Custom machined pure titanium sheet parts offer exceptional advantages across industries demanding superior performance materials. These specialized components combine titanium's natural corrosion resistance, lightweight properties, and biocompatibility with precision manufacturing techniques. Pure titanium sheet provides unmatched strength-to-weight ratios while maintaining excellent formability for complex applications. Industries from aerospace to medical devices rely on these custom solutions to meet stringent performance requirements while reducing overall system weight and maintenance costs.

Understanding Key Parameters of Pure Titanium Sheets

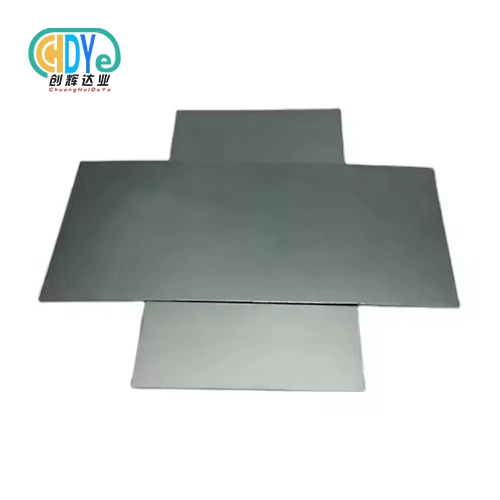

Pure titanium sheets are accessible in a few standardized grades, each advertising particular mechanical properties custom fitted to diverse applications. Review 1 titanium is the gentlest and most formable choice, containing roughly 99.5% unadulterated titanium. Its fabulous ductility and extraordinary erosion resistance make it perfect for complex shaping operations and chemically forceful situations. Review 2 titanium sheet gives an ideal adjust between quality and formability, which is why it is the most broadly utilized commercial review in businesses such as chemical preparing, marine building, and aerospace.

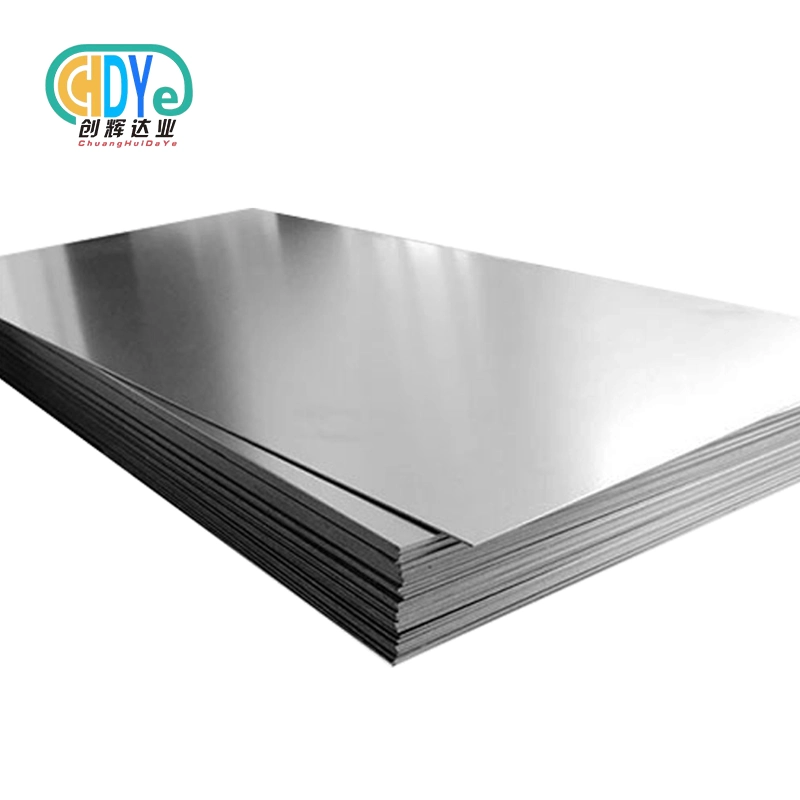

For applications requiring higher quality, Review 3 titanium offers expanded malleable quality whereas still keeping up great ductility and workability. Review 4 conveys the most elevated quality among commercially unadulterated titanium grades, making it reasonable for more requesting auxiliary and load-bearing applications. Titanium sheet thicknesses ordinarily extend from approximately 0.016 inches to a few inches, with standard widths accessible up to 60 inches. With a thickness of around 0.163 pounds per cubic inch, titanium sheets are generally 40% lighter than steel, contributing to critical weight lessening advantages.

