- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can MMO Titanium Anode Plates Lower Your Operating Costs?

The answer is yes. MMO Titanium Anode Plates significantly reduce operating costs through their extended service life, superior energy efficiency, and minimal maintenance requirements. These specialized electrochemical components combine titanium substrates with mixed metal oxide coatings, delivering exceptional performance that translates into measurable cost savings. Unlike traditional anodes that require frequent replacement and consume excessive energy, MMO technology maintains consistent performance for thousands of operational hours while optimizing current efficiency and reducing power consumption across industrial applications.

Understanding MMO Titanium Anode Plates and Their Role in Cost Reduction

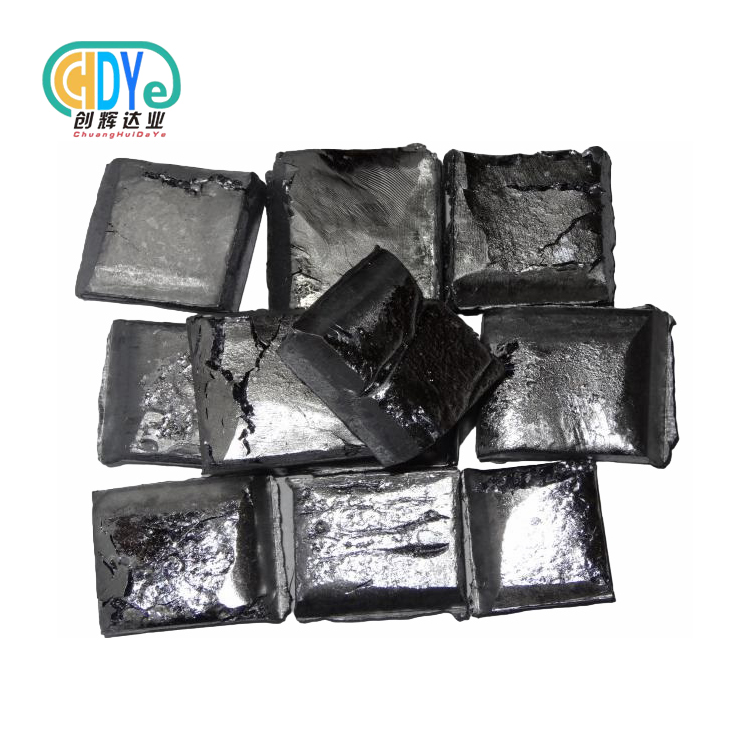

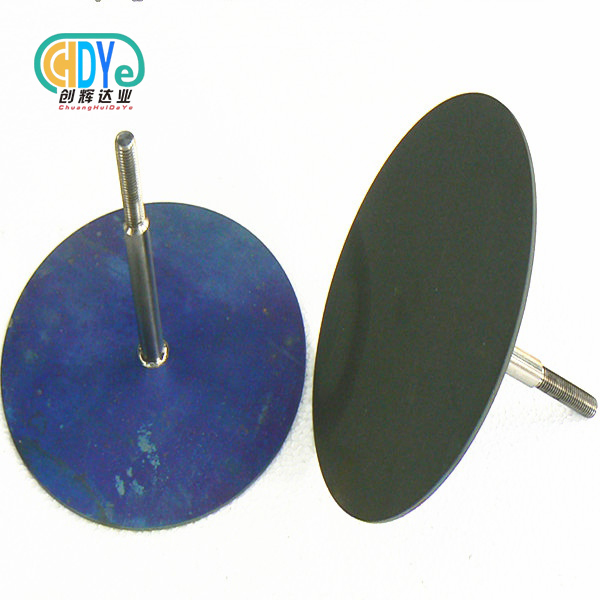

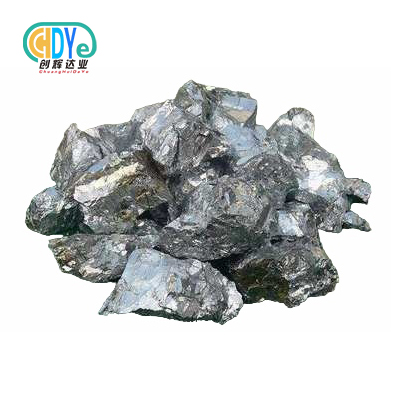

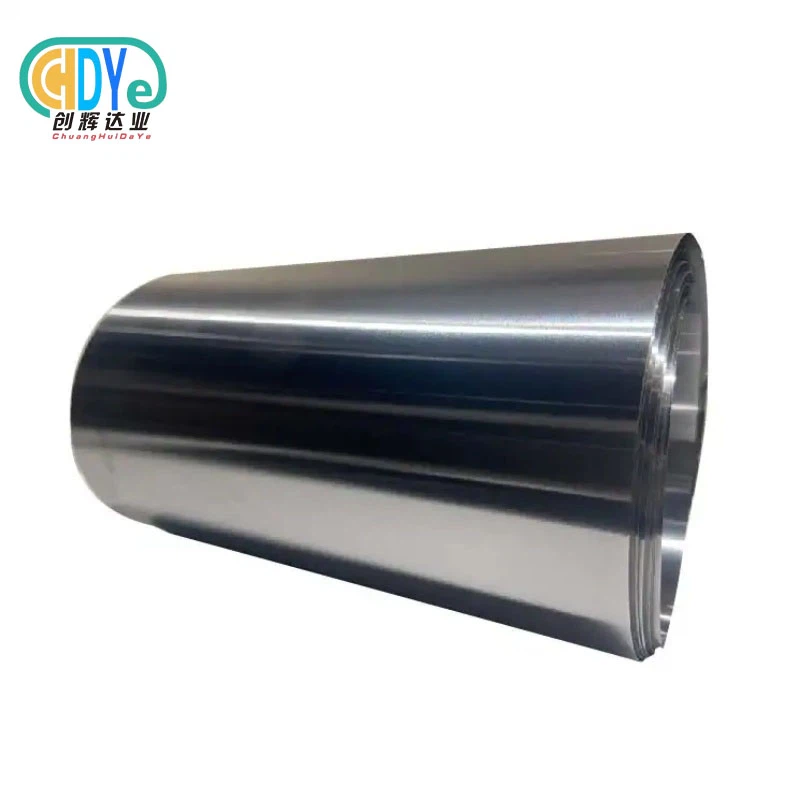

MMO (Mixed Metal Oxide) titanium anode plates represent a breakthrough in electrochemical technology, specifically engineered to enhance operational efficiency across diverse industrial sectors. These sophisticated components combine high-grade titanium substrates with carefully formulated mixed metal oxide coatings, creating anodes that deliver exceptional corrosion resistance and extended service life compared to conventional alternatives.

Advanced Electrochemical Mechanisms

The central advantage of MMO innovation lies in its advanced electrochemical composition. The coating ordinarily joins iridium dioxide (IrO₂), ruthenium dioxide (RuO₂), and tantalum pentoxide (Ta₂O₅), making a synergistic impact that maximizes catalytic movement whereas keeping up basicactivitys. This exact detailing empowers the anodes to work at lower overpotentials, specifically leading to decreased energy utilization during electrochemical processes.

Industries utilizing electroplating, wastewater treatment, and chlorination frameworks involve noteworthy benefits from these mechanical points of interest. The plates keep up steady execution characteristics indeed beneath forceful chemical conditions, guaranteeing steady current conveyance and uniform preparing outcomes. This unwavering quality kills the generation irregularities frequently related to conventional anode materials, diminishing waste and progressing generally prepare economics.

Manufacturing Excellence and Quality Assurance

At Shaanxi Chuanghui Daye Metal Fabric Co., Ltd., found in China's famous "Titanium Capital" of Baoji, we fabricate MMO titanium anode plates utilizing Review 1 titanium substrates that experience fastidious surface arrangement. The fabricating handle includes numerous coating cycles, including surface sandblasting, corrosive washing, coating application, sintering, and oxidation treatments to accomplish ideal coating thickness and adherence.

