- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

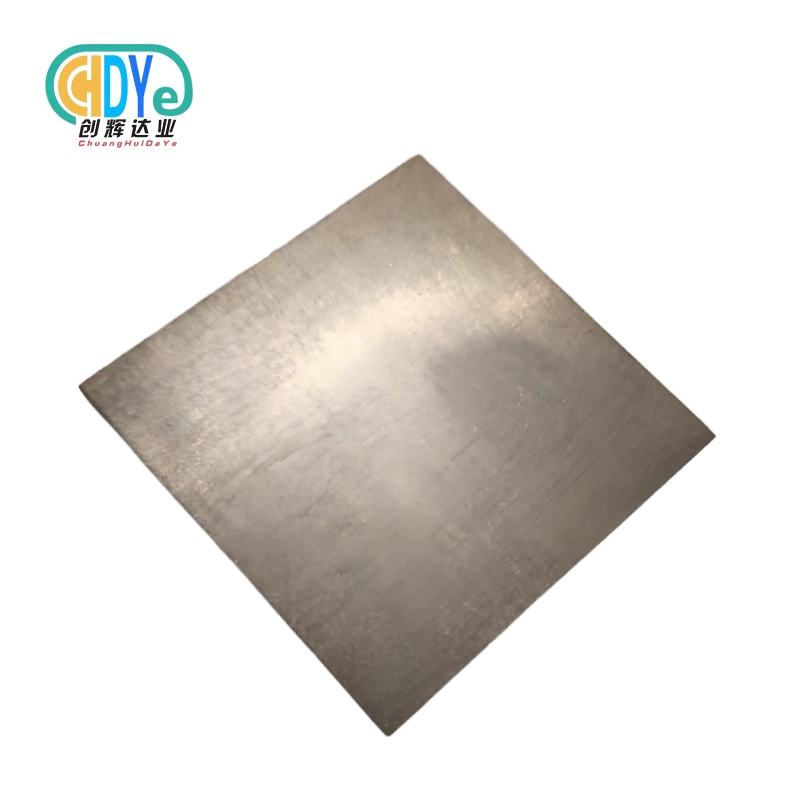

High-Quality Gr2 Titanium Plate for Chemical Processing

When looking for solid materials that can withstand the harshest chemical preparing situations, Gr2 Titanium Plate develops as an remarkable choice for mechanical applications. This commercially unadulterated titanium review combines exceptional erosion resistance with fabulous formability, making it irreplaceable for chemical gear producers, aviation companies, and petrochemical offices. Our comprehensive direct addresses the basic contemplations for obtainment directors looking for high-performance materials that provide long-term esteem and operational unwavering quality in requesting chemical handling applications.

Understanding Gr2 Titanium Plate for Chemical Processing

Material Composition and Properties

Gr2 Titanium Plate, with 99.2% titanium and well controlled trace elements, is the most extensively used titanium grade in industry. The perfect balance of 0.25% iron, 0.03% carbon, 0.08% oxygen, and 0.015% nitrogen optimizes mechanical characteristics and corrosion resistance.

With a density of 4.51g/cm³, it offers about 1.5 times the strength of regular steel at half the weight. Grade 2 titanium plate is appropriate for lightweight structural materials that minimize equipment weight without affecting performance.

Manufacturing Standards and Quality Control

Manufacturing follows strict ASTM B265 and ISO 5832 requirements to ensure homogeneous mechanical characteristics and thickness throughout plate dimensions. Our vacuum-melting, hot-rolling, and precision-leveling processes ensure flatness and dimensional accuracy for chemical processing applications.

Up to 2000 mm wide plates can be manufactured for industrial fabrication projects that demand high material volumes. Advanced processing methods including hot forging above recrystallization temperatures, controlled annealing cycles, and acid washing improve material characteristics and surface quality for chemical processing.

