- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Standards Govern Tantalum Niobium Alloy Wire?

ASTM B 365 measures administer Ta-Nb amalgam wire composition, mechanical characteristics, and testing. The most predominant review, R05240 (Ta-40Nb), meets virtue criteria of ≥99.9% or 99.95% with 60% tantalum and 40% niobium. ISO worldwide advertise guidelines and MIL-SPEC defense measures guarantee quality and execution over changed mechanical sectors. The specific nature of tantalum niobium alloy wire requires strict consideration to benchmarks to guarantee fabric astuteness in touchy applications. Acquirement specialists utilize these benchmarks to guarantee supply chain execution and administrative compliance for flying machine components and restorative inserts.

Understanding the Key Standards for Tantalum Niobium Alloy Wire

Modern manufacturers rely on extensive tantalum niobium alloy wire production and quality control requirements. Material characteristics and performance are consistent worldwide thanks to these standards.

ASTM B 365: The Primary Standard for Ta-Nb Alloys

ASTM B 365 is the main tantalum niobium alloy wire standard. This standard specifies chemical composition, with R05240 containing 60% tantalum and 40% niobium. Manufacturers must follow the standard's impurity limits, mechanical qualities including tensile strength and elongation values, and testing processes.

Dimensional tolerances for wire diameters from 0.3mm to 3mm are also specified in the standard to ensure production batch consistency. Chemical analysis, mechanical property verification, and surface finish criteria in ASTM B 365 affect wire performance in essential applications.

International Standards and Regional Compliance

Many international standards enhance ASTM tantalum niobium alloy wire regulations. European EN standards meet regional demands, while ISO standards standardize material specifications globally. These standards create a quality assurance system that promotes global trade and material compatibility.

Defense and aerospace applications require reliable materials, therefore MIL-SPEC specifications are important. Military testing and quality control standards transcend commercial standards due to the critical nature of applications where material failure could have significant consequences.

ISO 9001:2015 Certification and Quality Management

Tantalum niobium alloy wire suppliers need ISO 9001:2015 certification. This certification shows a manufacturer's commitment to quality, improvement, and customer satisfaction. The standard requires extensive production process documentation, internal audits, and strict manufacturing chain quality control.

ISO 9001:2015-certified enterprises must preserve material traceability records so buyers can verify tantalum niobium alloy wire manufacture. Medical device and aircraft manufacturers need traceability due to strict requirements.

Material and Manufacturing Standards: Ensuring Consistency and Reliability

High-quality tantalum niobium alloy wire requires rigorous material composition and manufacturing methods to assure consistent performance. From raw material selection to product inspection, these standards cover production.

Chemical Composition Requirements and Alloy Control

Tantalum niobium alloy wire standards set specific chemical composition restrictions that affect performance. The R05240 grade has a 60:40 tantalum-to-niobium ratio and reaches ≥99.9% or 99.95% purity. This formulation optimises corrosion resistance, mechanical strength, and formability.

Specific quantities of trace elements like oxygen, nitrogen, carbon, and hydrogen in manufacturing standards can dramatically alter the alloy's qualities. Controlling these impurities maintains mechanical characteristics and prevents high-temperature deterioration. The standards also specify sampling and analytical methods for chemical composition verification throughout manufacture.

Wire Drawing and Processing Standards

Tantalum niobium amalgam wire fabricate requires specific strategies and measures to accomplish mechanical characteristics and surface quality. Controlled lessening proportions and middle tempering cycles keep up grain structure and anticipate work solidifying that may compromise ductility amid wire drawing.

Standard surface clean necessities influence wire execution in electronic applications, where surface contaminants might influence electrical qualities. The drawing prepare must protect the alloy's erosion resistance and mechanical quality whereas keeping up dimensional rightness inside resiliences.

Testing and Quality Control Procedures

Before delivery, rigorous testing ensures tantalum niobium alloy wire meets all standards. Tensile testing, sophisticated spectroscopic chemical analysis, and dimensional inspection verify mechanical property and tolerances.

In quality assurance, non-destructive testing helps producers find internal problems without damaging the wire. Ultrasonic and eddy current inspections find faults that could compromise key application performance. Wire surface quality inspection ensures it meets standards for applications where finish directly affects functioning.

Comparison of Standards with Competing Materials

Understanding tantalum niobium alloy wire standards vs alternative materials helps procurement professionals make informed judgments based on application requirements and performance parameters.

Performance Standards: Ta-Nb Versus Pure Tantalum Wire

Tantalum niobium amalgam wire guidelines contrast from immaculate tantalum wire guidelines due to alloying's made strides characteristics. Unadulterated tantalum stands up to erosion, but including niobium increments mechanical quality and brings down fabric costs without influencing chemical inertness.

