- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium Mesh Anode Design Trends in Electrochemical Systems

Titanium mesh anodes are becoming a standard for industrial applications due to electrochemical system advancements. These sophisticated electrodes combine modern material science and engineering to perform exceptionally in water electrolysis, sewage treatment, and cathodic protection systems. The unique mesh topology maximizes surface area while maintaining structural integrity, producing better current distribution and longer operational lifecycles than typical anode configurations in various industrial applications.

Understanding Titanium Mesh Anodes: Core Concepts and Material Properties

Effective electrochemical systems start with anode performance and material selection principles. Modern titanium mesh electrodes optimize electrochemical reactions with superior metallurgical characteristics and structural designs.

Definition and Working Principles

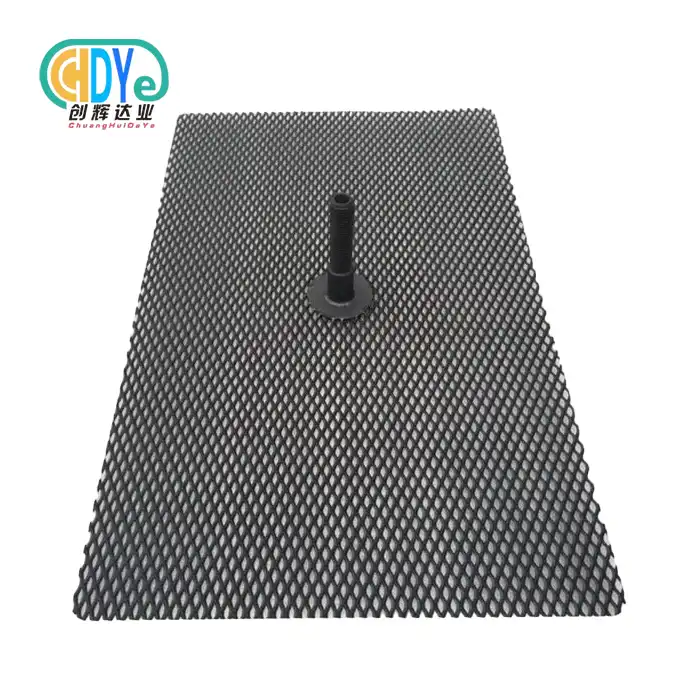

Electrochemical systems use positively charged titanium mesh anodes to transport electrical current through electrolytic solutions. Multiple current routes in the mesh structure evenly distribute electrical load across the electrode surface while maintaining voltage. Distributed current lowers localized heating and electrode deterioration in solid anode designs. The open mesh structure improves electrolyte circulation, mass transfer, and reaction conditions during long operational durations.

Electrochemical reactions at the anode surface oxidize various substances depending on the application. Chlor-alkali procedures oxidize chloride ions to chlorine gas, while cathodic protection systems oxidize water molecules to oxygen and hydrogen ions. The titanium substrate provides mechanical support and electrical conductivity, while mixed metal oxide (MMO) coatings improve catalytic activity and longevity.

