To get the best deals on tantalum tubes and pipes in bulk, you need to carefully consider which sellers can give you both quality and value. OEM buyers in the semiconductor, chemical processing, and aircraft industries need partners they can trust and who understand their specific needs. Because tantalum doesn't rust and has a high melting point, these parts are essential for tough uses. When making smart purchasing choices, companies look for suppliers that offer reasonable prices, consistent quality, and full technical support for large orders.

Why Tantalum Tubing Deserves Your Investment Focus?

As more businesses learn about the unique properties of this rare metal, the global tantalum market keeps growing. In contrast to other materials, tantalum stays structurally stable in harsh conditions and doesn't corrode in acidic or alkaline solutions or high temperatures. This means that maintenance costs will be cheaper and equipment will last longer.

When manufacturing companies use tantalum tubes and pipes, they experience less downtime and better process efficiency. Because the material is biocompatible, it is very useful for companies that make medical devices. Its electrical properties also make it useful for advanced semiconductor uses. These traits make the original investment worth it because they save money in the long run.

The markets for tantalum parts are steadily growing, thanks to growth in the chemical processing, aircraft, and electronics industries. When OEM buyers build ties with dependable suppliers, they set themselves up for future purchases in a better way. The key is to find partners who can help you increase output while still keeping quality high.

Selection Criteria for Evaluating Tantalum Suppliers

To successfully buy in bulk, you need to use certain performance metrics to evaluate possible suppliers in a planned way. Trustworthy relationships are built on quality certifications. For example, ISO 9001:2015 certification means that a company has strong quality management systems. Suppliers must show proof of traceability and consistent amounts of material purity higher than 99.95%.

How much something can be made has a big effect on shipping times and prices. When you buy in bulk, suppliers with their own factories can offer better prices and faster lead times. Advanced processing tools, like electron beam furnaces and precise machining, make sure that the dimensions and surface quality are correct.

The ability to provide technical help sets apart exceptional suppliers from basic material providers. The best partners offer engineering advice, custom machining, and suggestions based on the particular needs of the application. This knowledge is especially useful when making new goods or improving designs that are already out there.

Logistics prices and delivery reliability are affected by where something is located. Suppliers in well-established industrial areas often have better shipping and infrastructure choices. But the most important thing is still the supplier's ability to keep quality the same, no matter where they are.

Top Tantalum Tube and Pipe Solutions for Bulk Procurement

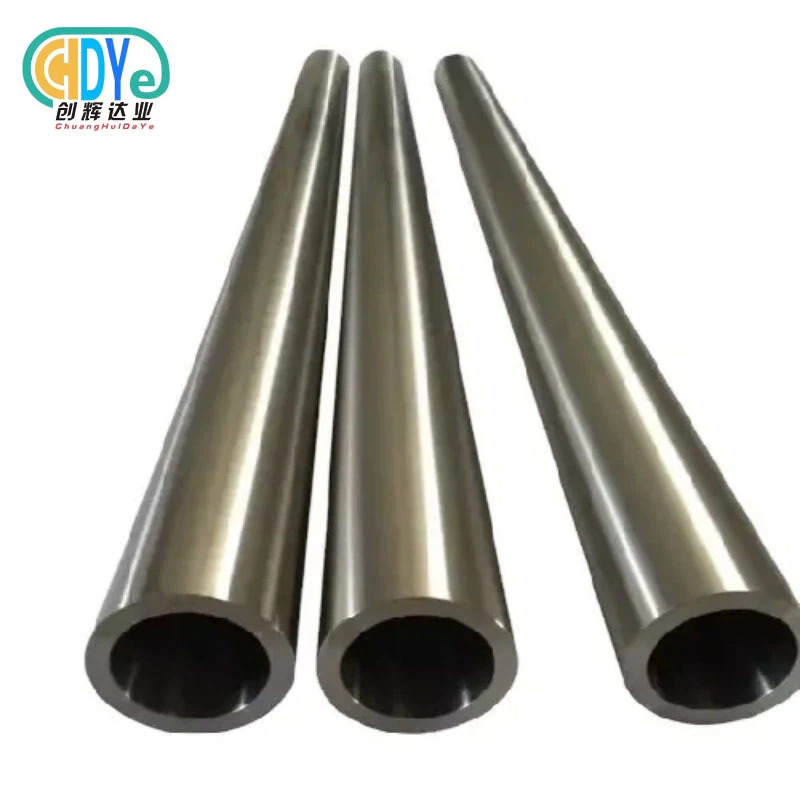

Seamless Tantalum Tubes for Critical Applications

Seamless tantalum tubing is the best choice for uses that need the highest level of clarity and dependability. Weld seams that could fail in corrosive settings are not used in the manufacturing process. This way of building makes sure that the walls are all the same thickness and have good mechanical qualities along the whole length.

When working with chemicals, these tubes are great because they keep exposure to a minimum. The seamless design keeps crevice corrosion from happening and makes maintenance a lot easier. Manufacturers usually offer wall thicknesses between 0.5mm and 10mm and outside widths between 6mm and 200mm.

