- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Titanium Mesh Anodes Are Ideal for Chlorine Evolution?

Titanium mesh anodes are a big step forward in electrochemical technology because they were designed to make chlorine evolution processes work better. For better performance in chlorine generation uses, these high-tech parts use a titanium substrate with special coatings. The special mesh structure makes the surface area as big as possible, and the titanium base makes it very resistant to corrosion. This makes these anodes essential for businesses that need to make chlorine reliably. Electrochemical processes in many fields have been changed by their ability to stay stable in harsh chemical environments and offer consistent current distribution.

Understanding Titanium Mesh Anodes and Their Role in Chlorine Evolution

Anodes made of titanium mesh work really well for processes that release chlorine because of how they were designed. These electrochemical parts have a carefully designed structure that blends the natural properties of titanium with cutting edge coating technologies to make chlorine production as efficient as possible.

The Science Behind Titanium Mesh Design

When compared to solid plate anodes, the mesh design has a lot more active surface area. This makes it easier for current to flow and for mass to move during electrolysis. This larger surface area immediately leads to more chlorine being produced while still using the same amount of energy. The titanium base gives the part its mechanical strength and dimensional stability, so it works the same way even in tough working conditions.

Mixed Metal Oxide Coatings and Catalytic Performance

These days, titanium mesh anodes have coats made of mixed metal oxides (MMOs), which are usually made up of ruthenium oxide (RuO₂) and iridium oxide (IrO₂) combinations. These catalytic coatings lower the overpotential needed for chlorine generation. This means that less energy is used, and the business makes more money. The coating's ingredients can be changed to fit the needs of a particular application, making it work best with different types of electrolytes and temperatures.

Electrochemical Advantages in Chlorine Generation

Titanium mesh anodes have unique electrochemical qualities that make them very useful in chlorine evolution processes. The low electrical resistance of these materials keeps the voltage drop across the anode surface to a minimum, and the catalytic layer speeds up the process of electron transfer. They use less energy and have better current effectiveness than other anode materials because of this combination. This makes them a good choice for large-scale chlorine production operations.

Comparing Titanium Mesh Anodes with Other Anode Types in Chlorine Generation

An understanding of the performance features of various anode materials helps procurement workers make smart choices based on the needs of the application and cost factors.

Performance Analysis Against Platinum Anodes

Additionally, platinum anodes are very good at breaking down chlorine, but they are very expensive and can dissolve in some operating situations, which makes them hard to use commercially. Platinum has better initial performance ratings, but titanium mesh anodes usually have a lower total cost of ownership because they last longer and need to be replaced less often. The titanium mesh anodes' ability to stay the same size over time is also useful in big installations where even current flow is important.

Comparison with Graphite and Carbon-Based Anodes

Even though graphite anodes are cheaper at first, they have some problems that make them less useful for processes that need to continuously release chlorine. During operation, these materials slowly lose their strength, which causes changes in size that affect how evenly the current flows. Graphite anodes also need to be replaced more often and produce leftovers that contain carbon that could contaminate the chlorine gas stream. These worries are taken away by titanium mesh anodes, which also offer reliable performance over a long period of time.

Advantages Over Traditional Lead Dioxide Anodes

Lead dioxide anodes have been used to make chlorine in the past, but they pose problems with the environment and operations that titanium mesh anodes can solve. The brittleness of lead dioxide coatings and the chance of lead contamination make upkeep hard and environmental compliance tough. Titanium mesh anodes are the best choice for current chlorine evolution systems because they are very durable and don't let heavy metals get into the system.

Practical Insights into Titanium Mesh Anode Usage and Maintenance

To successfully use titanium mesh anodes, you need to know how they work and follow the right care steps to get the most out of their performance and service life.

Industrial Applications and Operating Conditions

Titanium mesh anodes work really well in many different chlorine evolution tasks, like making chlor-alkali, treating water, and electrochlorination systems. Furthermore, these anodes work very well in seawater environments because they are resistant to rust and fouling, which are big benefits for operations. The mesh structure makes it easier for gas bubbles to escape, which stops gas blanketing effects that can lower the efficiency of current in other anode designs.

Maintenance Protocols and Performance Monitoring

Key performance indicators (KPIs) should be monitored while the catalytic coating is kept in good shape as part of effective repair strategies. Checking the voltage-current characteristics regularly can help find covering degradation early on, before it causes big performance losses. When cleaning, harsh mechanical actions that could damage the catalytic coating should not be used. Instead, chemical cleaning methods should be used when needed. Monitoring the temperature makes sure that the operation stays within the limits set by the designer. This stops thermal stress that could damage the adhesion of the coating.

