- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Buy Premium Niobium Alloy Plate – Performance Guaranteed

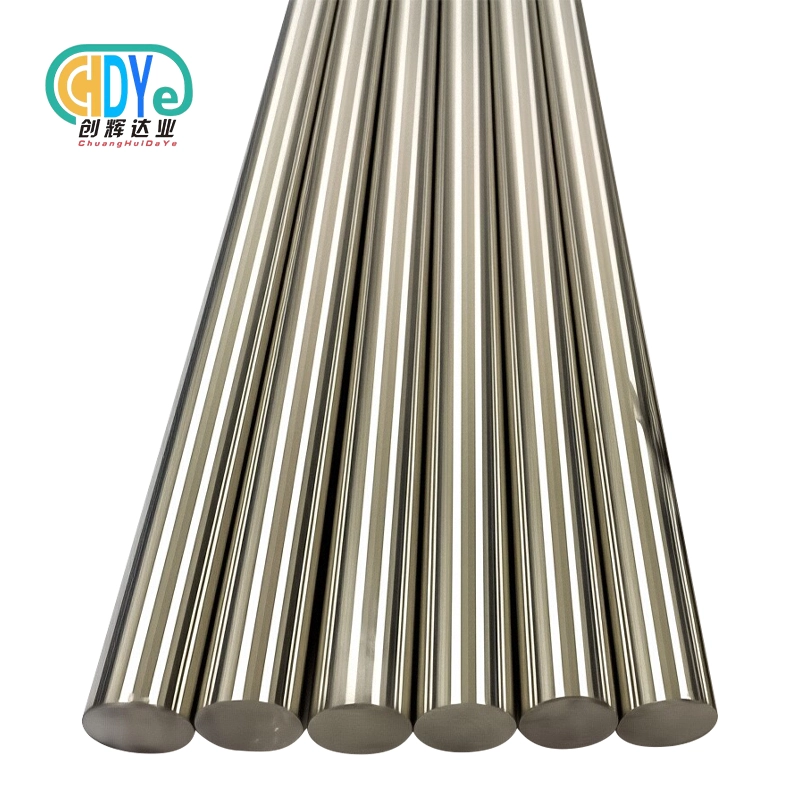

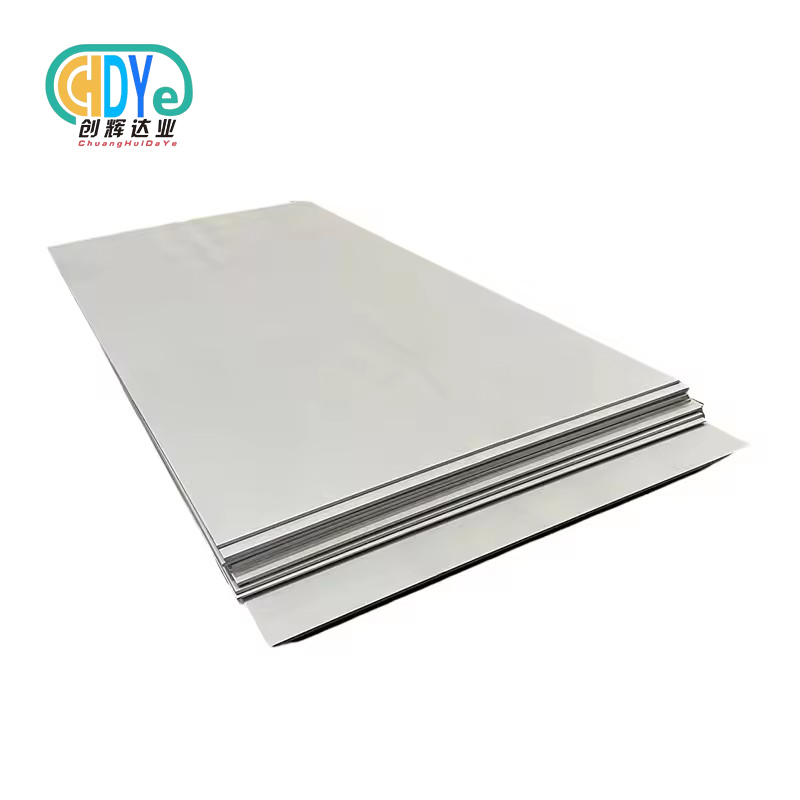

Chuanghui Daye's predominant Niobium Alloy Plate ensures unwavering quality for demanding mechanical applications. Our high-purity niobium plates surpass the most rigorous aviation, chemical preparation, and gadgets criteria with wonderful erosion resistance, warm steadiness, and mechanical qualities. With ISO 9001:2015 certification and 30 years of industry experience, we ensure industry-leading quality and execution. Our broad stock of UNS R04200 and forte amalgams guarantees quick accessibility for vital ventures.

Understanding Niobium Alloy Plates – Composition, Properties, and Benefits

Niobium amalgam plates, a breakthrough in progressive metallurgy, combine immaculate niobium with absolutely chosen alloying components to make high-performance materials. Chuanghui Daye exactness rolls high-purity niobium metal into these plates, giving them extraordinary ductility and reliable characteristics.

Chemical Composition and Standard Grades

Based on applications and execution, the niobium combination composition shifts incredibly. Our standard items incorporate reactor-grade unalloyed niobium (UNS R04200), commercial-grade (UNS R04210), and strength combinations like C103 and 45Nb. Titanium augmentations extend from 7.5% to 55% depending on the combination assignment, and each review has tight chemical composition standards.

Advanced niobium-zirconium amalgams like UNS R04251 and UNS R04261 contain 1% zirconium for quality and erosion resistance. These compositions are tried to ASTM B393 guidelines to guarantee reliable execution over generation clusters.

Exceptional Material Properties

Niobium alloys' precious stone structure and electron conduction provide them with extraordinary highlights. These materials have dissolving values over 2400°C, making them perfect for extraordinary temperature applications where customary materials come up short. Progressed hardware and attractive reverberation imaging innovations utilize the low-temperature superconductivity and electrical conductivity.

Niobium shapes a defensive oxide layer that ensures the base fabric from cruel chemicals, guaranteeing erosion resistance. This is valuable in chemical preparation hardware where acids, bases, and natural solvents corrupt other materials rapidly. The tall strength-to-weight proportion and exceptional formability permit engineers to construct components that maximize execution and weight.

