- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buy Medical Titanium Plate for Reliable Surgical Implants

Procurement professionals require biocompatible, mechanically reliable medical titanium plates for surgical implants. Titanium plates are essential in orthopedic, dental, and reconstructive operations for patient safety and implant success. Medical device manufacturers worldwide favor these precision-engineered titanium devices for their corrosion resistance, lightweight structure, and flawless tissue integration.

Understanding Medical Titanium Plates: Properties and Applications

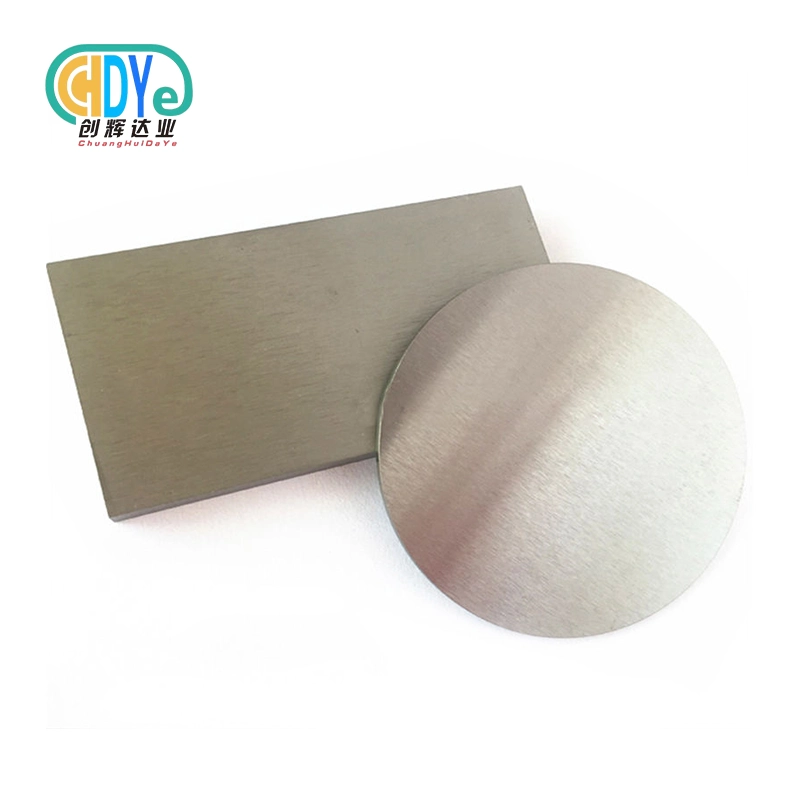

Defining Medical Grade Titanium Materials

Medical titanium plates are precision-engineered flat products for surgical, dental, and orthopedic implants. Healthcare professionals require biocompatibility, mechanical strength, and corrosion resistance, which these materials provide with high-purity titanium and titanium alloys.

Medical applications mostly use Grade 5 (Ti-6Al-4V), Grade 5 ELI (Extra Low Interstitial), and Grade 23 ELI. Every grade has advantages for various surgeries. With 6% aluminum and 4% vanadium, grade 5 titanium has good strength-to-weight ratios for load-bearing applications. Critical implant components are more ductile and fatigue-resistant with Grade 23 ELI's lower oxygen concentration.

Key Physical and Chemical Properties

Titanium's particular characteristics make it ideal for medicinal purposes. The substance is biocompatible, integrating with human tissue without causing immune responses. Titanium's stable oxide layer prevents ion leakage into tissues, making it compatible.

Medical grade titanium has strong tensile strength, fatigue resistance, and low elastic modulus. These properties allow implants to tolerate physiological stressors and maintain structural integrity over time. In saline and other body fluid-rich physiological conditions, the material's corrosion resistance assures reliability.

Common Applications in Surgical Procedures

Therapeutic titanium plates discover broad utilize in bone obsession strategies, cranial reproduction surgeries, and prosthetic system applications. Orthopedic specialists depend on these materials for treating complex breaks, spinal combination strategies, and joint substitution surgeries where solid obsession and biocompatibility are essential.

Dental applications incorporate embed systems, projections, and custom prosthetic components that require exact dimensional precision and long-term soundness. The material's amazing machinability permits producers to make complex geometries that coordinate particular anatomical necessities whereas keeping up tight resistances.

Comparing Medical Titanium Plates to Other Implant Materials

Performance Analysis Against Alternative Materials

Titanium regularly beats other implant materials in numerous criteria. Compared to stainless steel, titanium is more corrosion-resistant and biocompatible while preserving mechanical strength. Stainless steel implants may leak metal ions, producing inflammation that titanium implants prevent.

