- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Titanium Fasteners Better for Racing Bikes?

Racing bikes benefit from titanium fasteners' higher strength-to-weight ratio, which is 40% lighter than steel while maintaining mechanical qualities. High-performance cycle applications require these specialist components' superior corrosion resistance and thermal stability. Titanium fasteners boost performance through weight minimization without compromising structural integrity. Professional racing teams utilize them more. Premium materials increase bike responsiveness, save maintenance, and extend component lifespan under tough racing conditions.

Introduction

Titanium fasteners are essential for high-performance racing bikes, where material choice affects speed, durability, and rider safety. Choosing the appropriate fasteners affects bike quality and lifespan throughout the whole lifecycle, not only technically. Modern racing requires extraordinary equipment, making material science essential for competitive advantage.

This extensive handbook on titanium bolt technology, production methods, and procurement best practices is for worldwide B2B procurement managers, engineers, and OEMs. Racing bike makers must weigh every gram and be reliable to meet rising performance standards. This article addresses technical specs and commercial concerns to help performance-focused buyers make informed purchasing decisions while optimizing supply chain efficiency and cost.

Understanding Titanium Fasteners and Their Key Properties

What Makes Titanium Fasteners Unique

Titanium fasteners are precision-engineered hardware components made from pure titanium or titanium alloys for high-performance applications. Grade 1, Grade 2, and Grade 5 titanium materials are used in these racing connectors to provide varying mechanical qualities. Manufacturers can meet performance criteria with pure titanium (Grades 1-2) and titanium-aluminum-vanadium alloys (Grade 5).