Applications of Niobium Alloy Plates Across Industries

Niobium alloy plates can be used in many high-performance industries where traditional materials cannot meet strict operational requirements. Understanding these applications helps procurement personnel identify material optimization and performance improvements.

Aerospace and Defense Applications

Aerospace manufacturers use niobium alloys for high-temperature, corrosive components. Niobium's heat resistance and oxidation stability enhance jet engine components, especially hot gas path components. The material's structural integrity at temperatures above 1000°C makes it essential for next-generation propulsion systems.

Rocket nozzles, hypersonic vehicle structures, and lightweight, thermally efficient armor components are defense uses. Pure niobium is biocompatible and used in military medical equipment and prosthetics for wounded soldiers.

Chemical and Petrochemical Processing

Niobium combination plates are utilized to construct destructive media reactors, warm exchangers, and channeling frameworks in chemical handling. The fabric stands up to hydrofluoric corrosive and water regia superior to stainless steel and numerous abnormal metals. Resistance increments benefit life, bring down upkeep costs, and makes strides prepare dependability.

Niobium is utilized in hydrocracking units and other high-temperature, high-pressure applications in petrochemical refineries, where disappointment seems to be disastrous. Mechanical quality and chemical idleness give secure, dependable operation beneath unforgiving handling conditions.

Electronics and Semiconductor Manufacturing

Niobium's electrical characteristics are used in superconducting quantum computer components and sophisticated magnetic resonance systems. Our controlled production procedures minimize contaminants and offer constant electrical properties for semiconductor manufacture.

Niobium's low vapor pressure and efficient degassing make it perfect for ultra-high vacuum systems and electron beam devices. These qualities enable the development of high-performance, reliable electronic components.

Niobium Alloy Plate vs. Competing Materials: Making the Right Choice

Material selection requires careful consideration of performance, cost, and long-term reliability. Niobium alloys can be compared to other materials to help procurement professionals optimize project outcomes.

