- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buy Titanium Wire for Anodizing – Competitive Pricing

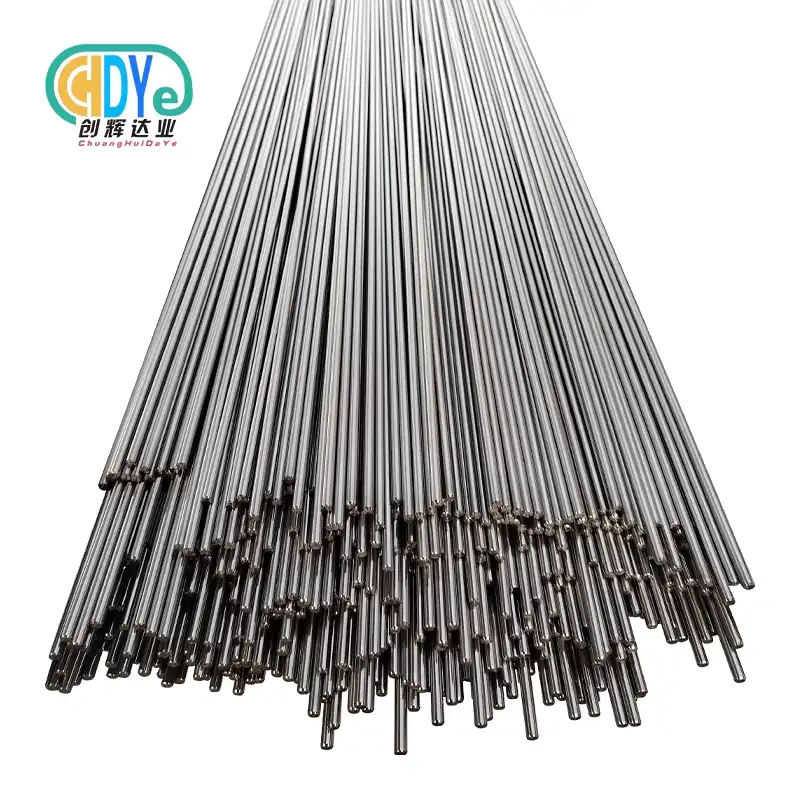

For quality-conscious manufacturers, titanium wire for anodizing is the best electrochemical surface treatment material. Our high-grade titanium wire meets aerospace, medicinal, and chemical processing industry demands for corrosion resistance and electrical conductivity in anodizing operations. This adaptable material meets your operations' reliability and cost-effectiveness with diameters from 0.2mm to 7mm and factory-direct pricing.

Understanding Titanium Wire for Anodizing

Titanium wire for anodizing with controlled electrochemical oxidation creates a high-performance material with improved surface characteristics. This treatment creates a protective oxide coating on the wire surface, enhancing its corrosion, wear, and chemical resistance while keeping the base metal's strength.

Fundamental Properties Making Titanium Ideal for Anodizing

Titanium's unusual metallurgical qualities make it ideal for anodizing. In harsh chemical conditions, the material resists corrosion from acids, alkalis, and salt solutions that would damage common metals. High strength-to-weight ratio ensures structural integrity under mechanical stress, and biocompatibility allows medical device manufacture.

By adding a regulated titanium dioxide (TiO2) coating to protect against environmental degradation, anodizing improves these natural qualities. Oxide formation is homogenous over the wire surface, assuring continuous protection and performance throughout its service life.

The Anodizing Process: Step-by-Step Breakdown

Before anodizing, the surface is degreased and etched to eliminate impurities and optimize oxide formation. An electrolytic cell with phosphoric or sulfuric acid uses cleaned titanium wire as the anode.

Electrolysis draws oxygen ions to the titanium surface, where they create the protective oxide layer with titanium atoms. Process variables like voltage, current density, temperature, and duration determine coating thickness and characteristics. Processing timeframes vary from minutes to hours depending on specifications and working voltages of 20 to 200 volts.

Safety Considerations and Quality Control

Appropriate security conventions secure staff and gear amid anodizing operations. Satisfactory ventilation frameworks oversee corrosive vapors, whereas individual defensive gear avoids chemical presentation. Temperature checking avoids overheating that may compromise wire keenness or coating quality.

Quality control measures incorporate pre-treatment assessment, prepare parameter checking, and post-anodizing testing to confirm coating thickness, attachment, and erosion resistance. These conventions guarantee reliable comes about and keep up the tall measures anticipated in basic applications.

Why Choose Titanium Wire Over Other Metals for Anodizing?

Manufacturing specialists consider several wire materials for anodizing. Aluminum, stainless steel, and copper have advantages, but titanium wire performs better in challenging situations.

Performance Comparison with Alternative Materials

Though cheap and easily anodised, aluminum wire lacks mechanical strength for high-stress applications. While anodized coatings protect against corrosion, titanium outperforms them in harsh chemical conditions and high temperatures. Despite its strength, stainless steel's chromium concentration makes anodizing difficult.

Even after anodizing, copper wire has low corrosion resistance despite its high conductivity. Copper surfaces have less durable protective coatings than titanium, resulting in lower service life and higher maintenance.

