- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What factors determine the quality of titanium seamless tube?

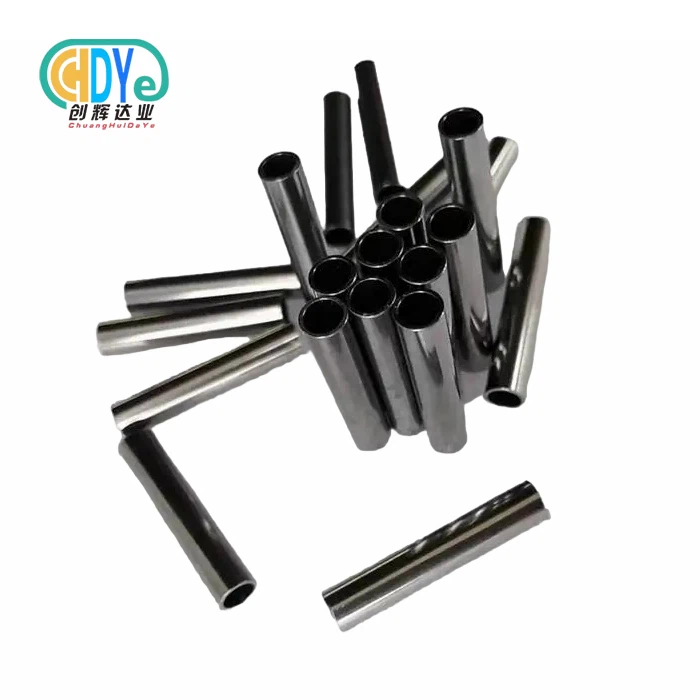

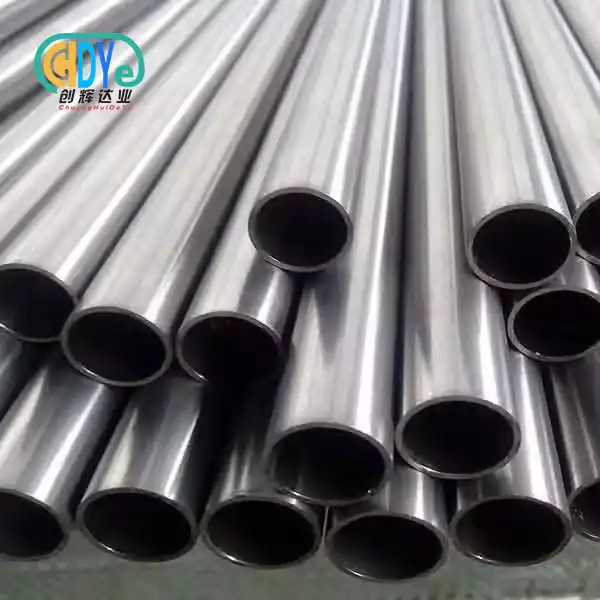

Titanium seamless tubes are very important in many fields because they are strong and light, prevent rust, and last a long time. These tubes must be of high quality because they are often used in situations where failure is not a choice. But what actually makes one titanium seamless tube better than another? This piece goes into detail about the main things that affect the quality, performance, and dependability of these important industry goods. We will look at how the quality of the material, the way it is made, and the properties of the end product all play important parts in deciding if a titanium seamless tube meets the strict standards needed for high-performance uses. Manufacturers, engineers, and end-users all need to know about these things so they can be sure they are working with or making titanium seamless tubes that will hold up in the toughest conditions and keep working well over time.

How material purity affects titanium seamless tubes

The importance of raw material selection

The materials used to make titanium seamless tubes affect their quality. To make tubes with better mechanical qualities and resistance to rust, you need high-purity titanium. Choosing the right titanium grade, like commercially pure (CP) titanium or certain metals such as Grade 2 or Grade 9, has a big effect on how the finished product works. If the raw material has impurities, the tube's structure might not be consistent, which could make it weaker and less resistant to hard conditions. When makers of titanium seamless tubes get their raw materials, they need to make sure that they meet or go beyond industry standards like ASTM B338 or ASTM B861. The tube's biocompatibility is also affected by how pure the titanium is. This is an important factor in pharmaceutical and medical uses of titanium seamless tubes.