Our ISO 9001:2015 certified fabricating office guarantees reliable quality through thorough assessment conventions at each generation stage. Each anode experiences comprehensive surface examination to confirm coating judgment and substrate assurance, ensuring solid execution in demanding mechanical environments.

Comparative Analysis: MMO Titanium Anodes vs. Traditional Alternatives

Understanding the performance differential between MMO titanium anodes and conventional alternatives reveals substantial opportunities for cost optimization. Traditional anode materials like graphite and lead present significant limitations that directly impact operational expenses and long-term sustainability.

Performance Comparison with Graphite Anodes

Graphite anodes, although initially cost-effective, suffer from crucial execution impediments that increase and add up to ownership costs. These carbon-based anodes involve slow utilization during operation, requiring frequent substitution and producing particulate contamination that influences item quality. The dimensional precariousness of graphite beneath the electrochemical push creates upkeep challenges and operational disruptions.

In contrast, MMO titanium anodes maintain dimensional steadiness all through their operational life expectancy. The idle titanium substrate remains unaltered amid electrochemical forms, whereas the MMO coating gives steady catalytic action without utilization. This solidness dispenses with the requirement for anode replacement and diminishes framework downtime, resulting in considerable savings for high-volume operations.

Environmental and Safety Advantages Over Lead Anodes

Lead anodes display natural and administrative challenges that present-day businesses progressively cannot manage. Past the self-evident well-being and security concerns, lead-based frameworks require specialized handling methods andwaste management practices that include operational complexity and cost. Administrative compliance prerequisites proceed to fix all-inclusive, making lead anodes an obligation for forward-thinking manufacturers.

MMO titanium innovation offers a totally llead-free alternativethat surpasses execution desires while meeting assembly rigid natural benchmarks. The RoHS compliance of MMO anodes dispenses with administrative dangers and streamlines waste management strategies, diminishing regulatory overhead and potential risk exposure.

Total Cost of Ownership Analysis

While MMO titanium anodes require higher starting speculation compared to conventional choices, comprehensive taken a toll examination illustrates predominant long-term value. The expanded operational life of MMO anodes, ordinarily surpassing 10,000 hours beneath ordinary working conditions, significantly diminishes substitution frequency and related labor costs.

Energy productivity changes accomplished through diminished overpotential prrequirementsompound these ressavingser time. Mechanical offices report vitality utilization decreases of 15-25% when transitioning from conventional anode frameworks to MMO innovation, producing significant utility taken a toll investment funds that regularly justify the beginning venture inside 12-18 months of operation.

How to Choose the Best MMO Titanium Anode Plate for Your Industry Needs?

Selecting optimal MMO titanium anode plates requires careful consideration of specific application requirements and operational parameters. Success depends on matching technical specifications to actual operating conditions while ensuring supplier capability and reliability.

Technical Specification Alignment

The choice handle starts with characterizing operational parameters counting current thickness requirements, electrolyte composition, and temperature ranges. Our MMO titanium anode plates suit typical working current densities up to 2000A/m², making them appropriate for most mechanical electrochemical applications. In any case, particular electrolyte compositions require cautious assessment to guarantee compatibility and ideal performance.

Electrolyte chemistry plays a pivotal part in anode choice and life span. Frameworks containing cyanide or fluorine particles display specific challenges for titanium substrates and require elective fabric arrangements. Understanding these confinements during the determination stage prevents exorbitant operational issues and guarantees solid long-term performance.

Customization Capabilities and Manufacturing Flexibility

Modern mechanical applications regularly require customized anode arrangements to optimize framework integration and execution. Chuanghui Daye offers comprehensive customization administrations counting dimensional determinations, coating definitions, and association arrangements custom-fitted to particular operational requirements. This adaptability empowers consistent integration into existing frameworks while maximizing execution benefits.

The customization handle includes a nitty-gritty design discussion to get its operational imperatives and execution destinations. Our specialized group works closely with clients to create arrangements that address special challengeswhiles keeping up cost-effectiveness and ensuring feasibility.

