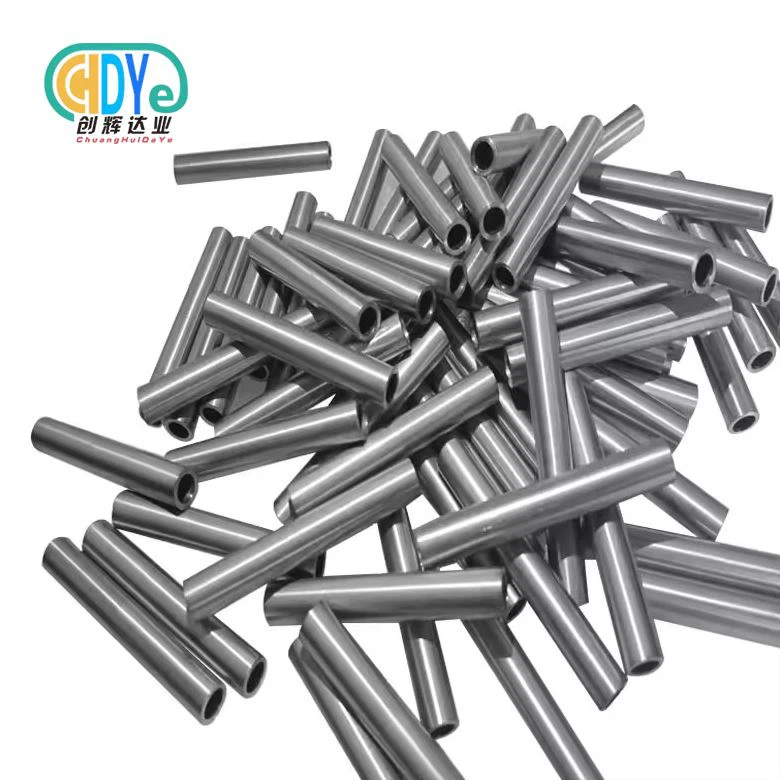

Tantalum seamless tube stands as the premier choice for semiconductor manufacturing due to its exceptional purity levels, superior corrosion resistance, and remarkable thermal stability. These tubes excel in chemical vapor deposition chambers, ion implantation systems, and high-temperature processing equipment where contamination control remains critical. The seamless construction eliminates potential failure points while maintaining dimensional accuracy required for precision semiconductor applications. With operating temperatures reaching 3000°C and resistance to aggressive chemicals, tantalum seamless tube delivers unmatched reliability in demanding manufacturing environments.

Why Tantalum Seamless Tube Dominates Semiconductor Applications?

The semiconductor industry requests materials that withstand extraordinary conditions whereas keeping up outright immaculateness. Conventional materials regularly come up short when uncovered to destructive handle gasses or high-temperature operations common in chip creation. Tantalum tubing addresses these challenges through its special metallurgical properties and consistent fabricating process.

Modern semiconductor fabs handle wafers worth millions of dollars day by day. Gear downtime costs producers thousands per miniature, making unwavering quality vital. Tantalum's remarkable chemical dormancy avoids defilement that seem crush whole generation runs. The consistent plan disposes of weld joints that might present pollutions or make stretch concentration points.

Industry insights appear that tantalum components can work persistently for over 10,000 hours without corruption in semiconductor situations. This life span deciphers to diminished support costs and progressed generation uptime, making tantalum pipe frameworks exceedingly cost-effective in spite of higher starting investment.

Essential Selection Criteria for Semiconductor-Grade Tantalum Tubes

Choosing the right tantalum seamless tube requires cautious assessment of numerous specialized parameters. Virtue levels must surpass 99.95% to avoid defilement of touchy semiconductor forms. Surface wrap up details ordinarily request Ra values underneath 0.4 micrometers to minimize molecule generation.

Wall thickness consistency influences warm exchange characteristics and mechanical steadiness. Varieties surpassing ±5% can make hot spots or push concentrations that compromise execution. Dimensional resistances must adjust with gear determinations, frequently requiring exactness inside ±0.05mm for basic applications.

Mechanical properties ended up pivotal for high-pressure applications. Abdicate quality, extreme pliable quality, and stretching values must coordinate operational necessities. Warm treatment history influences grain structure and execution, making provider certification essential.

Chemical composition confirmation guarantees compatibility with handle gasses. Indeed follow debasements can influence semiconductor gadget characteristics. Third-party examination reports give free affirmation of fabric specifications.

Purity Standards and Contamination Control

Semiconductor applications request extraordinary virtue levels that surpass standard mechanical grades. Follow components like press, nickel, and chromium must stay underneath 10 parts per million to anticipate gadget defilement. Outgassing characteristics gotten to be basic in vacuum applications where unstable compounds can store on wafer surfaces.