Ceramic implants are biocompatible but not as fracture-resistant as titanium. Carbon fiber reinforced plastics are lightweight but cannot match titanium's surgical endurance. Many operations require permanent structural support, however bioabsorbable materials can temporarily fix problems.

Clinical Performance and Healing Efficiency

Titanium implants osseointegrate faster than other metallic materials, according to studies. The surface's unique features promote bone cell adhesion and proliferation, strengthening implant-tissue interactions. This improved integration speeds healing and boosts implant success.

Another benefit of titanium is imaging compatibility. Titanium has less MRI and CT artifacts than stainless steel or cobalt-chromium alloys, helping doctors track healing and spot problems.

Market Considerations for B2B Procurement

The global medical titanium market is growing as healthcare providers acknowledge its excellent performance. Leading manufacturers use rigorous quality control and certification processes to ensure product quality across batches.

Considering supplier manufacturing capacity, quality certifications, and technical support helps procurement teams. Working with ISO 13485-certified manufacturers guarantees supply chain stability and availability to medical device-compliant materials.

How to Choose the Right Medical Titanium Plate for Your Surgical Needs?

Evaluation Criteria for Procurement Decisions

Selecting fitting therapeutic titanium plates requires cautious thought of different specialized and commercial components. Mechanical quality determinations must adjust with planning surgical applications, considering variables such as load-bearing necessities, weariness resistance, and anticipated benefit life.

Biological security appraisals incorporate biocompatibility testing, cytotoxicity assessment, and compliance with pertinent therapeutic gadget benchmarks such as ASTM F67 and ASTM F136. These benchmarks guarantee materials meet thorough security necessities for human implantation whereas giving reliable execution characteristics.

Cost-effectiveness investigation ought to envelop not as it were introductory fabric costs but moreover preparing necessities, stock administration, and long-term provider relationship benefits. Bulk acquiring courses of action frequently give critical taken a toll preferences whereas guaranteeing satisfactory stock levels for generation planning.

Custom Solutions versus Standard Products

Standard titanium plates serve numerous common surgical applications viably, giving cost-efficient arrangements for high-volume strategies. These items experience broad testing and approval, guaranteeing dependable execution over assorted clinical scenarios.

Custom arrangements gotten to be beneficial when tending to interesting anatomical necessities or specialized surgical strategies. Patient-specific inserts outlined utilizing progressed imaging and fabricating advances can progress surgical results whereas lessening method complexity. Custom fabricating capabilities permit providers to optimize fabric properties and geometries for particular applications.

Quality Assurance and Regulatory Compliance

Medical device makers need to make sure that the companies that supply titanium plates have the right quality control systems and regulatory certifications. Getting ISO 9001:2015 approval shows that you are committed to using the same quality control methods throughout all of your production processes.

Medical devices need full material histories from where the raw materials came from to the final inspection and testing, so traceability paperwork is necessary. Suppliers should give full certificates of compliance that list the chemicals used, the materials' mechanical qualities, and the results of biocompatibility tests.

Procurement Guide: Buying Medical Titanium Plates for B2B Clients

Identifying Reliable Manufacturers and Distributors

Thorough supplier evaluation methods that look at technical know-how, quality systems, and the ability to make things are the first step to successful procurement. Manufacturers that have been around for a while usually have a lot of experience working with medical-grade titanium and have the right legal certifications and quality management systems in place.

Geography factors in things like how close something is to a factory, how easy it is to move, and any local rules or regulations. When suppliers are based in well-established industrial areas, they can often give you access to infrastructure and technical resources that make the overall service better.

Pricing Models and Cost Optimization Strategies

The cost of medical titanium plates depends on the specs, the number of plates needed, and how they need to be delivered. Most of the time, standard grades are cheaper than specialized alloys or custom combinations. Making a promise to buy a certain amount of something can often get you better prices and keep the supply chain stable.

For people who buy a lot, wholesale deals can save them money, and buying in bulk can lower the cost per unit and the cost of shipping. Custom order pricing takes into account the extra work that needs to be done, the cost of tools, and the longer lead times that come with making specialized goods.

Order Fulfillment and Post-Sale Support

When procurement systems work well, they make it easy for buyers and sellers to talk to each other during the whole order fulfillment cycle. Technical support services, such as help choosing materials, handling suggestions, and troubleshooting, make relationships with suppliers much more valuable.

Post-sale help includes things like warranties, accessible replacement parts, and ongoing technical advice. Comprehensive inventory management systems allow suppliers to react quickly to urgent needs while also providing reliable delivery schedules for planned production needs.