Mechanical execution shifts by review, with Review 2 titanium commonly showing a surrender quality between 50,000 and 65,000 PSI. Immaculate titanium sheets can work persistently at temperatures up to 600°F without critical corruption in properties. Accessible surface wraps up incorporate process wrap up, salted, and cleaned alternatives to meet utilitarian and tasteful prerequisites. Strict control of chemical composition—particularly oxygen, nitrogen, and press content—ensures reliable fabric properties, dependable machinability, and reliable last portion performance.

Core Benefits of Custom Titanium Sheet Machining

Custom machining plays a basic part in changing standard titanium metal sheet into exceedingly exact components custom-made to particular mechanical and commercial applications. Through progressed CNC machining forms, producers can accomplish tight dimensional resistances that are troublesome or inconceivable to get utilizing conventional shaping strategies. This precision-driven approach minimizes fabric squander whereas maximizing plan adaptability, permitting engineers to make complex geometries, complicated highlights, and multi-axis forms that meet correct utilitarian necessities. As a result, custom machining essentially grows the potential applications of titanium sheet materials.

In the therapeutic field, biocompatibility is a key advantage that makes custom machined titanium components crucial. Titanium coordinating actually with human tissue and does not trigger unfavorable organic responses, making it perfect for inserts, surgical disobedient, and therapeutic gadget lodgings. Exact machining guarantees smooth surfaces and precise fits, which are basic for persistent security and long-term execution. These characteristics permit titanium parts to meet rigid administrative and cleanliness benchmarks in healthcare environments.

Aerospace and transportation businesses too advantage significantly from pure titanium sheets into custom components. Titanium’s tall strength-to-weight proportion empowers significant weight lessening without relinquishing auxiliary judgment. In numerous cases, a single machined titanium portion can supplant different steel components, rearranging gatherings, diminishing latches, and bringing down upkeep necessities. This proficiency leads to progressed fuel economy, upgraded execution, and more prominent unwavering quality in requesting working conditions.

Exceptional erosion resistance assist improves the esteem of machined titanium sheet components. Cruel situations such as marine applications, chemical handling offices, and extraordinary climate conditions have negligible affect on legitimately machined titanium parts. Furthermore, machining permits exact control over surface wraps up and basic interfacing, counting fixing surfaces and bearing ranges. In spite of the fact that the beginning venture may be higher, the expanded benefit life and diminished lifecycle costs make custom machined titanium arrangements a profoundly cost-effective choice over time.

Chuanghui Daye's Superior Titanium Sheet Solutions

Chuanghui Daye's pure titanium sheet stands separated through thorough quality control and progressed fabricating capabilities. Our office in Baoji, China's "Titanium Capital," gives get to to premium crude materials and specialized skill. Over 30 a long time of industry encounter guarantees steady quality and solid conveyance schedules.

Our ISO 9001:2015 certification ensures precise quality administration all through generation. Each titanium plate experiences comprehensive testing counting chemical investigation, mechanical property confirmation, and dimensional review. Electron pillar heaters guarantee uniform microstructure whereas accuracy rolling hardware keeps up reliable thickness tolerances.

