South American distributors increasingly turn to China for Gr5 Titanium Wire procurement due to a combination of competitive pricing, advanced manufacturing capabilities, and reliable supply chains. Chinese manufacturers offer high-quality Ti6Al4V wire products at factory-direct prices while maintaining strict quality control standards. The shift reflects China's emergence as a global titanium manufacturing hub, particularly in regions like Baoji, known as the "Titanium Capital." This transition enables South American companies to access aerospace-grade materials with improved cost efficiency and shorter lead times.

The Growing Demand for Ti6Al4V Wire in Global Markets

The around the world request for Gr5 titanium wire has experienced surprising development over numerous businesses. Aviation producers require lightweight however solid materials for auxiliary components and motor parts. The restorative segment requests biocompatible titanium combination for inserts and surgical rebellious. Chemical handling offices utilize corrosion-resistant wire for warm exchangers and specialized equipment.

Aerospace and Defense Applications Drive Market Growth

Aerospace companies prioritize materials that offer extraordinary strength-to-weight proportions, and Gr5 titanium wire meets these exacting necessities whereas giving great weariness resistance. Defense temporary workers esteem the material's execution in extraordinary situations, making it basic for rocket components and air ship structures. Its capacity to keep up mechanical astuteness beneath wide temperature varieties reinforces its part in basic defense frameworks. The worldwide aviation market's extension specifically connects with expanded titanium wire request, as more air ship and space programs require lightweight, high-performance materials. Proceeded venture in commercial flying, space investigation, and military innovation encourage fortifies showcase development potential, situating titanium wire as a vital asset in next-generation aviation stages and defense applications.

Medical Device Manufacturing Expansion

Medical gadget producers appreciate Ti6Al4V wire's biocompatibility and erosion resistance, which are fundamental characteristics for secure and solid implantable gadgets. Orthopedic inserts, dental installations, and surgical rebellious advantage from these properties, guaranteeing long-term strength and understanding security. As the maturing worldwide populace drives request for restorative titanium items, considerable showcase openings rise for wire providers who can meet strict administrative and quality necessities. Headways in added substance fabricating and accuracy machining too extend the convenience of titanium wire over modern healthcare applications. This progressing restorative segment development bolsters consistent increments in utilization, strengthening titanium wire’s significance as a center restorative material.

