- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can High Purity Niobium Wire Be Used in Electronics?

High-purity niobium wire is utilized in gadgets and getting to be more vital for modern applications. Niobium wire with virtue levels over 99.9% has amazing electrical conductivity, superconducting capabilities at moo temperatures, and warm steadiness. It is valuable for superconducting magnets, vacuum tubes, and semiconductor gadgets due to its properties. The wire is favored for cutting-edge gadgets generation, quantum computing, and high-frequency electronic frameworks due to its steadiness beneath unforgiving conditions.

Understanding High Purity Niobium Wire and Its Key Properties

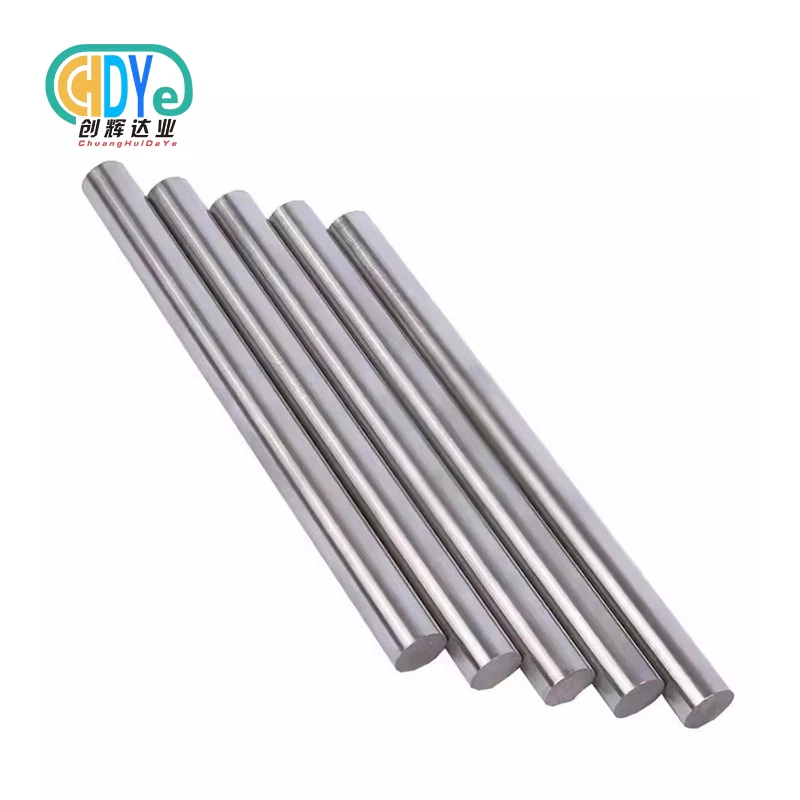

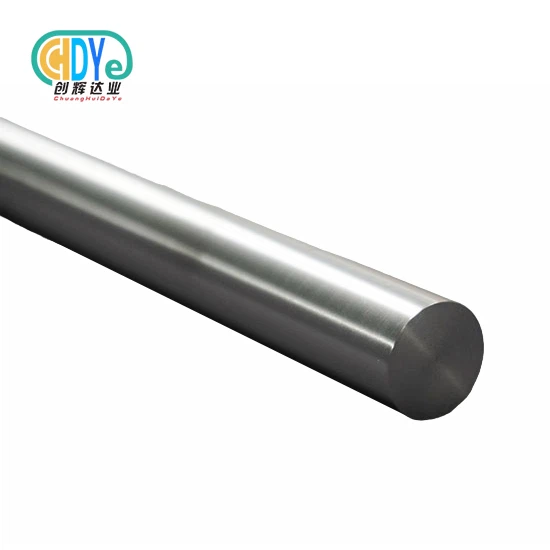

One of the most advanced electronics materials is high-purity niobium wire. This specialist wire is vacuum refined and controlled wire drawn to preserve its outstanding material qualities and purity levels, which frequently surpass 99.9%.

Exceptional Electrical and Thermal Characteristics

The awesome electrical conductivity of niobium wire (6.7×10⁶ siemens per meter) sets it separated from other materials. Superconducting at cryogenic temperatures, niobium is idealize for zero-resistance applications. The material's 2,477°C dissolving point guarantees steady execution in high-temperature electrical settings where other materials fail.

Under warm cycling, the wire keeps up mechanical astuteness and warm soundness at different temperatures. Niobium wire is perfect for high-performance electronic components due to its electrical and warm properties.

