When selecting materials for critical aerospace applications, Grade 2 titanium round bar stands as the premier choice for engineers worldwide. This commercially pure titanium offers exceptional corrosion resistance, lightweight properties, and reliable performance across extreme temperature ranges. After extensive research and industry analysis, I've identified the top titanium round bar grade 2 options that consistently deliver superior results for aerospace manufacturers, defense contractors, and precision component fabricators.

Essential Selection Criteria for Aerospace-Grade Titanium Bars

Choosing the right titanium round bar supplier requires careful evaluation of multiple factors that directly impact performance and reliability. Through decades of industry experience, I've developed a comprehensive framework for assessing material quality and supplier capabilities.

Material Purity and Chemical Composition

Grade 2 titanium round bar must meet rigid ASTM B348 details. The fabric ought to contain least 99.2% titanium with controlled levels of oxygen, nitrogen, and press. These follow components altogether impact mechanical properties and erosion resistance. Premium providers give point by point process test certificates reporting correct chemical investigation for each batch.

Manufacturing Standards and Certifications

Aerospace applications request materials fabricated beneath ISO 9001:2015 quality administration frameworks. Providers must illustrate compliance with AS9100 aviation quality benchmarks when serving flying clients. Appropriate warm treatment, controlled cooling rates, and reported traceability guarantee steady fabric properties all through each generation run.

Processing Capabilities and Customization

Modern aviation ventures frequently require custom measurements and specialized handling. The best providers offer comprehensive machining administrations, counting exactness crushing, cutting, and shaping operations. This capability diminishes lead times and guarantees dimensional precision for basic applications.

