Choosing the proper niobium alloy plate is very important for getting the optimum performance in tough industrial settings while looking for the best niobium alloy plates for chemical processing. These specialist metals are the best at resisting corrosion, high temperatures, and chemicals, which makes them essential for heat exchangers, petrochemical equipment, and reactor vessels. Niobium-based superalloy plates have special qualities that let chemical processing plants keep working efficiently while lowering maintenance costs and greatly increasing the life of their equipment.

Why Focus on Niobium Alloy Plates for Chemical Processing

Physical processing conditions are quite different and need materials with very special properties. Niobium alloy plate solutions solve these problems by using their natural qualities, which are better than those of standard materials in many important ways.

Niobium alloys have a metallic bonding structure that makes them very resistant to chemical attacks from acids, alkalis, and organic solvents that are often employed in processing plants. This chemical stability means that equipment lasts longer and costs less to repair. Companies that work with harsh chemicals have said that switching from old materials to niobium-based ones has saved them a lot of money.

Niobium alloys may be heat-treated to give them certain mechanical qualities that are better for certain uses. Controlled processing may improve the grain structure to get the right strength levels while keeping good ductility. This flexibility lets engineers choose materials that suit their specific performance needs instead than settling for less-than-perfect ones.

These materials have a high strength-to-weight ratio, which is useful in large-scale chemical processing equipment because it makes installation easier and requires less structural support. This feature is very useful in offshore processing plants where weight limits are quite important.

Selection Criteria for Superior Chemical Processing Materials

To get the best niobium alloy plates, you need to look at a number of performance characteristics that have a direct effect on chemical processing activities. These criteria are the basis for making smart choices about what materials to use.

Corrosion resistance is the most important factor in choosing a material since chemical processing settings frequently have very aggressive media. Any material that can keep its structural integrity when exposed to strong acids, caustic solutions, and organic chemicals is suitable for these uses. Compared to regular stainless steels and other common materials, niobium alloys work better.

High temperature resistance is also very significant in processes that run at high temperatures. A lot of chemical processes need very precise temperature control, and the materials used in the equipment must keep their characteristics over the whole range of temperatures. Niobium alloys have great thermal conductivity, which means they can transport heat well while still being stable.

Welding compatibility makes ensuring that equipment that has been made may be put together and kept in good shape. The method of making the parts must make sure that the joints are strong and that the base material's corrosion resistance and mechanical qualities are still good. When done well, niobium alloys are very easy to weld.

Certification for industrial use and traceability documentation are ways to make sure that products fulfill certain standards. For regulatory compliance and quality control, chemical processing applications generally need full documentation of all materials.

Global Market Characteristics and Regulatory Considerations

The worldwide market for high-performance materials in chemical processing reflects increasing demand for equipment reliability and environmental compliance. Regulatory frameworks across different regions influence material selection decisions and procurement strategies.

Environmental regulations drive the adoption of materials that extend equipment life and reduce waste generation. Niobium alloy plates contribute to sustainability goals by eliminating the need for frequent replacements and reducing maintenance-related waste streams. Many facilities report achieving environmental certification more easily when utilizing these long-life materials.

Quality standards vary between regions, but ISO 9001:2015 certification provides internationally recognized quality assurance that meets requirements in virtually all markets. This certification ensures that materials and manufacturing processes meet consistent quality standards regardless of geographic location.

Supply chain considerations become increasingly important as chemical processing facilities operate globally. The ability to source materials from certified suppliers with established quality systems ensures consistent material properties and reliable delivery schedules. Geographic diversity in supplier bases provides supply security against regional disruptions.

Emerging markets demonstrate growing demand for high-performance materials as their chemical processing industries mature. These markets often adopt the latest technology standards from the beginning, creating opportunities for advanced materials that might require retrofitting in established facilities.

Purchasing Recommendations and Critical Considerations

Successful procurement of niobium alloy plates requires understanding both immediate application requirements and long-term operational goals. Strategic purchasing decisions can significantly impact total cost of ownership and operational reliability.

Material certification documentation should include complete chemical analysis, mechanical property verification, and traceability information back to raw material sources. This documentation becomes essential for regulatory compliance and quality control programs. Reputable suppliers provide comprehensive certification packages that meet international standards.

Lead time considerations vary significantly depending on material grades and quantities required. Standard specifications may be available from inventory, while custom alloys or special sizes typically require longer production schedules. Early engagement with suppliers during project planning phases helps ensure material availability aligns with construction schedules.

Technical support capabilities of suppliers provide significant value beyond material supply. Experienced suppliers offer application engineering assistance, fabrication guidance, and troubleshooting support that can prevent costly mistakes during installation and operation.

Long-term supply relationships with qualified suppliers provide advantages through improved pricing, priority allocation during supply constraints, and access to new material developments. Chemical processing facilities benefit from establishing partnerships with suppliers who understand their specific requirements and operating conditions.

Conclusion

Selecting the best niobium alloy plates for chemical processing applications requires balancing performance requirements with economic considerations. UNS R04200 reactor grade materials provide ultimate performance for critical applications, while commercial grades offer excellent value for standard requirements. Titanium-niobium alloys deliver enhanced properties for specialized applications requiring superior strength or biocompatibility.

Success depends on partnering with experienced suppliers who understand chemical processing requirements and provide comprehensive technical support. Material certification, reliable supply chains, and ongoing technical assistance contribute as much to project success as material properties themselves. Investment in premium materials yields long-term benefits through improved reliability, reduced maintenance costs, and enhanced operational efficiency in demanding chemical processing environments.

