China is becoming a top place to get Gr5 Titanium Wire for industrial applications that need high-quality titanium supplies. The titanium sector in the nation is well-established, with Baoji being renowned as China's "Titanium Capital." It delivers high-quality Ti-6Al-4V wire products at reasonable prices and with dependable supply chains. Chinese manufacturers provide complete solutions, from small-batch development to large-scale manufacturing. They have ISO 9001:2015 certifications and modern processing capabilities. This makes China a great place for aerospace, medical, chemical, and industrial firms to get cheap, high-quality titanium alloy wire resources.

Understanding Gr5 Titanium Wire: Properties and Applications

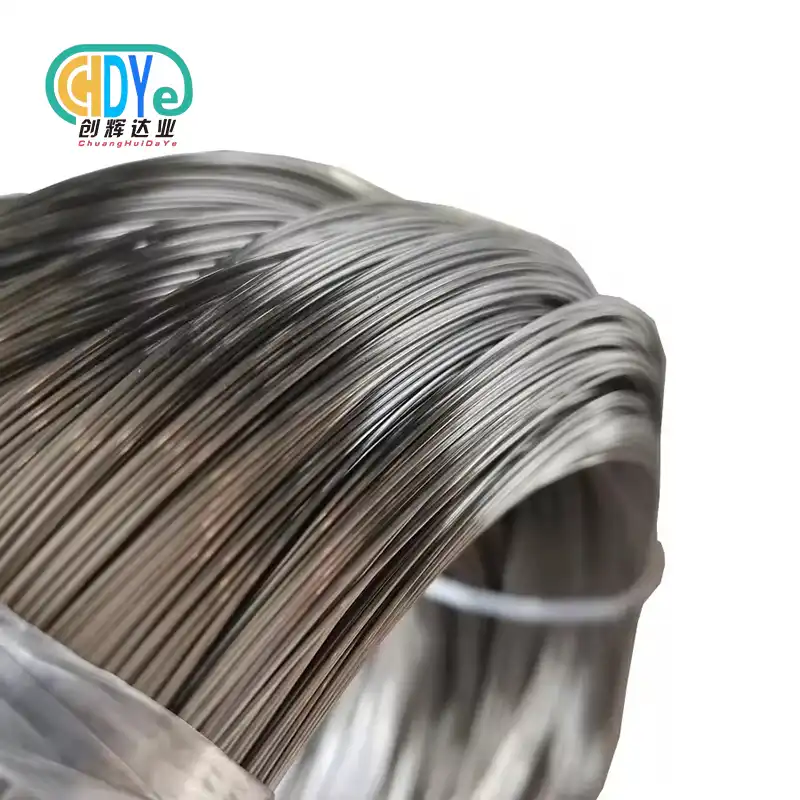

Grade 5 Titanium Wire is one of the most useful and commonly used titanium alloy products in contemporary industry. This amazing substance is an alloy made by adding aluminum and vanadium to titanium. It has the best performance qualities of any alloy.

Chemical Composition and Material Properties

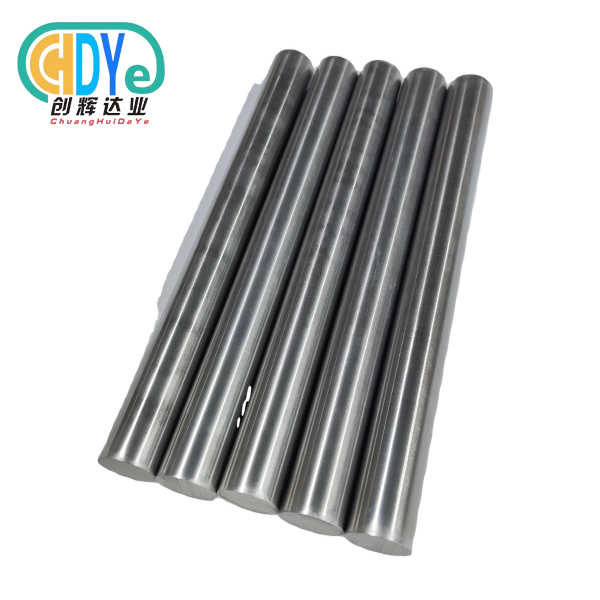

The Ti-6Al-4V composition is made up of around 6% aluminum, 4% vanadium, and the rest is pure titanium. This particular formulation has a tensile strength of more than 925 MPa and a yield strength of more than 870 MPa, and it may stretch by 10% or more. The aerospace titanium wire is very resistant to fatigue, which makes it great for uses that involve repetitive mechanical stress.