Top Grade 2 Titanium Round Bar Options for Aerospace Applications

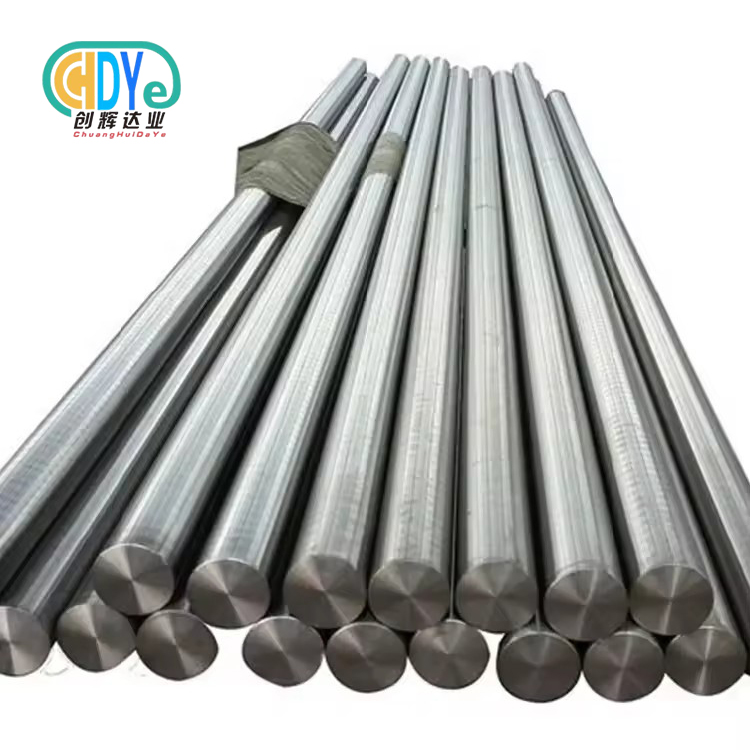

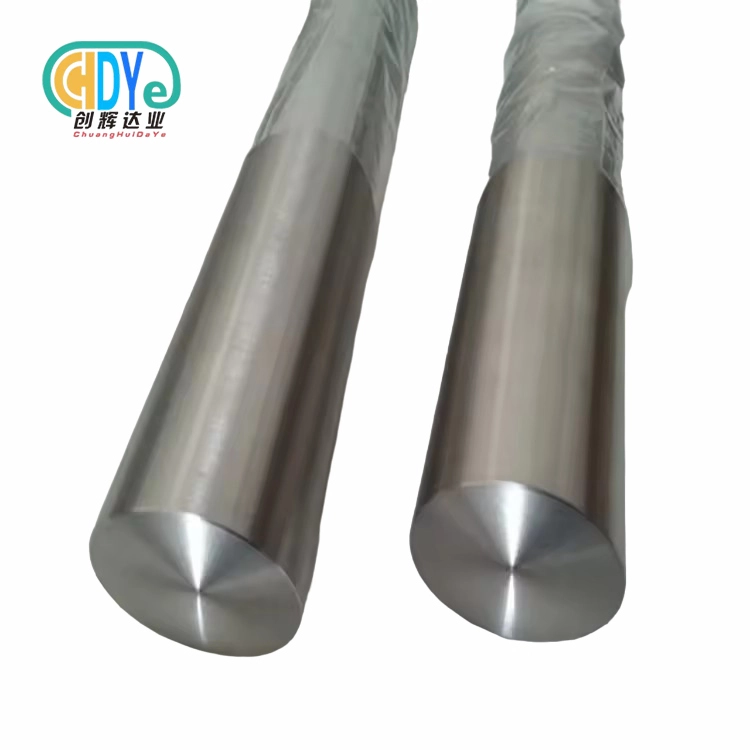

Premium Forged Titanium Round Bars

Grade 2 titanium round bar speak to the most noteworthy quality choice for basic aviation components. The manufacturing prepare refines grain structure, dispensing with potential powerless focuses and improving mechanical properties. These bars regularly accomplish pliable qualities surpassing 345 MPa with fabulous weariness resistance.

Manufacturing includes warming titanium ingots to 950-1050°C some time recently controlled distortion beneath water powered presses. This prepare adjusts grain boundaries and evacuates inside stresses that might compromise execution. Premium fashioned bars experience different warming and shaping cycles to accomplish ideal microstructure.

Key points of interest incorporate prevalent affect resistance, improved machinability, and steady fabric properties all through the cross-section. Aviation producers lean toward fashioned bars for landing adapt components, basic brackets, and high-stress latches where unwavering quality cannot be compromised.

Quality manufactured bars include fine, uniform grain structure unmistakable beneath metallographic examination. Surface wrap up ordinarily accomplishes Ra 1.6 or way better, decreasing machining time and progressing dimensional exactness. Ultrasonic testing affirms inside soundness, guaranteeing no covered up abandons that might cause untimely failure.

Leading providers keep up broad stock in standard aviation measurements, counting 12mm, 25mm, 50mm, and 100mm breadths. Custom sizes from 6mm to 350mm oblige specialized applications with conveyance times regularly extending from 2-4 weeks for non-standard dimensions.

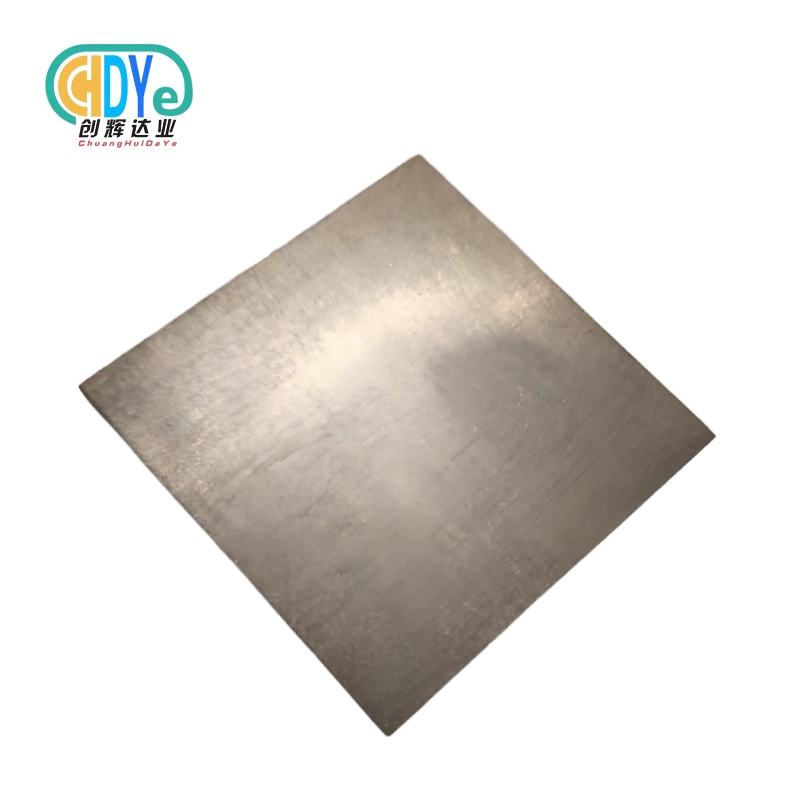

Hot-Rolled Titanium Round Stock

Hot-rolled titanium combination circular bar offers amazing esteem for applications where most extreme quality isn't basic. The rolling prepare produces reliable measurements with great surface quality appropriate for numerous aviation applications. Taken a toll preferences make this alternative alluring for bigger volume requirements.

Production includes warming titanium billets to rolling temperature some time recently passing through accuracy plants. Numerous rolling passes slowly diminish breadth whereas keeping up roundness and surface judgment. Controlled cooling avoids warm push that might influence fabric properties.

