- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best Titanium Baskets for High‑Acid Plating Solutions

When procurement workers look for the best titanium baskets for high-acid plating solutions, they need containers that are made to last and not rust. These carefully made titanium baskets work great in harsh electroplating conditions where other materials don't. They are more chemically compatible with strong acids like sulfuric, hydrochloric, and fluoboric acid solutions. Their advanced design includes a high-purity titanium mesh structure that keeps the structure strong while distributing current optimally and offering longer operational life in tough industrial settings.

Understanding Titanium Baskets and Their Relevance in High-Acid Plating

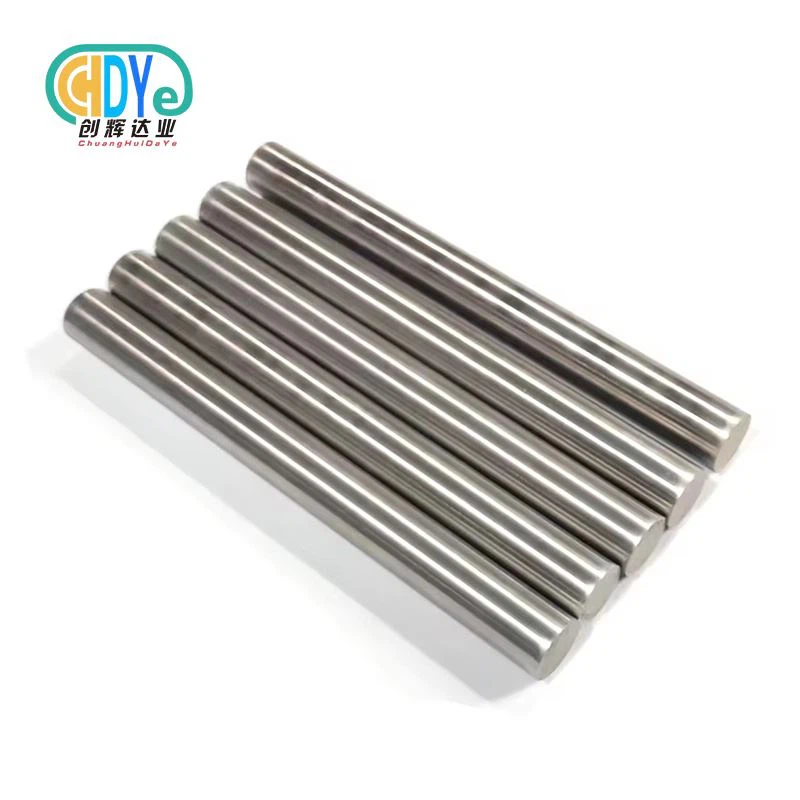

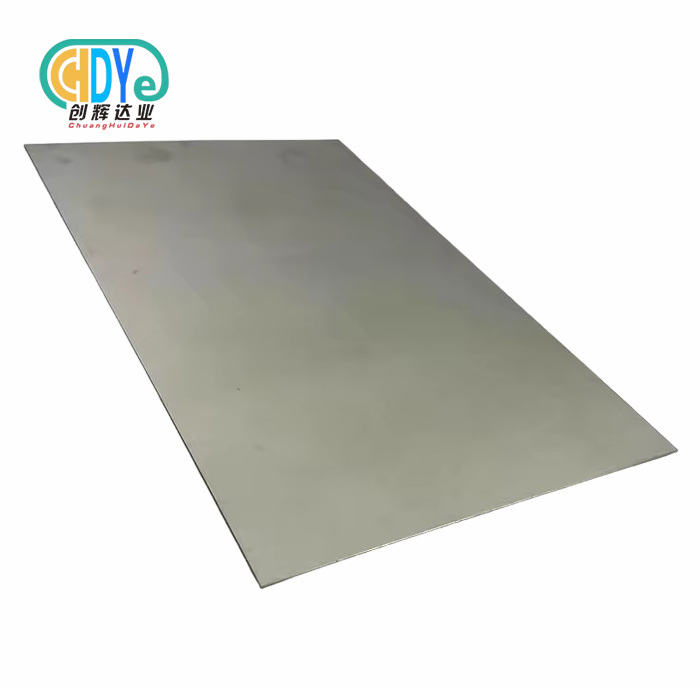

Titanium baskets are perfectly built containers that are made to handle the harsh chemicals that are used in high-acid plating processes. These special vessels are made of titanium alloys Grade 1 and Grade 2, which are very strong and don't rust, which is important for electroplating uses. Because titanium is so special, these baskets are a must-have for B2B procurement workers who need reliable solutions for harsh chemical processing.

Core Characteristics and Chemical Compatibility

Titanium baskets are very useful because they don't rust when they come in contact with strong acids that are often used in coating processes. Titanium, unlike most materials, makes a protective oxide layer that keeps it from breaking down when it comes in contact with sulfuric acid, hydrochloric acid, and fluoboric acid solutions. This chemical compatibility makes sure that the material always works the same way and removes the risk of contamination that can happen with cheaper materials.