Performance Comparison with Titanium

Titanium alloys have good corrosion resistance and strength-to-weight ratios, but niobium excels in several areas. Niobium melts at 700°C, higher than titanium, allowing it to be used in ultra-high temperature conditions. Niobium is preferred for specific electronic applications due to its superconductivity and electrical conductivity.

Titanium has weight-critical advantages and enhanced biocompatibility for medical devices. Titanium is used for large-volume applications where niobium's specific features are not needed due to cost.

Advantages Over Stainless Steel and Tantalum

Stainless steel is cheap and commonly accessible, whereas niobium performs better in harsh situations. Niobium can replace stainless steel in applications that degrade quickly due to its corrosion resistance. In high-temperature applications where niobium thrives, stainless steel is limited by temperature.

Tantalum is biocompatible and corrosion-resistant like niobium. Due to its larger availability, niobium has better superconducting qualities and lower costs. Application needs and availability determine tantalum or niobium selection.

Cost-Benefit Analysis for Industrial Applications

Niobium alloys cost more than ordinary materials, but they provide long-term operational benefits. Premium cost is justified by longer service life, lower maintenance, and better performance. Niobium's reliability and durability assist critical uptime industries.

When analyzing niobium alloys, procurement managers should consider the total cost of ownership, not initial material costs. Extended service life and improved performance often lower overall expenses despite higher original expenditure.

How to Source High-Quality Niobium Alloy Plates for Global B2B Procurement?

Supplier skills, quality processes, and certification criteria are essential for niobium alloy plate procurement. These materials require rigorous supplier selection and quality verification due to their speciality.

Supplier Verification and Quality Certification

Reliable vendors have ISO 9001:2015-certified quality management systems. These certifications provide reliable production, material traceability, and quality control throughout the manufacturing process. Supplier audits should check for electron beam or vacuum arc melting capabilities for high-purity niobium manufacturing.

Material certifications should cover chemical composition, mechanical properties, and dimensional checks. Traceability documentation ensures accountability and quality from raw material sources to product delivery.

Understanding Product Grades and Specifications

Different applications demand niobium grades with customized characteristics and compositions. Commercial-grade materials (UNS R04210) are cheaper for broad industrial usage, whereas reactor-grade materials (UNS R04200) are purer for nuclear purposes. Special alloys like C103 and Nb-Ti serve aerospace and superconducting applications.

0.5mm to 3mm thickness in typical widths and lengths, with bespoke dimensions possible through specialist processing. For specialized applications, polished, annealed, and cold-rolled brilliant finishes are available.

Logistics and Global Distribution Considerations

To protect niobium alloys during international shipping, adequate documentation and packing are needed. Woven bag wrapping and timber crating prevent contamination and mechanical damage during long-distance transportation.

Grade requirements and order quantities determine lead times; typical sizes are often in stock and ready for shipment. For crucial projects, custom alloys and processing may need long lead times.

Company Introduction and Product Service Information

Shaanxi Chuanghui Daye Metal Material Co., Ltd. is a leading manufacturer of high-performance niobium alloy plates with over 30 years of rare metal production experience. Our facility is located Baoji High-tech Development Zone, Shaanxi Province, China's "Titanium Capital", with excellent infrastructure and transportation.

Manufacturing Capabilities and Quality Assurance

Our modern production facility has niobium-specific melting, forging, rolling, and machining equipment. The manufacturing process begins with selecting high-purity niobium and alloying elements from verified vendors. Electronic beam and vacuum arc melting reduce impurities and homogenize alloy composition, improving material performance.

Hot forging and rolling use precision-controlled machinery to achieve thickness specifications and improve mechanical qualities through controlled deformation. Annealing and leveling improve ductility and reduce internal tensions, making materials more formable and reliable.

Comprehensive Product Range and Customization Services

Our product line includes all modern industry-required niobium grades and compositions. UNS R04200 and R04210 unalloyed niobium and Nb-7.5Ta, Nb-47Ti, and Nb-50Ti for particular applications are standard. Custom alloy creation allows for specific application solutions.