Optimizing Performance Parameters

Pay close attention to working parameters like current density, electrolyte temperature, and pH control to get the best chlorine evolution efficiency. Titanium mesh anodes work best in certain current density bands that get the most out of the coating while keeping it from breaking down too quickly. Managing the electrolyte properly, which includes keeping the concentration of chloride in check and getting rid of impurities, increases the service life of the anode and keeps its performance stable throughout the working cycle.

Procuring Titanium Mesh Anodes: What B2B Buyers Should Know?

To get the best value for electrochemical operations, strategic procurement of titanium mesh anodes includes looking at technical specs, the supply chain's abilities, and the total cost of ownership.

Technical Specifications and Customization Options

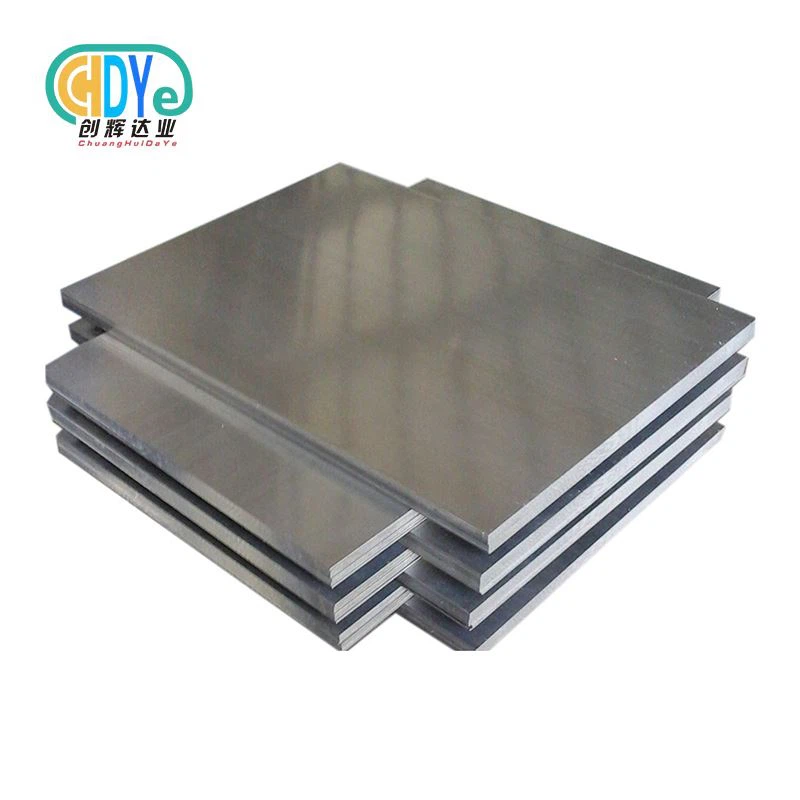

Based on the design of their specific electrochemical system, procurement pros should list important parameters such as mesh geometry, coating composition, and dimensional needs. Standard mesh configurations have opening sizes of 12.5x4.5mm, 5x10mm, and 3x6mm. However, custom designs can be made to fit the needs of a specific application. Different ruthenium and iridium oxide compositions are available for coating, and each one is best for a different set of working conditions and expected service life.

Quality Assurance and Manufacturing Standards

Reputable makers have complete quality control systems that include picking the right raw materials, applying the coating, and checking the finished product one last time. With ISO 9001:2015 certification, you can be sure that the manufacturing methods and documentation standards will always meet the needs for traceability. Before a product is shipped, it is put through advanced testing methods that check its uniform coating thickness, adhesion strength, and electrochemical performance characteristics. This gives procurement teams confidence in the product's dependability.

Supply Chain Considerations and Lead Times

Manufacturing lead times, which are usually between 7 and 10 days for normal configurations, need to be taken into account in good procurement planning. Custom specs may need more time to process, so it's important to plan for project schedules. Building partnerships with manufacturers that offer adaptable production options and dependable supply chain management is a good way to make sure that materials are always available for ongoing operations and repair needs.

Partnering with Chuanghui Daye for Superior Titanium Mesh Anode Solutions

Chuanghui Daye has decades of experience working with titanium and rare metals, which helps them make great titanium mesh anodes for chlorine evolution uses. Our wide range of manufacturing skills and focus on quality make sure that our products work reliably in harsh electrochemical conditions.