Hot-rolled bars excel in applications requiring excellent corrosion resistance with moderate strength requirements for Grade 2 titanium round bar. Insides auxiliary components, non-critical brackets, and auxiliary latches perform well with this fabric review. The fabricating prepare actually soothes inside stresses, progressing dimensional solidness amid machining.

Surface quality ordinarily meets commercial aviation measures with negligible planning required for welding or machining operations. Straightness resiliences of ±0.5mm per meter fulfill most application prerequisites whereas keeping up fetched adequacy for budget-conscious projects.

Availability in standard lengths up to 6 meters suits most fabricating prerequisites. Custom cutting administrations guarantee ideal fabric utilization whereas minimizing squander. Quality providers give fabric certification archiving compliance with appropriate aviation specifications.

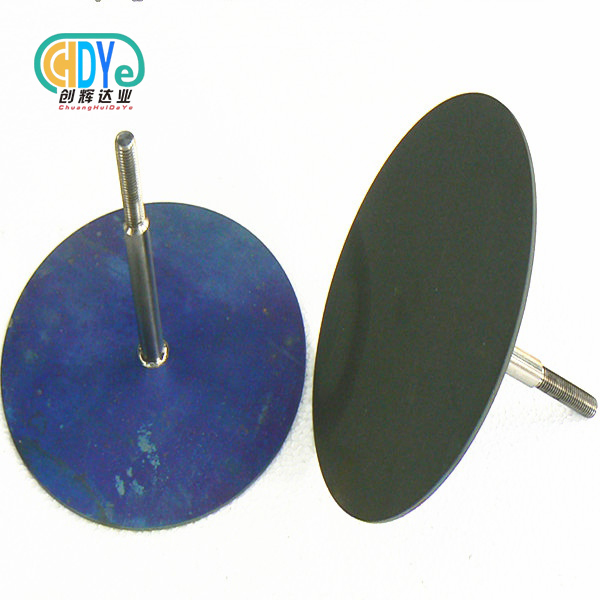

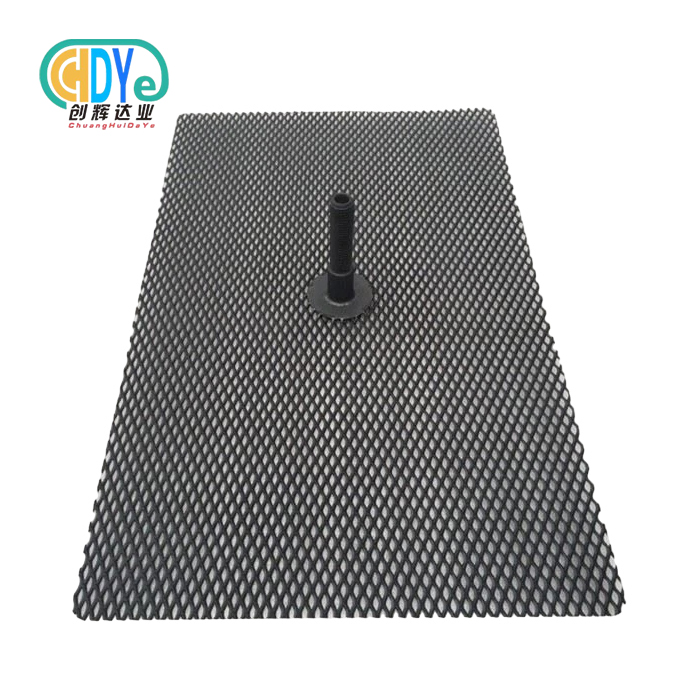

Precision Ground Titanium Rounds

Precision ground review 2 titanium metal rounds provide the most secure dimensional resiliences accessible in commercial titanium items. Centerless pounding operations accomplish distance across resistances of ±0.025mm with surface wraps up drawing closer 0.4 Ra. This exactness dispenses with auxiliary machining for numerous applications.

The pounding handle evacuates surface flaws whereas keeping up center fabric properties. Specialized coolant frameworks avoid warm harm amid pounding operations. Different passes with dynamically better abrasives accomplish mirror-like surface wraps up that improve erosion resistance.

Precision rounds demonstrate important for pressure driven components, exactness clasp, and instrumented applications where dimensional precision specifically impacts execution. The prevalent surface wrap up diminishes grinding in moving congregations whereas anticipating push concentration focuses that might start weariness failures.

Quality control amid pounding incorporates nonstop breadth observing and surface harshness confirmation. Measurable prepare control guarantees reliable comes about over whole generation runs. Last review with arrange measuring machines affirms dimensional compliance some time recently shipment.

These premium items command higher costs but convey critical esteem through decreased machining time and moved forward portion execution. Lead times ordinarily amplify 3-5 weeks due to the specialized preparing prerequisites and quality confirmation procedures.