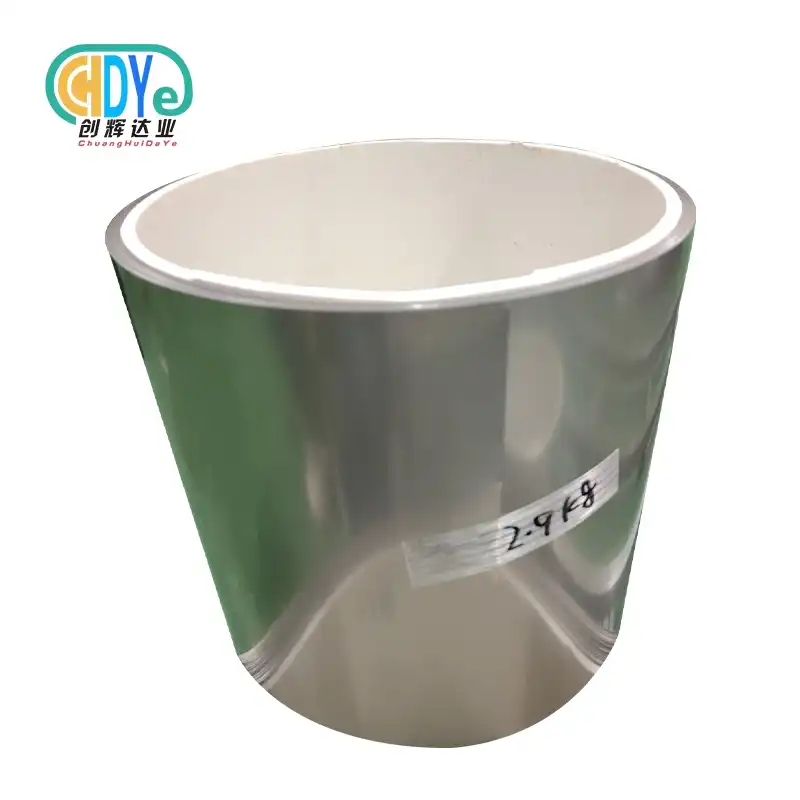

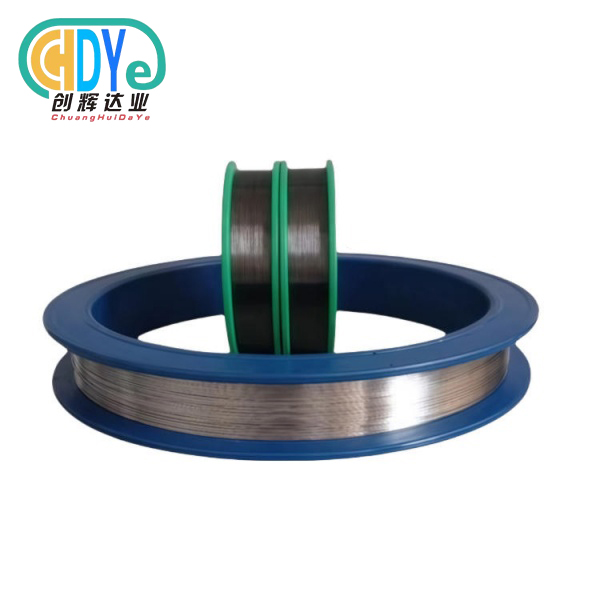

Our titanium baskets are made up of three main parts: titanium mesh plates, titanium frame plates, and titanium hooks. All three are made using precise argon arc welding methods. This way of building guarantees strong parts that won't leak and will stay together even in harsh chemical environments. When it comes to durability and operating life, the high-purity titanium construction (99.7% purity in Grade 2 material) is better than other materials.

Superior Durability and Performance Benefits

Because titanium baskets are very strong for how light they are, they are useful for plating processes. These containers can hold a lot of weight without losing their shape, which means they don't need to be replaced as often, and production doesn't have to stop. Titanium constructions have a lower total cost of ownership because they don't need much upkeep. This makes them an economical choice for industrial uses.

Companies that use titanium baskets in their electroplating processes say that the quality of their products and the regularity of their processes have gotten a lot better. Titanium's high conductivity makes sure that the current flows evenly throughout the plating bath. This makes the coating thickness more reliable and the quality of the finished product better. These improvements in performance have a direct effect on how efficiently things are made and help companies stay ahead of the competition in tough industrial settings.

Comparing Titanium Baskets with Alternative Materials for Plating Solutions

Knowing the pros and cons of titanium baskets compared to other materials helps you make smart purchasing choices that affect the long-term success of your business. At first glance, stainless steel, aluminum, and plastic baskets may seem like good deals, but their problems in high-acid environments often lead to higher total ownership costs and operating problems.