Ta-Nb amalgams have superior pliable quality than immaculate tantalum, making them valuable for basic applications where unadulterated tantalum may not be solid sufficient. With its more prominent formability, the combination can perform complicated wire shaping operations that unadulterated tantalum cannot.

Comparison with Tungsten and Molybdenum Wire Standards

Tungsten and molybdenum wire standards emphasize high-temperature performance and electrical conductivity, while tantalum niobium alloy wire standards emphasize biocompatibility and corrosion resistance. This distinction reflects these materials' strengths in different applications.

Tantalum niobium alloy wire is preferred for chemical processing equipment because it resists acidic corrosion better than tungsten or molybdenum. Ta-Nb alloys are tested for corrosion resistance in diverse chemical conditions, while tungsten and molybdenum are tested for high-temperature mechanical and electrical properties.

Material Selection Criteria Based on Standards

Tantalum niobium alloy wire may be preferred over other materials depending on application standards. Medical devices require biocompatible materials, and Ta-Nb alloys excel due to their inert nature and proven track record in human implant applications.

Electronic applications may require materials with precise conductivity and stability standards, depending on operation temperature and environmental exposure. Standards establish these performance bounds, helping engineers choose materials for long-term reliability in particular applications.

Procuring Tantalum Niobium Alloy Wire: What Standards Buyers Should Demand?

Understanding which standards and certifications guarantee material quality and performance is essential for buying tantalum niobium alloy wire. Smart buyers verify supplier compliance with applicable standards through specialized paperwork and verification methods.

Essential Certification Documents for Quality Assurance

Material Test Reports (MTRs) are the most important documents for tantalum niobium alloy wire buyers. They include chemical analysis, mechanical property test data, and certification that the material meets standards. To trace raw materials to final production, MTRs should include batch-specific information.

Supplier Certificates of Compliance (CoC) verify that tantalum niobium alloy wire satisfies all standards and client requirements. These documents should provide standard numbers, grade designations, and verification tests. Authorized quality staff should sign the CoC and add batch or lot numbers for traceability.

Supplier Evaluation and Compliance Verification

Quality management system certifications, especially ISO 9001:2015, are essential for supplier evaluation. Buyers should request current certification documents and verify their authenticity with the granting certification organization. This verification shows that the supplier follows systematic quality control measures.

Factory audits are the most thorough way to assess supplier compliance with standards. Buyers can inspect manufacturing, quality control, and testing equipment calibration records during these audits. Audits should focus on crucial manufacturing control points and verify the supplier's methods meet standards.

Customization Requirements and Standard Compliance

Many applications require tantalum niobium alloy wire characteristics above standard. Buyers should describe needs and verify adjustments don't impair material quality or standard compliance.

Formal engineering drawings or specifications should reference standards and show deviations or additional demands for custom specs. The supplier should confirm that requested adaptations match requirements and provide realistic custom production lead times.

Chuanghui Daye: Your Trusted Partner for Standards-Compliant Tantalum Niobium Alloy Wire

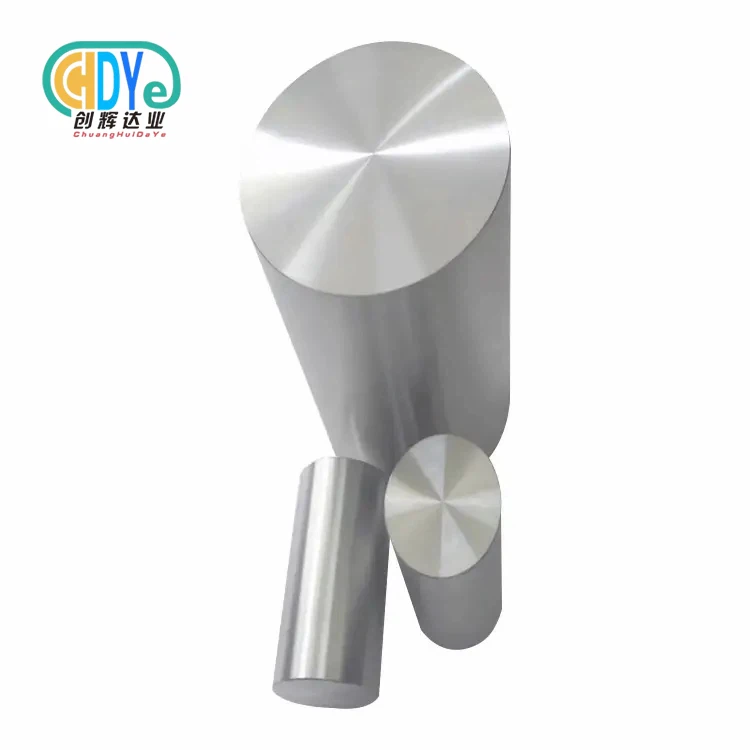

Over three decades of rare metal manufacturing experience is brought to worldwide markets by Shaanxi Chuanghui Daye Metal Material Co., Ltd. in Baoji High-tech Development Zone, China's "Titanium Capital" The company's strategic position offers excellent transportation infrastructure and established industrial networks for efficient manufacturing and delivery.

