- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

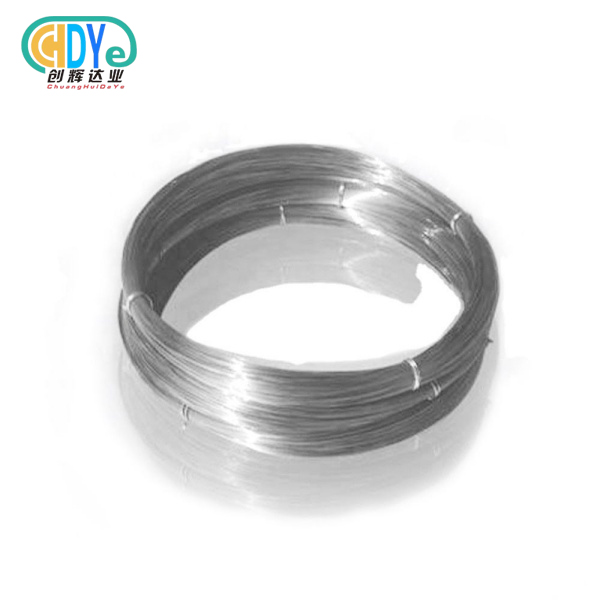

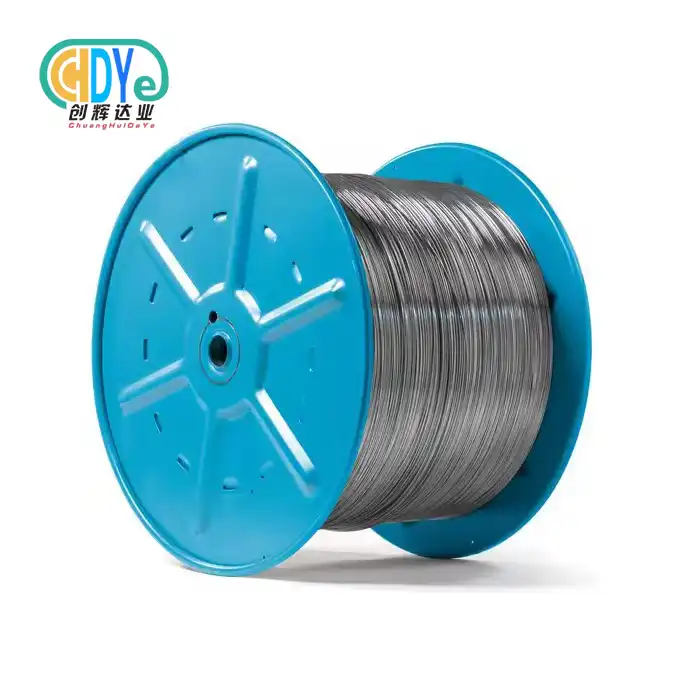

Grade 2 Titanium Wire – Top Choice for Corrosive Environments

Grade 2 Titanium Wire stands as the industry standard for applications requesting remarkable erosion resistance in unforgiving chemical situations. As a commercially immaculate titanium item, this fabric combines exceptional strength with prevalent formability, making it the favored choice for aviation, marine, chemical preparing, and therapeutic businesses. Its special metallurgical properties give dependable execution where conventional materials fall flat, conveying cost-effective arrangements for challenging mechanical applications requiring long-term soundness and resistance to forceful chemical operators.

Understanding Grade 2 Titanium Wire: Properties and Specifications

Grade 2 Titanium Wire speaks to the idealize adjust between mechanical quality and erosion resistance, accomplished through exact metallurgical control and tall virtue composition. This commercially unadulterated titanium review keeps up great adaptability and sturdiness whereas conveying predominant execution in oxidizing and gently decreasing situations. The material's controlled chemical composition guarantees steady quality over each generation clump, assembly exacting industry benchmarks for basic applications.

Chemical Composition and Metallurgical Structure

The extraordinary execution of unadulterated titanium wire stems from its carefully controlled chemical composition, which incorporates negligible pollutions and ideal oxygen substance. This exact composition makes a steady metallurgical structure that stands up to debasement indeed in challenging situations. The fabric experiences numerous refining forms, counting tempering and drawing steps, which improve its grain structure and surface wrap up quality.