Material Performance Analysis

While stainless steel baskets are often used in general situations, they have a lot of problems when they come in contact with high-acid plating solutions. In harsh acidic conditions, the chromium content in stainless steel drops, which causes pitting, crevice corrosion, and eventually failure. This wear and tear can make plating baths dirty, which leads to bad covering quality that needs to be replaced more often and costs more to maintain.

When acid treating, aluminum baskets are even more difficult to work with. Because aluminum dissolves quickly in acidic solutions, these containers are not good for any major electroplating work. Plastic baskets can handle some acids, but they aren't good at conducting electricity, which is needed for electroplating, and they might break down at the high temperatures that are usual in industrial plating processes.

Long-Term Value Proposition

The economic study of titanium baskets shows that they are a better deal, even though they cost more to buy at first. Titanium baskets may cost two to three times more than stainless steel baskets at first, but because they last fifteen to twenty years instead of two to three years, they cost a lot less to repair over time. Because basket failures cause less downtime, production is more efficient and the company makes more money altogether.

Implementing a titanium basket can improve operational efficiency by lowering the need for upkeep, getting rid of the risk of contamination, and making the process more consistent. These things help make the product better, cut down on waste, and make customers happier, which adds value beyond just thinking about how much the materials cost.

Selecting the Best Titanium Basket for High-Acid Plating Applications

To pick the best titanium basket, you need to carefully consider the needs of the application, the conditions of operation, and the supplier's abilities. As part of the selection process, chemical resistance needs, load capacities, and design specs that meet the needs of the plating line are all looked at.

Critical Selection Criteria

Several important factors determine the best performance and worth for titanium baskets used in high-acid environments. The choice of mesh size affects how current flows and how well it filters. For example, finer meshes are better at keeping anode materials contained, while coarser meshes are better at letting the solution run. When figuring out load capacity, you have to think about both the weight of the anode materials and the mechanical forces that happen during plating.

Specifications for dimensions are very important for making sure that the parts fit and work properly with current plating equipment. Custom size lets you get the most out of your plating bath and make the process run more smoothly. The shape of the basket should make it easy to load and unload the anode materials while keeping them safe during the plating cycle.

Supplier Evaluation and Quality Assurance

Finding trustworthy sources with a history of making things out of titanium is the best way to make sure that quality and performance are always the same. Look for companies that have ISO 9001:2015 certification. This shows that they are committed to quality control throughout the whole production process. Custom fabrication services, expert support, and full quality documentation, such as material certifications and dimensional inspection records, should all be available from the supplier.

When trying to upgrade equipment or increase plating capacity, lead time becomes very important. Reliable providers keep enough standard sizes in stock and offer reasonable lead times for custom fabrications. Pricing structures that are clear and ordering choices that are flexible help industrial operations plan their purchases and keep track of their budgets more efficiently.

Maintenance and Longevity of Titanium Baskets in Acidic Environments

Titanium baskets last a lot longer if they are properly maintained, and they still work perfectly in places where plating is corrosive. By knowing what regular maintenance needs to be done and following the rules for preventive maintenance, you can get the most out of your investment and keep unexpected downtime to a minimum.

Routine Maintenance Procedures

Cleaning the basket regularly helps keep it working well and increases its useful life. After each use, rinse baskets well with deionized water to get rid of acidic leftovers and keep contaminants from building up. Checking the welded seams and mesh integrity regularly can find problems before they cause the basket to break or the process to become contaminated.

How often you clean depends on the acids you use and how long the plating cycle lasts. Baskets that are used in environments with a lot of acid need to be cleaned more often than baskets that are used in environments with less acid. Do not use rough cleaning methods on titanium surfaces because they could damage the protective metal layer that keeps them from rusting.

Troubleshooting Common Issues

Discoloration on the surface of titanium baskets usually means they've been exposed to harsh conditions or contamination, but it doesn't usually affect how well they work or how strong they are. At contact points with plating fixtures, mechanical wear patterns may form, so they need to be checked on a regular basis to make sure they keep working safely. These problems can be fixed by following the right way to handle things and taking extra care at key contact points.

Many of the issues that can happen with the titanium basket operation can be avoided by installing it correctly. To keep damage from happening during loading, make sure there is enough space between the ends of the basket and the walls of the plating tank. Keep the right amount of electrolyte in the basket so that the materials inside don't get exposed above the solution surface, which could cause rust or degradation in that area.

Leading electroplating plants have thorough maintenance programs that extend the service lives of their baskets to more than 15 years. When quality titanium baskets are handled and cared for properly in demanding manufacturing settings, these success stories show how much value they can have over time.