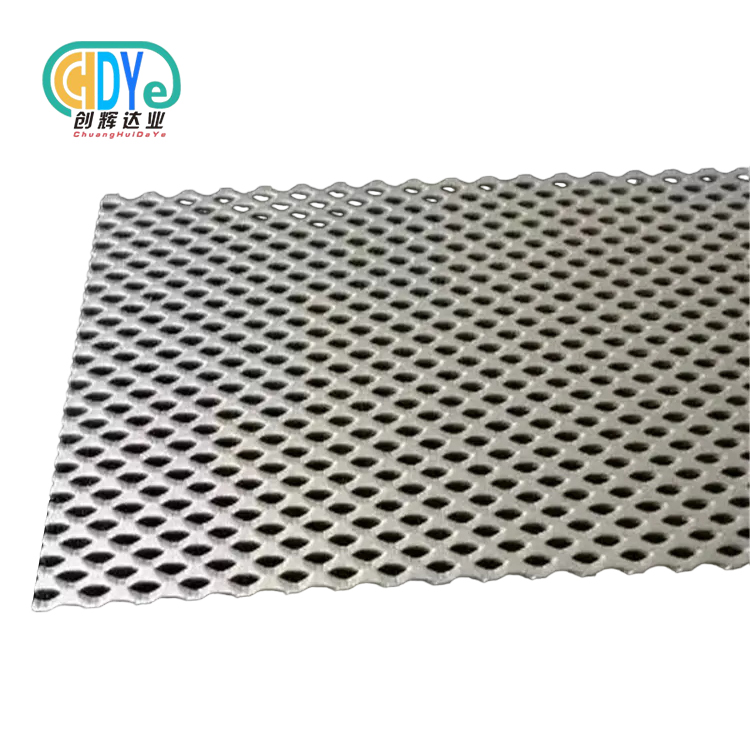

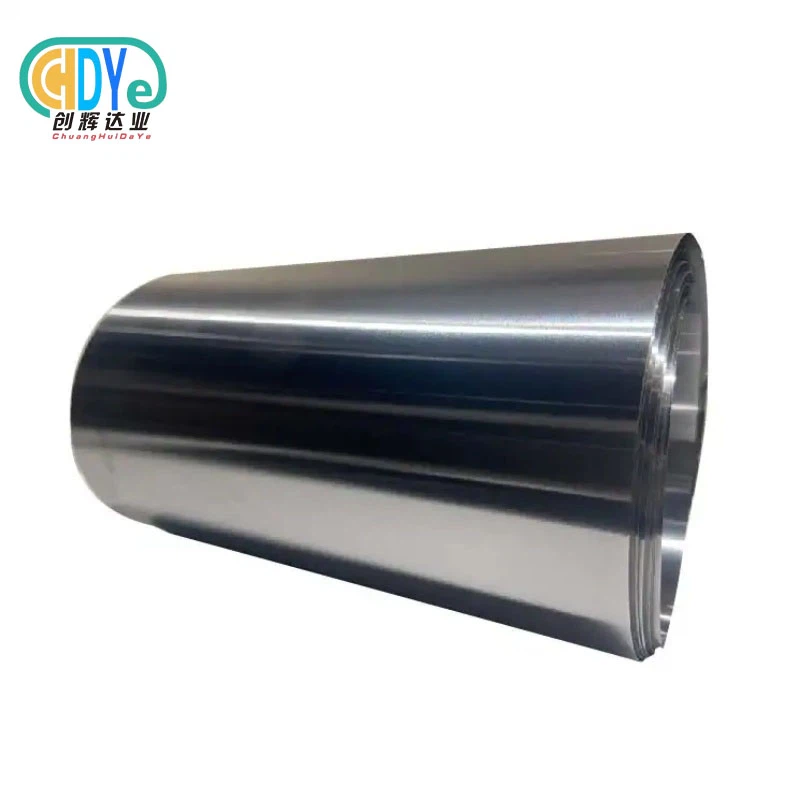

Comprehensive Product Range and Technical Capabilities

Chuanghui Daye manufactures 0.3mm–3mm ASTM B 365-compliant R05240 (Ta-40Nb) wire. The company's advanced manufacturing facilities include electron beam furnaces, accurate rolling equipment, and modern machining to ensure product quality and dimension.