Global Market Analysis for Aerospace Titanium Applications

The around the world aviation titanium advertise reflects territorial varieties in fabricating capabilities, administrative necessities, and taken a toll structures. Understanding these contrasts makes a difference obtainment groups make educated provider choice decisions.

North American aviation producers emphasize residential sourcing for defense applications, driving request for DFARS-compliant titanium items. European markets center on natural maintainability, favoring providers with reusing capabilities and diminished carbon impressions. Asian producers prioritize fetched effectiveness whereas keeping up quality standards.

Regulatory systems change altogether over districts. FAA necessities contrast from EASA benchmarks, possibly influencing fabric acknowledgment for worldwide ventures. Driving providers keep up certifications over different locales, disentangling worldwide supply chain management.

Transportation costs altogether affect add up to landed costs for titanium items. Vital provider determination considers shipping separations, traditions methods, and stock administration capabilities. Territorial dispersion centers offer assistance relieve coordinations challenges whereas guaranteeing quick reaction to pressing requirements.

Strategic Purchasing Recommendations and Key Considerations

Successful titanium procurement requires balancing multiple factors including quality, cost, delivery, and long-term supplier relationships. Smart buyers develop comprehensive evaluation criteria addressing both immediate needs and future requirements.

Supplier financial stability for Grade 2 titanium round bar deserves careful consideration given the long-term nature of aerospace programs. Companies with strong balance sheets can invest in quality improvements and capacity expansion. Technical support capabilities help resolve application challenges and optimize material selection.

Quality documentation requirements vary by application but generally include mill test certificates, dimensional inspection reports, and traceability records. Suppliers should maintain detailed batch records enabling rapid response to any quality concerns that might arise during manufacturing or service.

Pricing strategies should consider total cost of ownership rather than just initial material costs. Premium suppliers often deliver better value through reduced scrap rates, faster delivery, and superior technical support. Long-term agreements can provide price stability while ensuring supply security.

Industry Trends and Future Outlook

The aerospace titanium industry continues evolving driven by technological advances and changing market demands. Additive manufacturing creates opportunities for complex geometries previously impossible with traditional methods. Recycling initiatives address environmental concerns while reducing raw material costs.

Digital transformation enables better supply chain visibility and predictive quality management. Smart sensors monitor production parameters in real-time, preventing defects before they occur. These advances benefit customers through improved consistency and reduced lead times.

Conclusion

Selecting the right Grade 2 titanium round bar supplier significantly impacts project success in aerospace applications. Premium forged bars offer maximum performance for critical components, while hot-rolled options provide excellent value for less demanding applications. Precision ground rounds deliver unmatched dimensional accuracy for specialized requirements.

Successful procurement balances quality, cost, and delivery considerations while building strong supplier relationships. The global nature of aerospace manufacturing requires suppliers capable of meeting diverse regulatory requirements and providing consistent support across international operations.

As the aerospace industry continues advancing, titanium will remain essential for next-generation aircraft and spacecraft. Partnering with experienced suppliers ensures access to quality materials and technical expertise needed for future innovations.

FAQ

Q: What makes Grade 2 titanium suitable for aerospace applications?

A: Grade 2 titanium offers an optimal combination of strength, corrosion resistance, and lightweight properties essential for aerospace applications. Its excellent strength-to-weight ratio reduces aircraft weight while maintaining structural integrity. The material performs reliably across temperature ranges from -200°C to +300°C, making it ideal for various aircraft systems and components.

Q: How do I verify the quality of titanium round bars for critical applications?

A: Quality verification requires reviewing mill test certificates, chemical composition analysis, and mechanical property test results. Reputable suppliers provide detailed documentation including ultrasonic testing reports and dimensional inspection certificates. ISO 9001:2015 certification ensures consistent quality management throughout the manufacturing process.

Q: What dimensional tolerances can I expect for precision titanium round bars?

A: Standard hot-rolled titanium rounds typically achieve diameter tolerances of ±0.5mm, while precision ground bars can maintain ±0.025mm tolerances. Straightness specifications usually range from ±0.5mm to ±2.0mm per meter depending on diameter and processing method. Custom tolerances are available for specialized applications with appropriate lead time adjustments.

Partner with Chuanghui Daye for Premium Aerospace Titanium Solutions

Shaanxi Chuanghui Daye stands as your trusted Grade 2 titanium round bar manufacturer, combining three decades of rare metal expertise with state-of-the-art processing capabilities. Our ISO 9001:2015 certified facility in China's "Titanium Capital" delivers consistent quality and competitive pricing for global aerospace applications. We maintain extensive inventory in standard dimensions while offering rapid customization services for specialized requirements. Our comprehensive quality control ensures every shipment meets stringent aerospace specifications with full traceability documentation. Experience the difference that professional expertise and reliable supply chain management make for your critical projects. Contact us at info@chdymetal.com to discuss your titanium requirements today.