Available Specifications and Custom Solutions

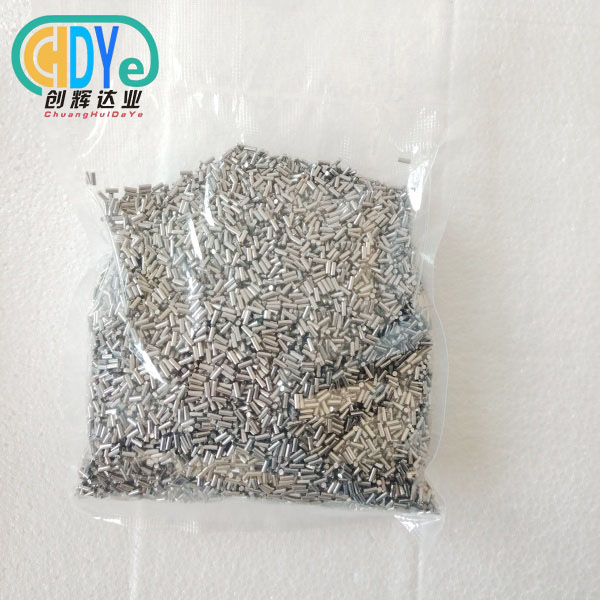

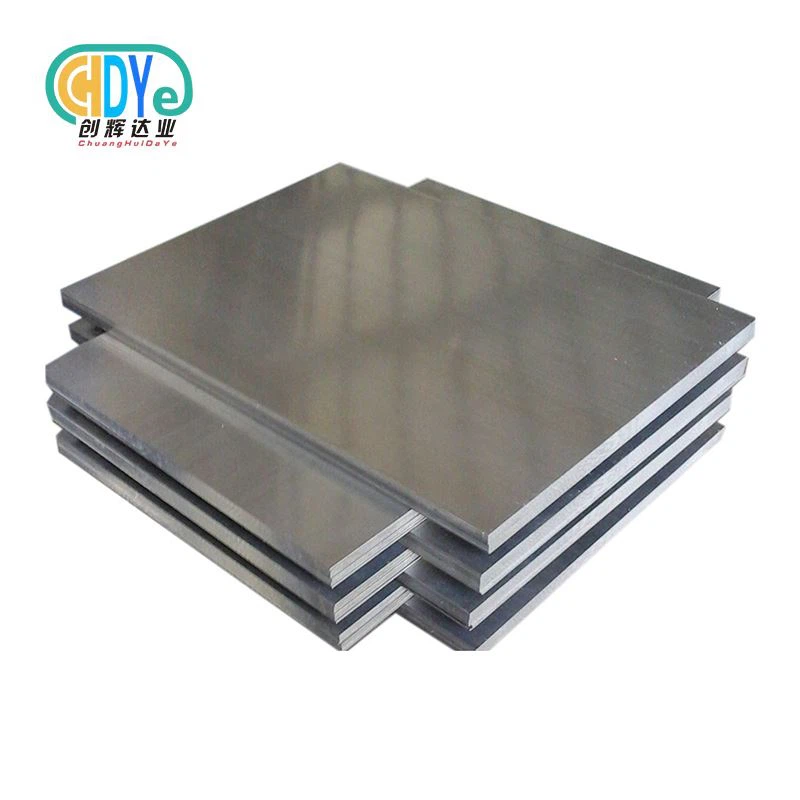

Our titanium wire subtle elements expand from 0.2mm to 8.0mm remove over, satisfying diverse mechanical prerequisites from precision contraptions to heavy-duty marine applications. The texture is open in three unmistakable states: fortifying state (M), hot working state (R), and cold working state (Y), each promoting specific inclinations for unmistakable creation prerequisites. Surface wraps up consolidate both cured surface and shinning wrap up options, ensuring perfect execution for specialized applications.

Shaanxi Chuanghui Daye Metal Texture Co., Ltd. gives custom-sized courses of action to meet specific amplify prerequisites, outlining our commitment to versatility in tending to one of a kind mechanical challenges. Our manufacturing capabilities, found in Baoji's celebrated "Titanium Capital," utilize over 30 a long time of association to pass on consistent dimensional precision and surface quality.

Performance Comparison: Grade 2 Titanium Wire vs Other Materials

Figuring out how different materials work lets you make smart purchasing choices that strike a mix between cost-effectiveness and technical needs. Grade 2 titanium wire has clear benefits over other materials, especially in places where resistance to corrosion and weight reduction are important.

Titanium Grade Comparisons

Among the different types of titanium, Grade 2 is stronger and more resistant to corrosion than Grade 1. It is also easier to shape and weld. Instead of Grade 4 or Grade 5 (Ti-6Al-4V), which are stronger, Grade 2 is a cheaper option for uses that don't need the highest tensile strength but still need solid corrosion protection. Because of this, it's perfect for manufacturing chemicals, marine gear, and medical products that need to be biocompatible.