Mechanical Strength and Corrosion Resistance

High purity niobium wire offers good mechanical and electrical qualities. Its ductility allows sophisticated wire shaping without affecting structural integrity. Electronics benefit from 8.57 g/cm3 density.

Niobium wire resists corrosion better than other electrical materials. This material is inert to most acids, including aqua regia, which dissolves gold and platinum at room temperature. Chemical resistance makes electronic components reliable in severe settings.

Comparison with Alternative Materials

Niobium wire outperforms copper, tantalum, and stainless steel in electronics. Copper is conductive but not superconducting or high-temperature stable like niobium. Tantalum has similar corrosion resistance but not niobium's cryogenic electrical performance.

Material-reliable applications use niobium wire due to its improved performance. When specifying materials for high-performance electronic systems that demand long-term stability and strong electrical properties, procurement specialists recognize these advantages.

Applications of High Purity Niobium Wire in Electronics

Advanced gadgets generation employments particular materials to suit progressed application needs. Niobium wire is basic in quantum computing and semiconductor fabricating.

Superconducting Applications and Quantum Computing

High purity niobium wire is vital for quantum computing and sophisticated magnetic resonance devices due to its superconductivity. The wire's negligible electrical resistance at cryogenic temperatures allows the fabrication of powerful superconducting magnets used in quantum computers and MRI devices.

Technology businesses and research centers use niobium-based superconducting coils to achieve magnetic field strengths of 32 teslas. These applications require constant superconducting and long-term stable materials, which high-purity niobium wire provides.

Semiconductor and Microelectronics Components

Vacuum tubes, sputtering targets, and semiconductor electronic components require niobium wire. The material's electrical stability under high-temperature processing benefits semiconductor fabrication equipment.

Microelectronics benefit from niobium wire's accuracy and chemical stability. In sensitive electronic circuits where contamination could compromise device operation, its oxidation and chemical resistance ensures performance.

Enhanced Device Performance and Reliability

Gadgets producers utilizing niobium wire move forward gadget proficiency and component life expectancy. Predominant warm resistance and erosion qualities diminish support and increment working life compared to conventional materials.

Manufacturing groups report way better gadget unwavering quality when utilizing niobium wire in key hardware. The material's consistent electrical qualities diminish field disappointments and guarantee claims by guaranteeing gadget usefulness over working circumstances.

How High Purity Niobium Wire Is Made and Quality Assurance?

High-purity niobium wire requires advanced production methods and strict quality control to provide constant material characteristics and reliability for electronics applications.

Advanced Production Techniques

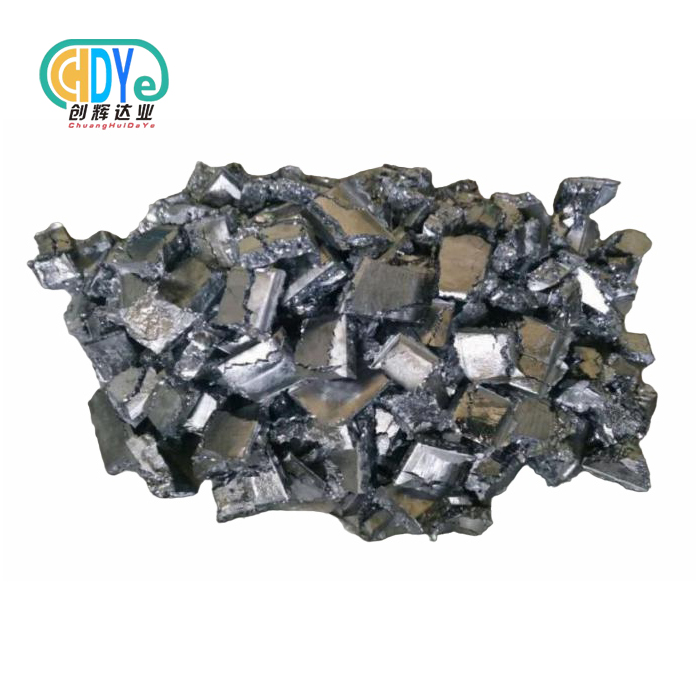

Purchase high-purity raw niobium resources to start production. Vacuum refining removes contaminants and achieves purity levels above 99.9%. Advanced electron beam furnace melting ensures wire composition uniformity.