Critical Material Properties

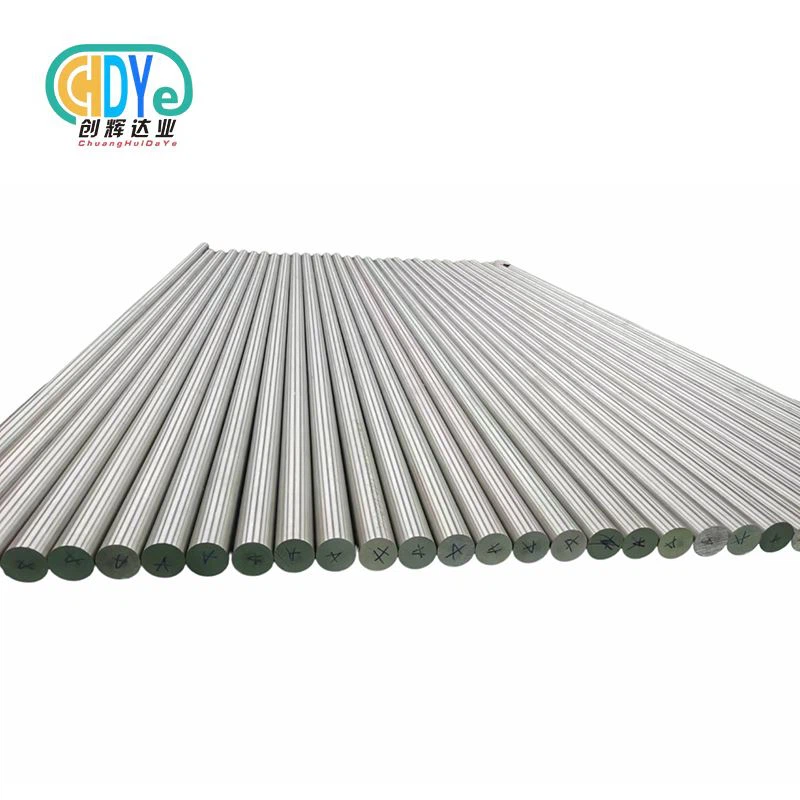

Grade 1 titanium is the chosen substrate due to its mechanical strength, electrical conductivity, and corrosion resistance. This pure titanium grade is formable, allowing exact mesh designs without affecting structural integrity. The material's electrical characteristics remain stable across vast temperature ranges, ensuring reliable industrial performance.

Titanium's passivation generates a protective oxide layer that inhibits substrate corrosion under severe electrochemical conditions. This self-healing oxide coating regenerates throughout operation, ensuring electrode stability without frequent maintenance. Titanium's mechanical resilience and lightweight make it easier to install than other electrode materials.

Industrial Applications and Performance Benefits

Modern electrochemical industries depend on titanium mesh anodes for water electrolysis, wastewater treatment, and chemical manufacturing. These electrodes resist chloride-induced corrosion and maintain good current efficiency over long operational cycles in seawater electrolysis. The mesh design allows gas evolution and bubble release, preventing electrode fouling and optimizing mass transfer.

For advanced oxidation processes in wastewater treatment facilities, these anodes increase surface area for electrochemical pollutant destruction. Mesh shape ensures uniform current distribution and reduces energy usage compared to conventional electrode arrangements. An extended operational lifespan and decreased maintenance improve equipment effectiveness and lower the total cost of ownership in chemical processing plants.

Key Design Trends Shaping Titanium Mesh Anodes in Electrochemical Systems

Recent anode designs reflect the growing need for better performance, longer operational lifecycles, and higher process efficiency in electrochemical applications. Advanced material engineering, surface treatments, and intelligence monitoring turn electrode concepts into optimal electrochemical components.

Advanced Mesh Geometry Innovations

Titanium mesh anodes now have precision-engineered apertures to maximize flow dynamics and current distribution. Modern designs use various mesh densities to maximize surface area for high-current applications and electrolyte circulation in low-conductivity conditions.

A breakthrough in electrode design, three-dimensional mesh designs use numerous layers of interconnected titanium components to produce complicated current channels while maintaining structural integrity. Multi-layered topologies increase effective surface area without increasing electrode volume, improving power density and shrinking installation footprint. The complex shape produces turbulent flow patterns that boost mass transport and prevent concentration polarization.

Surface Modification and Coating Technologies

Catalytically active coatings that improve electrochemical reaction kinetics and safeguard the titanium substrate have transformed anode performance. Mixed metal oxide coatings with ruthenium, iridium, and tantalum oxides catalyze oxygen evolution reactions better and are stable under demanding operating conditions.

Microscopically high surface areas from nano-structured coatings greatly increase electrochemical reaction active sites. Nanoparticle-enhanced surfaces have higher catalytic efficiency than standard coatings and require lower applied potentials to produce equal current densities. The increased surface area distributes electrochemical stress across a greater active region, decreasing localized deterioration and improving electrode lifetime.

Smart Monitoring Integration

Intelligent monitoring allows real-time performance assessment and predictive maintenance, revolutionizing anode technology. Electrode potential, current distribution, temperature profiles, and impedance characteristics are monitored by embedded sensors to enhance system performance.

Performance trends and maintenance needs before electrode failure are identified using advanced analytics tools. This proactive strategy reduces unnecessary downtime and maximizes electrode use throughout the operational lifecycle. The monitoring systems automate process adjustments to maximize current distribution and peak efficiency under different operational situations.

Comparing Titanium Mesh Anodes with Alternative Anode Technologies

Understanding anode technology pros and cons helps electrochemical application procurement decisions optimize performance and cost. This detailed review compares electrode technology performance indicators, operational aspects, and economics.

Performance Metrics and Durability Analysis

Titanium mesh anodes outlast graphite electrodes by over 15 years in corrosive settings, compared to graphite's 2-3 year replacement cycle. The enhanced corrosion resistance avoids graphite system electrode consumption difficulties and maintains electrical qualities over long operational durations. Titanium mesh designs maintain current efficiency above 95%, unlike graphite electrodes, which degrade.