Economic Advantages and Total Cost of Ownership

Titanium wire for anodizing costs more than other materials, but its superior performance often lowers its total cost of ownership. Extended service life minimizes replacement frequency, downtime, and maintenance expenses. Chemical resistance eliminates the need for periodic coating repairs or component replacement.

Titanium's weight savings in aircraft applications balance material costs during the component's lifespan by improving fuel economy. Titanium's biocompatibility eliminates the need for protective coatings or treatments for medical device producers.

Addressing Titanium's Limitations

Despite its benefits, titanium wire has drawbacks that procurement experts should consider. High-cost materials require cost-benefit analysis to justify selection. Limited availability compared to common metals may affect supply chain planning and lead times.

Titanium processing involves specific equipment and knowledge, which can raise manufacturing prices. However, working with experienced suppliers that understand these obstacles can reduce risks and maximize material gains.

How to Buy Titanium Wire for Anodizing: Factors and Best Practices?

Effective acquirement of titanium wire requires cautious thought of numerous components that impact both quick venture victory and long-term operational productivity. Understanding these key components makes a difference buyers make educated choices that adjust execution necessities with budget imperatives.

Material Grade Selection and Specifications

Commercially pure titanium (Grade 2) is suited for ordinary anodizing applications where strength is not important due to its corrosion resistance and formability. Chemical processing equipment and electronic components benefit from this grade's performance-to-cost ratio.

Titanium alloy Grade 5 (Ti-6Al-4V) has better mechanical qualities due to aluminum and vanadium. This grade is ideal for aeronautical and medical applications when performance justifies expense. Its enhanced strength-to-weight ratio makes the alloy useful in weight-sensitive applications.

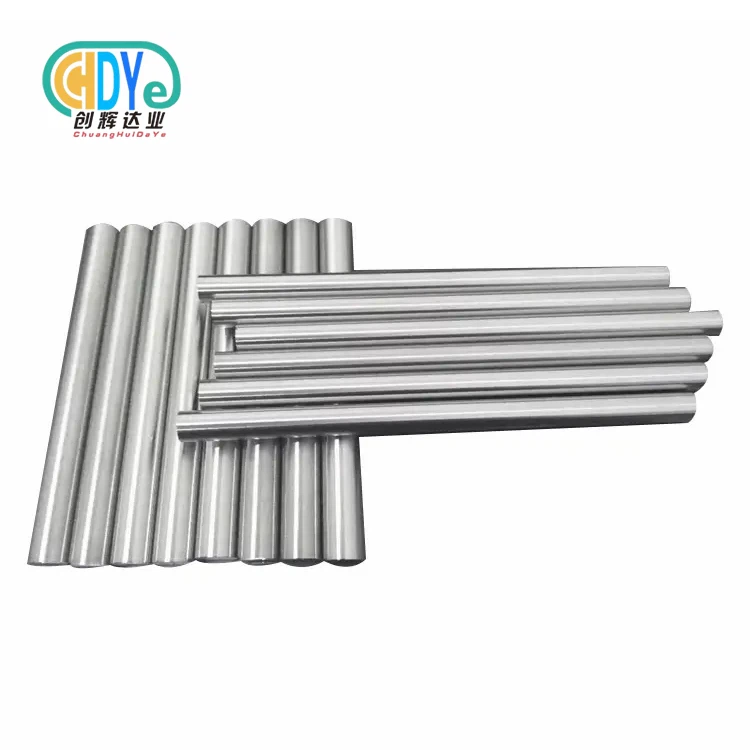

Application needs and processing constraints determine wire diameter. Sizes 0.2-1.0mm are suitable for electrical applications and tiny mesh production, while 3.0-7.0mm strengthen mechanical components.

Quality Certifications and Supply Chain Reliability

ISO 9001:2015 certification guarantees providers keep up reliable quality administration frameworks all through their operations. This certification shows commitment to prepare control, documentation, and nonstop enhancement that specifically impacts item reliability.

Material traceability documentation gives total records of crude fabric sources, preparing parameters, and quality test comes about. These records bolster compliance with industry benchmarks and empower quick issue determination if quality issues arise.

Supplier assessment ought to incorporate appraisal of generation capacity, conveyance unwavering quality, and specialized back capabilities. Set up providers with demonstrated track records in titanium handling offer more noteworthy confirmation of reliable quality and on-time conveyance.

Pricing Strategies and Bulk Purchasing Benefits

Titanium wire prices depend on raw material costs, supply-demand balance, and worldwide economic conditions. Buyers can plan purchases to maximize costs and negotiate supplier conditions by understanding these aspects.

Volume discounts and lower per-unit handling expenses make bulk purchase cost-effective. Buyers must weigh these savings against inventory carrying costs and obsolescence risks. Volume pricing and inventory flexibility can be achieved using blanket orders and planned releases.

Custom specifications may increase unit costs but save time-consuming secondary procedures. Working with providers who can customise things is typically cheaper than buying standard materials and modifying them.