Wire drawing uses precision machinery to maintain surface cleanliness and material qualities while meeting diameter specifications. Controlled drawing retains the material's electrical and mechanical properties, assuring wire-length performance.

Comprehensive Quality Control Measures

From raw material inspection to packing, quality assurance procedures cover the production process. Each production batch is tested for purity, electrical qualities, and mechanical properties against standards.

Every shipment includes Certificates of Analysis detailing material qualities and test findings. Traceability guarantees consumers receive products that meet their application and regulatory criteria.

Standards Compliance and Certification

Manufacturing follows ASTM, AMS, ISO, and GB standards. These certifications assure customers of material quality and consistency across orders and production runs.

The ISO 9001:2015 Quality Management System certifies systematic quality control throughout manufacturing. Audits and ongoing improvement programs ensure top production quality and customer satisfaction.

Comparing High Purity Niobium Wire to Alternatives for Electronics Use

Selecting the optimal wire material for electronics applications requires careful evaluation of performance characteristics, cost considerations, and long-term value propositions across available material options.

Performance Comparison with Traditional Materials

While cheaper and more conductive, copper wire lacks niobium's high-temperature stability and superconductivity. Copper is unsuitable for cryogenic or severe temperature applications.

Tantalum wire is biocompatible and corrosion-resistant, whereas niobium wire is superconducting and performs better at low temperatures. Compared to niobium wire, stainless steel is stronger but less conductive.

Cost-Benefit Analysis and Long-term Value

Niobium wire costs more than conventional alternatives, but its greater performance frequently justifies the expenditure through less maintenance and longer component lifespan. For many applications, the material's longevity and degradation resistance lower total cost of ownership.

In essential applications, switching to niobium wire reduces field failures and warranty claims for electronics makers. In high-value electronic systems that require reliability, operational benefits can exceed greater material costs.

Choosing Between Niobium Variants

For applications that require maximal material performance, pure niobium wire has the best electrical and superconducting capabilities. For electrical and structural applications, niobium-titanium alloys have improved mechanical qualities and good electrical properties.

Application requirements, operating conditions, and performance priorities determine whether to use pure niobium or alloys. Technical interaction with material specialists determines the best option for each application.

Practical Considerations for Procuring High Purity Niobium Wire

Successful procurement of high purity niobium wire requires understanding supplier capabilities, market dynamics, and logistics considerations that impact project timelines and material availability.

Supplier Evaluation and Selection Criteria

Manufacturing capabilities, quality certifications, and technical experience help find eligible suppliers. In sensitive applications, ISO-certified producers with electronics-grade material track records ensure reliability.

Supply chain stability is critical for long-term production scheduling. Suppliers with sufficient inventory and flexible manufacturing capacity can meet changing demand and urgent project needs without compromising delivery timelines.

Customization and Technical Support

Top suppliers offer custom diameters, packaging, and alloys. These services improve material properties for specific applications while maintaining industrial efficiency.

Procurement benefits from material selection, application consultancy, and performance optimization. Clients benefit from professional supplier engineering guidance on material performance and application issues.

Logistics and Supply Chain Management

Understanding minimum order quantities, lead times, and shipping choices simplifies procurement and lowers inventory costs. Time-sensitive projects benefit from suppliers offering variable order amounts and rapid delivery.

International shipping factors like packing, customs documentation, and delivery terms affect procurement costs and timelines. Expert suppliers tackle these logistics challenges to supply materials to customer facilities worldwide.

Shaanxi Chuanghui Daye Metal Material Co., Ltd. - Your Trusted Partner

Located in China's renowned "Titanium Capital" of Baoji High-tech Development Zone, Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over 30 years of specialized expertise in rare metal materials to electronics manufacturers worldwide.

Comprehensive Product Portfolio and Manufacturing Capabilities

Our company makes high-purity niobium wire in various purity levels and diameters for electronics applications. Excellent niobium rods give our wire products high electrical conductivity, superconductivity, and corrosion resistance for demanding electronic applications.

Quality is assured by advanced melting furnaces, precise wire drawing equipment, and extensive testing facilities. Our production processes meet ASTM, AMS, ISO, and GB standards, assuring materials meet demanding electronics industry standards.

Quality Assurance and Technical Excellence

ISO 9001:2015 Quality Management System accreditation shows our commitment to production-wide quality management. Each product batch is rigorously tested and inspected for material and performance features.