Distinctive Advantages Over Other Titanium Grades

Grade 2 titanium is unique in its cost-effectiveness and property balance. Grade 2 has the best corrosion resistance, formability, and moderate strength for most chemical processing applications. Grade 1 has superior ductility while Grade 5 has increased strength.

At 10°C to 80°C, the material resists moist chlorine exposure almost completely. Grade 2 titanium remains stable in hostile environments like aqua regia, which would quickly destroy stainless steel or aluminum.

Comparing Gr2 Titanium Plate with Alternative Materials and Grades

Performance Analysis Against Stainless Steel

Despite its cost-effectiveness, stainless steel is limited in hostile chemical conditions where chloride stress corrosion cracking and pitting corrosion can damage equipment. Chemical processing plants containing chlorinated chemicals, acidic solutions, or high-temperature oxidizing conditions typically encounter premature stainless steel failures that require costly replacements and unplanned maintenance shutdowns.

The passive oxide layer in grade 2 titanium plate regenerates continually, protecting it from corrosion. The material retains mechanical qualities at temperatures that would weaken stainless steel or create stress corrosion fractures, especially in chloride-containing chemical processing settings.

Economic Considerations and Total Cost of Ownership

When considering equipment longevity, maintenance, and operational reliability, initial material prices are only a small part of ownership costs. Titanium costs more than stainless steel or aluminum, but its longer service life and lower maintenance costs frequently lead to better economic performance during equipment lifecycles.

Chemical processing facility maintenance cost assessments show that titanium components replace stainless steel alternatives in corrosive service applications, reducing downtime and replacement frequency. These long-term savings frequently justify the equipment's original investment price.

Strength and Durability Comparisons

Grade 2 titanium has good mechanical qualities for pressure vessel and structural applications. With tensile strength from 345 to 483 MPa and yield strength from 275 to 410 MPa, the material performs well under mechanical stress and resists fatigue.

Titanium is stronger and corrosion-resistant than aluminum alloys, which are lighter. Aluminum degrades quickly in alkaline or high-temperature chemical processing settings, compromising equipment dependability and safety.

How to Procure High-Quality Gr2 Titanium Plates?

Supplier Evaluation and Certification Requirements

Suppliers with extensive quality management systems and applicable industry certifications are the foundation of successful procurement. ASTM compliance assures material specifications satisfy worldwide chemical processing standards, while ISO 9001:2015 accreditation guarantees quality control methods are consistent.

Manufacturing, quality control, and traceability documentation systems that enable regulatory compliance should be evaluated in suppliers. Leading suppliers provide complete traceability from raw material sourcing to product delivery with material certificates, mechanical property test reports, and chemical composition analysis.