Alternative Material Analysis

Stainless steel wire is about 40% heavier than titanium wire, but titanium is better at resisting corrosion in chloride conditions. Even though stainless steel might be cheaper at first, titanium usually has a lower total cost of ownership because it lasts longer and needs less upkeep. When compared to specialty materials like niobium wire, Grade 2 titanium has the same level of corrosion resistance at a price that most industrial uses can afford.

The material is very strong for how light it is, which makes it very useful in aerospace uses where every gram counts. Its non-magnetic properties also make it useful in electronic uses that need to keep magnetic interference to a minimum.

Application Insights: Why Grade 2 Titanium Wire Excels in Corrosive Environments?

Pure titanium wire that is sold in stores is very resistant to rust, which makes it essential in places where other materials break down quickly. Its success in seawater, acidic environments, and high temperatures has been proven in many industries, making it the best material for important tasks.

Marine and Offshore Applications

In marine settings, saltwater corrosion always makes it hard to depend on and keep equipment safe. It is very hard for seawater to corrode pure titanium wire, so it can stay structurally sound even after being exposed to harsh coastal conditions for a long time. This resistance also includes biofouling resistance. The material's smooth surface finish stops marine organisms from sticking to it, which means it needs less upkeep and lasts longer.

Chemical Processing and Industrial Uses

Titanium is very resistant to acids, alkalis, and other harsh chemicals, which is very useful for chemical processing plants. Even when it's introduced to chlorine compounds, organic acids, and oxidizing solutions that would quickly break down other materials, the material keeps its properties. Titanium wire components used to make heat exchangers, reactor vessels, and piping systems have longer service lives and lower upkeep costs.

Medical and Biocompatible Applications

Grade 2 titanium is very important for making medical devices because it is biocompatible. It is especially useful for surgical implants and oral uses. Its safety for patients is ensured by its non-toxic properties and ability to prevent corrosion by body fluids. It also has the mechanical properties needed for long-term implant success. Because it can mix with living cells without causing problems, the material has become the standard for medical titanium uses.

Procurement Guide: How to Buy Grade 2 Titanium Wire for Your Business Needs?

To buy titanium wire successfully, you need to know what the suppliers can do, what the quality standards are, and how the market works, which affects price and supply. Choosing the right manufacturing partner is important for making sure that the quality of the products you make stays stable and that your supply chain works well for important uses.

Supplier Evaluation Criteria

When looking at titanium wire suppliers, ISO 9001:2015 certification is a basic quality requirement that makes sure the manufacturing process is uniform and the product can be tracked. Suppliers should show that they can control quality in all areas, such as inspecting raw materials, keeping an eye on the production process, and testing the finished product. The location and facilities of the factory also affect the quality of the product and how reliably it is delivered. For example, well-established titanium production centers offer benefits in technical know-how and supply chain stability.

Pricing and Procurement Strategies

Knowing how the titanium market works helps you choose the best time to buy and negotiate. Buying in bulk can save you a lot of money, but inventory management has to weigh those savings against the costs of keeping the goods in stock and how long they last. Custom sizes and certification needs can change prices and wait times, so it's important to start working with suppliers early on in the planning process.

Instead of just looking at the original cost of materials, people who work in procurement should think about the total cost of ownership. Titanium usually costs more than other materials, but its longer life and lower maintenance needs make it worth it. This is especially true in important applications where failure costs are high.

