- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are Typical Uses of Tantalum Tube and Pipe?

Due to erosion resistance, biocompatibility, and warm soundness, tantalum tube and pipe are utilized in numerous high-performance businesses. These specialized components are fundamental for chemical preparing, semiconductor generation, restorative gadgets, and aviation. Tantalum tubes and channels are basic in cruel settings where dependable, long-lasting arrangements that hold virtue and auxiliary astuteness are required.

Introduction to Tantalum Tubes and Pipes

Tantalum's characteristics explain why it shines in tubular applications. Tantalum is one of the most thermally stable industrial metals, melting above 2996°C. This heat resistance and corrosion immunity against most acids except hydrofluoric acid and strong alkalis at high temperatures make it exceptional.

Unique Physical and Chemical Properties

Tantalum performs well because to its dense oxide layer that occurs naturally in air. Even in harsh conditions with hydrochloric, sulfuric, and nitric acid, this barrier resists chemical attack like no other. The material is biocompatible and suited for medicinal applications that touch human tissue.

Manufacturing complicated shapes without compromising structural integrity is possible with tantalum's exceptional cold-working properties. This formability allows seamless tubes with precise dimensional tolerances for applications demanding precision specifications and leak-proof performance.

Distinguishing Tubes from Pipes

Tantalum tubes and pipes differ mostly in size and usage, although are commonly used interchangeably. For precision fluid handling or electrical applications, tubes have smaller diameters and thinner walls. Pipes are designed for structural support and high-pressure applications with greater diameters and thicker walls.

Dimensional variances effect manufacturing and performance. Welded tantalum tubes are cheaper but less strong and pressure-resistant than seamless ones.

Typical Industrial Applications of Tantalum Tubes and Pipes

Tantalum tube excels in several industries where conventional materials fail. Each application uses tantalum's unique qualities to meet rigorous operational circumstances.

Chemical Processing Industry Applications

Chemical processing industries use tantalum tubes to handle corrosive media that would ruin other materials. These components work well in reactors with harsh chemicals and high temperatures. Tantalum's thermal conductivity and chemical resistance make heat exchangers efficient and contamination-free.

Tantalum tubing protects product purity in distillation columns and condensers from acidity. The material's inertness prevents catalytic reactions that could damage products or pose safety risks. Tantalum thermocouple protection tubes allow accurate temperature monitoring in corrosive conditions where ordinary protection fails.

Semiconductor and Electronics Manufacturing

Tantalum tubes are used in vacuum furnaces and semiconductor processing equipment in electronics. Materials that are vacuum compatible and thermally stable are needed for these applications. Tantalum is useful for ultra-high vacuum systems due to its low outgassing.

Ion implantation equipment handles reactive gases without contamination with tantalum tubing. Its thermal stability and electrical qualities allow plasma generating systems to be precisely controlled and function well during high-temperature processing cycles.

Medical Device and Pharmaceutical Uses

Biocompatibility and corrosion resistance in physiological conditions make tantalum useful in medicine. Pharmaceutical processing equipment uses the material's chemical inertness to prevent product contamination, while implantable device components benefit from its tissue-friendly properties.

Medical surgical instruments using tantalum tubes are durable and sterilizable. Radiopacity makes the material useful for imaging, while mechanical qualities assure stable functioning in crucial medical devices.

Aerospace and Defense Components

Biocompatibility and corrosion resistance in physiological conditions make tantalum useful in medicine. Pharmaceutical processing equipment uses the material's chemical inertness to prevent product contamination, while implantable device components benefit from its tissue-friendly properties.

Medical surgical instruments using tantalum tubes are durable and sterilizable. Radiopacity makes the material useful for imaging, while mechanical qualities assure stable functioning in crucial medical devices.

Advantages and Performance Characteristics of Tantalum Tubes and Pipes

Tantalum tube and pipe's many advantages make it reliable in demanding applications. Extended service life and lower maintenance yield operational benefits that justify the material's premium cost.