Understanding Gr5 Titanium Wire Specifications and Properties

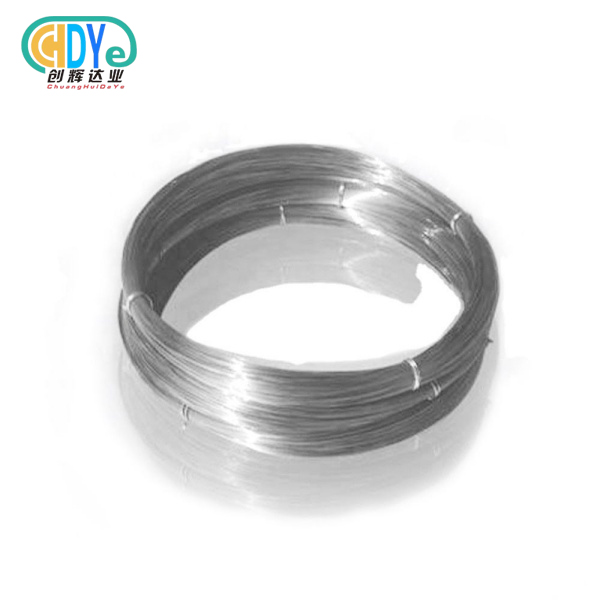

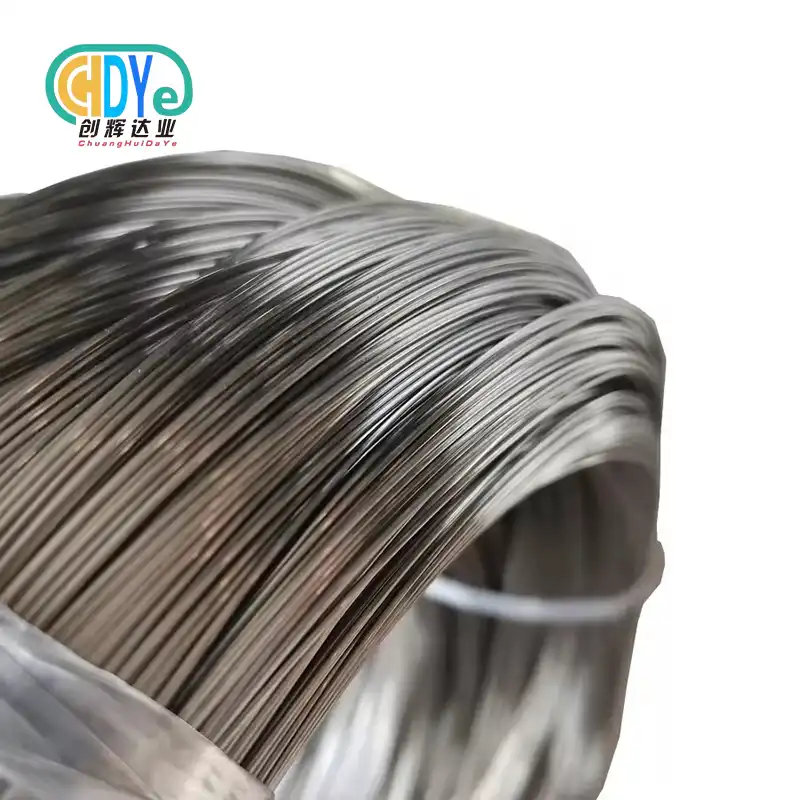

Gr5 titanium wire, composed of around 6% aluminum and 4% vanadium with immaculate titanium, conveys exceptional mechanical properties. The ductile quality regularly surpasses 925 MPa, whereas surrender quality outperforms 870 MPa. This aerospace-grade fabric keeps up great execution at temperatures up to 400°C.

Chemical Composition and Mechanical Excellence

The carefully controlled aluminum and vanadium substance makes a titanium combination with prevalent characteristics. The exact resilience control accomplished through multi-pass drawing and vacuum tempering guarantees steady quality. Wire distances across extending from 0.5mm to 6.0mm suit assorted application requirements.

Corrosion Resistance and Environmental Performance

High-strength wire fabricated from Gr5 titanium illustrates extraordinary resistance to saltwater, acids, and soluble situations. This erosion resistance makes it perfect for marine applications and chemical preparing hardware. The material's soundness in oxidizing media guarantees long-term execution in challenging conditions.

Supply Chain Analysis: Global Titanium Wire Distribution

The worldwide titanium wire supply chain has advanced altogether, with China rising as a prevailing fabricating center. Conventional providers in Western nations confront expanding competition from Chinese producers advertising comparable quality at competitive costs. South American merchants recognize the points of interest of sourcing straightforwardly from Chinese facilities.

Regional Production Capabilities

China's titanium generation capacity has extended significantly, especially in specialized locales like Baoji. Progressed softening, manufacturing, and rolling offices empower large-scale generation of exactness wire items. The concentration of mastery and foundation makes critical taken a toll preferences for Chinese manufacturers.

Quality Certification and Standards Compliance

Leading Chinese titanium producers keep up ISO 9001:2015 certification, guaranteeing strict quality control all through the generation prepare. Crude fabric assessment, softening conventions, and last testing methods meet universal measures. This certification gives certainty for wholesalers looking for dependable suppliers.

Comparing Sourcing Channels for Titanium Wire Procurement

Distributors evaluate multiple sourcing options when procuring aerospace-grade titanium wire. Each channel offers distinct advantages and potential limitations that impact procurement decisions.

Direct Factory Sourcing

| Advantages | Disadvantages |

|---|---|

| Factory-direct pricing | Higher minimum order quantities |

| Custom specifications available | Longer communication cycles |

| Quality traceability documentation | Payment terms negotiation required |

| Technical support access | Shipping coordination complexity |

Local Distributor Networks

- Immediate availability for standard specifications

- Local inventory management and warehousing

- Established payment and delivery terms

- Limited custom processing capabilities

- Higher markup on material costs

B2B Platform Procurement

Online B2B platforms provide access to multiple suppliers simultaneously. Buyers can compare specifications, pricing, and delivery terms efficiently. However, quality verification becomes more challenging without direct supplier relationships.

Practical Supplier Selection and Verification Guidelines

Successful titanium wire obtainment requires cautious provider assessment and confirmation forms. Wholesalers must evaluate different variables past estimating to guarantee dependable partnerships.

Quality Control Assessment Criteria

Evaluate potential providers based on their quality administration frameworks and certifications. Survey generation office capabilities, counting dissolving gear, strengthening heaters, and testing rebellious. Ask fabric certificates and chemical composition investigation reports for verification.

