Titanium mesh anodes have revolutionized industrial electrochemical processes across mining and manufacturing sectors worldwide. These advanced electrode materials combine exceptional corrosion resistance with superior electrical conductivity, making them indispensable for water treatment, metal recovery, and chemical production applications. Through their unique mesh structure and specialized coatings, these anodes deliver enhanced surface area and optimized current distribution, significantly improving process efficiency while reducing operational costs in demanding industrial environments.

Understanding the Core Benefits of Advanced Electrode Technology

Modern industry requires durable electrode solutions that can withstand harsh chemical environments. These harsh conditions suit titanium-based electrodes due to their oxidation resistance and thermal stability. The mesh design maximizes electrochemically active surface area while being lightweight for large-scale installations.

Specialized coatings on these electrodes include RuO₂, IrO₂, and platinum. Each coating has advantages for different applications. RuO₂ coatings thrive in chlorine evolution, while IrO₂ coatings excel in oxygen evolution. This adaptability lets engineers choose the best electrode combinations for their processes.

In corrosive media, Grade 1 or Grade 2 titanium substrates are chemically stable. Compared to typical electrode materials that may need replacement within months, this stability extends service life to 5-10 years in continuous operation.

Water Treatment and Electrochlorination Systems

Water treatment facilities globally disinfect and oxidize by electrochlorination. Mesh electrodes produce chlorine from seawater or brine solutions, avoiding chemical chlorine storage and handling. This on-site generation method improves safety and cuts transportation expenses.

These technologies disinfect drinking water in municipal water treatment plants without releasing toxic byproducts. The mesh construction distributes current uniformly, boosting chlorine generation and lowering energy usage.

Continuous electrochlorination reduces biofouling and bacterial development in industrial cooling water systems. These technologies keep heat exchangers efficient and prevent biological deposits from causing downtime in power plants, refineries, and factories.

For reliability and automation, swimming pools and recreational water facilities are adopting electrochlorination technology. The device controls chlorine production based on water flow and quality to maintain optimal sanitation without operator intervention.

Mining and Metal Recovery Applications

Mining electrowinning procedures require high-performance anodes to recover metal from ore solutions. Copper, zinc, nickel, and precious metal recovery procedures use optimized electrode designs to increase current efficiency and reduce energy use.

Advanced anode technology in copper electrowinning facilities achieves current densities of 300 A/m², greatly increasing production rates over typical lead anodes. The inert titanium substrates remove metal contamination concerns that affect conventional electrode materials.

In acidic sulfate solutions, coated titanium electrodes resist corrosion better for zinc recovery. Titanium mesh anodes last for years in these extreme environments, while traditional anodes decay quickly.

Alkaline electrodes are used to recover gold and silver from cyanide solutions. Titanium substrates are chemically inert, preventing side reactions that could reduce precious metal recovery.

Hydrometallurgical rare earth element extraction uses electrode designs for specific solution chemistries. Modern mining operations can optimize process requirements by customizing coating formulas.

Chemical and Petrochemical Industry Applications

One of the greatest industrial uses for improved electrode technology is chlor-alkali. Membrane cell electrolyzers create chlorine and caustic soda from brine using dimensionally stable anodes. Due to better electrode performance, mercury and diaphragm cell technologies have been replaced by membrane techniques.

These electrodes are used in sodium chlorate and perchlorate production plants for high-current, long-term oxidation operations. Modern electrode designs provide months of maintenance-free operation because to their charge efficiency and cycle stability.

Electrochemical specialized chemical synthesis requires precision electrode reaction control. Electrodes affect product quality and yield in electrochemical processing of pharmaceutical intermediates, electronic compounds, and advanced materials.

Chemical plant wastewater treatment uses electrochemical oxidation to eliminate organic contaminants that defy biological treatment. The strong oxygen evolution overpotential on coated titanium surfaces stimulates hydroxyl radical production, mineralizing persistent organic molecules completely.

Cathodic Protection Systems for Infrastructure

To avoid corrosion, marine structures, pipelines, and underground storage tanks need cathodic protection. Impressed current cathodic protection systems use anodes that last decades in soil or ocean.