Exceptional Corrosion Resistance and Chemical Inertness

Tantalum resists acid corrosion better than stainless steel and titanium. The substance resists hydrochloric, sulfuric, and nitric acids at concentrations and temperatures that would quickly damage other materials. This resistance prolongs equipment life, maintains system integrity, and prevents costly failures.

Chemical inertness of tantalum minimizes undesired reactions that could taint operations or pose safety risks. This feature is very useful in pharmaceutical and food manufacturing, where product purity is crucial. Tantalum performs consistently without adding trace elements that could impact product quality, unlike reactive metals.

Mechanical Strength and Durability

Seamless tantalum tubes have higher pressure ratings and fatigue resistance than welded ones. Lack of weld seams eliminates failure sites and ensures component strength. Mechanical dependability decreases the danger of unexpected breakdowns that could cause costly downtime or safety problems.

With its great formability, the material can create complicated geometries without compromising structural integrity. Deep sketching allows intricate structures that fragile materials cannot make, enhancing design options for particular applications.

Thermal and Electrical Properties

Tantalum's thermal conductivity improves heat exchanger heat transmission and structural stability at high temperatures. In temperature-sensitive applications, the material's low thermal expansion reduces stress during thermal cycling, extending component life.

Tantalum's electrical characteristics make it suited for fine conductivity control. Its resistance is steady across temperatures, ensuring continuous electrical performance in electronic applications.

Customization Capabilities

Modern manufacturing can produce tantalum tubes with precise dimensions and unique characteristics. For different applications, capillaries below 1mm and big pipes above 150mm are available. Different pressure and mechanical loads can be met with wall thicknesses from 0.2mm to 5.0mm.

Custom lengths up to 12 meters allow for particular installation requirements without system-compromising junctions. Standard mill finishes to highly polished pharmaceutical surfaces are available.

Manufacturing Process of Tantalum Tubes and Pipes

High-quality tantalum tubing requires advanced manufacturing techniques to assure consistent characteristics and dimensions. Technologically advanced facilities turn raw tantalum into precision-engineered components that match industrial standards.

Raw Material Selection and Preparation

At least 99.95% pure tantalum ingots are chosen for manufacturing. This high purity ensures superior corrosion resistance and mechanical qualities in finished goods. Certified suppliers provide supply chain evidence of material composition and traceability.

Electron beam furnace refinement increases purity and creates homogeneous grain structures for mechanical qualities. This melting technique removes contaminants that could affect performance and ensures ingot material composition homogeneity.

Seamless and Welded Manufacturing Techniques

Hot forging and careful rolling provide uniform microstructures in seamless tubes. Precision dimensions and optimal material qualities are achieved by multi-stage cold drawing with intermediate annealing. This removes weld seams that could fail in high-stress situations.

Welded pipes use tantalum strip or foil linked by automated fusion welding without filler metal. This method produces larger diameters and thinner walls than seamless techniques while keeping great performance for appropriate applications.

Quality Control and Certifications

Thorough inspections guarantee every component fulfills specifications before delivery. Material testing verifies composition and mechanical qualities, while dimension verification verifies tolerances. Non-destructive testing finds performance-affecting internal defects.

Astm B521 assures products fulfill industry composition, mechanical, and dimensional tolerance criteria. ISO 9001:2015 accreditation shows factory quality management consistency. Material properties are traceable and verified with documentation packages.

Procurement Considerations for Tantalum Tubes and Pipes

Successful tantalum tube procurement demands careful consideration of performance and cost aspects. Understanding these factors allows educated decision-making that combines technical requirements with budgetary limits and supplier reliability.

Material Specification and Application Matching

Applications and environments determine tantalum grade selection. R05400 powder metallurgy material has fine grain structure for some shaping procedures, while R05200 electron-beam melted tantalum is best for most applications. For high-stress applications, tantalum-tungsten alloys R05252 and R05255 are stronger.