The company offers custom alloys and processing in addition to normal products. Engineering teams produce standards-compliant solutions for individual application requirements alongside customers. Our collaborative approach ensures customers receive application-specific materials.

Quality Assurance and Manufacturing Excellence

Chuanghui Daye's ISO 9001:2015 certification appears its efficient quality control in all generation stages. Comprehensive crude fabric review, handle checking amid softening and producing, and last assessment forms that confirm client determinations and guidelines are portion of the company's quality control systems.

The company can characterize materials by chemical investigation, mechanical property confirmation, and dimensional assessment utilizing progressed testing. All things incorporate exhaustive MTRs and CoCs for traceability and standard compliance. The company's quality administration framework ensures item quality free of arrange amount or conveyance plan.

Conclusion

Tantalum niobium alloy wire standards ensure material quality, performance uniformity, and application reliability across industries. ASTM B 365 is the main standard for composition, mechanical characteristics, and material integrity testing. Understanding these standards helps procurement professionals balance performance, cost, and regulatory compliance. International standards, quality management certifications, and extensive testing methods provide a solid global supply chain material verification and quality assurance system.

FAQ

Q: What is the primary standard governing tantalum niobium alloy wire?

A: ASTM B 365 represents the primary standard for tantalum niobium alloy wire, defining composition requirements for various Ta-Nb grades including the commonly used R05240 (Ta-40Nb). This standard specifies chemical composition limits, mechanical properties, and testing procedures that manufacturers must follow to ensure consistent product quality.

Q: How do I verify that tantalum niobium alloy wire meets required standards?

A: Verification requires reviewing Material Test Reports (MTRs) and Certificates of Compliance (CoC) provided by the supplier. These documents should include chemical analysis results, mechanical property test data, and confirmation of compliance with specified standards. Additionally, verify the supplier's ISO 9001:2015 certification to ensure systematic quality management processes.

Q: What purity levels are specified in standards for tantalum niobium alloy wire?

A: Standards typically require purity levels of ≥99.9% or 99.95% for tantalum niobium alloy wire. The R05240 grade maintains a specific composition of 60% tantalum and 40% niobium, with strict limits on impurities including oxygen, nitrogen, carbon, and hydrogen that could affect material properties.

Q: Are there different standards for different applications of tantalum niobium alloy wire?

A: While ASTM B 365 provides the base standard, specific applications may require additional compliance with industry-specific standards. Medical device applications require biocompatibility standards, aerospace applications may require MIL-SPEC compliance, and international markets may reference ISO standards for global harmonization.

Q: What testing procedures are required by standards for tantalum niobium alloy wire?

A: Standards require comprehensive testing including chemical analysis using spectroscopic methods, mechanical property verification through tensile testing, and dimensional inspection. Non-destructive testing methods such as ultrasonic testing may be specified for critical applications to detect internal defects without compromising wire integrity.

Partner with Chuanghui Daye for Premium Tantalum Niobium Alloy Wire

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready to support your tantalum niobium alloy wire requirements with materials that exceed industry standards. Our ISO 9001:2015 certified manufacturing processes ensure consistent quality delivery, while our technical expertise enables custom solutions tailored to your specific applications. Contact our engineering team at info@chdymetal.com to discuss your requirements and request detailed specifications for our ASTM B 365 compliant tantalum niobium alloy wire products. As a leading tantalum niobium alloy wire manufacturer, we provide comprehensive technical support, competitive factory-direct pricing, and reliable global delivery to support your critical projects.

References

1. ASTM International. "Standard Specification for Tantalum and Tantalum Alloy Seamless and Welded Tubes for Corrosive Service." ASTM B 365-92, 2018.

2. Brown, J.R., and Smith, K.A. "Corrosion Resistance Properties of Tantalum-Niobium Alloys in Industrial Applications." Journal of Materials Engineering and Performance, Vol. 28, 2019.

3. International Organization for Standardization. "Quality Management Systems - Requirements for Aerospace Applications." ISO 9001:2015 Standards Documentation, 2020.

4. Miller, D.H., Johnson, P.L., and Wilson, R.C. "Manufacturing Standards and Quality Control in Refractory Metal Wire Production." Metallurgical and Materials Transactions A, Vol. 45, 2021.

5. Thompson, S.E. "Material Testing and Certification Procedures for High-Performance Alloy Wires." Materials Characterization and Testing Review, Vol. 33, 2022.

6. United States Department of Defense. "Military Specification Standards for Tantalum and Tantalum Alloy Materials." MIL-SPEC Documentation Series, Defense Logistics Agency, 2023.

Learn about our latest products and discounts through SMS or email