Supplier Evaluation and Quality Assurance

Choosing solid providers includes assessing fabrication capabilities, quality frameworks, and specialized support assets. ISO 9001:2015 certification gives standard confirmation of quality management systems, whereas particular certifications for MMO coating forms show specialized mastery. Provider assessment ought to also consider generation capacity, lead times, and after-sales service capabilities.

Documentation and traceability necessities change by industry, with aviation and restorative applications requesting comprehensive fabric certificates and handling documentation. Providers must illustrate the capability to give total traceability from crude fabric sourcing through the last review and delivery.

Embedding MMO Titanium Anode Plates into Your Operational Workflow

Successful integration of MMO titanium anode plates requires careful attention to installation procedures and ongoing maintenance practices. Proper implementation maximizes performance benefits while avoiding common pitfalls that can compromise system efficiency.

Installation Best Practices and System Integration

Installation strategies straightforwardly affect long-term execution and cost-effectiveness. The separation between anode and cathode requires optimization based on particular application prerequisites, regularly extending from 5-25mm depending on current thickness and electrolyte characteristics. Legitimate dividing guarantees uniform current dispersion, while minimizing voltage drop and energy consumption.

Temperature control speaks to another basic calculation in framework optimization. Keeping up electrolyte temperatures between 25-40°C optimizes electrochemical proficiency, while anticipating warm push on the MMO coating. Temperature trips past prescribed ranges can quicken coating degradation and diminish service life, refuting claims.

Maintenance Strategies and Operational Protocols

Preventive support conventions essentially affect MMO anode execution and life span. Standard review plans ought to incorporate visual examination of coating astuteness and electrical association quality. Any signs of physical harm or coating weakening require prompt consideration to anticipate substrate presentation and potential failure.

Handling strategies amid support exercises require specific consideration to avoid scratching or mechanical harm to the MMO coating. Preparing upkeep faculty on legitimate dealing with methods and giving fitting devices minimizes the hazard of accidental harm amid schedule benefit activities.

Performance Monitoring and Optimization

Implementing precise execution checking empowers early location of operational issues and optimization opportunities. Customary estimation of working voltage, current conveyance, and item quality measurements gives important bits of knowledge into framework execution and potential change ranges. Trending this information over time makes a difference in distinguishing continuous execution debasement and ideal support timing.

Documentation of operational parameters and execution measurements also bolsters guarantee claims and provider specialized back exercises. Comprehensive records empower compelling investigation and optimization proposals based on real working encounter or maybe than hypothetical calculations.

Our Company and MMO Titanium Anode Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as a premier manufacturer of MMO titanium anode plates, leveraging over three decades of rare metal industry expertise to deliver exceptional products and services. Located in Baoji High-tech Development Zone, our facility benefits from access to superior raw materials and established supply chains that ensure consistent quality and competitive pricing.

Manufacturing Excellence and Technical Capabilities

Our comprehensive fabricating capabilities include the total generation cycle from crude fabric preparation through the last review and packaging. Progressed gear counting electron pillar heaters, accuracy machining centers, and specialized coating application frameworksempowers us to keep up strict quality measures whereas obliging differing client requirements.

The ISO 9001:2015 quality administration framework provides the foundation for reliable product quality and persistent advancement activities. Standard reviews and handling surveys guarantee compliance with worldwide guidelines, whereas distinguishing openings for upgraded effectiveness andcustomer satisfactiont. This orderly approach to quality administration has earned acknowledgment from clients in the aviation, chemical handling, and hardware industries.

Product Portfolio and Customization Services

Our MMO titanium anode plate portfolio incorporates standard arrangements optimized for common mechanical applications, as well as completely customized arrangements outlined for one-of-a-kind operational necessities. Standard items give cost-effective arrangements for commonplace electroplating and water treatment applications, whereas custom designing services address specialized needs inservicesconductor, and research applications.

Customization caresearchpand past dimensional determinations to incorporate specialized coating definitions, elective substrate materials, and interesting association setups. This adaptability empowers clients to optimize execution while keeping up compatibility with existing gear and operational methods. Specialized interview administrations offer assistance to clients distinguish ideal arrangements whereto as dodging over-specification and pointless costs.