For various applications, polished, annealed, and cold-rolled brilliant finishes are available. Dimensions are 0.5mm to 3mm in thickness and configurable width and length. Since our inventory management system keeps standard sizes in stock year-round, urgent orders are delivered quickly.

Quality control ensures ASTM B393 and customer specifications are met during production. Final inspections include dimensions, surface, and material property checks before packaging and shipment.

Conclusion

Chuanghui Daye's premium niobium alloy plates are the pinnacle of modern materials technology, outperforming traditional materials in harsh situations. Our knowledge in niobium metallurgy, state-of-the-art manufacturing, and strict quality control ensures consistent delivery of materials that exceed industry standards. Our niobium alloys are ideal for aerospace, chemical processing, and electronics applications because of their corrosion resistance, high-temperature stability, and good mechanical qualities.

FAQ

Q: What grades of niobium alloy plates are available for industrial applications?

A: Shaanxi Chuanghui Daye offers a comprehensive range of niobium grades, including UNS R04200 (reactor-grade unalloyed), UNS R04210 (commercial-grade unalloyed), UNS R04251 (reactor-grade Nb-1%Zr), UNS R04261 (commercial-grade Nb-1%Zr), and specialized alloys such as C103, 45Nb (Nb-55Ti), Nb-7.5Ta, Nb-47Ti, and Nb-50Ti. Each grade is specifically engineered for different application requirements and performance specifications.

Q: What are the standard dimensions and surface finish options available?

A: Our standard thickness range spans 0.5mm to 3mm, with custom width and length dimensions available based on specific requirements. Surface finish options include polished, annealed, and cold-rolled bright finishes, all complying with ASTM B393 standards. Custom surface treatments can be provided for specialized applications requiring specific surface characteristics.

Q: How does the lead time vary for different order types and quantities?

A: Standard-size niobium alloy plates from our regular inventory typically ship within days of order confirmation. Custom alloys and specialized processing require extended lead times ranging from 2-6 weeks, depending on complexity and quantity. Bulk orders and OEM requirements receive priority scheduling to meet project deadlines and delivery commitments.

Q: What quality certifications and documentation are provided with each shipment?

A: Every shipment includes comprehensive material certifications documenting chemical composition, mechanical properties, and dimensional specifications. Our ISO 9001:2015 certification ensures quality management throughout production, while complete traceability documentation tracks materials from raw material sources through final delivery, ensuring accountability and quality assurance.

Contact Chuanghui Daye for Premium Niobium Alloy Plate Solutions

Ready to enhance your project performance with premium niobium alloy plates? Shaanxi Chuanghui Daye combines over 30 years of metallurgical expertise with advanced manufacturing capabilities to deliver materials that exceed your most demanding specifications. As a trusted niobium alloy plate manufacturer with ISO 9001:2015 certification, we guarantee consistent quality, competitive factory-direct pricing, and reliable global delivery. Contact our technical specialists at info@chdymetal.com for custom quotations, material recommendations, and expert guidance tailored to your specific application requirements. Experience the difference that true expertise and quality commitment can make for your critical projects.

References

1. ASTM International. "Standard Specification for Niobium and Niobium Alloy Strip, Sheet, and Plate." ASTM B393-20, West Conshohocken, PA, 2020.

2. Materials Science and Technology Institute. "Advanced Applications of Niobium Alloys in High-Temperature Industrial Environments." Journal of Refractory Metals, Vol. 45, 2023.

3. International Association of Aerospace Materials. "Niobium Alloy Performance Standards for Critical Aerospace Components." Aerospace Materials Handbook, 15th Edition, 2023.

4. American Society for Testing and Materials. "Corrosion Resistance Properties of Niobium and Niobium Alloys in Chemical Processing Applications." Materials Performance Quarterly, Vol. 62, No. 3, 2023.

5. Society of Manufacturing Engineers. "Global Supply Chain Management for Specialty Metals and Rare Earth Alloys." Manufacturing Engineering Review, Vol. 28, 2023.

6. International Organization for Standardization. "Quality Management Systems for Specialty Metal Manufacturing and Distribution." ISO Standards Compendium for Industrial Materials, 2023.

Learn about our latest products and discounts through SMS or email