Impact of alloying elements on tube properties

Adding features to titanium seamless tubes makes a big difference in how they work. Alloys with certain traits are made by adding small amounts of metals like aluminum, vanadium, and molybdenum to pure titanium. For example, aluminum makes the metal stronger and less dense, and vanadium makes it easier to shape and stronger at high temperatures. To get the right mix of qualities in the titanium seamless tube, these alloying elements must be carefully managed. Adding too much or too little of an alloying element can change how the tube resists rust, how easy it is to join, or how well it works mechanically. To make sure that the high-quality titanium seamless tubes that meet the needs of the aircraft, chemical processing, and marine industries are always the same, manufacturers must follow strict material standards.

Effects of impurities on tube performance

Titanium seamless tubes that are made with impure materials may not work as well or last as long. Just a little bit of something that doesn't belong there, like air, nitrogen, or carbon, can change the way the tube behaves when force is applied to it. For example, too much oxygen can make the tube more rigid and less ductile, which lowers its resistance to impact. Nitrogen can make titanium nitrides, which can be places where stress builds up and cause failure too soon. If there are carbon impurities in the mix, they can form titanium carbides, which change the microstructure of the tube and possibly makes it more likely to corrode. Titanium seamless tube makers use tough quality control methods, like spectrometric analysis and microstructural study, to keep impurity levels within accepted limits and help deal with these problems. This focus on clarity is very important for keeping the amazing qualities that make titanium seamless tubes perfect for heat exchanges, chemical processing equipment, and aircraft uses.

Impact of manufacturing processes on titanium seamless tube integrity

Role of melting and forging techniques

Titanium seamless tubes are made by first melting titanium bars. This is usually done with vacuum arc remelting (VAR) or electron beam melting (EBM). These methods make sure that the flaws are removed and a uniform structure is reached. The melting process affects the tube's end features right away. Once the titanium is melted, it is shaped into a regular microstructure, which makes the metal stronger and better able to handle stress. To avoid problems and get the best grain structure in titanium seamless tubes, the forging process needs to be carefully control temperature and distortion rates. Isothermal forging and other complex forging methods can make titanium smooth tubes that are stronger and more wear-resistant. At this point, the tube's stability is very important. Any problems that happen while freezing or shaping can carry on to the next steps and hurt the performance of the end result in fields from chemical processing to rocket parts.

Importance of extrusion and cold working

In the making of titanium seamless tubes, extrusion is an important step that gives the formed block a tubular shape. This method needs the temperature, extrusion ratio, and die design to be carefully controlled so that the tubes have a uniform wall thickness and not a lot of internal stress. By polishing the grain structure and boosting the material's strength, the extrusion process can make the dynamic qualities of titanium seamless tubes much better. After extrusion, cold working methods like cold drawing or cold pilgering are often used to make the tube's measurements more exact and improve its mechanical properties. These methods can make titanium seamless tubes stronger and harder without hurting their great ability to fight rust. Cold working must be done carefully so that the mechanical qualities are in line with the need to keep enough flexibility and formability. Following these steps correctly is very important for making high-quality titanium seamless tubes. These tubes need to be able to handle the tough demands of working in fields like oil and gas, power generation, and naval engineering.

Heat treatment and its effects on tube quality

A very important part of making titanium seamless tubes is heat treatment, which has a big effect on how they turn out and how good they are. The process of heat treatment can ease internal pressures, improve the microstructure, and change the tubes' dynamic qualities so that they can be used in the right way. Annealing, solution treating, and seasoning are all popular ways to heat titanium seamless tubes. Annealing makes the tube more formable and less likely to suffer stress corrosion cracks by improving its flexibility and lowering its residual loads. Some titanium metals can become much stronger after being treated and then aged. This makes them good for high-stress uses. But, to keep the tube's performance intact, the heat treatment process must be carefully monitored to avoid problems like too much grain growth or the formation of stages that are not wanted. Proper heat treatment is important to make sure that titanium seamless tubes keep the best mix of strength, flexibility, and rust resistance. This makes them perfect for use in tough settings like deep-sea oil extraction or aircraft hydraulic systems.

Why mechanical properties and surface finish matter for the titanium seamless tube

Significance of tensile strength and yield strength

The tensile strength and yield strength of titanium seamless tubes are very important when deciding if they are suitable for different uses. The tensile strength tells you the maximum stress the tube can take without breaking, and the yield strength tells you the stress level at which the tube starts to bend permanently. These traits are very important in places where titanium seamless tubes are often used, since there are high-pressure and high-temperature conditions. For instance, in aircraft uses, titanium tubes' high strength-to-weight ratio makes it possible to build hydraulic systems that are both light and strong. In chemical processing plants, titanium seamless tubes are strong enough to handle the forces of fluids that can damage chemicals without hurting safety. Manufacturers need to carefully oversee the production process to get the right mix of strength and flexibility. If the strength is too high, the tube could become flimsy, which might hurt its performance when the conditions are repetitive loading or impact.