Custom Processing and Dimensional Flexibility

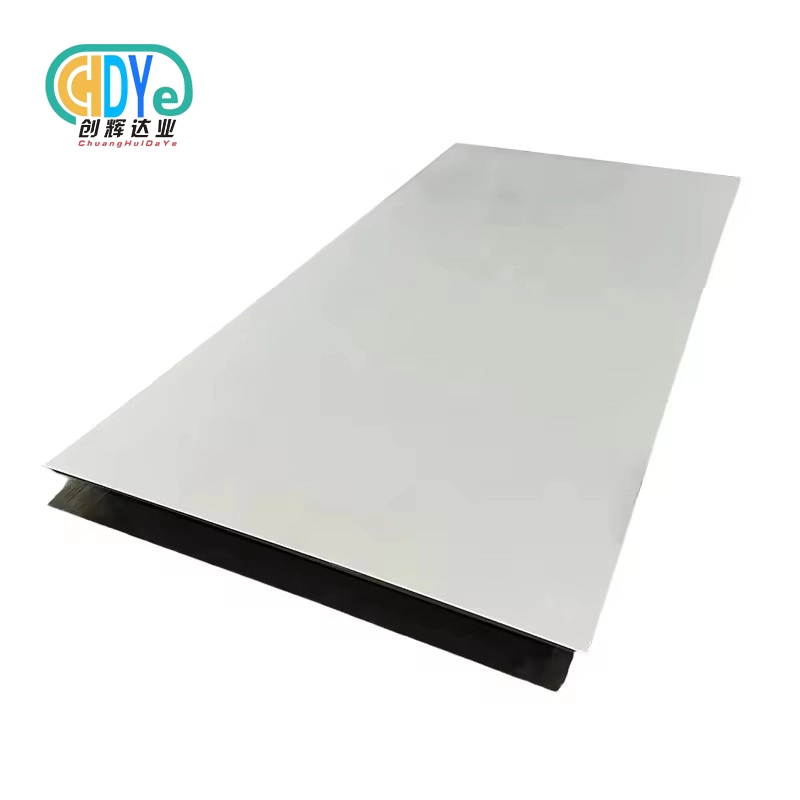

Standard stock materials cannot meet chemical processing equipment's plate size, surface treatments, or edge preparations. Reliable vendors offer bespoke cutting, precision machining, and surface treatments to eliminate extra processing and shorten project schedules.

Our processing capabilities include unique plate dimensions up to 2000 mm width and thicknesses from thin sheets to heavy plates over 100 mm. Water jet cutting, plasma cutting, and precision sawing ensure dimensional accuracy and edge quality for welding and fabrication.

International Logistics and Supply Chain Management

Global procurement demands vendors with logistical networks and export facilitation capabilities to expedite international transactions. Comprehensive documentation, customs clearance, and shipment coordination eliminate delivery delays and ensure international commerce compliance.

Supply chain stability is crucial for major projects because material delivery dates affect construction timetables. For rigorous project needs, suppliers with significant inventory, flexible production scheduling, and established shipping partnerships are responsive.

Advantages of Using High-Quality Gr2 Titanium Plates in Chemical Processing

Corrosion Resistance in Aggressive Environments

Gr2 Titanium Plate has excellent corrosion resistance because it forms a durable, protective oxide layer that regenerates when damaged. The passive layer protects against chloride stress corrosion cracking, pitting corrosion, and other corrosion mechanisms that damage traditional materials in chemical processing environments.

Titanium components in chlorine manufacturing, pulp bleaching, and petrochemical refining have longer lifecycles and lower maintenance than stainless steel. The material resists acidic, alkaline, and oxidizing conditions found in most chemical processing applications.

Temperature and Pressure Performance

Grade 2 titanium retains mechanical qualities from cryogenic to 400°C, which is common in chemical processing. The thermal expansion coefficient and thermal conductivity of the material ensure steady dimensional behavior under thermal cycle circumstances that challenge conventional materials.

Titanium's fatigue resistance and strength-to-weight ratio improve pressure vessel applications. The material's resistance to pressure variations and fatigue cracks improves operational safety and decreases inspection needs.

Operational Safety and Maintenance Benefits

Titanium is biocompatible and non-toxic, eliminating material degrading product health and safety issues to process streams and workers. This is useful in pharmaceutical, food processing, and specialty chemical industries where product purity requires strict material standards.

Maintenance reduction lowers operational costs and increases plant availability. When titanium components replace stainless steel in aggressive service applications, chemical processing facilities save over 40% on maintenance and increase safety owing to fewer equipment failures.

Company Introduction and Product & Service Information

From China's "Titanium Capital" in Baoji High-tech Development Zone, Shaanxi Chuanghui Daye Metal Material Co., Ltd. has over 30 years of rare metal manufacturing and processing experience. Our titanium plates, rods, tubes, wires, and precision-machined components meet international standards for worldwide B2B markets.

Our modern production facilities have vacuum melting equipment, precision rolling mills, and extensive machining for specialized fabrication. Chemical processing applications require constant product quality, which electron beam furnaces, controlled environment annealing systems, and precise measuring equipment provide.

