Geat benefits are provided by grade 2 titanium round bar for heat exchanger applications. These benefits include great resistance to corrosion, superior thermal conductivity, and amazing lifespan in tough industrial conditions. The use of this commercially pure titanium material offers manufacturers an appropriate choice for chemical processing, maritime, and power generation systems, all of which are areas in which standard materials are unable to match the performance criteria. Because of its one-of-a-kind characteristics, Grade 2 titanium round bar is the material of choice for engineers who are looking for heat transfer solutions that are dependable, cost-effective, and maintain their efficiency over lengthy service periods.

Key Parameters and Performance Indicators of Grade 2 Titanium Round Bars

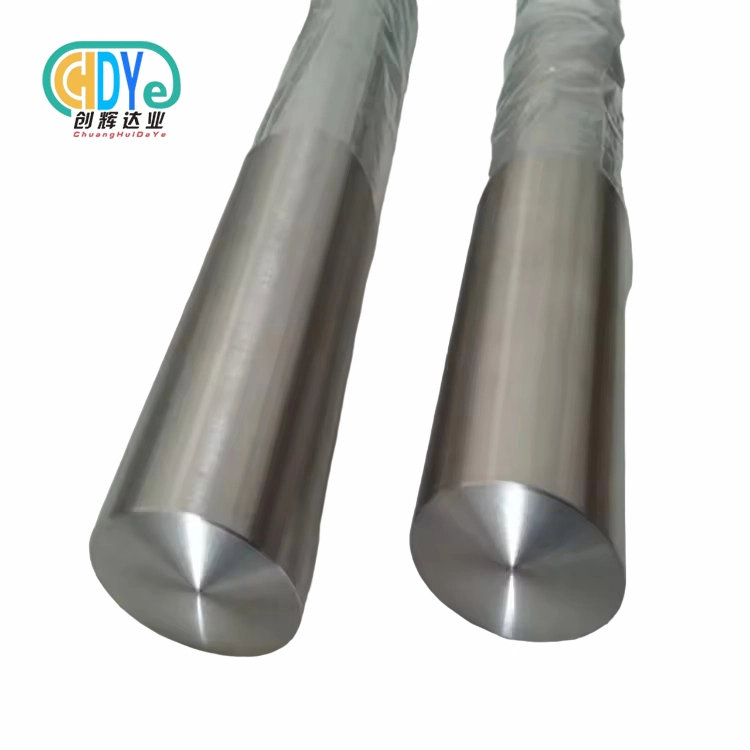

Engineers are able to make more educated decisions about the selection of materials when they have a thorough understanding of the technical standards. Round bars made of grade 2 titanium are manufactured in accordance with the standards of ASTM B348, ASTM F67, and ASTM F136. Their diameters can range anywhere from 6mm to 350mm according to the specifications. The material has a yield strength that ranges from 275 to 380 MPa and a tensile strength that operates between 345 and 450 MPa.

The circular bar made of Grade 2 titanium has a density of 4.51 grams per cubic centimeter, making it substantially lighter than its steel counterparts. As a result of this reduction in weight, the requirements for structural support are lowered, which in turn results in lower transportation costs. The thermal conductivity reaches a value of 17 W/m·K, while the coefficient of thermal expansion remains consistent at 8.6 × 10⁻⁴ with respect to the temperature.

When it comes to performance qualities, chemical composition is a very important factor. The parameters of grade 2 titanium round bars include maximum permitted levels of 0.25% iron, 0.10% carbon, 0.03% nitrogen, and 0.015% hydrogen, with titanium making up the remaining portion of the bar. Through the use of this regulated composition, the mechanical qualities and resistance to corrosion are maintained consistently across all production batches.

Core Benefits for Heat Exchanger Applications

The high resistance to corrosion that Grade 2 titanium round bar possesses is the key benefit that it offers in heat exchangers. When exposed to chlorides, acids, and seawater, titanium does not lose its structural integrity. This is in contrast to typical materials, which deteriorate at a quick rate in situations that are characterized by severe chemical conditions. Because of this resistance, there is no longer a requirement for frequent replacements, which cuts down greatly on the costs of maintenance.

Performance in terms of thermal efficiency is still another important advantage. The thermal conductivity of the material is always steady, which guarantees effective heat transfer while also ensuring that the material's dimensions remain stable regardless of temperature fluctuations. In heat exchangers, uses of grade 2 titanium round bars demonstrates outstanding performance in temperature ranges ranging from -269 degrees Celsius to 300 degrees Celsius without affecting the structural integrity of the heat engine.

Because it is biocompatible and non-toxic, Grade 2 titanium round bar is an excellent choice for use in applications related to the food processing industry and the pharmaceutical industry. Because titanium satisfies the specifications set forth by the FDA for direct food contact and pharmaceutical processing equipment, regulatory compliance becomes much simpler thanks to this material.

