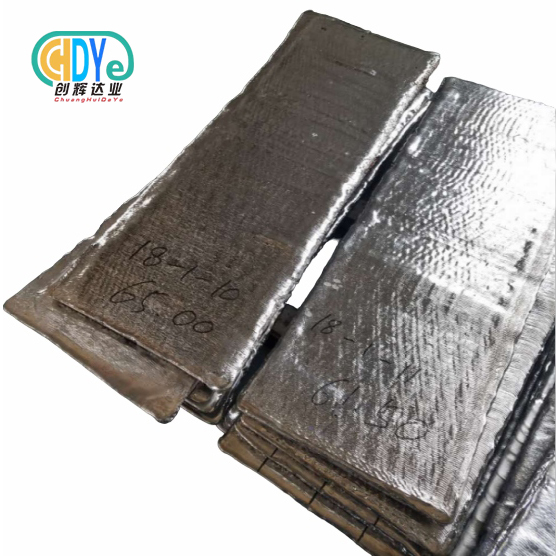

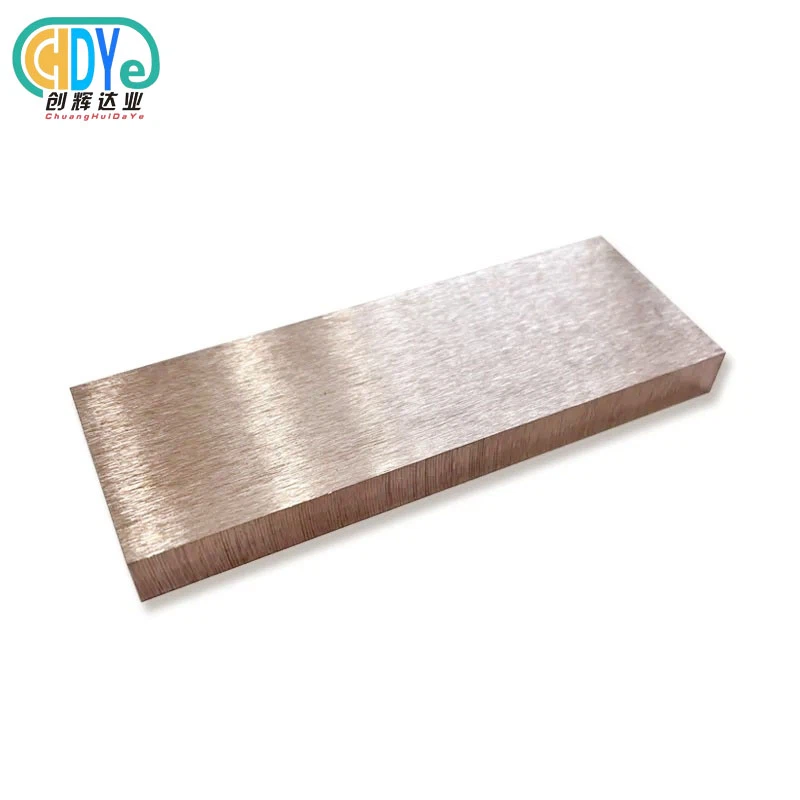

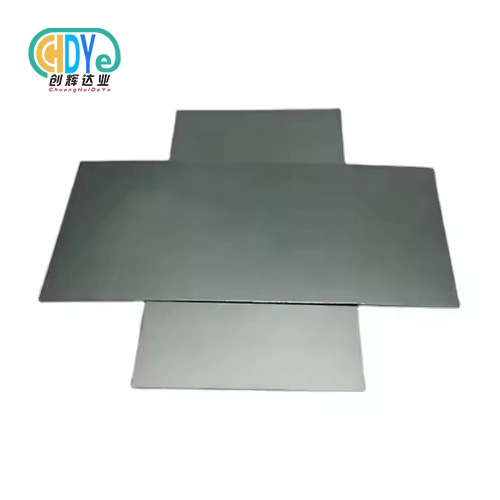

When sourcing pure titanium sheet at competitive prices, China emerges as the premier destination due to its advanced manufacturing capabilities, comprehensive supply chain infrastructure, and cost-effective production methods. Chinese manufacturers offer grades GR1-GR4 with strict quality controls, ISO certifications, and reliable delivery schedules. The country's "Titanium Capital" in Baoji, Shaanxi Province, houses specialized facilities equipped with electron beam furnaces and precision rolling equipment, ensuring consistent product quality while maintaining competitive pricing structures that benefit global buyers.

Why Source Pure Titanium Sheet from China?