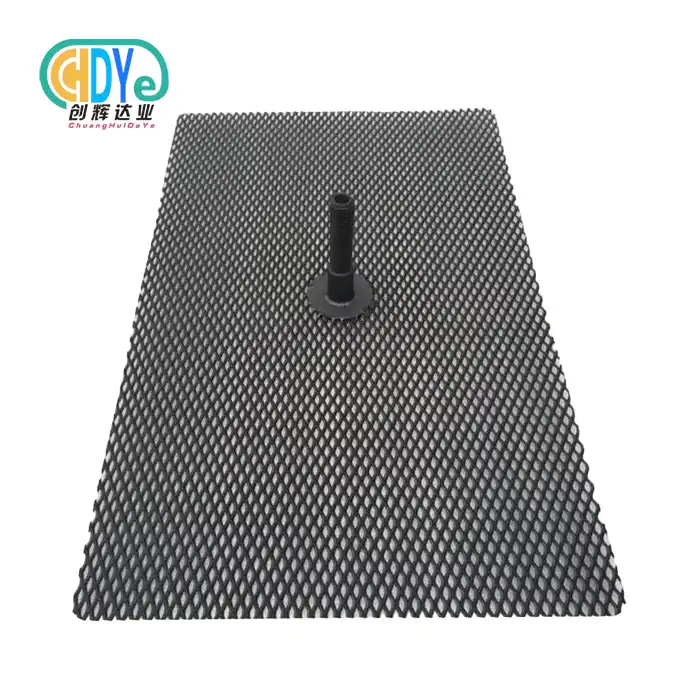

Offshore oil installations and ports use anodes that can survive marine fouling and maintain current output. The lightweight mesh construction minimizes installation complexity and improves current distribution over solid electrodes.

Strategically placed anode systems maintain protective current levels in thousands-kilometer pipeline networks. Modern electrode installations provide real-time performance assessment and predictive maintenance scheduling via remote monitoring.

Deep anodes protect tank bottoms and pipework in storage tank farms. Titanium mesh anodes last longer and lessen environmental dangers.

Electroplating and Surface Treatment Operations

Inert anodes are needed for industrial electroplating to avoid solution contamination and deposit quality issues. Advanced electrode materials provide dimensional stability and reliable performance for decorative and functional coatings.

Aerospace and automotive hard chromium plating requires anodes that can operate in concentrated chromic acid solutions at high temperatures. Corrosion and contamination damage coating quality and require frequent replacement of lead anodes.

PCB manufacture uses precision electroplating, where consistent current distribution affects trace quality and dependability. Superior throwing force ensures constant copper deposition in complex geometries with the mesh structure.

Inert anode technique reduces maintenance and extends solution life for decorative plating. Superior surface quality and lower operating costs are achieved in jewelry, car trim, and consumer electronics.

Food Processing and Sterilization Systems

More and more, rules about food safety demand that cleaning methods work well and don't leave behind chemicals or lower the quality of the food. Electrochemical sterilization systems use salt solutions to make cleaning agents that clean food preparation equipment without leaving any residue.

Electrolyzed water systems are used to clean and sanitize bottling lines, storage tanks, and transfer pipes in beverage production sites. The on-demand generation of cleaning solutions gets rid of the need to store chemicals and makes sure that they always kill germs.

Electrochemically activated water is used in fresh produce washing systems to kill pathogenic germs and extend the shelf life of food. Electrochemically produced sanitizers are gentle, so they keep the quality of the product while still meeting strict food safety standards.

These devices are used to clean equipment between production runs in dairy processing plants. Making cleaning and sanitizing solutions on-site cuts down on the cost of chemicals and makes work safer.

Environmental Benefits and Sustainability

Electrochemical technologies are being used more and more in many fields because they are better for the environment. Making treatment chemicals on-site gets rid of emissions linked to transportation and cuts down on packaging waste. Quality electrodes last a long time, which means they don't need to be replaced as often and create as much trash.

When electrode designs are optimized, they become more energy efficient. This helps industrial processes leave smaller carbon footprints. The current efficiency of modern systems is much better than that of older technologies. This means that less energy is used per unit of production.

Getting rid of the need to store and handle dangerous chemicals in dangerous ways lowers environmental risks and makes following the rules easier. Many businesses save a lot of money on their insurance by not having to store chlorine gas or other dangerous chemicals.

Manufacturing Excellence and Quality Assurance

At Chuanghui Daye, we know that the performance of your electrodes has a direct effect on how well your operations go. Our factory in Baoji, which is known as China's "Titanium Capital," blends 30 years of experience with rare metals with cutting-edge production tools. We keep our ISO 9001:2015 certification, which means that we have strict quality control at every stage of the manufacturing process.