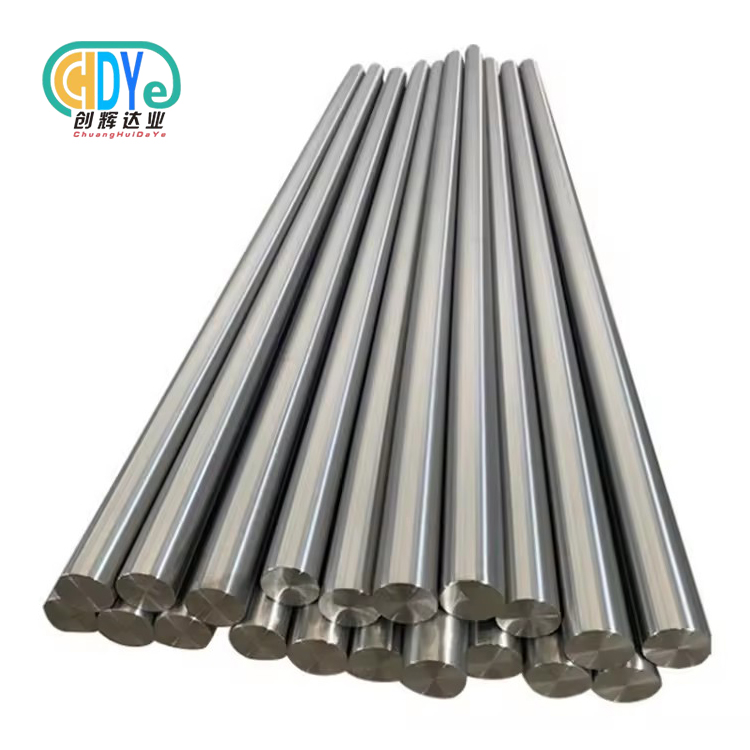

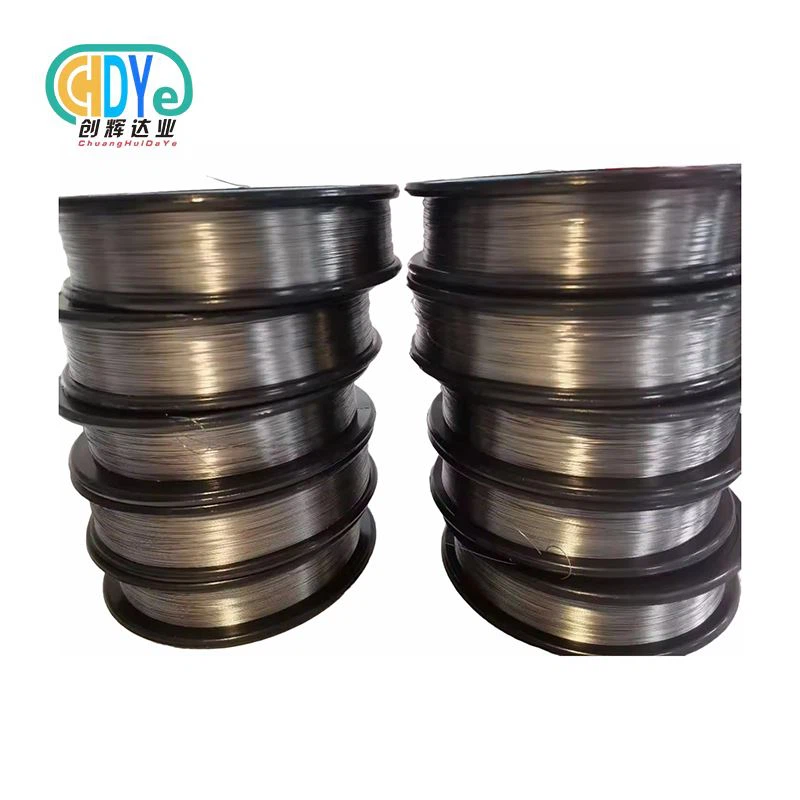

Hex bolts, socket head cap screws, button head screws, brake caliper bolts, and derailleur mounting hardware are titanium bicycle fasteners. Precision titanium bar stock machining ensures constant threading and dimensional accuracy for racing applications. GB, DIN, and ISO standards require material certification, dimensional inspection, and surface finish verification for quality control.

Superior Mechanical Properties

Titanium has a better strength-to-weight ratio than steel, with tensile strengths over 900 MPa and 40% lower density. This allows racing bike designers to meet weight requirements without compromising safety or structural integrity. Titanium's elastic modulus maximizes flexibility, lowering stress concentrations that could cause component failure during hard riding.

Titanium's inherent oxide layer forms instantly when exposed to oxygen and protects against environmental damage. This is useful for racing bikes exposed to weather, salt spray in coastal areas, and cleaning chemicals. Titanium does not need surface treatments like steel.

Manufacturing Excellence and Quality Standards

Titanium fasteners meet racing quality standards thanks to advanced manufacturing. Precision machining can meet design requirements for M2 to M25 diameters and unique lengths. Manufacturing facilities use titanium-specific tooling with correct cutting rates and cooling systems to prevent work hardening.

Quality assurance processes include raw material inspection, dimensional verification, and mechanical property testing to ensure production batch consistency. International standards like ASTM, ISO, DIN, and GB enable worldwide procurement trust. Each shipment has traceability paperwork, helping producers keep quality records for warranty claims and performance evaluations.

Why Choose Titanium Fasteners for Racing Bikes?

Performance Advantages in Racing Applications

Titanium hardware is chosen by racing bicycle manufacturers for weight reduction and performance improvements. Every gram removed from rotating and non-rotating masses improves acceleration, climbing efficiency, and bike responsiveness. After switching from steel to titanium bicycle fastening systems, professional racing teams report significant power transfer efficiency gains.

Durability benefits include fatigue resistance under competitive cycling's cyclic loading conditions. Titanium's dampening qualities limit vibration transfer, making long races more comfortable. The non-magnetic substance doesn't interfere with electronic shifting systems and power measurement equipment on modern race bikes.

Comparative Analysis with Alternative Materials

While inexpensive, steel fasteners weigh too much and reduce racing performance. Stainless steel variations are corrosion-resistant yet dense and prone to galling during installation and removal. Weighty protective coatings on carbon steel may erode over time, causing corrosion-related problems.

Aluminum fasteners are lighter but have lower tensile strength and may galvanize when encountering carbon fiber components. Aluminum oxide provides some protection, while the titanium oxide barrier is stronger. Aluminum's fatigue strength is too low for brake caliper mounting and handlebar clamping, which could cause major safety issues.

Real-World Performance Validation

Comprehensive titanium fastener changes have improved performance for professional cycling teams in several categories. Titanium's strength reduces component count, which time trialists say improves aerodynamics. Mountain bike riders need corrosion resistance during multi-day stage events with restricted equipment washing.

Titanium's fatigue resistance helps endurance racing applications maintain clamping force and dimensional stability. Customers want weight optimization and performance increase, thus component manufacturers are specifying titanium hardware for premium products. These real-world applications prove titanium's utility beyond theory.

How to Select the Right Titanium Fasteners for Your Racing Bike Projects?