Manufacturing Excellence and Infrastructure

China's titanium fabricating division benefits from decades of innovative headway and considerable foundation speculation. The nation works state-of-the-art offices including vacuum softening innovation, electron bar heaters, and accuracy cold rolling gear. These progressed fabricating capabilities guarantee that titanium metal sheet items meet worldwide quality guidelines whereas keeping up fetched efficiency.

Comprehensive Grade Availability

Chinese providers give total get to to commercially unadulterated titanium grades counting GR1, GR2, GR3, and GR4. Each review offers particular characteristics custom fitted to diverse applications. GR1 gives most extreme formability for complex shapes, whereas GR4 conveys upgraded quality for auxiliary applications. This comprehensive extend permits buyers to select ideal materials for their particular requirements.

Competitive Pricing Structure

The coordinates supply chain in China makes critical taken a toll preferences. Crude fabric sourcing, handling, and wrapping up operations happen inside concentrated mechanical zones, lessening transportation and coordinations costs. This proficiency deciphers into pure titanium sheet cost structures that advantage worldwide buyers without compromising quality standards.

Technical Specifications and Quality Standards

Critical Material Properties

High-quality titanium plate materials display particular mechanical and chemical properties fundamental for mechanical applications. Ductile quality ranges from 240-550 MPa depending on review, whereas abdicate quality shifts between 170-485 MPa. Stretching properties guarantee amazing formability, with values extending from 15-24% for distinctive grades. These details specifically affect execution in aviation, therapeutic, and chemical preparing applications.

Industry Standards Compliance

Reputable Chinese producers follow to worldwide guidelines counting ASTM B265, ASME SB-265, and AMS determinations. These benchmarks oversee chemical composition, mechanical properties, and surface wrap up necessities. Compliance guarantees compatibility with worldwide fabricating forms and administrative necessities over distinctive industries.

Quality Control Measures

Leading providers actualize comprehensive quality administration frameworks counting crude fabric assessment, prepare checking, and last item testing. The pure titanium sheet group experiences ultrasonic testing, dimensional confirmation, and chemical examination. Documentation bundles incorporate fabric certificates, test reports, and traceability records fundamental for controlled industries.

Understanding Import/Export Procedures

Trade Terms and Responsibilities

Understanding exchange terms makes a difference clarify taken a toll obligations and chance exchange focuses. Coxcomb (Free On Board) terms cruel providers convey products to the takeoff harbour, with buyers capable for worldwide shipping and protections. CIF (Taken a toll, Protections, Cargo) incorporates shipping and protections to the goal harbour, with venders bearing these costs. EXW (Ex Works) places most extreme obligation on buyers, who handle all transportation from the supplier's facility.

Complete Transaction Process

The moment prepare starts with point by point request accommodation indicating review necessities, measurements, amounts, and conveyance timelines. Providers react with comprehensive citations counting fabric costs, preparing expenses, and conveyance terms. After cost transactions and assention, formal contracts or proforma solicitations set up exchange terms, installment plans, and conveyance commitments.

Documentation Requirements

Essential records incorporate commercial solicitations enumerating item determinations and values, pressing records indicating amounts and bundling points of interest, and bills of filling affirming shipment. Extra documentation may incorporate certificates of beginning, fabric test certificates, and traditions affirmations. Appropriate documentation guarantees smooth traditions clearance and administrative compliance.

Navigating Regulations and Compliance

Certification Requirements

Medical and aviation applications require particular certifications illustrating biocompatibility and execution characteristics. ISO 9001:2015 certification shows efficient quality administration, whereas industry-specific endorsements may be fundamental for controlled divisions. Providers ought to give pertinent certifications coordinating end-use applications.

Import Regulations and Restrictions

Different nations keep up changing moment directions for titanium amalgam sheet materials. A few locales require pre-shipment reviews, whereas others command particular labeling or documentation. Understanding goal nation necessities avoids delays and compliance issues amid traditions clearance processes.

Safety and Handling Standards

Titanium materials require appropriate taking care of and capacity strategies to keep up quality and security. Providers ought to give taking care of rules, capacity proposals, and security information sheets. Appropriate bundling avoids defilement and harm amid transportation, guaranteeing materials arrive in ideal condition.

Why Shaanxi Chuanghui Daye Metal Material Co., Ltd. is Your Ideal Import Partner?

Strategic Location and Infrastructure

Located in Baoji High-tech Advancement Zone, known as China's "Titanium Capital," Chuanghui Daye benefits from concentrated industry skill and set up supply chains. This vital area gives get to to specialized hardware, talented professionals, and proficient coordinations systems. The company's nearness to crude fabric sources and handling offices makes operational efficiencies that advantage clients through competitive estimating and dependable conveyance schedules.