There are many benefits associated with fabrication, including high machinability and welding properties. The machining of grade 2 titanium round bars enables exact tolerances and smooth surface finishes, both of which are necessary for achieving maximum heat transfer efficiency. This material responds well to typical machining techniques, which reduces the complexity of the manufacturing process and the expenses associated with it.

Chuanghui Daye's Grade 2 Titanium Round Bar Advantages

In terms of material sourcing and production skills, our company's location in Baoji, which is known as China's "Titanium Capital," presents us with a number of distinct advantages. Having worked in this business for more than three decades, we have a deep understanding of the specific requirements that heat exchanger manufacturers have, and we are able to provide solutions that surpass their performance expectations.

Throughout the entirety of the production process, our ISO 9001:2015 accreditation guarantees that quality control is maintained consistently. Each and every step adheres to stringent quality norms, beginning with the inspection of raw materials and ending with the packing. By taking such a methodical approach, we ensure that the dimensions and qualities of our Grade 2 titanium round bar fulfill or even surpass the requirements of international standards.

We differentiate ourselves from our competitors by having advanced production skills. Our facility is equipped with cutting-edge annealing machinery, precision rolling machines, and electron beam furnaces, among other cutting-edge technologies. By utilizing these technologies, we are able to manufacture Grade 2 titanium round bars that possess superior grain structure and mechanical qualities in comparison to the mainstream products available on the market.

It is because of our direct production technique that we are able to offer competitive price structures for Grade 2 titanium round bars. Through the elimination of intermediaries, we are able to provide large cost savings while maintaining first-rate quality standards. The versatile production capabilities that we possess allow us to fulfill both large-scale orders and the specialized small-batch requirements that are necessary for research applications.

Optimization Strategies for Maximum Performance Benefits

An awareness of the specific requirements of your application is the first step in making an appropriate material decision. When calculating the specifications for Grade 2 titanium round bars, it is important to take into consideration a variety of aspects, including the working temperature, pressure conditions, and chemical exposure. To guarantee that you make the best possible choice when selecting materials for your heat exchanger design, our technical team offers comprehensive consultancy services.

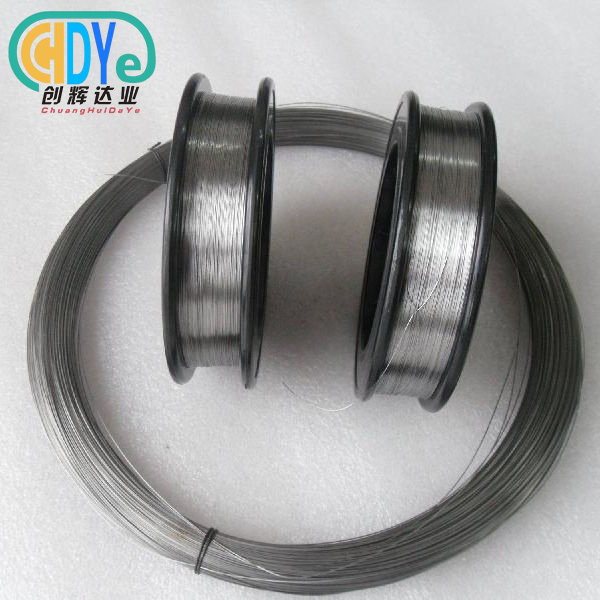

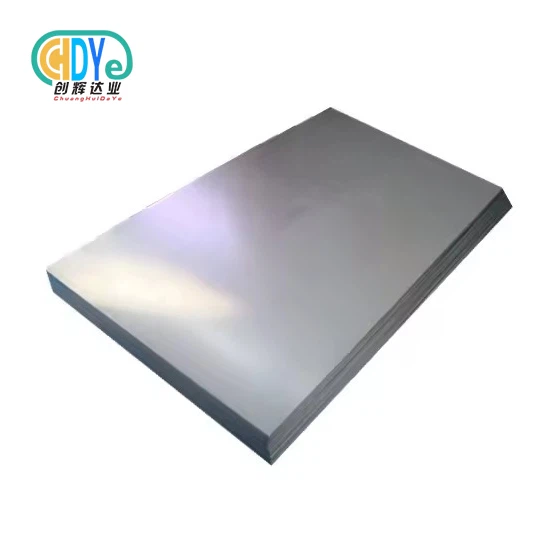

Selecting the appropriate surface finish has a considerable impact on the efficiency of heat transfer. Variations of hot-rolled, forged, and precision-ground titanium round bars are available as surface finishes for grade 2 titanium round bars. The coefficients of heat transfer are improved by smooth finishes, whereas various surface textures may be advantageous for certain applications that need better fluid mixing.