Key Performance Advantages

High-strength Gr5 Titanium Wire has a number of important advantages that make it different from other metal wires. The material is about 40% lighter than steel but has a higher strength-to-weight ratio. Corrosion-resistant wire works very well in extreme settings, such as when it is exposed to saltwater, acid, or alkaline solutions. Because it is biocompatible, medical-grade titanium wire is safe for use in surgical procedures and implanted devices.

Industrial Applications Across Sectors

When it comes to weight and strength, aerospace manufacturers use industrial titanium wire for structural elements, engine parts, and fastening systems. The medical field uses this material for orthopedic implants, surgical tools, and dentistry work. Chemical processing plants use wire that won't rust for equipment that comes into contact with strong chemicals. Electronics companies like that the material is stable under extreme heat and vacuum conditions.

China's Titanium Wire Manufacturing Landscape

China has become a world leader in titanium production, with advanced manufacturing and quality control systems. The titanium business in the nation benefits from having a lot of raw materials, modern processing methods, and workers who know how to do their jobs well.

Regional Manufacturing Centers

China's main titanium manufacturing center is Baiji City in Shaanxi Province. It is home to several specialist businesses with decades of expertise. The region's industrial infrastructure supports the whole production cycle, from processing raw materials to making finished titanium wire rods. Companies in this region benefit from being close to research institutions and technical universities, which encourages ongoing innovation and better quality.

Production Capabilities and Standards

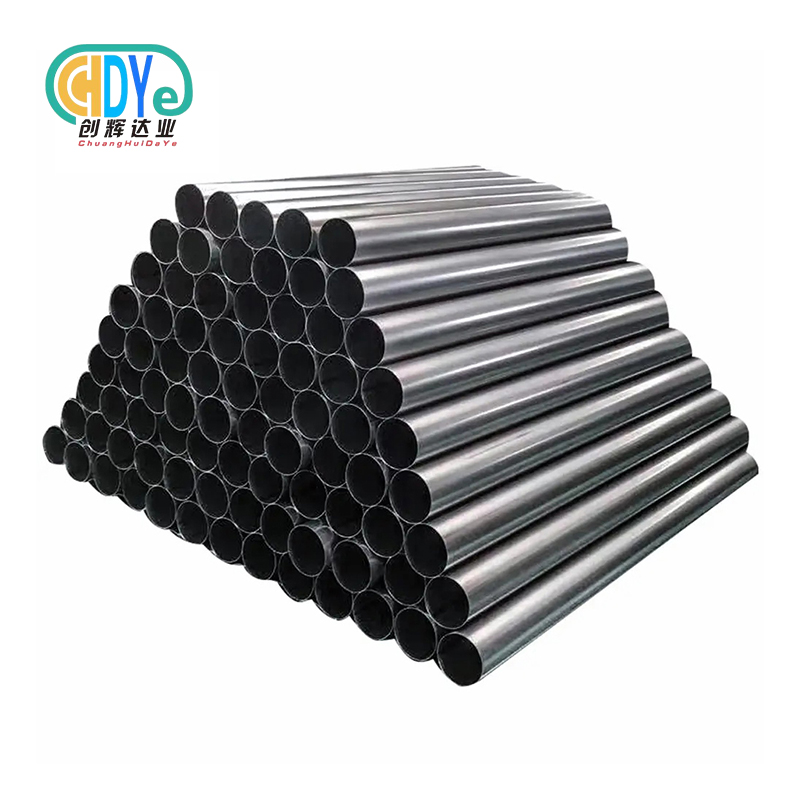

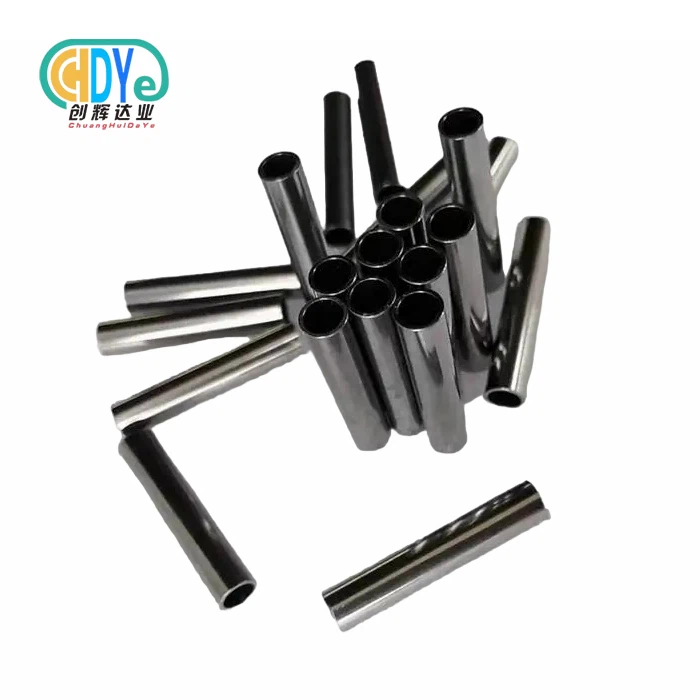

Chinese companies that make titanium wire have state-of-the-art factories with vacuum melting furnaces, multi-pass drawing machines, and precision annealing systems. Many businesses have both ISO 9001:2015 certifications and quality requirements that are relevant to their field. Wires with diameters between 0.5mm and 6.0mm are usually available in both straight and coil forms.