Extensive Industry Experience

Founded by an expert with over 30 years in the rare metal industry, Chuanghui Daye combines deep technical knowledge with practical manufacturing experience. This expertise ensures accurate material selection guidance, process optimization recommendations, and reliable quality outcomes. The company's long-term industry relationships facilitate access to premium raw materials and specialized processing capabilities.

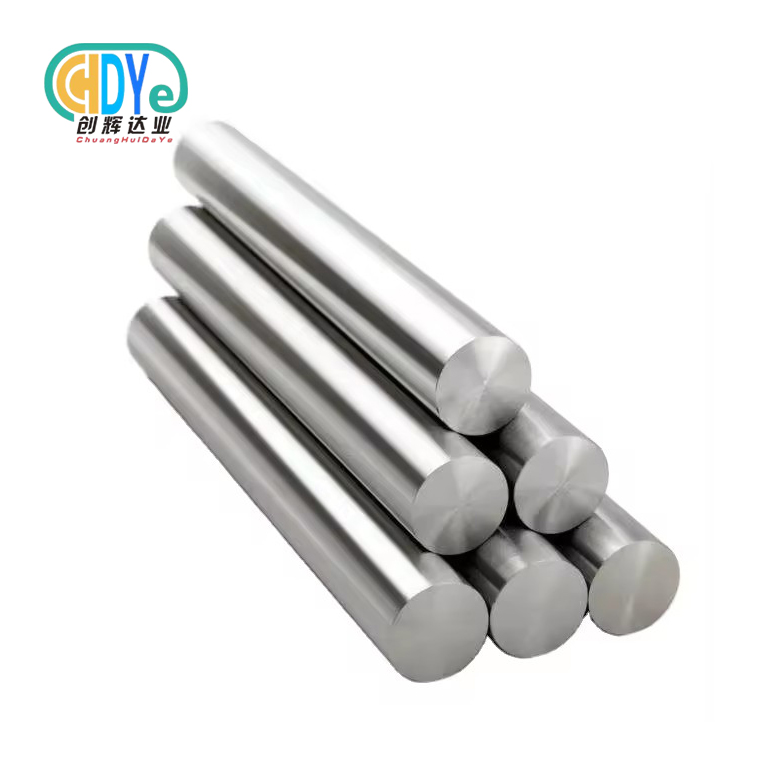

Comprehensive Processing Capabilities

The company operates advanced equipment including electron beam furnaces, CNC rolling machines, annealing furnaces, and precision machining tools. This comprehensive capability enables pure titanium sheet fabrication services including cutting, forming, welding, and surface finishing. Customers receive complete solutions rather than basic materials, reducing supply chain complexity and improving project timelines.

Cost Structure and Transparency

Pricing Components Analysis

Transparent estimating incorporates crude fabric costs, handling costs, quality control exercises, and coordinations coordination. Crude materials regularly speak to 60-70% of add up to costs, whereas handling and quality control account for 20-25%. Regulatory and coordinations costs contain the remaining 10-15%. Understanding these components makes a difference buyers assess recommendations and arrange effectively.

Value-Added Services

Beyond essential fabric supply, value-added administrations incorporate custom cutting to details, surface medications, bundling optimization, and specialized bolster. These administrations decrease client preparing prerequisites and progress venture productivity. Whereas extra administrations increment unit costs, they regularly give net reserve funds through diminished taking care of and preparing time.

Long-Term Partnership Benefits

Establishing long-term connections with dependable providers makes common benefits counting special estimating, need planning, and upgraded specialized back. Reliable volume commitments empower providers to optimize generation arranging and expand favorable terms to committed clients. These organizations too encourage ceaseless change activities and modern item improvement collaboration.

Supply Chain Reliability and Lead Times

Production Scheduling and Capacity

Established producers keep up generation plans pleasing both standard items and custom necessities. Pure titanium sheet thickness choices and common measurements are regularly accessible from stock, empowering 1-5 day conveyance times. Custom determinations ordinarily require 2-4 weeks depending on complexity and amount requirements.

Quality Assurance Processes

Systematic quality control includes incoming material inspection, process monitoring at critical stages, and comprehensive final testing. Each production batch receives unique identification enabling full traceability throughout the supply chain. Quality documentation accompanies shipments, providing verification of compliance with specified requirements.

Logistics and Shipping Coordination

Experienced suppliers coordinate international shipping including port handling, customs documentation, and freight forwarding services. Proper packaging protects materials during transit while optimizing shipping costs. Tracking systems provide visibility throughout the logistics process, enabling proactive management of delivery schedules.

Communication and Technical Support

Engineering Assistance

Technical support includes material selection guidance, application engineering advice, and processing recommendations. Experienced engineers help customers optimize material choices for specific applications, potentially reducing costs while improving performance. This consultation capability distinguishes professional suppliers from commodity vendors.