Dimensional Accuracy Requirements

Manufacturing resiliences in semiconductor hardware require exact dimensional control. Tube concentricity, straightness, and divider thickness consistency specifically affect hardware execution. Progressed fabricating strategies guarantee reliable measurements all through the tube length.

Surface Quality Specifications

Interior surface wrap up influences gas stream characteristics and molecule era. Electropolished surfaces give ideal smoothness whereas expelling surface contaminants. Specialized cleaning methods dispense with leftover fabricating greases and taking care of contamination.

Top Tantalum Seamless Tube Applications in Semiconductor Manufacturing

Chemical Vapor Deposition (CVD) Chamber Components

CVD forms require materials that stand up to forceful antecedent gasses whereas keeping up dimensional solidness at lifted temperatures. Tantalum consistent tube exceeds expectations in these requesting situations through its extraordinary chemical resistance and warm properties.

- Gas Conveyance Frameworks: Tantalum tubing conveys forerunner gasses without defilement or debasement. The consistent development disposes of spill ways that might compromise prepare uniformity.

- Heating Components: Tall electrical resistance and temperature capability make tantalum perfect for warming applications. Uniform warm conveyance guarantees reliable testimony rates over wafer surfaces.

- Exhaust Manifolds: Destructive byproducts created amid CVD forms assault customary materials. Tantalum tube congregations keep up judgment whereas dealing with forceful debilitate streams.

- Temperature Checking: Thermocouple security sheaths manufactured from tantalum give exact temperature estimation without sensor contamination.

Recent progresses in CVD innovation put indeed more noteworthy requests on chamber materials. Nuclear layer statement requires exact control over film thickness and composition. Tantalum's chemical inactivity avoids undesirable responses that might change statement characteristics. The consistent tube plan disposes of cleft where forerunner gasses might break down or make molecule contamination.

Operating temperatures in progressed CVD chambers regularly surpass 1000°C whereas keeping up vacuum conditions underneath 10^-6 Torr. tantalum seamless tube keeps up basic astuteness all through these extraordinary conditions without outgassing or dimensional changes. This steadiness guarantees steady prepare comes about over different generation runs.

Ion Implantation System Components

Ion implantation forms besiege wafer surfaces with high-energy particles to adjust electrical properties. Hardware components must withstand radiation harm whereas keeping up ultra-high vacuum conditions. Tantalum tubing gives extraordinary strength in these challenging environments.

- Beam Line Components: Particle pillar transport requires materials with moo sputtering rates and negligible outgassing. Tantalum's tall thickness and chemical solidness make it perfect for bar line construction.

- Target Gatherings: Source materials must stand up to particle assault whereas keeping up dimensional exactness. Consistent tantalum tubes give dependable control for unstable source compounds.

- Vacuum Chambers: Ultra-high vacuum prerequisites request materials with amazingly moo outgassing rates. Tantalum's surface characteristics back vacuum levels underneath 10^-10 Torr.

- Cooling Frameworks: Warm expulsion frameworks must work dependably in radiation situations. Tantalum tube warm exchangers stand up to radiation harm whereas giving productive warm management.

Modern particle implanters work at pillar energies surpassing 1 MeV with current densities that produce noteworthy warm loads. Routine materials endure radiation-induced embrittlement that leads to untimely disappointment. Tantalum's body-centered cubic gem structure gives inborn radiation resistance that keeps up mechanical properties all through amplified service.

High-Temperature Processing Equipment

Advanced semiconductor fabricating utilizes high-temperature forms for toughening, oxidation, and dissemination. Gear must work dependably at temperatures drawing closer 1200°C whereas keeping up exact barometrical control. Erosion safe tube gatherings created from tantalum give unmatched execution in these applications.

- Furnace Tubes: Coordinate wafer contact requires materials that won't sully or outgas amid preparing. Tantalum consistent tubes keep up virtue all through warm cycles.

- Gas Infusion Frameworks: Prepare gas conveyance requests materials that stand up to erosion from responsive climates. Tantalum tubing handles oxygen, hydrogen, and halogen compounds without degradation.

- Exhaust Frameworks: High-temperature debilitate gasses contain destructive compounds that assault ordinary materials. Tantalum tube gatherings give solid control and transport.

- Support Structures: Mechanical components must keep up quality at lifted temperatures. Custom tantalum tube manufactures give basic bolster without warm extension issues.

Thermal cycling makes push concentrations that can cause splitting in welded congregations. Consistent metal tube development kills these potential disappointment focuses whereas keeping up dimensional soundness all through rehashed warming and cooling cycles. The characteristic ductility of tantalum obliges warm extension without push cracking.

Global Market Characteristics and Regional Preferences

The around the world semiconductor industry shows unmistakable territorial inclinations impacted by neighborhood fabricating capabilities and supply chain contemplations. Asian markets, especially Taiwan and South Korea, emphasize high-volume generation proficiency and fetched optimization. These locales lean toward standardized tantalum tube determinations that bolster large-scale fabricating operations.