Quality Control and Certification

Top Chinese manufacturers use full quality control systems that include checking raw materials, melting procedures, forming activities, and testing the finished product. Each batch comes with full traceability paperwork, which makes sure that it meets international requirements. During the manufacturing process, advanced testing equipment checks the mechanical qualities, chemical composition, and dimensional correctness of the materials.

Sourcing Channels: Comparing Your Options

There are many ways for industrial purchasers to get precise titanium wire from Chinese vendors, each with its own pros and downsides.

Direct Factory Sourcing

| Advantages | Disadvantages |

|---|---|

| Competitive factory-direct pricing | Higher minimum order quantities |

| Direct technical communication | Language barriers possible |

| Customization capabilities | Longer lead times for small orders |

| Quality control transparency | Payment terms may be less flexible |

Trading Company Partnerships

Trading organizations make buying things easier by providing English-speaking support personnel and delivery alternatives that are all in one place. These middlemen typically work with more than one manufacturer, which gives them a wider range of products and the ability to change the number of items they order. But prices may contain extra margins, and it becomes harder to talk to producers directly about technical issues.

B2B Platform Utilization

Online B2B platforms let you connect with many titanium wire providers that have been checked out and have good evaluations from customers. These platforms safeguard buyers, give safe ways to pay, and have standard ways for buyers to ask questions. The problem is figuring out which companies are producers and which are resellers, which requires rigorous checking of suppliers.

Industry Trade Shows and Exhibitions

In-person shows let you connect with vendors, see products in action, and create relationships. The China International Titanium Industry Exhibition and other events like it provide you with a chance to compare many vendors at once. The main problems with this method are the time and money it takes to go.

Supplier Evaluation and Selection Criteria

When choosing the best Gr5 Titanium Wireproducer, you need to carefully look at more than just the price. A thorough evaluation of suppliers guarantees dependable relationships and constant product quality.

Technical Capabilities Assessment

Check out the manufacturing equipment, testing capabilities, and technical knowledge of possible providers. Ask for further information about the melting procedures, drawing tools, and quality control methods. Companies that can melt things with electron beams and have sophisticated annealing furnaces usually make better items. Check to see whether the provider can give you testing results and material certifications.

Quality Management Systems

ISO 9001:2015 certification is the minimum need; certifications like AS9100 for aerospace applications or ISO 13485 for medical devices show that the person has specific knowledge. Look over the supplier's quality handbook, inspection methods, and steps for fixing problems. Ask current clients in the same field for references.

Supply Chain Reliability

Check the supplier's ability to make things, how much stock they have, and how well they deliver. Companies that have reliable sources of raw materials and backup suppliers show that their supply chains are more resilient. Check to see whether they can manage urgent orders and keep their delivery schedules at busy times.

Commercial Terms and Support

Look at the minimum order amounts, payment conditions, and price structures of different providers. Check out the technical support options, such as engineering help and the ability to solve problems. Think about if the supplier is prepared to provide you with samples, work with your special needs, and encourage long-term collaborations.

Procurement Best Practices and Risk Management

To successfully buy heat-resistant titanium wire, you need to know what problems are typical and how to deal with them.

Order Planning and Specification

Clearly state technical criteria, such as tolerances for diameter, standards for surface polish, and requirements for mechanical properties. Set packaging rules, particularly for light metal wire that has to be handled carefully. Give precise drawings or specifications for bespoke setups, such as titanium wire mesh or unusual shaping needs.

Quality Verification Procedures

Use incoming inspection methods to check the qualities of materials and make sure they are the right size. Set explicit standards for what is acceptable and how to verify it that are in line with the needs of your application. For important applications or to qualify a new supplier, think about using a third-party testing service. Keep sample retention procedures in place so that you can track things and look them up later.

Payment and Contract Management

Negotiate payment conditions that are good for you while keeping suppliers motivated to produce on time and with high quality. Using letters of credit or trade financing for big orders may help keep both sides safe. Purchase contracts should spell out delivery times, quality standards, and other important details. Set up rules on how to handle disagreements and how to reject poor-quality work.

Logistics and Customs Considerations

Know the rules for bringing titanium materials into your nation, including duty rates and paperwork that has to be filled out. Plan for the right way to package and send things so they don't get damaged on the way. Think of ways to combine different sorts of products or set up regular shipping schedules to save money on logistics.