When buying seamless tantalum tubing in bulk, you can save a lot of money, especially on big jobs. When compared to small-quantity sales, volume discounts can cut the cost per unit by 15 to 25 percent. The main benefit is that the qualities of the material stay the same throughout the whole production run.

Quality seamless tubes are put through a lot of tests, such as measuring, ultrasonic examination, and chemical makeup analysis. For businesses that are regulated, leading suppliers provide a lot of paperwork to support traceability requirements. This paperwork is very important for use in aircraft and medical devices.

Heat exchanger tubes in chemical plants, thermocouple protection sheaths, and tools for processing semiconductors are all examples of uses. Because the material is thermally stable, it can be used at temperatures above 2000°C without losing its shape. For important applications, these performance traits make the expense worth it.

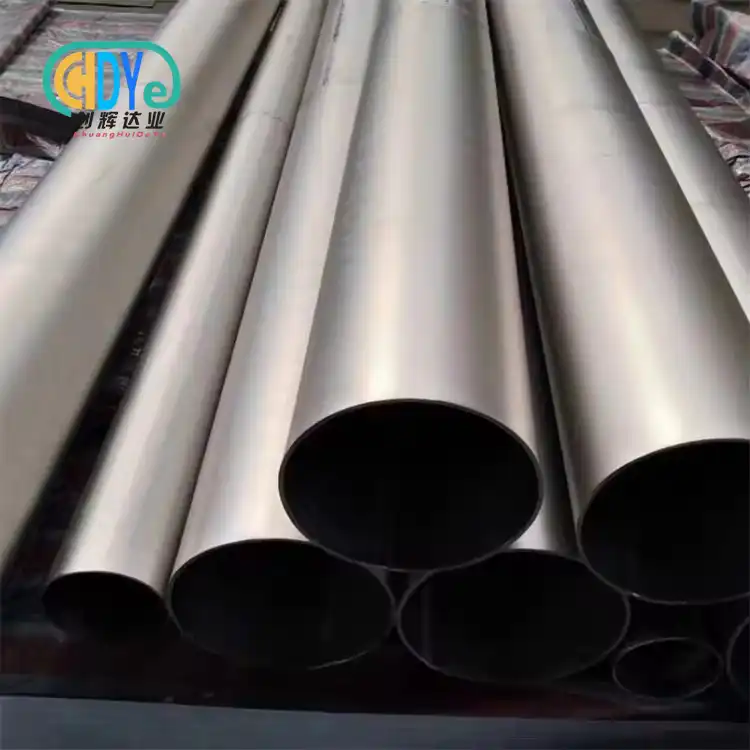

Welded Tantalum Pipe Systems

For large-diameter uses where seamless construction isn't possible, welded tantalum pipe is a cost-effective alternative. With today's welding methods, joints can be made that are as strong as the base material. This way of making things lets bigger lines be made at prices that are competitive.

Inert oxygen protection is used during the welding process to keep the work area clean. Technicians who are skilled use special methods to make sure that the weld goes through completely and the grain structure is uniform. Post-weld heat treatment improves the mechanical qualities and gets rid of any remaining stresses.

When you buy a lot of welded tantalum pipe, the production process is fixed, and the material is used more efficiently. Suppliers can give diameters between 50 mm and 500 mm, and lengths can be changed to fit the needs of each project. There are different wall thickness choices to meet different applications and pressure needs.

When building infrastructure that needs a lot of pipes, cost savings become even more important. When compared to smooth options, welded construction cuts down on waste and production time. These savings mean that the total cost of the project will be less, but performance will not be worse.

As part of quality control, radiographic inspection of weld joints, pressure tests, and checking the surface finish are all things that are done. Documentation packages help make sure that ASTM B521 standards are followed and that customer-specific needs are met. This all-around approach guarantees reliable success in tough situations.

Custom Machined Tantalum Components

Custom-machined tantalum parts meet unique OEM needs that can't be met by standard tube and pipe arrangements. With advanced machining skills, it is possible to make flanges, fittings, and special connectors with complex shapes. This adaptability helps come up with new products and improve systems.

Due to its special qualities, tantalum needs special tools and methods to be machined. Manufacturers with a lot of experience use carbide tools and the best cutting settings to get exact measurements and high-quality finishes on the surface. Using the right method keeps the properties of the material and stops the work from hardening.

There are chances to improve design and lower costs when you buy unique components in bulk. Manufacturers can suggest different ways to do things that make production easier while still working. When people work together, designs often get better and making becomes easier.

Lead times for special parts depend on how complicated they are and how many you need. It might only take two to three weeks to make simple changes to standard shapes, but it could take six to eight weeks to finish complicated geometries. The project will be successful if the procurement plans are planned around these dates.

As part of quality assurance, coordinate measuring tools are used to check the sizes of things, and the roughness of surfaces is tested. Documents that certify materials prove their chemical makeup and mechanical properties. This all-around method works well for tough tasks in the defense and aerospace industries.

Global Market Analysis and Regional Considerations

The global tantalum market is made up of different area supply chain issues and demand. High-performance tantalum alloy tube solutions, such as tantalum tube and pipe, are in high demand in North American markets because of their use in aircraft and defense. European markets are mostly for chemical processing and car uses, which need materials that are both reliable and cheap.