Selection of wall thickness must include pressure, corrosion, and mechanical loads. For low-pressure applications, thin-wall tubing saves money and is strong. In corrosive conditions, thick-wall pipes support high-pressure systems and last longer.

Supplier Evaluation and Quality Assurance

Reliable vendors have quality management systems, certifications, and testing capabilities. ISO 9001:2015 accreditation pledges quality, whereas ASTM compliance guarantees product compliance. Supply chain transparency allows material source verification and ethical purchase.

Manufacturing capabilities effect buyer customisation and lead times. Advanced electron beam melting and precision machining facilities can handle complex specifications and tight tolerances. Technical support helps buyers choose materials and design applications.

Pricing and Delivery Considerations

Raw material costs, production complexity, and market demand affect tantalum prices. Seamless tubes cost more than welded ones due to manufacturing complexity and performance. Custom dimensions and tolerances cost more but may improve performance.

Minimum orders effect unit prices and delivery times. Custom requirements feature higher minimums and longer lead times than standard dimensions. Long-term supply agreements can stabilize prices and grant precedence during peak demand.

OEM and Custom Manufacturing Capabilities

Many applications demand unique dimensions or processing beyond catalog possibilities. Comprehensive manufacturers can meet particular surface treatments, precise machining, and assembly needs. Custom engineering optimises systems for individual applications while reducing costs.

Prototypes allow testing and confirmation before mass production. Small-batch production suits research and specialty equipment manufacturing where regular sizes fail.

Conclusion

Tantalum tube and pipe applications show its significance in industries that need corrosion resistance, thermal stability, and biocompatibility. In chemical processing and semiconductor production, these components work well when other materials fail. Tantalum tubing is essential for demanding applications due to its excellent characteristics and configurable requirements. While initial prices are higher than other materials, the extended service life and decreased maintenance give compelling long-term value for important applications demanding complete reliability and performance.

FAQ

Q: What is the difference between seamless and welded tantalum tubes?

A: Seamless tantalum tubes are manufactured through extrusion and drawing processes without any welded joints, providing superior strength and pressure resistance. These tubes offer uniform mechanical properties throughout their structure and eliminate potential failure points associated with weld seams. Welded tantalum pipes are fabricated from flat-rolled tantalum strip using fusion welding without filler metal, enabling larger diameters and thinner walls at lower costs while maintaining excellent performance for appropriate applications.

Q: How does tantalum compare to stainless steel for corrosive applications?

A: Tantalum significantly outperforms stainless steel in acidic environments, particularly with hydrochloric, sulfuric, and nitric acids. While stainless steel may suffer pitting corrosion or stress corrosion cracking, tantalum remains virtually unaffected by these aggressive chemicals. The superior corrosion resistance of tantalum extends equipment life and maintains system integrity in applications where stainless steel would require frequent replacement or compromise process purity.

Q: What factors influence tantalum tube pricing and delivery times?

A: Tantalum tube pricing depends on raw material costs, manufacturing complexity, dimensional requirements, and order quantities. Seamless tubes cost more than welded alternatives due to manufacturing complexity. Custom dimensions and tight tolerances increase costs compared to standard catalog items. Delivery times vary based on inventory availability, manufacturing schedules, and specification complexity, with standard sizes typically shipping faster than custom configurations.