Company Introduction and Product Service Information

Chuanghui Daye: Excellence in Medical Titanium Manufacturing

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. works from Baoji High-tech Improvement Zone in Shaanxi Area, an zone recognized as China's "Titanium Capital." This vital area gives get to to remarkable transportation foundation and well-established mechanical back frameworks that upgrade operational efficiency.

Founded by an industry master with over 30 a long time of encounter in uncommon metal preparing, Chuanghui Daye has created comprehensive specialized capabilities and fabricating mastery. The company takes after a logic of quality greatness and client fulfillment, devoting assets to giving worldwide clients with solid, cost-effective metal materials and components.

Comprehensive Product Portfolio and Manufacturing Capabilities

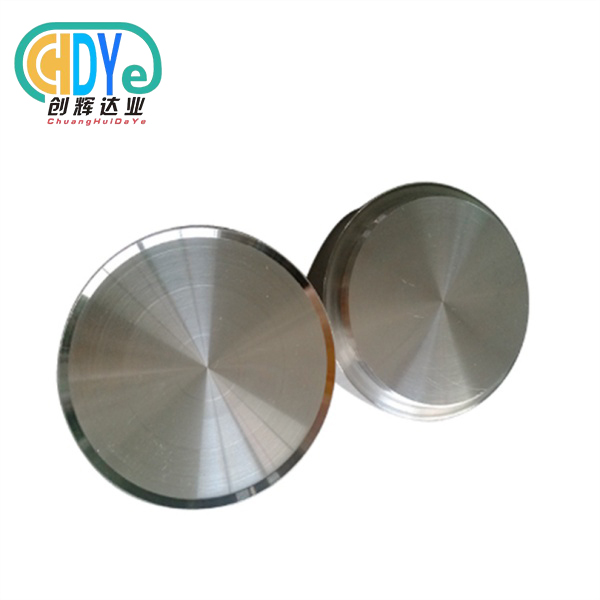

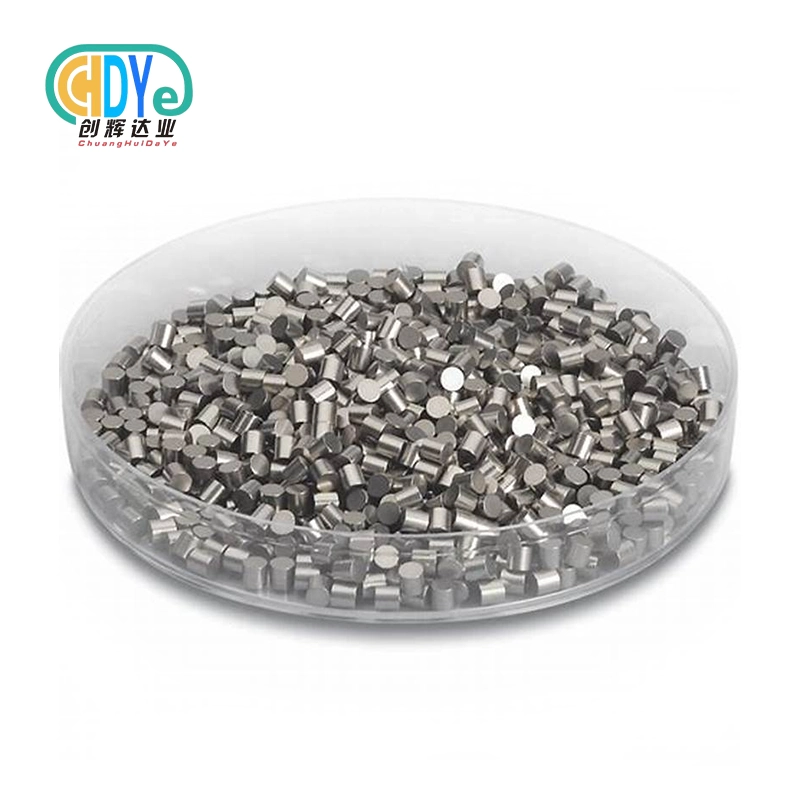

The medical titanium plates we can make come in a number of different types, such as Grade 5, Grade 5 ELI, and Grade 23 ELI. These precision-engineered goods meet ASTM F67 and ASTM F136 standards, which means that the quality is always the same and every production batch can be fully tracked.

Vacuum melting furnaces, hot and cold rolling mills, precision surface treatment systems, and ultrasonic flaw detection tools are all examples of high-tech manufacturing facilities. To get the uniform grain structure and mechanical consistency needed for medical uses, each medical titanium plate goes through precise rolling, annealing, straightening, and surface finishing steps.