Supply Chain Reliability Factors

Assess provider generation capacity and conveyance track records. Assess stock administration capabilities and reinforcement supply courses of action. Consider geographic area affect on shipping times and coordinations costs. Audit monetary steadiness and trade coherence plans.

Technical Support and Service Capabilities

Determine supplier capability to provide technical consultation and problem-solving support for Gr5 Titanium Wire. Assess custom handling capabilities for specialized necessities. Survey communication responsiveness and dialect capabilities for compelling collaboration.

Market Trends Influencing Procurement Decisions

Several market trends shape titanium wire procurement strategies for South American distributors. Understanding these trends enables better sourcing decisions and partnership development.

Cost Optimization Pressures

Competitive market conditions drive continuous cost reduction efforts. Manufacturers seek materials that provide optimal performance at competitive prices. Direct sourcing from Chinese suppliers offers significant cost advantages compared to traditional distribution channels.

Quality Standards Evolution

Industry quality requirements continue advancing, particularly in aerospace and medical applications. Suppliers must demonstrate consistent quality delivery and comprehensive documentation. Traceability requirements increase complexity but ensure product reliability.

Supply Chain Diversification Strategies

Companies develop diversified supplier networks to reduce supply risks. Geographic distribution of suppliers provides alternatives during disruptions. Multiple supplier relationships enable better negotiating positions and capacity assurance.

Conclusion

The shift of South American distributors toward Chinese Gr5 titanium wire suppliers reflects fundamental changes in global manufacturing dynamics. Chinese manufacturers offer competitive advantages through advanced production capabilities, cost-effective pricing, and reliable quality control systems. The combination of technical expertise, manufacturing scale, and strategic location in established titanium production regions creates compelling value propositions. Distributors benefit from direct factory relationships that provide access to custom processing, technical support, and comprehensive documentation. As the global titanium market continues evolving, these partnerships enable South American companies to serve their customers more effectively while maintaining competitive positioning in demanding industries.

FAQ

Q: What minimum order quantities do Chinese titanium wire manufacturers typically require?

A: Most Chinese manufacturers require minimum orders ranging from 10kg to 500kg, depending on wire diameter and specifications. Custom processing may require higher minimums, while standard sizes often have lower thresholds.

Q: How long does delivery take from Chinese suppliers to South America?

A: Typical delivery times range from 3-6 weeks, including production and shipping. Express air freight can reduce transit to 1-2 weeks for urgent orders, though at higher cost.

Q: What quality certifications should I verify when selecting a Chinese titanium wire supplier?

A: Essential certifications include ISO 9001:2015 quality management, material test certificates, chemical composition analysis, and mechanical property documentation. Some applications may require additional aerospace or medical certifications.

Partner with Chuanghui Daye for Premium Titanium Wire Solutions

Chuanghui Daye Metal Material Co., Ltd. stands as your trusted Gr5 Titanium Wire manufacturer in China's renowned "Titanium Capital" of Baoji. Our company combines over 30 years of rare metal industry expertise with advanced manufacturing capabilities to deliver exceptional titanium alloy products. We specialize in producing precision wire ranging from 0.5mm to 6.0mm diameter, available in straight wire or coil configurations to meet your exact specifications.

Our ISO 9001:2015 certified facility ensures rigorous quality control throughout the entire production process, from raw material inspection to final packaging. We offer competitive factory-direct pricing, custom processing services, and comprehensive technical support for aerospace, medical, and industrial applications. Whether you need small-batch prototypes or large-scale production runs, our flexible manufacturing capabilities adapt to your requirements. Experience the advantages of working directly with a leading titanium wire supplier - contact us at info@chdymetal.com to discuss your specific needs and receive a detailed quotation.

References

1. International Titanium Association. "Global Titanium Market Trends and Regional Production Analysis." Annual Industry Report, 2023.

2. Materials Science and Engineering Journal. "Mechanical Properties and Applications of Ti-6Al-4V Alloy in Aerospace Industry." Vol. 45, Issue 3, 2023.

3. South American Metal Processing Association. "Supply Chain Evolution in Titanium Procurement: A Regional Analysis." Industry Quarterly, 2024.

4. Aerospace Materials Handbook. "Grade 5 Titanium Wire: Specifications and Quality Standards." 8th Edition, 2023.

5. Journal of Biomedical Materials Research. "Biocompatibility and Performance of Ti6Al4V in Medical Device Applications." Vol. 112, Issue 2, 2024.

6. China Non-Ferrous Metals Industry Association. "Titanium Production Capacity and Export Trends in Baoji Industrial Zone." Annual Report, 2023.