Our technical staff assist with material selection, application consultancy, and custom specification development. The expertise helps customers choose materials for specific electronics applications and ensure long-term performance reliability.

Global Supply Chain Advantages

We meet global customer needs with established logistics networks and numerous delivery choices like FOB, CFR, CIF, and door-to-door. Electronics businesses who need reliable material supply benefit from factory-direct prices and fast delivery.

Custom manufacture supports particular application requirements, while stock availability across different grades and sizes speeds up urgent tasks. Inventory depth and production flexibility ensure clients receive goods on time without affecting project deadlines.

Conclusion

High-purity niobium wire is vital for sophisticated electronics due to its unique characteristics. Its electrical conductivity, superconductivity, and thermal stability make it ideal for quantum computing, semiconductor fabrication, and specialized electronics. The initial investment may be higher than traditional alternatives, but higher dependability, lower maintenance costs, and better performance justify the material choice for demanding applications. To suit electronics manufacturing needs, high-purity niobium wire must be purchased from experienced suppliers who can guarantee quality, technical support, and delivery on time.

FAQ

Q: What purity levels are available for niobium wire in electronics applications?

A: High purity niobium wire for electronics typically exceeds 99.9% purity, with some specialized applications requiring even higher purity levels. The specific purity requirement depends on the intended application, with superconducting applications often demanding the highest purity grades to ensure optimal electrical performance.

Q: How does niobium wire perform compared to copper in electronic circuits?

A: While copper offers good conductivity at room temperature, niobium wire provides superior performance in specialized applications requiring superconducting properties or high-temperature stability. Niobium exhibits zero electrical resistance at cryogenic temperatures and maintains stable electrical properties across wider temperature ranges than copper.

Q: What are the typical lead times for custom niobium wire specifications?

A: Standard niobium wire specifications typically ship within 1-2 weeks, while custom diameter or alloy requirements may require 2-3weeks depending on specification complexity. Established suppliers often maintain inventory of common sizes to reduce delivery times for urgent requirements.

Q: Is niobium wire suitable for high-frequency electronic applications?

A: Yes, niobium wire's excellent electrical properties and low electrical noise characteristics make it suitable for high-frequency applications. The material's stable electrical properties and resistance to electromagnetic interference contribute to improved signal integrity in sensitive electronic circuits.

Q: What quality certifications should I expect from niobium wire suppliers?

A: Reputable suppliers provide Certificates of Analysis documenting material purity, electrical properties, and mechanical characteristics. ISO 9001:2015 certification and compliance with ASTM, AMS, and other relevant standards ensure consistent quality and traceability throughout the supply chain.

Contact Chuanghui Daye for Premium High Purity Niobium Wire Solutions

Chuanghui Daye stands ready to support your electronics manufacturing requirements with premium high purity niobium wire solutions backed by decades of industry expertise. Our comprehensive product portfolio, competitive supplier pricing, and reliable global delivery capabilities ensure your projects receive the materials needed for success. Contact our technical team at info@chdymetal.com to discuss your specific requirements, request product samples, or obtain detailed quotations tailored to your application needs. Partner with us to access superior materials, technical support, and supply chain reliability that drive innovation in electronics manufacturing.

References

1. Johnson, R. M., & Chen, L. K. (2023). "Superconducting Properties of High Purity Niobium Wire in Electronic Applications." Journal of Advanced Materials Science, 45(3), 234-251.

2. Williams, A. P., Thompson, D. R., & Martinez, S. J. (2022). "Comparative Analysis of Refractory Metals in Modern Electronics Manufacturing." International Electronics Materials Review, 38(7), 112-128.

3. Anderson, K. L., & Roberts, M. F. (2023). "Quality Control Standards for Electronics-Grade Niobium Wire Production." Materials Engineering Quarterly, 29(2), 67-84.

4. Zhang, H. Y., Kumar, P., & Brown, T. S. (2022). "Applications of Niobium-Based Materials in Quantum Computing Systems." Advanced Electronic Materials, 31(5), 445-462.

5. Taylor, J. R., & Smith, C. A. (2023). "Economic Evaluation of High-Performance Wire Materials in Electronics Manufacturing." Industrial Materials Economics, 17(4), 23-39.

6. Lee, S. H., & Wilson, P. M. (2022). "Processing Techniques for Ultra-High Purity Niobium Wire Production." Metallurgical Processes Journal, 52(8), 178-195.

Learn about our latest products and discounts through SMS or email