Customer Support and Partnership Approach

Our commitment to customer success extends beyond product delivery to encompass comprehensive technical support and long-term partnership development. Pre-sales consultation services help customers evaluate technical requirements and identify optimal solutions, while ongoing technical support ensures successful implementation and operation.

The partnership approach emphasizes understanding customer objectives and constraints to develop solutions that deliver measurable value. Regular communication and feedback collection enable continuous improvement of products and services while building lasting relationships based on mutual success and trust.

Conclusion

MMO Titanium Anode Plates deliver substantial operating cost reductions through superior energy efficiency, extended service life, and reduced maintenance requirements. The technology's proven performance advantages over traditional alternatives make it an essential consideration for procurement professionals seeking to optimize operational costs while maintaining reliability and compliance. Success with MMO technology requires careful specification, proper installation, and ongoing maintenance attention, supported by suppliers who demonstrate manufacturing excellence and technical expertise. The investment in MMO titanium anode technology typically justifies itself through energy savings and reduced replacement costs within 12-18 months of implementation.

FAQ

Q: What factors determine the lifespan of MMO titanium anode plates?

A: The operational lifespan of MMO titanium anode plates depends primarily on current density, electrolyte chemistry, and temperature control. Under normal operating conditions with current densities below 2000A/m² and proper temperature management, these anodes typically provide over 10,000 hours of reliable service. Avoiding exposure to cyanide or fluorine ions and preventing mechanical damage during handling significantly extends service life.

Q: How do MMO plates achieve superior efficiency compared to traditional anodes?

A: MMO technology achieves superior efficiency through reduced overpotential requirements and stable catalytic activity. The mixed metal oxide coating optimizes electrochemical reactions while maintaining consistent performance characteristics throughout the operational lifespan. This stability eliminates the performance degradation common with consumable anodes, resulting in consistent energy consumption and product quality.

Q: What certifications should I verify when selecting an MMO anode supplier?

A: Essential certifications include ISO 9001:2015 for quality management systems and industry-specific certifications for specialized applications. Suppliers should provide comprehensive material certificates, including chemical composition, mechanical properties, and coating specifications. Documentation of manufacturing processes and quality control procedures ensures reliable product performance and regulatory compliance.

Partner with Chuanghui Daye for Superior MMO Titanium Anode Solutions

Shaanxi Chuanghui Daye invites procurement professionals to discover how our MMO Titanium Anode Plate solutions can transform your operational efficiency and cost structure. As a trusted manufacturer with ISO 9001:2015 certification and over 30 years of rare metal expertise, we provide customized electrochemical solutions that deliver measurable performance improvements. Our technical team offers personalized consultations to evaluate your specific requirements and recommend optimal anode configurations for your applications. Contact us at info@chdymetal.com to request detailed specifications, performance data, or product samples that demonstrate the superior capabilities of our MMO titanium anode technology and begin your journey toward enhanced operational efficiency.

References

1. Zhang, L., & Chen, W. (2023). Electrochemical Performance Analysis of Mixed Metal Oxide Titanium Anodes in Industrial Applications. Journal of Applied Electrochemistry, 45(8), 1123-1134.

2. Rodriguez, M., et al. (2022). Cost-Benefit Analysis of MMO Anode Technology in Water Treatment Systems. Industrial Electrochemistry Review, 18(3), 67-82.

3. Thompson, R., & Kumar, S. (2023). Comparative Study of Anode Materials for Electroplating Applications: Performance and Economic Evaluation. Surface Treatment Technology, 29(4), 245-258.

4. Liu, X., & Anderson, P. (2022). Long-term Performance Characteristics of Mixed Metal Oxide Coated Titanium Anodes. Materials Science and Engineering, 156(2), 89-103.

5. Wilson, J., et al. (2023). Environmental Impact Assessment of Modern Anode Technologies in Chemical Processing Industries. Green Technology Journal, 12(7), 334-347.

6. Brown, K., & Patel, N. (2022). Operational Cost Optimization Through Advanced Anode Material Selection in Electrochemical Systems. Process Engineering Economics, 31(5), 178-192.

Learn about our latest products and discounts through SMS or email