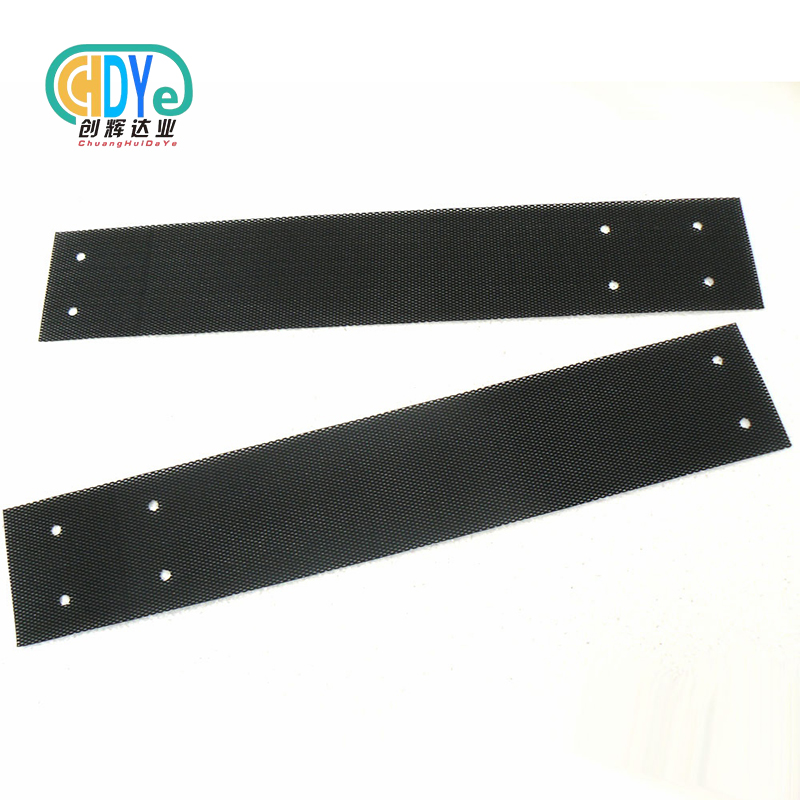

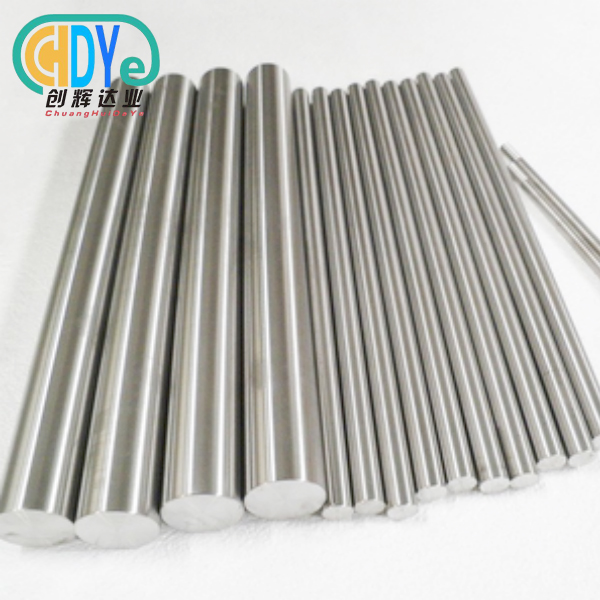

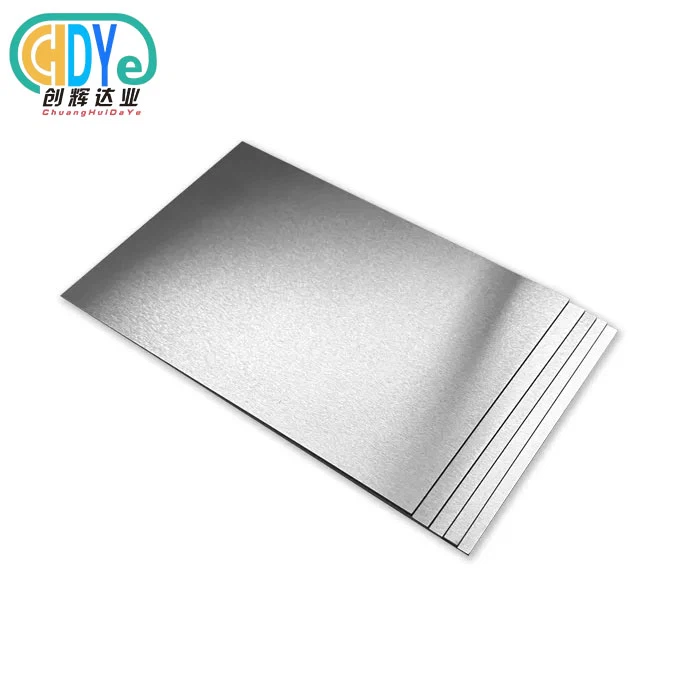

The first step in our production process is choosing a high-purity Grade 1 titanium substrate. Next, we use advanced expansion or weaving methods to make a precision mesh. To get the best coating bonding, surfaces need to be cleaned, degreased, and sandblasted in a controlled way. We use thermal decomposition techniques to apply special coatings that make sure the thickness is regular and the coatings are stable electrochemically.

Each electrode goes through a lot of tests, such as checking its electrical performance, measuring its dimensions, and measuring the thickness of its coating. Our quality management system gives full traceability documents, so customers can keep track of where materials came from and how they were processed for legal reasons.

Conclusion

Titanium mesh anodes represent a critical technology enabling efficient, sustainable industrial processes across diverse applications. From water treatment and mining operations to chemical production and infrastructure protection, these advanced electrodes deliver superior performance, extended service life, and reduced environmental impact. The combination of titanium's inherent corrosion resistance, specialized coating technologies, and optimized mesh geometries creates electrode solutions capable of operating reliably in the most demanding industrial environments. As industries continue prioritizing efficiency, sustainability, and operational safety, the adoption of advanced electrode technologies will undoubtedly expand, driving continued innovation and application development.

FAQ

Q: How long do titanium mesh anodes typically last in industrial applications?

A: Service life varies depending on operating conditions, but properly designed and manufactured anodes typically operate for 5-15 years in continuous service. Factors affecting lifespan include current density, solution chemistry, temperature, and coating type. Our electrodes often exceed design life expectations due to superior coating adhesion and substrate quality.

Q: Can titanium mesh anodes be customized for specific applications?