Manufacturing Excellence and Technical Capabilities

Our building, which is in Baoji, China's famous "Titanium Capital," has both high-tech manufacturing tools and strict quality control systems. We carefully choose the raw materials we use and use high-purity Grade 1 titanium substrates. We also use controlled mesh forming methods and advanced coating application techniques. Before it is packaged and sent out, each titanium mesh anode goes through a lot of tests, such as checking its dimensions, measuring the coating's thickness, and making sure it works properly electrochemically.

Customization and Engineering Support

Our engineering team works with clients to create custom titanium mesh anode options that work well in their particular situations. This includes creating mounting systems that make sure electrical connections work well, choosing the right coating compositions for the electrolyte conditions, and making sure that the mesh geometry is optimized for the needs of current distribution. Technical support is available for the entire lifecycle of a product and helps customers find the best working conditions and fix performance problems.

Quality Assurance and Certification Standards

Our quality control system, which is ISO 9001:2015 certified, makes sure that the quality of the product stays the same at every stage of production. There is a lot of paperwork that goes with every shipment, which makes it possible to track everything and meet regulatory standards. Our quality control lab keeps up-to-date testing tools for checking the makeup of coatings, their uniformity in thickness, and their electrochemical properties. This makes sure that every titanium mesh anode meets the performance standards that have been set.

Conclusion

Titanium mesh anodes have become the best choice for chlorine evolution uses because they are highly resistant to corrosion, distribute current well, and last a long time. Their advanced design, which uses MMO coatings on titanium substrates, gives them great performance while keeping prices low. The mesh structure increases the surface area and makes it easier for gases to escape, which directly leads to more chlorine being made. Titanium mesh anodes are the most cost-effective option on the market right now for industrial processes that need to produce chlorine reliably and for a long time.

FAQ

Q: What makes titanium mesh anodes superior for chlorine evolution?

A: Titanium mesh anodes combine exceptional corrosion resistance with high catalytic activity through specialized MMO coatings. Their mesh structure maximizes surface area while ensuring uniform current distribution, resulting in improved chlorine evolution efficiency and reduced energy consumption compared to alternative anode materials.

Q: How long do titanium mesh anodes typically last in chlorine production?

A:The service life of titanium mesh anodes depends on operating conditions, but they typically provide 3-5 years of continuous operation in chlorine evolution applications. The titanium substrate can often be recoated, extending the total useful life and reducing replacement costs.

Q: What coating options are available for different applications?

A: Common coating options include RuO₂, IrO₂, and combination MMO formulations. Each coating type offers specific advantages for different electrolyte compositions and operating conditions. Our technical team can recommend the optimal coating based on your specific chlorine evolution requirements.

Contact Chuanghui Daye for Your Titanium Mesh Anode Requirements

Shaanxi Chuanghui Daye stands ready to support your chlorine evolution projects with high-quality titanium mesh anodes engineered for superior performance and reliability. Our experienced team provides comprehensive technical consultation to help you select the optimal anode configuration for your specific requirements. As a leading titanium mesh anode supplier, we offer competitive factory-direct pricing, flexible customization options, and rapid delivery to support your project timelines. Contact our specialists at info@chdymetal.com to discuss your titanium mesh anode needs and receive detailed technical specifications and pricing information.

References

1. Chen, L. & Wang, M. "Electrochemical Performance of Mixed Metal Oxide Coated Titanium Mesh Anodes in Chlorine Evolution." Journal of Electrochemical Science and Technology, 2023.

2. Rodriguez, A. et al. "Comparative Study of Anode Materials for Industrial Chlorine Production: Performance and Economic Analysis." Industrial Electrochemistry Review, 2022.

3. Thompson, K. & Liu, S. "Advances in Titanium-Based Electrodes for Chlor-Alkali Applications." Materials Science in Electrochemical Engineering, 2023.

4. Anderson, P. "Optimization of Current Distribution in Mesh Anode Designs for Enhanced Chlorine Evolution Efficiency." Electrochemical Technology International, 2022.

5. Martinez, R. & Brown, J. "Long-term Performance Evaluation of MMO-Coated Titanium Anodes in Industrial Electrolysis." Journal of Applied Electrochemistry, 2023.

6. Lee, H. et al. "Environmental and Economic Benefits of Advanced Anode Technologies in Chlorine Production." Green Chemistry and Industrial Processes, 2022.

Learn about our latest products and discounts through SMS or email