In order to avoid contamination and surface damage, suitable handling practices are among the installation issues that must be attended to. When cutting round bars made of grade 2 titanium, it is important to employ the necessary tools and processes in order to preserve the surface integrity. It is important to avoid contaminating carbon steel tools, as this can result in localized corrosion problems that are localized.

When it comes to welding methods, special techniques are required in order to preserve corrosion resistance. The welding of titanium round bars of grade 2 requires the use of inert gas shielding and the preparation of the joints correctly. In order to achieve the highest possible joint strength and resistance to corrosion, our technical support staff offers comprehensive welding processes and recommendations.

Critical Implementation Considerations

Maintaining the integrity of the material prior to installation is protected by storage and handling regulations. In order to be stored properly, grade 2 titanium round bar must be kept in a clean, dry environment, free from carbon steel products. The potential for surface contamination, which could impact performance, can be avoided by using the appropriate lifting procedures and protective coverings.

The utilisation of quality verification processes guarantees the validity of the material and its performance characteristics. Before accepting the delivery, it is important to check the documentation of the mechanical properties and the chemical composition certificates. Traceability of materials is included in our complete quality documentation, beginning with the raw material source and continuing through the final processing.

Calculations of thermal expansion become absolutely necessary for the construction of an appropriate heat exchanger. Certain considerations need to be taken into account while conducting a thermal stress analysis on Grade 2 titanium round bar due to its low modulus of elasticity. Expansion joints that are designed correctly prevent stress concentration and extend the service life of the joint.

The excellent durability of titanium is beneficial to the scheduling of maintenance schedules. The heat treatment and inherent qualities of Grade 2 titanium round bar allow for extended service intervals, in contrast to the standard materials, which require frequent inspection and replacement cycles. This resilience helps to reduce the expenses associated with maintenance and operating disruptions.

Conclusion

Grade 2 titanium round bar represents the optimum material choice for heat exchanger applications needing exceptional corrosion resistance, thermal performance, and long-term durability. Titanium is an intelligent investment for demanding industrial applications because of its remarkable material qualities, low pricing, and proven performance across a variety of applications. Because of Chuanghui Daye's knowledge, modern production capabilities, and commitment to quality, you can rest assured that the materials you obtain for your heat exchanger projects will be of premium quality, in addition to exceeding your expectations regarding performance and providing you with long-term value.

FAQ

Q: What makes Grade 2 titanium round bar superior to stainless steel for heat exchangers?

A: Grade 2 titanium round bar offers superior corrosion resistance in chloride environments, lighter weight, and longer service life compared to stainless steel. While initial costs may be higher, the extended lifespan and reduced maintenance requirements provide better long-term value for demanding applications.

Q: Can Grade 2 titanium round bar be used in high-pressure heat exchanger applications?

A: Yes, Grade 2 titanium round bar tensile strength and yield strength properties make it suitable for high-pressure applications. The material maintains structural integrity under pressure while providing excellent corrosion resistance and thermal performance.

Q: What delivery timeframes can I expect for custom Grade 2 titanium round bar orders?

A: Standard specifications typically ship within 2-3 weeks, while custom dimensions may require 4-6 weeks, depending on complexity. Our flexible production capabilities and strategic inventory management help minimize lead times for urgent projects.

Partner with Chuanghui Daye for Superior Grade 2 Titanium Round Bar Solutions

Shaanxi Chuanghui Daye stands ready as your trusted Grade 2 titanium round bar manufacturer, offering comprehensive solutions tailored to your heat exchanger requirements. Our commitment to quality, competitive pricing, and technical excellence ensures your project success from initial consultation through final delivery. Experience the advantages of working directly with a certified manufacturer that understands your industry's demanding requirements and delivers consistent results. Contact us at info@chdymetal.com to discuss your specific needs and receive detailed technical specifications.

References

1. Boyer, R.R. "Titanium for Aerospace: Rationale and Applications." Advanced Performance Materials, Vol. 2, No. 4, 1995, pp. 349-368.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio, 2000.

3. Schutz, R.W. and Thomas, D.E. "Corrosion of Titanium and Titanium Alloys." Metals Handbook, 9th Edition, Vol. 13, ASM International, 1987.

4. Peters, M., Kumpfert, J., Ward, C.H., and Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, No. 6, 2003.

5. Lutjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2007.

6. Cotton, J.D., Briggs, R.D., Boyer, R.R., Tamirisakandala, S., Russo, P., Shchetnikov, N., and Fanning, J.C. "State of the Art in Beta Titanium Alloys for Airframe Applications." Journal of Metals, Vol. 67, No. 6, 2015.