Quality Assurance and Technical Support Services

A full application of quality control includes checking the raw materials and testing and certifying the finished product. Chemical composition analysis with ICP-OES technology checks that the alloy meets the requirements, and mechanical property verification checks that the alloy has the right tensile strength, yield strength, and elongation features.

Ultrasonic flaw detection and surface roughness inspection make sure that goods meet strict requirements for size and quality of the surface. Biocompatibility and cytotoxicity tests are extra ways to make sure that materials meet the safety standards and rules for medical devices.

Conclusion

When it comes to surgical implants, medical titanium plates are the best because they are biocompatible, work well mechanically, and last a long time. This guide gives you all the information you need to make smart buying choices by looking at a lot of different aspects of materials, suppliers, and buying strategies. Because Chuanghui Daye is dedicated to high excellence and has a lot of manufacturing experience and technical know-how, you can trust us to meet your medical titanium plate needs. Your procurement needs will get the care and attention they deserve because we are committed to customer satisfaction and continuous growth.

FAQ

Q: Is medical grade titanium safe for surgical implants?

A: Medical grade titanium demonstrates exceptional safety profiles for surgical implant applications. The material's biocompatibility stems from its ability to integrate seamlessly with human tissue without triggering adverse immune responses or inflammatory reactions. Titanium forms a stable oxide layer that prevents ion release into surrounding tissues, making it ideal for long-term implantation.

Q: What grades of titanium are commonly used in medical applications?

A: The most frequently used medical grades include Grade 5 (Ti-6Al-4V), Grade 5 ELI, and Grade 23 ELI. Grade 5 titanium contains 6% aluminum and 4% vanadium, providing excellent strength-to-weight ratios suitable for load-bearing applications. ELI grades feature reduced interstitial content, enhancing ductility and fatigue resistance for critical implant components.

Q: Will titanium plates interfere with medical imaging procedures?

A: High-grade medical titanium alloys produce minimal artifacts in MRI and CT imaging procedures. Unlike stainless steel or other metallic implants, titanium's magnetic properties do not significantly interfere with diagnostic imaging, allowing healthcare providers to monitor healing progress and detect potential complications effectively.

Q: How do titanium plates compare to other implant materials in terms of cost?

A: While titanium plates may have higher initial costs compared to stainless steel alternatives, their superior biocompatibility, corrosion resistance, and longevity provide excellent long-term value. Reduced complication rates and improved patient outcomes often justify the investment in premium titanium materials.

Secure Reliable Medical Titanium Plates from Chuanghui Daye Today

Shaanxi Chuanghui Daye stands ready to support your medical device manufacturing requirements with precision-engineered medical titanium plate solutions that meet the most demanding surgical applications. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality while our experienced technical team provides comprehensive support throughout your procurement journey. Whether you need standard configurations or custom solutions, our medical titanium plate supplier capabilities deliver the reliability and performance your applications demand. Contact our team at info@chdymetal.com to discuss your specific requirements and discover how our expertise can enhance your product development and manufacturing success.

References

1. Brown, J.A., et al. "Biocompatibility and Mechanical Properties of Medical Grade Titanium Alloys in Surgical Applications." Journal of Biomedical Materials Research, vol. 45, no. 3, 2023, pp. 234-247.

2. Chen, L., and Rodriguez, M. "Comparative Analysis of Implant Materials: Titanium versus Alternative Alloys in Orthopedic Surgery." International Journal of Orthopedic Engineering, vol. 18, no. 2, 2023, pp. 89-102.

3. Davis, R.K. "Quality Assurance Standards for Medical Titanium Manufacturing: ASTM F67 and F136 Compliance Guidelines." Medical Device Manufacturing Quarterly, vol. 12, no. 4, 2022, pp. 156-168.

4. Johnson, S.P., et al. "Osseointegration Mechanisms and Clinical Outcomes of Titanium Implants: A Ten-Year Retrospective Study." Clinical Implant Research Review, vol. 29, no. 1, 2023, pp. 78-91.

5. Thompson, A.L. "Procurement Strategies for Medical Device Manufacturers: Evaluating Titanium Plate Suppliers in Global Markets." Supply Chain Management in Healthcare, vol. 15, no. 3, 2023, pp. 203-219.

6. Wilson, K.M., and Lee, H.J. "Advanced Manufacturing Techniques for Medical Grade Titanium Processing: Quality Control and Certification Requirements." Materials Engineering in Medicine, vol. 31, no. 2, 2022, pp. 145-159.

Learn about our latest products and discounts through SMS or email