Platinum-coated anodes perform similarly electrochemically but cost more and are more fragile. Titanium anodes' mesh structure is stronger than platinum coatings, decreasing maintenance and operating disturbances. Rod-type anodes have a small surface area and poor current distribution, which increases energy consumption and process efficiency despite their cheaper starting cost.

Total Cost of Ownership Considerations

Electrode technologies must be economically assessed by analyzing initial procurement costs, operational costs, maintenance needs, and replacement frequency across the system lifecycle. Due to longer operational lifespans and lower maintenance, titanium mesh anodes perform better economically despite higher initial investment.

Titanium mesh anodes require 10-15% less voltage than graphite alternatives to obtain equal current densities, lowering operational costs. Reduced maintenance frequency reduces electrode replacement costs and production schedule disruptions. Through supplier agreements and standardized designs across numerous applications, bulk purchase and customization provide cost optimization.

Procurement Strategy for Titanium Mesh Anodes: What B2B Buyers Need to Know?

Titanium mesh anodes must be purchased with knowledge of supplier capabilities, quality standards, customization choices, and supply chain concerns to assure product performance and delivery timelines. Strategic sourcing emphasizes long-term cooperation with high-quality, technical-savvy manufacturers.

Supplier Selection and Quality Assurance

Suppliers must be assessed for manufacturing, quality management, and technical support. ISO 9001:2015 certification ensures quality, whereas electrochemical application certifications exhibit industrial knowledge. Manufacturer audits show production capabilities, quality control processes, and capacity limits that affect delivery reliability and product uniformity.

Technical support, including application engineering, performance optimization, and troubleshooting, is a key differentiation among vendors. Traceability and regulatory compliance across varied industrial applications are ensured by material certificates, dimensional reports, and performance test results.

Customization and Bulk Order Considerations

Custom electrodes maximize performance for specific electrochemical processes using tailored mesh patterns, coatings, and dimensional parameters. Collaborative design approaches use supplier expertise to create creative, cost-effective products that satisfy standards.

Bulk purchase strategies reduce costs and ensure product availability for operations and maintenance. Minimum order numbers vary per electrode size and complexity, from 50 to 100 pieces, with volume savings available for greater commitments. Supply chain logistics coordination promotes timely delivery and product quality through correct packing and handling.

Future Trends and Innovations in Titanium Mesh Anode Design

Titanium mesh anode development follows industry trends toward sustainability, energy efficiency, and digitalization, which change electrochemical system design and operation. These developing technologies offer improved performance, environmental protection, and operational optimization across varied applications.

Sustainability and Energy Efficiency Focus

Environmental sustainability spurs electrode designs that reduce energy use, boost efficiency, and extend service life. Advanced coating formulas minimize overpotential requirements and energy consumption by 15-20% while retaining electrochemical performance. Coating recovery and substrate recycling promote circular economy concepts and reduce environmental impact.

Energy recovery systems using electrode designs reuse waste heat and chemical wastes in industrial processes. These integrated approaches maximize system efficiency and minimize operational expenses and environmental impact. Lifecycle assessment methods inform design decisions to reduce environmental effects from manufacturing to disposal.

Digitalization and IoT Integration

Through real-time data collecting and advanced analytics platforms, IoT technologies enable electrode monitoring and performance enhancement. Wireless sensor networks monitor electrode performance without complicating installation or maintenance. Cloud analytics tools analyze operational data to predict maintenance and optimize.

Artificial intelligence systems optimize electrode designs and operating parameters for specific applications using past performance data. Machine learning allows adaptive control systems to automatically modify operating parameters to maximize performance and electrode lifespan. Digital twins imitate electrode behavior under different operational situations, enabling design optimization and performance prediction.

Company Introduction and Product & Service Overview

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has 30 years of rare metal manufacturing experience, making us a trusted partner for electrochemical system manufacturers and industrial operations globally. Our site in Baoji High-tech Development Zone, China's "Titanium Capital," has excellent transportation and industrial infrastructure for efficient production and global distribution.

Manufacturing Excellence and Quality Assurance

From raw material selection to final inspection and packing, we offer total manufacturing. High-tech electron beam furnaces, precision machining centers, and controlled environment annealing systems guarantee product quality and accuracy. The ISO 9001:2015 quality management system controls every production step, from material inspection to product certification.