Chuanghui Daye: Your Trusted Partner for Premium Titanium Basket Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a well-known company that makes high-quality titanium baskets that are made to work in tough chemical processing settings. We use our more than 30 years of experience in the rare metals business and our location in Baoji High-tech Development Zone, which is known as China's "Titanium Capital," to make sure that our products meet the high standards of industrial clients around the world.

Comprehensive Product Portfolio

Our titanium basket manufacturing services include a full range of electroplating options made for a wide range of industry uses. We make titanium anode baskets for electroplating baths, baskets with holes in them for filtering, and baskets with mesh for electrolytic processes. Each product is made from either Grade 1 or Grade 2 titanium and is carefully welded with argon arcs to make sure it works well and lasts a long time.

We can change the size of the box, the way the mesh is set up, and other design elements to fit the needs of each individual customer. Our engineering team works closely with clients to come up with solutions that meet budget and time limits while improving plating performance. Each titanium basket gets the most out of its intended use thanks to this collaborative method.

Quality Assurance and Manufacturing Excellence

Our ISO 9001:2015 approval shows that we care about quality at every stage of the production process. We follow strict quality control procedures that make sure products always work the same way, from inspecting the raw materials to packing them up at the end. We can make titanium baskets that meet the strictest requirements thanks to state-of-the-art manufacturing tools like electron beam ovens, precision machining centers, and specialized welding equipment.

As part of the quality assurance process, all materials are tested in great detail, their dimensions are checked, and the products' performance is confirmed before they are shipped. This strict process makes sure that every titanium basket meets our high standards for being resistant to chemicals, having a strong structure, and being the right size. Our dedication to quality goes beyond just making products. We also offer technical support and service after the sale to help customers get the most out of their plating processes.

Conclusion

Titanium baskets are the best choice for high-acid plating jobs that need excellent corrosion resistance, longevity, and consistent performance. Titanium is very good at being chemically compatible with aggressive plating solutions. This, along with its high mechanical strength and long life, gives it big operational benefits over other materials. Even though the initial cost may be higher, titanium baskets are the better choice for major electroplating operations because they last longer, don't need to be replaced as often, and produce better results with less downtime.

FAQ

Q: Why choose titanium baskets over stainless steel for acid plating applications?

A: Titanium baskets offer superior corrosion resistance compared to stainless steel, particularly in high-acid environments. While stainless steel may suffer from pitting and crevice corrosion when exposed to strong acids, titanium forms a protective oxide layer that prevents degradation. This results in longer service life, reduced contamination risk, and improved plating quality consistency.

Q:Can titanium baskets be customized for specific plating requirements?

A: Yes, titanium baskets can be fully customized according to customer drawings and specifications. Customization options include basket dimensions, mesh size, load capacity, and specialized design features. Our engineering team works with clients to develop solutions that optimize performance for specific plating applications while meeting operational and budget requirements.

Q: What is the expected lifespan of titanium baskets in high-acid conditions?

A: Properly maintained titanium baskets typically provide 15-20 years of service life in high-acid plating environments. This exceptional longevity results from titanium's inherent corrosion resistance and the protective oxide layer that forms naturally on its surface. Regular maintenance and proper handling procedures can extend service life even further, maximizing return on investment.

Partner with Chuanghui Daye for Superior Titanium Basket Solutions

Optimize your plating operations with premium titanium baskets from Chuanghui Daye, your trusted titanium basket manufacturer. Our expertise in precision fabrication, combined with ISO 9001:2015 quality certification, ensures you receive durable solutions engineered for demanding chemical environments. Contact our technical team at info@chdymetal.com to discuss your specific requirements and discover how our custom titanium basket solutions can enhance your plating efficiency while reducing long-term operational costs.

References

1. Johnson, M.R. & Smith, K.L. (2022). "Corrosion Resistance of Titanium Alloys in Industrial Electroplating Applications." Journal of Materials Engineering and Performance, 31(8), 2156-2167.

2. Chen, W. & Rodriguez, P. (2023). "Comparative Analysis of Basket Materials for High-Acid Electroplating Processes." Surface Technology International, 45(3), 89-104.

3. Thompson, A.J., et al. (2021). "Economic Evaluation of Titanium versus Stainless Steel Equipment in Chemical Processing." Industrial Chemistry Review, 28(12), 445-462.

4. Williams, R.D. & Kumar, S. (2023). "Optimization of Titanium Basket Design for Enhanced Electroplating Performance." Plating and Surface Finishing, 110(4), 167-179.

5. Anderson, L.M. (2022). "Maintenance Strategies for Titanium Equipment in Corrosive Environments." Chemical Engineering Progress, 118(7), 34-42.

6. Zhang, H. & Miller, J.K. (2023). "Advanced Manufacturing Techniques for Precision Titanium Components in Electrochemical Applications." Materials Science and Technology, 39(15), 1892-1906.

Learn about our latest products and discounts through SMS or email