Importance of fatigue resistance and toughness

Titanium seamless tubes need to be tough and able to fight fatigue, especially when they are used in situations where they might get hit or are loaded cyclically. Fatigue resistance is the tube's ability to avoid breaking after being under the same stress multiple times. This is very important in fields like aircraft, where parts experience constant changes in pressure and motion. On the other hand, toughness is a measure of how well a material can absorb energy and change shape without breaking. This feature is very important for titanium seamless tubes that are used in places where they may experience quick pressure changes or hits. Because titanium doesn't get tired easily and is very tough, titanium seamless tubes are great for tough uses like offshore oil and gas extraction. In these situations, the tubes have to fight harsh conditions, including acidic seawater and the stresses that waves cause. To get these qualities just right, manufacturers need to carefully manage the composition and processing of titanium seamless tubes. This makes sure that they can be used in important situations where safety and dependability are needed.

Role of surface finish in corrosion resistance

How well titanium seamless tubes fight rust and work in general depends a lot on their surface finish. A solid, inactive oxide layer is formed on titanium that makes it naturally resistant to rust. To get the best out of this property, the metal needs to have a smooth surface with no flaws. Because it protects the metal underneath from acidic surroundings, this layer makes titanium seamless tubes perfect for chemical processing, naval uses, and other toxic settings. The surface finish also changes how resistant the tube is to pitting corrosion, which is a type of rust that happens in one place and can cause things to break very quickly if nothing is done about it. To make titanium seamless tubes more resistant to rust, manufacturers use a range of surface treatments, including passivation, cleaning, or electropolishing. A high-quality surface finish makes the tube better at resisting rust and flowing. This lowers friction and makes the system more efficient when used in heat exchangers. Also, because biofilms and deposits can't build up on a smooth surface, titanium seamless tubes are a great choice for the food and drug handling industries, where cleaning is very important.

Conclusion

The quality of titanium seamless tubes is determined by a complex interplay of factors, from raw material purity to manufacturing processes and final product characteristics. High-quality tubes exhibit superior mechanical properties, excellent corrosion resistance, and consistent performance across various demanding applications. As industries continue to push the boundaries of material capabilities, the importance of these quality factors in titanium seamless tube production cannot be overstated. For those seeking reliable, high-performance titanium products, partnering with experienced manufacturers like Shaanxi Chuanghui Daye Metal Material Co., Ltd. is crucial. With their commitment to quality and extensive expertise in titanium processing, they offer products that meet the most stringent industry standards. For more information, contact them at info@chdymetal.com.

FAQ

Q: What are the most common grades of titanium used for seamless tubes?

A: The most common grades are Grade 1, Grade 2, Grade 7, Grade 9, and Grade 12, each offering different properties suitable for various applications.

Q: How does the manufacturing process affect the quality of titanium seamless tubes?

A: The manufacturing process, including melting, forging, extrusion, and heat treatment, significantly impacts the tube's microstructure, mechanical properties, and overall quality.

Q: Why is surface finish important for titanium seamless tubes?

A: Surface finish affects corrosion resistance, flow characteristics, and cleanliness, which are crucial for many applications, especially in corrosive environments.

Q: What standards govern the production of titanium seamless tubes?

A: Common standards include ASTM B338, ASTM B337, ASTM B861, and ASTM B862, which specify requirements for various grades and applications.

Q: How does material purity affect the performance of titanium seamless tubes?

A: Higher purity leads to better corrosion resistance, mechanical properties, and overall performance, especially in demanding environments.

References

1. ASTM International. (2021). ASTM B338 - Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers.

2. Lutjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer-Verlag Berlin Heidelberg.

3. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. (2003). Titanium alloys for aerospace applications. Advanced Engineering Materials, 5(6), 419-427.

4. Donachie, M. J. (2000). Titanium: A Technical Guide (2nd ed.). ASM International.

5. Gurrappa, I. (2003). Characterization of titanium alloy Ti-6Al-4V for chemical, marine, and industrial applications. Materials Characterization, 51(2-3), 131-139.

6. Boyer, R. R. (1996). An overview of the use of titanium in the aerospace industry. Materials Science and Engineering: A, 213(1-2), 103-114.

Learn about our latest products and discounts through SMS or email