Our production procedures, from raw material inspection to product packing and transportation, follow ISO 9001:2015 quality assurance methods. Our quality extends beyond manufacturing to technical support, application engineering, and thorough documentation to help customers succeed in difficult situations.

Organizations seeking trusted titanium material suppliers choose us for our technical experience, manufacturing competence, and customer-focused service. Our global export experience and logistical networks provide flawless international transactions at affordable prices to promote customer profitability.

Conclusion

Gr2 Titanium Plate for chemical processing is a strategic investment in operational excellence, safety, and long-term cost optimization. Chemical processing equipment that needs to perform in harsh environments should use the material due to its corrosion resistance, mechanical durability, and proven performance in demanding environments. Our comprehensive analysis shows that titanium selection in critical applications is economically justified by its longer equipment lifecycles, lower maintenance, and improved operational safety, even though initial material costs may be higher.

FAQ

Q: What makes Grade 2 titanium plate ideal for chemical processing applications?

A: Grade 2 titanium plate offers an exceptional combination of corrosion resistance, mechanical strength, and formability that makes it particularly suitable for chemical processing environments. The material's passive oxide layer provides immunity to chloride stress corrosion cracking and pitting corrosion that commonly affect stainless steel in aggressive chemical environments. Additionally, the biocompatibility and non-toxic nature of titanium eliminate contamination concerns in sensitive applications while maintaining structural integrity under temperature and pressure variations typical in chemical processing operations.

Q: How does Grade 2 compare to Grade 5 titanium in terms of cost and performance?

A: Grade 2 titanium provides superior corrosion resistance and formability compared to Grade 5, making it more suitable for chemical processing applications where aggressive media exposure is the primary concern. While Grade 5 offers higher strength characteristics, the additional alloying elements increase material costs and can reduce corrosion resistance in certain environments. Grade 2 represents the optimal balance of performance and cost-effectiveness for most chemical processing applications, particularly where moderate strength requirements allow the corrosion resistance advantages to justify material selection decisions.

Q: Can you provide custom-sized Grade 2 titanium plates for specialized equipment requirements?

A: Our manufacturing capabilities support extensive customization options including plate dimensions up to 2000 mm width, thickness variations from thin sheets to heavy plates exceeding 100 mm, and specialized surface finishes or edge preparations. Custom cutting services utilizing water jet, plasma cutting, and precision sawing technologies ensure dimensional accuracy while maintaining edge quality standards essential for welding and fabrication operations. Technical support services assist with specification development and application engineering to optimize material selection for specific equipment requirements.

Contact Chuanghui Daye for Premium Gr2 Titanium Plate Solutions

Leverage our three decades of titanium manufacturing expertise to enhance your chemical processing operations with premium Grade 2 titanium plates that deliver exceptional corrosion resistance and reliability. As a leading Gr2 Titanium Plate manufacturer, Chuanghui Daye combines advanced processing capabilities with comprehensive quality assurance to support your most demanding applications. Our technical specialists provide personalized consultation services, competitive pricing structures, and flexible production scheduling that streamline procurement processes while ensuring optimal material performance. Contact our team at info@chdymetal.com to discuss your specific requirements and experience the advantages of partnering with a trusted titanium supplier committed to your operational success.

References

1. ASTM International. "Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM B265-20, West Conshohocken, PA, 2020.

2. Boyer, R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, OH, 1994.

3. Schutz, R.W. "Corrosion of Titanium and Titanium Alloys in Chemical Process Industries." Materials Performance, Vol. 45, No. 7, 2006.

4. Donachie, Matthew J. "Titanium: A Technical Guide, Second Edition." ASM International, Materials Park, OH, 2000.

5. Cotton, J.D. "Titanium in Chemical and Petrochemical Applications." Materials and Corrosion, Vol. 58, No. 4, 2007.

6. International Organization for Standardization. "Implants for Surgery - Metallic Materials - Titanium." ISO 5832-2:2018, Geneva, Switzerland, 2018.

Learn about our latest products and discounts through SMS or email