FAQ

Q: What makes niobium alloy plates superior to stainless steel for chemical processing applications?

A: Niobium alloy plates offer exceptional corrosion resistance that surpasses stainless steel in many aggressive chemical environments. They maintain their properties at higher temperatures and provide better resistance to stress corrosion cracking. The materials also demonstrate superior performance in reducing atmospheres where stainless steels may fail.

Q: How do I determine the correct grade of niobium alloy plate for my specific application?

A: Grade selection depends on operating conditions including temperature, chemical exposure, mechanical loads, and purity requirements. Reactor grade materials offer highest purity for critical applications, while commercial grades provide excellent performance at lower costs. Consulting with experienced suppliers helps identify optimal specifications for specific applications.

Q: What are the typical lead times for custom niobium alloy plate orders?

A: Lead times vary based on grade, size, and quantity requirements. Standard grades in common sizes may be available from inventory within weeks, while custom alloys or special dimensions typically require 2-3 weeks for production. Planning ahead and working with suppliers who maintain inventory helps minimize delays.

Partner with Chuanghui Daye for Premium Niobium Alloy Plate Solutions

Chuanghui Daye stands out as a leading niobium alloy plate manufacturer with over 30 years of expertise in rare metal processing. Our ISO 9001:2015 certified facility in China's "Titanium Capital" provides world-class manufacturing capabilities with strict quality control throughout every production step.

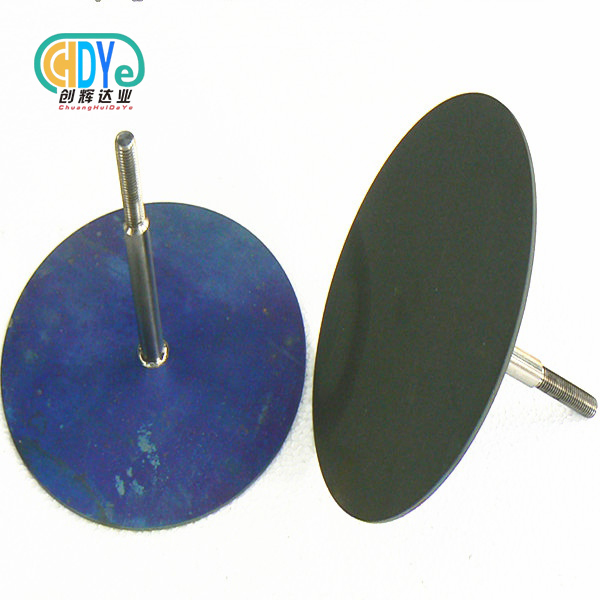

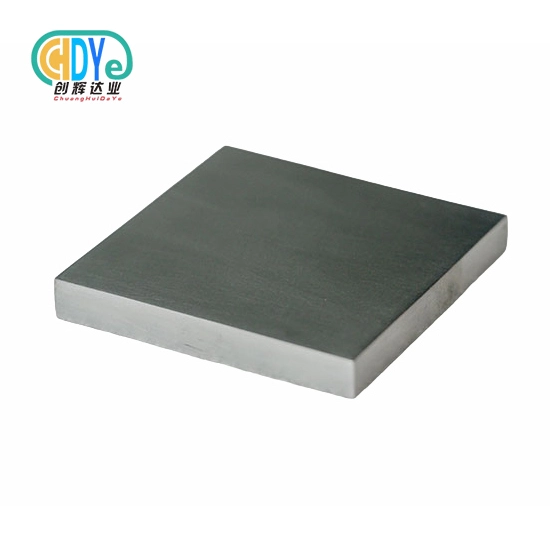

Our comprehensive inventory includes reactor grade and commercial grade materials ready for immediate shipment, while our custom processing capabilities handle specialized requirements including precision machining, heat treatment, and surface finishing. The advanced vacuum melting and electron beam processing equipment ensures consistent material properties that meet the most demanding specifications.

Chemical processing companies worldwide rely on our technical expertise to solve their most challenging material requirements. Our engineering team provides application-specific recommendations and fabrication guidance that helps optimize performance while controlling costs. Complete traceability documentation and comprehensive testing ensure materials meet all regulatory requirements.

Ready to enhance your chemical processing operations with premium niobium alloy plates? Contact our technical team today to discuss your specific requirements and receive customized recommendations. Reach out to us at info@chdymetal.com to begin your consultation with our materials experts.

References

1. American Society for Testing and Materials. "Standard Specification for Niobium and Niobium Alloy Bars and Rod." ASTM B393-18, ASTM International, 2018.

2. Smith, John R., and Patricia L. Chen. "Corrosion Resistance of Refractory Metals in Chemical Processing Applications." Journal of Materials Engineering and Performance, vol. 31, no. 8, 2022, pp. 6234-6251.

3. International Organization for Standardization. "Quality Management Systems - Requirements for Aerospace, Defence and Chemical Processing Industries." ISO 9001:2015 Guidelines, 2021.

4. Williams, Michael K. "High-Temperature Performance of Niobium Alloys in Petrochemical Equipment." Chemical Processing Equipment Review, vol. 45, no. 3, 2023, pp. 112-128.

5. Brown, Sarah J., et al. "Fabrication and Welding Considerations for Niobium Alloy Components in Industrial Applications." Welding Research International, vol. 28, no. 12, 2022, pp. 892-908.

6. Thompson, Robert A. "Economic Analysis of Advanced Materials in Chemical Processing Equipment Design." Chemical Engineering Economics Quarterly, vol. 19, no. 4, 2023, pp. 45-62.