Quality Documentation and Traceability

Comprehensive documentation includes chemical analysis reports, mechanical property certifications, and dimensional inspection records. Full traceability from raw material sources through final processing ensures compliance with quality requirements and regulatory standards. Digital documentation systems enable rapid access to historical records and certifications.

Responsive Customer Service

Professional customer service includes prompt inquiry responses, detailed technical discussions, and proactive communication throughout order fulfillment. Regular updates on production progress, shipping schedules, and delivery confirmations maintain transparency and enable effective project planning.

Common Pitfalls and Best Practices

Specification Clarity

Incomplete specifications create potential for misunderstandings and quality issues. Buyers should provide detailed requirements including grade designations, dimensional tolerances, surface finish specifications, and packaging requirements. Clear specifications prevent disputes and ensure delivered materials meet application needs.

Supplier Verification

Verifying supplier capabilities prevents quality problems and delivery delays. Review certifications, inspect facilities if possible, and request references from similar customers. Established suppliers with proven track records reduce risks associated with international sourcing.

Payment Terms and Risk Management

Balanced payment terms protect both parties while facilitating smooth transactions. Letter of credit arrangements provide security for international transactions, while progress payments support cash flow for suppliers. Understanding payment options and their implications helps structure mutually beneficial agreements.

Conclusion

Sourcing high-quality pure titanium sheet from China offers significant advantages through advanced manufacturing capabilities, competitive pricing, and comprehensive technical support. Success depends on selecting qualified suppliers with proven capabilities, clear communication of requirements, and proper attention to quality standards and compliance requirements. Established manufacturers like those in China's Titanium Capital provide the expertise, infrastructure, and reliability necessary for successful long-term partnerships. By following systematic sourcing procedures and working with experienced suppliers, buyers can achieve optimal outcomes combining quality materials, competitive pricing, and reliable delivery performance.

FAQ

Q: What are the typical lead times for pure titanium sheet orders from China?

A: Standard sizes and grades (GR1-GR4) are often available from stock with 1-5 day delivery times. Custom dimensions and specifications typically require 2-3weeks depending on complexity and order quantity. Rush orders may be accommodated with expedited processing for urgent project requirements.

Q: How do I verify the quality and authenticity of titanium materials?

A: Request comprehensive material certificates including chemical analysis, mechanical property testing, and dimensional inspection reports. Reputable suppliers provide full traceability documentation and maintain ISO 9001:2015 certification. Consider third-party inspection services for critical applications or large orders.

Q: What minimum order quantities should I expect when importing titanium sheets?

A: Minimum order quantities vary by supplier and product specifications. Many manufacturers accommodate small research quantities of 10-50 kg for universities and development projects, while production orders typically start at 100-500 kg. Custom processing may require higher minimums to justify setup costs.

Q: How should titanium sheets be packaged and shipped to prevent damage?

A: Professional packaging includes protective films, foam cushioning, wooden crating, and moisture barriers. Sheets should be separated to prevent scratching and secured to prevent movement during transit. Proper packaging protects surface finish and dimensional accuracy throughout international shipping.

Q: What certifications are most important when sourcing titanium for medical applications?

A: Medical applications require ASTM F67 or ISO 5832 compliance for biocompatibility. Suppliers should provide material certificates demonstrating compliance with relevant standards, along with documentation supporting FDA or CE marking requirements. ISO 13485 certification indicates medical device quality management systems.

Partner with Chuanghui Daye for Premium Pure Titanium Sheet Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready to become your trusted pure titanium sheet supplier, combining three decades of industry expertise with cutting-edge manufacturing capabilities. Our strategic location in China's Titanium Capital, comprehensive grade selection (GR1-GR4), and ISO 9001:2015 certification ensure consistent quality and reliable delivery performance. Whether you need standard dimensions from our ready stock or custom fabrication services, our advanced electron beam furnaces and precision rolling equipment deliver materials meeting the most demanding specifications. Experience the advantages of working with a dedicated manufacturer committed to quality excellence and customer satisfaction. Contact us at info@chdymetal.com to discuss your titanium sheet requirements and discover competitive solutions for your projects.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio, 1994.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, 2000.

3. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, No. 6, 2003.

4. Schutz, R.W. & Thomas, D.E. "Corrosion of Titanium and Titanium Alloys." ASM Handbook Volume 13: Corrosion, ASM International, 1987.

5. ASTM International. "ASTM B265 - Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM Standards, West Conshohocken, PA.

6. Lütjering, Gerd & Williams, James C. "Titanium: Engineering Materials and Processes, 2nd Edition." Springer-Verlag Berlin Heidelberg, 2007.