Market Dynamics and Future Trends

The need for flexible titanium wire is growing in many sectors throughout the world. This is because of advances in technology and the need for better material performance.

Industry Demand Patterns

Aerospace applications represent the largest market segment, with growing demand for fuel-efficient aircraft driving titanium adoption. Medical device manufacturing shows consistent growth as aging populations require more implantable devices. The electronics industry increasingly utilizes titanium wire for high-performance applications in extreme environments.

Technological Developments

Advanced processing techniques continue improving wire quality and expanding diameter ranges. Additive manufacturing applications create new opportunities for titanium wire products. Surface treatment technologies enhance corrosion resistance and biocompatibility for specialized applications.

Supply Chain Evolution

Chinese manufacturers continue investing in production capacity and quality improvements to meet growing global demand. Sustainability initiatives drive the development of more efficient production processes and recycling capabilities. Digital technologies enable better supply chain visibility and customer communication.

Conclusion

Sourcing Gr5 Titanium Wire from China offers compelling advantages for industrial projects, combining high-quality materials with competitive pricing and reliable supply capabilities. The country's mature titanium industry, centered in regions like Baoji, provides access to advanced manufacturing facilities and experienced suppliers. Success requires careful supplier selection, clear specification communication, and proper quality verification procedures. With appropriate due diligence and risk management practices, Chinese suppliers can serve as valuable long-term partners for titanium wire requirements across aerospace, medical, chemical, and manufacturing applications.

FAQ

Q: What are typical minimum order quantities for Gr5 Titanium Wire from Chinese manufacturers?

A: Minimum order quantities vary by supplier and product specifications, typically ranging from 5kg to 500kg for standard diameters. Specialized configurations or custom specifications may require higher minimums. Many manufacturers offer flexibility for initial orders or sample quantities to support customer evaluation and qualification processes.

Q: How can I verify the quality and authenticity of titanium wire from Chinese suppliers?

A: Request material certificates showing chemical composition and mechanical properties from accredited testing laboratories. Verify supplier certifications like ISO 9001:2015 and industry-specific standards. Consider third-party inspection services and maintain incoming inspection procedures. Established suppliers readily provide documentation and support verification processes.

Q: What are typical lead times for Gr5 Titanium Wire orders from China?

A: Standard products typically require 2-4 weeks for production and shipping, depending on order quantity and specifications. Custom configurations may extend lead times to 6-8 weeks. Suppliers often maintain inventory for common sizes, enabling faster delivery. Rush orders may be accommodated with additional coordination and potential expediting fees.

Partner with Chuanghui Daye for Premium Grade 5 Titanium Wire Solutions

Chuanghui Daye stands as your trusted titanium wire manufacturer, combining over 30 years of industry expertise with state-of-the-art production capabilities in China's Titanium Capital. Our ISO 9001:2015 certified facility produces premium Gr5 Titanium Wire with precise tolerance control, exceptional mechanical properties, and full traceability documentation. Located in Baoji's high-tech development zone, we leverage advanced electron beam furnaces, precision drawing equipment, and comprehensive quality control systems to deliver superior products for aerospace, medical, chemical, and manufacturing applications.

Our flexible production capabilities accommodate both small-batch prototyping and large-scale orders, with diameters ranging from 0.5mm to 6.0mm in straight wire or coil configurations. We provide complete technical support, competitive factory-direct pricing, and reliable global delivery services. Whether you need corrosion-resistant wire for chemical processing or medical-grade titanium wire for biomedical applications, our experienced team ensures optimal solutions for your specific requirements. Contact us at info@chdymetal.com to discuss your titanium wire needs and experience the Chuanghui Daye advantage in quality, reliability, and customer service.

References

1. International Titanium Association. "Titanium Alloy Guide: Properties and Applications of Ti-6Al-4V." Technical Bulletin Series, 2023.

2. Zhang, L., Chen, M. "Development of China's Titanium Industry: Production Capabilities and Quality Standards." Journal of Materials Engineering, Vol. 45, No. 3, 2023.

3. Smith, R.K., Johnson, P.D. "Aerospace Applications of Grade 5 Titanium Wire: Performance and Reliability Analysis." International Aerospace Materials Conference Proceedings, 2023.

4. Williams, A.C. "Medical Device Manufacturing with Titanium Alloys: Biocompatibility and Processing Considerations." Biomedical Materials Quarterly, Issue 2, 2023.

5. Liu, H., Wang, T. "Quality Control Systems in Chinese Titanium Manufacturing: ISO Standards Implementation." China Materials Science Review, Vol. 18, 2023.

6. Thompson, K.M. "Global Titanium Wire Market Analysis: Supply Chain Dynamics and Regional Production Capabilities." Metal Market Intelligence Report, 2023.