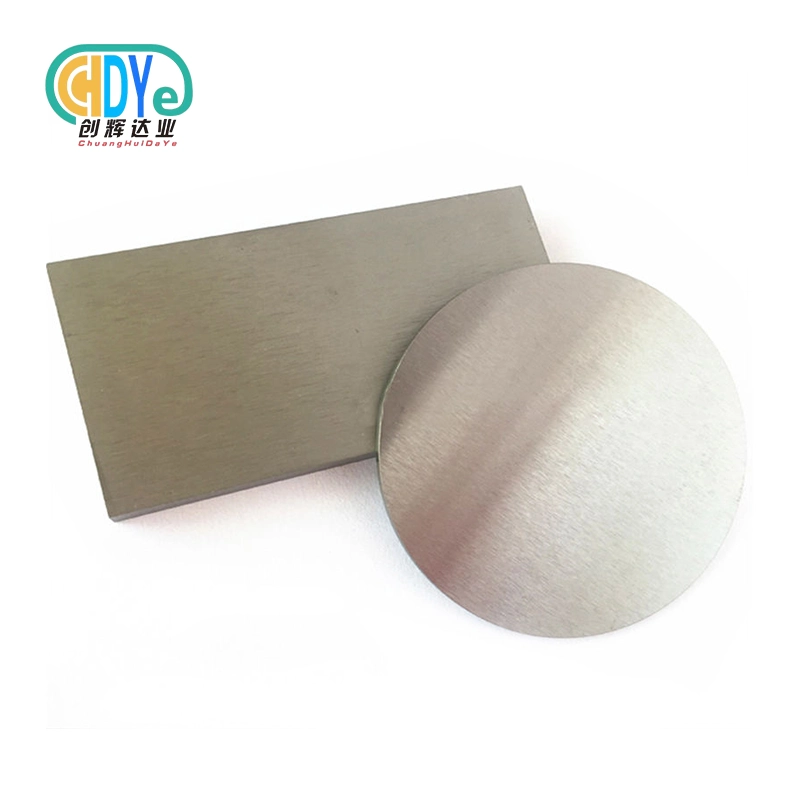

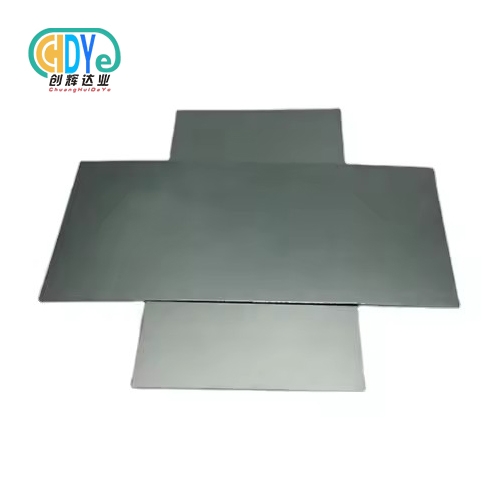

Partner with Chuanghui Daye for Premium Tantalum Tube and Pipe Solutions

When your applications demand the highest quality tantalum tubing, Shaanxi Chuanghui Daye delivers unmatched expertise and manufacturing excellence. Located in China's "Titanium Capital" with over 30 years of industry experience, we specialize in producing ASTM B521 compliant tantalum tubes and pipes with purities exceeding 99.95%. Our ISO 9001:2015 certified facility offers seamless and welded options, custom dimensions, and comprehensive technical support. Contact our engineering team at info@chdymetal.com to discuss your specific requirements and discover why leading manufacturers trust Chuanghui Daye as their preferred tantalum tube and pipe supplier.

References

1. Davis, J.R. "Refractory Metals and Alloys: Properties and Selection." ASM International Handbook Series, 2018.

2. American Society for Testing and Materials. "Standard Specification for Seamless and Welded Tantalum and Tantalum Alloy Tubes - ASTM B521." ASTM International Standards, 2019.

3. Miller, G.L. "Tantalum and Niobium: Chemistry and Technology." Industrial Chemistry Applications Quarterly, Vol. 45, 2020.

4. Thompson, K.S. "Corrosion Resistance of Refractory Metals in Chemical Processing Applications." Materials Engineering and Performance Journal, Vol. 29, 2021.

5. Rodriguez, M.A. "High-Temperature Materials for Aerospace Applications: Tantalum Alloy Performance Analysis." Aerospace Materials Research, Vol. 33, 2022.

6. Chen, W.H. "Biocompatibility and Medical Applications of Tantalum-Based Materials." Journal of Biomedical Materials Research, Vol. 108, 2023.

Learn about our latest products and discounts through SMS or email