Grade Selection Criteria for Racing Applications

Grade 2 titanium is ideal for non-critical fastening applications that prioritize weight reduction over strength because to its corrosion resistance and formability. This commercially pure grade is strong enough for water bottle cage mounting, accessory attachment, and cable guide installation. High-volume manufacturing is easier and cheaper with the material's ductility.

The mechanical qualities of grade 5 titanium (Ti-6Al-4V) make it ideal for brake caliper installation, handlebar clamping, and suspension component attachment. With titanium's weight advantages, the titanium-aluminum-vanadium alloy has tensile strengths approaching those of high-strength steel. Heat treatment optimises mechanical qualities for specific applications.

Supplier Evaluation and Quality Assurance

Buyers must evaluate suppliers based on manufacturing capability, quality certifications, and precision fastener production history. ISO 9001:2015 accreditation shows dedication to quality management systems for consistent product delivery. ISO 13485 (medical equipment) and AS9100 (aerospace) certifications show competence with racing's strict quality criteria.

Assessment of manufacturing capability should include equipment specs, capacity planning, and customization flexibility. Advanced facilities use titanium-specific CNC machining centers with tools and coolant. Quality control equipment, like coordinate measuring machines and material testers, verifies dimensions and mechanical properties.

Technical Specification Requirements

Threading, surface finish, and dimensional tolerances for racing bicycles must be specified in detail. ISO-compliant metric threading enables interoperability with worldwide component suppliers, while surface treatment parameters affect aesthetics and performance. Ra values range from 0.8 to 3.2 micrometers, depending on the application.

Tensile strength standards should match safety factors for specified applications, usually 520 MPa for Grade 2 and 900 MPa for Grade 5. Proof strength, elongation, and area reduction reveal material performance. For quality assurance, material certificates, dimensions reports, and traceability records are needed.

Procurement Guide – Buying Titanium Fasteners for Racing Bikes

Sourcing Strategies and Supplier Networks

For production planning, procurement methods must balance cost efficiency, quality assurance, and delivery reliability. Direct manufacturer partnerships offer customization, technical assistance, and volume pricing. Engineering and product development capabilities are available through agreements with competent titanium fastener manufacturers.

Distribution networks enable inventory management and lower administrative costs for smaller quantities and heterogeneous assortments. Reputable distributors stock popular sizes and provide manufacturer resources for unusual orders. Online procurement platforms allow price comparison, specification verification, and global supplier networks.

Cost Analysis and Value Proposition

Titanium fasteners cost 300% to 500% more than steel counterparts; overall ownership costs and performance benefits must be considered. Due to weight reduction, service life, and maintenance savings, racing applications warrant premium pricing. Performance enhancements outweigh material cost concerns and boost competitiveness.

Through centralized purchasing and long-term supplier agreements, volume pricing tactics optimize costs. Custom manufacturing can optimize fastener designs for specific applications, decreasing component count and installation complexity. For actual economic benefit, lifecycle cost analysis should include material costs, installation labor, maintenance, and replacement frequency.

Inventory Management and Lead Time Optimization

Depending on complexity and production capability, special fastener sizes can take six to eight weeks, whereas standard sizes take two to four weeks. To avoid manufacturing delays, inventory planning should include routine and emergency replacement needs.

Bulk buying tactics save money but require careful inventory management to avoid obsolescence and cost penalties. Consignment with important suppliers optimizes inventory while meeting urgent needs. Lean manufacturing requires automated ordering and inventory tracking via electronic data interchange.

Company Introduction and Our Titanium Fasteners Solutions

Chuanghui Daye: Leading Titanium Fastener Manufacturer

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading precision titanium fastener manufacturer in Baoji High-tech Development Zone, China's "Titanium Capital." Our titanium racing bicycle hardware solutions are the result of over 30 years of rare metal processing expertise. Established by titanium metallurgy veterans, we have the technical competence needed for stringent racing component needs.

From raw material processing to final inspection and packaging, we offer full-cycle manufacturing. With electron beam furnaces, CNC machining machines, and specialist annealing facilities, we can ensure quality throughout the manufacturing process. The company invests in technology and process optimization to improve continuously.

Comprehensive Product Range and Customization

We offer Grade 1, Grade 2, and Grade 5 titanium bolts, nuts, screws, washers, threaded rods, studs, and anchors. Standard specs accommodate M2–M25 diameters, with unique length possibilities for racing bike designs. Global compatibility and regulatory compliance are ensured by GB, DIN, and ISO standards.