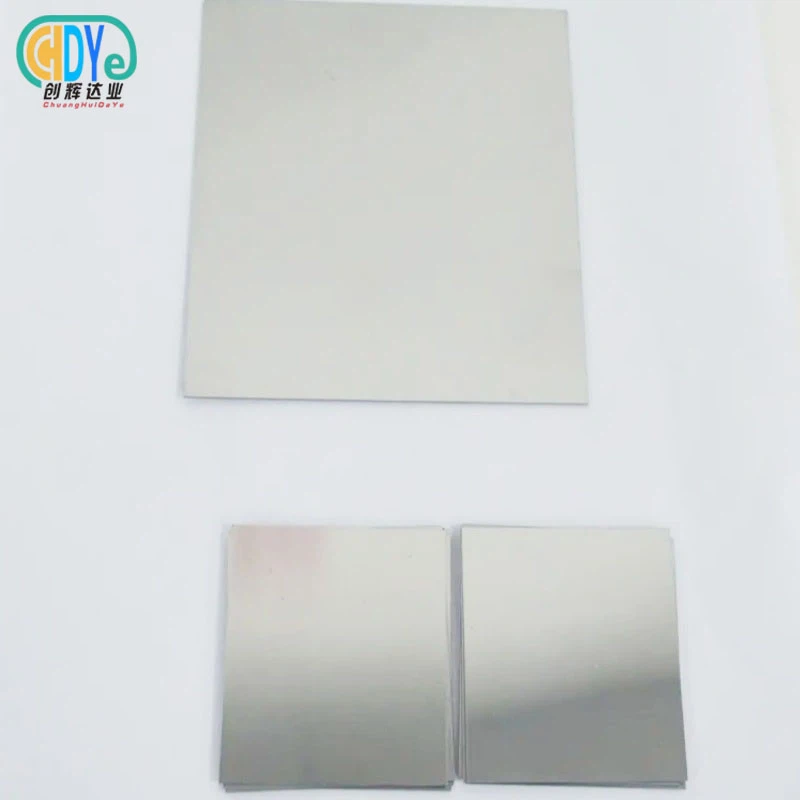

Available grades incorporate GR1, GR2, GR3, and GR4 in standard sizes with 1-5 day conveyance. Custom measurements and specialized preparing suit one of a kind extend necessities. Our titanium sheet surface wrap up choices incorporate process wrap up, cured, and cleaned surfaces to meet particular application needs.

Competitive factory-direct estimating dispenses with merchant markups whereas keeping up premium quality measures. Specialized back helps with fabric determination, preparing proposals, and application-specific direction. Test accessibility empowers careful testing some time recently committing to bigger orders.

Maximizing Benefits Through Proper Selection and Usage

Selecting fitting titanium sheet thickness depends on basic necessities and shaping operations. More slender gages offer predominant formability for complex shapes whereas thicker areas give improved quality. Review choice equalizations quality necessities with preparing contemplations and fetched factors.

Proper machining parameters optimize surface wrap up and device life. Lower cutting speeds and sharp carbide tooling minimize work solidifying whereas surge coolant avoids overheating. Climb processing procedures diminish burr arrangement and make strides dimensional exactness. Legitimate workholding anticipates twisting amid machining operations.

Storage conditions secure fabric properties some time recently handling. Clean, dry situations avoid defilement whereas appropriate dealing with dodges surface harm. Defensive movies keep up surface wrap up amid transportation and capacity. Temperature control avoids warm extension issues amid accuracy machining.

Welding strategies require particular methods to keep up titanium properties. Inactive gas protecting avoids defilement whereas controlled warm input minimizes twisting. Post-weld stretch help may be vital for basic applications. Legitimate joint plan suits warm extension and stretch distribution.

Critical Applications and Performance Considerations

Aerospace applications request remarkable strength-to-weight proportions and weakness resistance. Titanium sheet manufacture empowers complex airframe components, motor parts, and auxiliary components. Temperature cycling and push varieties require cautious fabric choice and handling control.

Medical gadget fabricating depends on titanium's biocompatibility and erosion resistance. Surgical disobedient, inserts, and symptomatic gear advantage from custom machining capabilities. Sterilization compatibility guarantees secure rehashed utilize without fabric degradation.