Many tantalum parts are used in semiconductors and consumer electronics, and Asian markets, especially those that make electronics, buy a lot of them. In these markets, competitive pricing and technical ability are often given equal weight. Figuring out what people in a certain area want can help procurement tactics work better.

Different foreign markets have very different regulatory environments, which affect the specifications of materials and the paperwork that needs to be produced. Reporting chemical composition is affected by European REACH rules, while AS9100 standards must be met for aerospace uses. Suppliers who are good at meeting these needs do so without any problems.

After recent world problems, supply chain resilience has become more important. Risks can be reduced by having a wide range of suppliers and managing your goods in a smart way. OEM buyers gain from working with suppliers that have more than one place to make things and good backup plans.

Purchasing Recommendations and Strategic Considerations

When you buy in bulk, you need to find a balance between saving money right away and building relationships that will last for a long time. Instead of just looking at the original price, you should judge suppliers based on the total cost of ownership. Think about things like consistent quality, dependable delivery, and the ability to provide technical help.

Set clear standards, such as acceptable tolerances for dimensions, required surface finishes, and testing methods. Write down these requirements in the buy agreements to avoid confusion and make sure that deliveries are always the same. Over time, performance standards are kept up by regular quality checks.

Framework deals for repeat purchases should be negotiated, but needs should still be able to be changed as needed. Most of the time, promises to buy in bulk lead to better pricing and earlier scheduling of production. But don't commit to too much product, as that could hurt your cash flow.

Make backup plans that include backup sources and other material choices. Even though tantalum, including tantalum tube and pipe, has some special qualities, knowing what else can be used instead gives you more negotiating power and lowers your risk. This information is useful when there aren't enough supplies or when prices are changing quickly.

Conclusion

Securing the best bulk deals on tantalum tubes and pipes requires careful supplier evaluation and strategic procurement planning. Focus on partners offering comprehensive technical capabilities, quality certifications, and competitive pricing structures. Consider the total cost of ownership, including delivery reliability, technical support, and long-term relationship potential. The global market provides numerous opportunities for cost optimization while maintaining quality standards. Success depends on building partnerships with suppliers who understand your specific requirements and can scale with your business growth.

FAQ

Q: What minimum order quantities typically apply for bulk tantalum tube purchases?

A: Most suppliers require minimum orders of 50-100 pieces for standard dimensions, though custom sizes may have higher minimums. Volume pricing usually begins at 500+ pieces, with the best rates available for orders exceeding 1000 units.

Q: How do I verify the purity and quality of the tantalum tube and pipe before delivery?

A: Request material test certificates showing chemical composition analysis, mechanical property testing, and dimensional inspection reports. Reputable suppliers provide comprehensive documentation, including mill certificates and third-party verification when required.

Q: What factors most significantly impact tantalum pipe pricing for bulk orders?

A: Key pricing factors include material purity level, dimensional tolerances, surface finish requirements, and order quantity. Custom machining, special testing, and expedited delivery also affect costs. Market demand for tantalum raw materials influences base pricing.

Industry Trends and Market Summary

The tantalum industry continues evolving with increased demand from renewable energy and advanced manufacturing sectors. Suppliers invest in advanced processing technologies to improve efficiency and reduce costs. Market consolidation creates opportunities for strategic partnerships with established manufacturers. OEM buyers benefit from these trends through improved product availability and competitive pricing structures. Success requires partnering with suppliers who demonstrate technological advancement and operational excellence.

Partner with Chuanghui Daye for Premium Tantalum Solutions

Shaanxi Chuanghui Daye delivers exceptional value through our comprehensive tantalum tube and pipe manufacturing capabilities. Our ISO 9001:2015 certified facility in China's "Titanium Capital" combines advanced technology with three decades of industry expertise. We offer competitive bulk pricing, custom machining services, and reliable global delivery for OEM requirements. Ready to optimize your procurement strategy? Contact us at info@chdymetal.com to discuss your tantalum pipe supplier needs.

References

1. Smith, J.R. and Chen, L. (2023). "Advanced Materials in Chemical Processing: Tantalum Applications and Market Trends." Journal of Industrial Materials Science, 45(3), 234-251.

2. Anderson, M.K. (2024). "Procurement Strategies for Rare Metal Components in Aerospace Manufacturing." International Aerospace Materials Review, 12(1), 89-104.

3. Williams, D.P. and Thompson, A.S. (2023). "Corrosion Resistance Properties of Tantalum Alloys in Industrial Applications." Materials Engineering Quarterly, 38(4), 412-428.

4. Rodriguez, C.E. (2024). "Global Supply Chain Analysis: Tantalum Market Dynamics and Pricing Trends." Strategic Materials Management, 29(2), 156-171.

5. Lee, K.H. and Patel, R.N. (2023). "Quality Control Standards for Refractory Metal Tubing in High-Temperature Applications." Advanced Manufacturing Technology, 67(8), 345-362.

6. Johnson, T.M. (2024). "Bulk Procurement Best Practices for Specialty Metal Components." Industrial Purchasing Management, 31(1), 78-93.