European producers center on progressed handle improvement and natural compliance. Stricter controls drive request for materials with recorded natural affect appraisals. Tantalum tube providers must give comprehensive fabric certifications and lifecycle investigation information to meet European requirements.

North American semiconductor companies prioritize advancement and cutting-edge innovation improvement. These clients frequently require custom tantalum tube plans with special details for exploratory forms. Quick prototyping capabilities and designing back gotten to be basic differentiators in this market.

Emerging markets in Southeast Asia and India emphasize innovation exchange and nearby sourcing inclinations. Government motivating forces regularly favor providers with in-country fabricating capabilities or innovation sharing understandings. Understanding these territorial flow makes a difference optimize advertise section strategies.

Purchasing Recommendations and Key Considerations

Successful tantalum tube procurement requires careful evaluation of supplier capabilities beyond basic material specifications. Manufacturing experience in semiconductor applications provides valuable insights that can prevent costly mistakes. Look for suppliers with documented experience in similar applications and established quality management systems.

Long-term supply security becomes critical given tantalum's limited global production. Establish relationships with multiple tantalum seamless tube to mitigate supply chain risks. Consider suppliers with direct access to raw materials or strategic inventory arrangements.

Technical support capabilities differentiate professional suppliers from commodity vendors. Complex semiconductor applications often require engineering assistance for optimal tube design and installation. Evaluate suppliers based on their ability to provide application-specific guidance and troubleshooting support.

Quality documentation must include material certifications, dimensional inspection reports, and surface analysis data. Request samples for independent verification of critical specifications. Establish incoming inspection procedures to verify supplier claims and maintain quality standards.

Cost considerations extend beyond initial purchase price to include total ownership costs. Factor in expected service life, maintenance requirements, and replacement costs when evaluating alternatives. High purity tantalum tubes often provide better long-term value despite higher initial investment.

Industry Trends and Summary

Semiconductor manufacturing continues evolving toward smaller geometries and more complex device structures. These advances drive increased demand for ultra-pure materials with exceptional performance characteristics. Tantalum tube applications expand as manufacturers recognize the long-term benefits of superior corrosion resistance and thermal stability. Advanced manufacturing techniques enable production of seamless tubes with tighter tolerances and improved surface finishes. Market growth accelerates as semiconductor production capacity expands globally, particularly in emerging markets seeking advanced manufacturing capabilities.

Conclusion

Tantalum seamless tube represents the optimal material choice for demanding semiconductor manufacturing applications where purity, reliability, and performance cannot be compromised. The combination of exceptional chemical resistance, high-temperature stability, and seamless construction provides unmatched value in critical processing equipment. Understanding application requirements and supplier capabilities ensures successful implementation of tantalum tubing solutions. Investment in high-quality tantalum components delivers long-term benefits through reduced maintenance costs, improved uptime, and consistent process results. The growing semiconductor industry continues driving innovation in tantalum tube technology, creating new opportunities for manufacturers who prioritize quality and performance.

FAQ

Q: What makes tantalum seamless tube superior to welded alternatives in semiconductor applications?

A: Seamless construction eliminates weld joints that can introduce contamination, create stress concentrations, or develop leak paths. The uniform grain structure throughout seamless tubes provides consistent mechanical properties and superior corrosion resistance compared to welded assemblies where heat-affected zones can compromise performance.

Q: How do I specify the correct wall thickness for my tantalum tubing application?

A: Wall thickness selection depends on operating pressure, temperature, and mechanical loads. Industry standards recommend minimum wall thickness of 0.5mm for vacuum applications and thicker walls for pressurized systems. Consult with experienced tantalum tube manufacturers who can perform stress analysis calculations for your specific operating conditions.

Q: What surface treatments are available for semiconductor-grade tantalum tubes?

A: Common surface treatments include electropolishing for ultra-smooth finishes, chemical etching for improved adhesion, and specialized cleaning procedures for contamination removal. Electropolished surfaces typically achieve Ra values below 0.2 micrometers while removing surface impurities that could affect semiconductor processes.

Partner with Chuanghui Daye for Premium Tantalum Seamless Tube Solutions

Shaanxi Chuanghui Daye combines over 30 years of rare metal expertise with advanced manufacturing capabilities to deliver exceptional tantalum seamless tube products. Our ISO 9001:2015 certified facility in China's "Titanium Capital" ensures consistent quality while providing competitive factory-direct pricing. We specialize in custom dimensions and rapid prototyping for semiconductor applications, with global shipping capabilities and comprehensive technical support. As a trusted tantalum seamless tube supplier, we maintain extensive inventory and flexible production schedules to meet urgent project requirements. Contact us at info@chdymetal.com to discuss your specific requirements and receive expert application guidance.