A: Absolutely. We specialize in custom electrode design and manufacturing. Our engineering team works with customers to optimize mesh patterns, dimensions, coating formulations, and mounting configurations for specific process requirements. Custom solutions ensure optimal performance and cost-effectiveness for unique applications.

Q: What maintenance is required for titanium mesh anode systems?

A: Maintenance requirements are minimal compared to traditional electrode materials. Regular visual inspection, periodic electrical testing, and occasional cleaning to remove deposits are typically sufficient. The inert nature of titanium substrates eliminates corrosion-related maintenance issues common with other electrode types.

Partner with Chuanghui Daye for Superior Electrode Solutions

Shaanxi Chuanghui Daye delivers world-class titanium mesh anode solutions backed by three decades of rare metal expertise and ISO 9001:2015 quality certification. Our Baoji facility provides factory-direct pricing, rapid prototyping capabilities, and flexible production for both large-scale projects and research applications. As a trusted titanium mesh anode manufacturer, we offer comprehensive technical support, complete traceability documentation, and reliable global shipping to meet your most demanding project timelines. Contact us at info@chdymetal.com to discuss your electrode requirements with our engineering team.

References

1. Chen, G. (2020). "Advances in Dimensionally Stable Anodes for Industrial Electrochemistry." Journal of Applied Electrochemistry, 50(4), 425-441.

2. Walsh, F.C., & Ponce de León, C. (2018). "Titanium-Based Electrodes for Water Treatment and Industrial Electrolysis." Electrochimica Acta, 280, 121-139.

3. Martínez-Huitle, C.A., & Ferro, S. (2019). "Electrochemical Treatment of Mining Wastewaters Using Advanced Electrode Materials." Chemical Engineering Journal, 365, 234-248.

4. Kraft, A. (2021). "Doped Diamond and Titanium Mesh Anodes in Chlor-Alkali and Water Treatment Applications." Current Opinion in Electrochemistry, 27, 100-112.

5. Zhang, Y., Liu, H., & Wang, D. (2019). "Performance Evaluation of Titanium Mesh Anodes in Electrowinning Operations." Hydrometallurgy, 188, 156-164.

6. Thompson, R.K., & Anderson, M.J. (2020). "Cathodic Protection Systems Using Advanced Titanium Electrode Technology." Corrosion Engineering, Science and Technology, 55(3), 187-201.