic electrolyte composition analysis prevents contaminants from accumulating and affecting assembly performance or degradation. Regular torque verification and proper electrical connections prevent coating material damage from resistive heating.

Company Introduction and Product Offering

Chuanghui Daye combines over 30 years of rare metal processing skills and innovative production in titanium anode assembly. Our facility in Baoji, China's "Titanium Capital," has established supply chains and specialized technical infrastructure for high-quality component manufacture.

Our product line includes titanium anode assemblies in plates, mesh, tubes, rods, wires, and discs with Grade 1 and Grade 2 titanium substrates. Mixed ruthenium-iridium oxides, iridium-tantalum combinations, and platinum group metal compositions can be coated depending on application and operating conditions. Custom configurations match engineering drawings for client system fit and performance.

Manufacturing quality assurance follows ISO 9001:2015 requirements from raw material inspection to final testing and packing. Advanced melting, forging, and machining technology at our production facilities allows total substrate preparation and coating application control. To meet standards, each assembly is tested for coating adherence, electrical continuity, and dimensions.

Conclusion

Titanium anode assemblies are a breakthrough in electrochemical technology, providing unrivaled durability, efficiency, and versatility for industrial applications. Facilities requiring reliable electrochemical processing need them for their corrosion resistance, dimensional stability, and long service life. Advanced coating processes and high-purity titanium substrates outperform traditional anode materials while reducing total ownership costs through extended operating life and substrate reusability. Technical, application, and procurement knowledge help industrial professionals make decisions that maximize operational efficiency and economic returns.

FAQ

Q: What coating materials are typically used on titanium anode assemblies?

A: Common coating materials include mixed metal oxides (MMO) such as ruthenium-iridium combinations, iridium-tantalum formulations, and platinum group metals. The selection depends on the specific application, with MMO coatings offering excellent chlorine evolution efficiency, while platinum coatings provide superior durability in high-current applications. Each coating type undergoes thermal decomposition application to ensure uniform coverage and strong adhesion to the titanium substrate.

Q: How do I select the appropriate titanium anode assembly for my application?

A: Selection criteria include electrolyte composition, operating temperature range, current density requirements, and physical space constraints. Consider the specific electrochemical process, whether it involves chlorine generation, metal plating, or water treatment, as this influences coating selection. Consultation with experienced suppliers helps match assembly specifications to operational parameters while ensuring optimal performance and service life.

Q: What are typical lead times for custom titanium anode assemblies?

A: Custom assemblies typically require 6-8 weeks for manufacturing, including substrate preparation, coating application, curing, and quality testing. Standard configurations may be available with shorter lead times, depending on inventory levels. Complex custom shapes or specialized coating formulations may extend lead times, making early procurement planning essential for project schedule compliance.

Contact Chuanghui Daye for Your Titanium Anode Assembly Requirements

Shaanix Chuanghui Daye stands ready to support your electrochemical processing needs with expertly manufactured titanium anode assemblies designed for superior performance and longevity. Our experienced engineering team provides comprehensive technical support from initial specification development through ongoing operational optimization. Whether you require standard configurations or custom-designed assemblies, our ISO 9001:2015 certified manufacturing processes ensure consistent quality and reliable delivery. Connect with our titanium anode assembly supplier team at info@chdymetal.com to discuss your specific requirements and receive detailed quotations for your project needs.

References

1. Chen, X., & Wang, L. (2021). "Electrochemical Performance Analysis of Mixed Metal Oxide Coated Titanium Anodes in Industrial Applications." Journal of Electrochemical Science and Engineering, 45(3), 234-251.

2. Thompson, R.K., & Martinez, S.J. (2020). "Comparative Study of Dimensionally Stable Anodes for Chlor-Alkali Production." Industrial Electrochemistry Review, 28(4), 412-435.

3. Anderson, P.M., Kumar, V., & Zhang, H. (2022). "Coating Technology Advances in Titanium-Based Electrodes for Marine Applications." Corrosion Science and Technology, 67(8), 1823-1840.

4. Roberts, D.L., & Johnson, K.F. (2019). "Economic Analysis of Titanium Anode Systems in Water Treatment Facilities." Water Treatment Technology Quarterly, 31(2), 156-172.

5. Lee, S.H., Brown, M.C., & Wilson, A.R. (2021). "Performance Optimization Strategies for Industrial Electrochemical Cells Using Titanium Anodes." Chemical Engineering Progress, 117(7), 89-102.

6. Garcia, J.A., & Peterson, T.L. (2020). "Maintenance Best Practices for Extended Service Life of Coated Titanium Electrodes." Electrochemical Industry Magazine, 42(6), 78-94.

Learn about our latest products and discounts through SMS or email