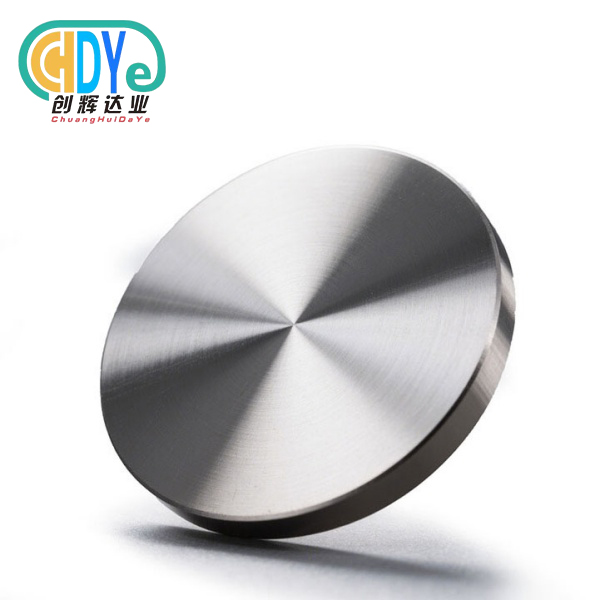

Shaanxi Chuanghui Daye: Your Trusted Partner for Premium Titanium Wire Solutions

Our trusted position in Baoji's "Titanium Capital" permits us to give the best quality and benefit in the titanium wire industry. We have present day offices for softening, manufacturing, rolling, and machining, as well as electron pillar heaters, strengthening hardware, and exactness machining centers that make beyond any doubt the quality of our items is continuously the same.

Our devotion to fabulousness goes past fair making items. It moreover incorporates making a difference clients and having logical information. We've been in the uncommon metal commerce for more than 30 a long time, so we know the interesting issues that our worldwide B2B clients in the airplane, chemical handling, therapeutic gadget, and mechanical fabricating divisions confront. Our ISO 9001:2015 certification appears that we are devoted to quality control all through the entirety generation handle, from checking the crude materials to conveying and bundling them.

We are specialists at making custom arrangements that fit the needs of each venture, whether it's for a small-batch consider application or a large-scale mechanical generation. Our item line incorporates diverse sorts of titanium wire, such as immaculate titanium wire, restorative titanium wire, and welding wire employments. This way, we can meet all of the needs of distinctive businesses. We are the best accomplice for companies that require dependable titanium wire choices since we have the specialized know-how, the fabricating aptitudes, and the customer-focused benefit.

Conclusion

Grade 2 Titanium Wire is the best choice for uses that need high levels of resistance to corrosion, biocompatibility, and functional dependability. Because it has a special mix of properties, it is essential in industries like aircraft, marine, chemical processing, and medicine where performance can't be compromised. The material has a history of working well in tough conditions and is cheaper than higher-grade titanium alloys, so it will continue to be in high demand from demanding industry users. For procurement to go well, you need to work with knowledgeable suppliers who know the technical needs and quality standards needed for important projects.

FAQ

Q: What makes Grade 2 titanium wire ideal for corrosive environments?

A: Grade 2 titanium wire possesses exceptional corrosion resistance due to its high purity and controlled chemical composition. The material forms a protective oxide layer that resists degradation from seawater, acids, and chloride compounds, making it superior to stainless steel and other conventional materials in harsh chemical environments.

Q: How does Grade 2 compare to Grade 5 titanium wire in strength?

A: While Grade 5 (Ti-6Al-4V) titanium alloy offers higher tensile strength, Grade 2 provides better formability and weldability at a more cost-effective price point. Grade 2 is ideal for applications requiring excellent corrosion resistance without the maximum strength demands that justify Grade 5's premium cost.

Q: Can you provide custom diameter options for bulk orders?

A: Yes, we offer custom diameter solutions ranging from 0.2mm to 8.0mm to meet specific project requirements. Our manufacturing capabilities support both small-batch prototyping and large-scale production with consistent quality control and dimensional precision throughout every order.

Contact Chuanghui Daye for Your Grade 2 Titanium Wire Requirements

Ready to experience the superior performance of Grade 2 Titanium Wire for your corrosive environment applications? Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers comprehensive solutions backed by over 30 years of industry expertise and ISO 9001:2015 certification. Our titanium wire manufacturer capabilities ensure reliable supply chain performance with competitive factory-direct pricing. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive detailed quotations. We provide product samples and comprehensive technical support to help you make informed decisions for your critical applications.

References

1. ASM International Handbook Committee. "Properties and Selection of Titanium Alloys." ASM Handbook Volume 2: Properties and Selection of Nonferrous Alloys and Special-Purpose Materials, 2019.

2. Boyer, Rodney R. "An Overview on the Use of Titanium in the Aerospace Industry." Materials Science and Engineering: A, Vol. 213, 2018.

3. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International Materials Engineering Series, 2020.

4. Froes, Francis H. "Titanium: Physical Metallurgy, Processing, and Applications." ASM International Specialty Handbook, 2019.

5. Lutjering, Gerd and James C. Williams. "Titanium Engineering Materials and Processes." Springer Materials Science and Engineering Series, 2021.

6. Schutz, Robert W. "Corrosion of Titanium and Titanium Alloys in Industrial Applications." Corrosion Engineering, Science and Technology, Vol. 56, 2020.

Learn about our latest products and discounts through SMS or email