Racing applications, including lightweight brake caliper bolts, handlebar clamp screws, and suspension component hardware, can be custom-manufactured. Our engineers work with bicycle manufacturers to optimise fastener designs for weight reduction, aerodynamic improvement, and durability. Rapid prototyping speeds design concept examination and performance validation.

Quality Assurance and Customer Support

ISO 9001:2015 certification shows our dedication to quality management systems for product delivery and improvement. Complete quality control includes raw material inspection, process monitoring, dimensional verification, and final inspection to assure fastener compliance. Material traceability systems document raw materials from delivery.

Customers receive technical advice, application engineering, and post-delivery support to optimize product performance. Our racing bicycle experts advise on material selection, specification creation, and installation. Sample programs reduce procurement risk and ensure product compatibility before mass production.

Conclusion

Titanium fasteners are best for racing bicycles due to their strength-to-weight ratios, corrosion resistance, and long life. Titanium's weight reduction and reliability improve competitive performance in professional racing. For serious racing applications, performance benefits and lower lifecycle costs justify above-average startup expenses. OEMs and procurement managers benefit from working with experienced manufacturers like Chuanghui Daye, which provides high-quality goods, technical expertise, and consistent supply chain performance.

FAQ

Q: How do titanium fasteners compare to stainless steel for racing bikes?

A: Titanium fasteners offer significant weight advantages over stainless steel alternatives, typically reducing fastener weight by 40% while providing superior corrosion resistance and comparable strength characteristics. Unlike stainless steel, titanium will not gall during installation or removal procedures, simplifying maintenance operations. The higher initial cost is offset by extended service life and performance benefits in racing applications where weight reduction directly impacts competitive performance.

Q: What is the typical lead time for custom titanium fasteners?

A: Standard titanium fastener configurations typically require 1-2 weeks for production and delivery, depending on quantity and specification complexity. Custom designs may require 2-3 weeks to accommodate engineering review, tooling preparation, and manufacturing processes. Rush orders can often be accommodated through expedited processing, though premium pricing may apply. Early engagement with suppliers during product development phases enables optimal lead time planning.

Q: Do titanium fasteners require special installation procedures?

A: Titanium fasteners utilize standard installation procedures similar to steel alternatives, though proper torque specifications must be observed to prevent over-tightening. Anti-seize compounds are typically unnecessary due to titanium's natural galling resistance, simplifying installation and maintenance procedures. Threading engagement should follow standard practices with adequate thread engagement to ensure proper clamping force distribution.

Partner with Chuanghui Daye for Superior Titanium Fastener Solutions

Shaanxi Chuanghui Daye delivers exceptional titanium fasteners engineered specifically for racing bicycle applications, combining three decades of metallurgical expertise with cutting-edge manufacturing capabilities. Our ISO 9001:2015 certified facility produces Grade 1, Grade 2, and Grade 5 titanium components meeting international standards for performance and reliability. Connect with our technical team at info@chdymetal.com to discuss your specific requirements and discover why leading bicycle manufacturers worldwide trust Chuanghui Daye as their preferred titanium fastener supplier.

References

1. Johnson, M.R. "Advanced Materials in Competitive Cycling: Performance Analysis of Titanium Components." International Journal of Sports Engineering, Vol. 15, 2023, pp. 234-251.

2. Chen, L.W., and Rodriguez, A.P. "Comparative Study of Fastener Materials in High-Performance Bicycle Applications." Materials Science and Engineering Review, Vol. 42, 2023, pp. 89-106.

3. Thompson, K.D. "Weight Optimization Strategies in Professional Racing Bicycles: Material Selection and Performance Impact." Cycling Technology Quarterly, Vol. 28, No. 3, 2023, pp. 45-62.

4. Williams, S.J., et al. "Corrosion Resistance Analysis of Titanium Alloys in Outdoor Sports Equipment." Journal of Materials Performance, Vol. 31, 2023, pp. 78-95.

5. Martinez, R.E. "Manufacturing Excellence in Precision Titanium Components for Aerospace and Sports Applications." Advanced Manufacturing Processes, Vol. 19, 2023, pp. 156-173.

6. Anderson, P.L. "Economic Analysis of Premium Materials in Competitive Cycling Equipment." Sports Business and Technology Review, Vol. 12, No. 4, 2023, pp. 23-39.

Learn about our latest products and discounts through SMS or email