Company Introduction and Product & Service Information

Shaanxi Chuanghui Daye Metal Material Co., Ltd. serves the global titanium wire market with over 30 years of rare metal processing experience. In Baoji High-tech Development Zone, Shaanxi Province—China's "Titanium Capital"—our company has access to high-quality raw materials and established supply networks that provide reasonable pricing.

Manufacturing Capabilities and Quality Assurance

Our modern production facilities include precision wire drawing equipment, controlled environment heat treatment furnaces, and extensive testing laboratories to ensure product quality. After selecting raw materials from reputable vendors, diamond dies are used to draw regular diameter tolerances.

Heat treatment optimizes mechanical qualities and maintains surface integrity for anodizing. The entire production process, from incoming material inspection to final packing, is tested to ensure customer satisfaction.

We are ISO 9001:2015 certified for systematic quality management and continuous development. We are certified from supplier qualification to customer delivery, ensuring product quality and reliable service.

Comprehensive Product Range and Customization Services

Our titanium wire item line includes breadths from 0.2mm to 7.0mm in both commercially immaculate and combination grades. Review 2 titanium offers fabulous erosion resistance and formability for common anodizing applications, whereas Review 5 gives upgraded quality for requesting aviation and therapeutic applications.

Customization capabilities incorporate exact length cutting, uncommon bundling prerequisites, and surface planning custom-made to particular anodizing forms. Our specialized group works closely with clients to get it application prerequisites and prescribe ideal fabric details that maximize execution whereas controlling costs.

Value-added administrations incorporate specialized interview, fabric certification documentation, and sped up conveyance choices for pressing ventures. These administrations reflect our customer-first logic and commitment to supporting fruitful extend results.

Conclusion

Titanium wire for anodizing is a premium material that performs well in aerospace, medical, chemical, and electronics applications. Through anodizing, its unique combination of corrosion resistance, mechanical strength, and biocompatibility delivers long-term value that frequently compensates the initial material expenditure. Grade selection, supplier competencies, and total cost of ownership must be considered for successful purchase. Expert vendors who understand titanium metallurgy and anodizing ensure optimal outcomes, low price, and on-time delivery.

FAQ

Q: What diameter options are available for titanium anodizing wire?

A: Our titanium wire for anodizing applications is available in diameters ranging from 0.2mm to 7.0mm, accommodating diverse application requirements from fine electronic components to structural elements. Smaller diameters suit precision applications requiring detailed surface treatment, while larger sizes provide the mechanical strength needed for load-bearing components. Custom diameter specifications can be accommodated through our precision drawing capabilities.

Q: How does anodized titanium wire compare to untreated material in chemical resistance?

A: Anodized titanium wire exhibits significantly enhanced chemical resistance compared to untreated material. The anodic oxide layer provides additional protection against aggressive acids, alkalis, and salt solutions commonly encountered in chemical processing environments. While pure titanium already offers excellent corrosion resistance, the anodizing process creates a uniform protective barrier that extends service life and maintains performance in extreme chemical conditions.

Q: What safety protocols should be followed during titanium wire anodizing?

A: Proper safety measures include adequate ventilation to manage acid vapors, use of appropriate personal protective equipment including acid-resistant gloves and eye protection, and temperature monitoring to prevent overheating. Work areas should be equipped with emergency eyewash stations and chemical spill containment materials. Personnel should receive training in chemical handling procedures and emergency response protocols specific to the anodizing chemicals being used.

Q: Can anodizing thickness be customized for specific applications?

A: Anodizing thickness can be precisely controlled through adjustment of process parameters including voltage, current density, electrolyte concentration, and treatment duration. Typical thickness ranges from 2 to 25 microns, depending on application requirements. Thinner coatings provide enhanced electrical properties for electronic applications, while thicker layers offer maximum corrosion protection for harsh environment exposure. Our technical team can recommend optimal thickness specifications based on specific performance requirements.

Partner with Chuanghui Daye for Superior Titanium Wire Solutions

Shaanxi Chuanghui Daye stands ready to support your anodizing projects with premium-quality titanium wire that meets the most demanding specifications. Our comprehensive product range, competitive pricing, and expert technical support make us the ideal titanium wire for anodizing supplier for your manufacturing operations. Contact our specialists at info@chdymetal.com today to discuss your specific requirements and receive detailed pricing quotations. Experience the advantages of working with a trusted manufacturer committed to delivering consistent quality, reliable supply, and exceptional customer service that drives your project success.

References

1. Boyer, R., Welsch, G., & Collings, E.W. (2007). Materials Properties Handbook: Titanium Alloys. ASM International Press.

2. Donachie, M.J. (2000). Titanium: A Technical Guide, 2nd Edition. ASM International Publications.

3. Lütjering, G. & Williams, J.C. (2003). Titanium: Engineering Materials and Processes. Springer-Verlag Berlin.

4. Rack, H.J. & Qazi, J.I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering Review Journal.

5. Schutz, R.W. & Thomas, D.E. (1987). Corrosion of titanium and titanium alloys. Metals Handbook: Corrosion, ASM International.

6. Veiga, C., Davim, J.P., & Loureiro, A.J.R. (2012). Properties and applications of titanium alloys: A brief review. Reviews on Advanced Materials Science.

Learn about our latest products and discounts through SMS or email