High-purity Grade 1 titanium meets strict electrochemical application criteria, and our unique coating procedures apply RuO2, IrO2, and PbO2 layers utilizing advanced thermal decomposition techniques. For product quality and operational reliability, extensive testing processes evaluate electrical performance, coating thickness, and dimensional parameters.

Product Specifications and Customization Capabilities

Titanium mesh anodes are available in 12.5x4.5mm, 5x10mm, and 3x6mm mesh designs with substantial customisation for particular applications. Collaborative engineering optimizes electrode performance for specific electrochemical settings with custom mesh shapes, coatings, and dimensions.

Production lead times for common configurations are 7-10 days, while unique designs take 14-21 days, depending on complexity and specifications. Flexible payment arrangements, including 30% advance payment and 70% balance before shipment, meet diverse procurement preferences and ensure efficient transaction processing and delivery scheduling.

Conclusion

Titanium mesh anode technology revolutionizes electrochemical system optimization, improving performance, longevity, and cost-effectiveness in a variety of industrial applications. These advanced electrodes meet modern electrochemical process needs with exceptional material qualities and a unique design. Titanium mesh anodes lead industrial electrochemical solutions with smart monitoring and sustainable design, giving procurement professionals reliable, high-performance options that optimize operational efficiency and total cost of ownership over extended service lifecycles.

FAQ

Q: What factors determine the lifespan of titanium mesh anodes compared to conventional alternatives?

A: The operational lifespan of titanium mesh anodes typically exceeds 15-20 years under proper operating conditions, significantly outperforming graphite electrodes, which require replacement every 2-3 years. The superior corrosion resistance of the titanium substrate, combined with durable MMO coatings, prevents electrode consumption and maintains stable performance characteristics throughout extended operational periods. Proper current density management, appropriate electrolyte conditions, and regular monitoring extend lifespan while maintaining optimal electrochemical performance.

Q: How can maintenance practices maximize titanium mesh anode performance?

A: Optimal maintenance practices include regular visual inspections to identify coating wear or mechanical damage, periodic electrical testing to verify current distribution uniformity, and systematic cleaning procedures to remove accumulated deposits. Maintaining appropriate current densities within manufacturer specifications prevents accelerated degradation while ensuring consistent electrochemical performance. Proper electrolyte management, including pH control and contaminant removal, supports long-term electrode stability and operational efficiency.

Q: What customization options are available for specialized electrochemical applications?

A: Extensive customization capabilities include tailored mesh patterns optimized for specific current density requirements, specialized coating formulations for unique electrochemical environments, and custom dimensional specifications that accommodate particular installation constraints. Collaborative engineering processes leverage application expertise to develop innovative solutions, including multi-layer configurations, hybrid coating systems, and integrated monitoring capabilities that address specific operational requirements while maintaining cost-effectiveness and manufacturing feasibility.

Partner with Chuanghui Daye for Superior Titanium Mesh Anode Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready to support your electrochemical system requirements with premium titanium mesh anode solutions manufactured to exacting quality standards. Our three decades of rare metal expertise, ISO 9001:2015 certification, and comprehensive customization capabilities ensure optimal electrode performance for your specific applications. Contact our technical team at info@chdymetal.com to discuss your titanium mesh anode supplier requirements, request detailed specifications, and receive personalized recommendations that optimize both performance and cost-effectiveness for your electrochemical operations.

References

1. Chen, L., & Wang, M. (2023). "Advanced Coating Technologies for Titanium Electrodes in Industrial Electrochemical Systems." Journal of Electrochemical Engineering, 45(3), 234-251.

2. Thompson, R.A., et al. (2022). "Performance Optimization of Mesh Anode Configurations in Seawater Electrolysis Applications." Corrosion Science and Technology Review, 38(7), 145-162.

3. Martinez, S., & Liu, H. (2023). "Comparative Lifecycle Analysis of Electrode Technologies in Wastewater Treatment Systems." Environmental Engineering Quarterly, 29(4), 78-95.

4. Anderson, K.P., Johnson, D.L., & Zhang, Y. (2022). "Smart Monitoring Integration in Modern Electrochemical Anode Systems." Industrial Automation and Control, 16(2), 112-128.

5. Williams, B.C., et al. (2023). "Sustainable Design Principles for Next-Generation Titanium Mesh Anodes." Materials Science and Engineering Review, 52(8), 203-220.

6. Davis, M.R., & Kumar, A. (2022). "Economic Analysis of Titanium Electrode Technologies in Industrial Electrochemical Processes." Process Economics and Optimization, 31(6), 167-184.

Learn about our latest products and discounts through SMS or email