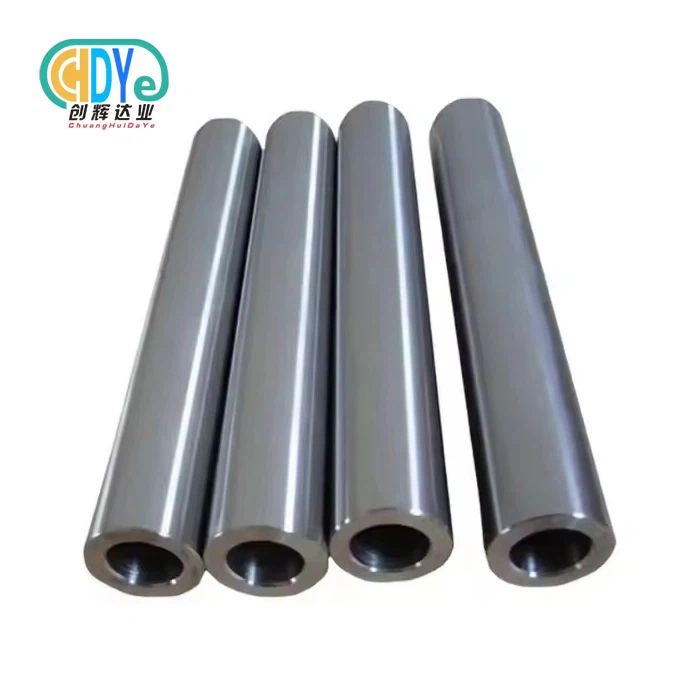

Chemical handling gear utilizes titanium's remarkable erosion resistance. Warm exchangers, weight vessels, and channeling frameworks work dependably in forceful situations. Custom machining empowers complex inner entries and exact fixing surfaces.

Marine applications confront steady salt water presentation and mechanical push. Titanium components stand up to cleft erosion and keep up quality beneath energetic stacking. Custom machining obliges complex frame fittings and impetus framework components.

Conclusion

Custom machined pure titanium sheet parts deliver unmatched performance across demanding applications. The combination of superior material properties and precision manufacturing creates components that outlast conventional alternatives while reducing system weight. Chuanghui Daye's expertise in titanium sheet production and processing ensures reliable quality and competitive pricing. Our comprehensive capabilities from raw material sourcing through custom machining provide complete solutions for complex projects. The investment in titanium sheet technology pays dividends through extended service life, reduced maintenance, and enhanced performance. Partner with experienced professionals to maximize the benefits of this exceptional material in your next project.

FAQ

Q: What thickness ranges are available for custom machined titanium sheets?

A: We stock titanium sheets from 0.016 inches to 4 inches thick, with custom thickness options available upon request. Standard widths reach up to 60 inches, while length dimensions can be customized for specific applications.

Q: How does Grade 2 titanium sheet compare to other grades for machining applications?

A: Grade 2 offers the optimal balance of strength, formability, and machinability. It provides 50,000-65,000 PSI yield strength while maintaining excellent ductility for complex forming operations. This grade represents the most versatile option for general machining applications.

Q: What delivery timeframes can be expected for standard and custom titanium sheet orders?

A: Standard sizes ship within 1-5 days from our inventory. Custom dimensions and specialized processing typically require 2-3weeks depending on complexity and quantity. Rush orders can be accommodated with expedited processing schedules.

Partner with Chuanghui Daye for Premium Titanium Sheet Solutions

Shaanxi Chuanghui Daye combines decades of expertise with state-of-the-art manufacturing capabilities to deliver exceptional pure titanium sheet solutions. As a trusted titanium sheet supplier, we maintain extensive inventory for rapid delivery while offering custom processing services for specialized requirements. Our commitment to quality and customer satisfaction has established lasting partnerships across aerospace, medical, and industrial sectors. Contact us at info@chdymetal.com to discuss your specific titanium sheet applications and experience the Chuanghui Daye advantage.

References

1. Boyer, R., Welsch, G., & Collings, E. W. "Materials Properties Handbook: Titanium Alloys." ASM International, 1994.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, 2000.

3. Lutjering, G., & Williams, J. C. "Titanium: Engineering Materials and Processes." Springer-Verlag, 2007.

4. Peters, M., Kumpfert, J., Ward, C. H., & Leyens, C. "Titanium and Titanium Alloys: Fundamentals and Applications." Wiley-VCH, 2003.

5. Schutz, R. W., & Watkins, H. B. "Recent Developments in Titanium Alloy Application in the Energy Industry." Materials Science and Engineering A, 1998.

6. Veiga, C., Davim, J. P., & Loureiro, A. J. R. "Properties and Applications of Titanium Alloys: A Brief Review." Reviews on Advanced Materials Science, 2012.