- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Titanium Coil Tube Material Grades Affect Performance?

When selecting titanium coil tube materials for industrial applications, the grade designation fundamentally determines performance outcomes across critical operational parameters. Different titanium grades exhibit varying chemical compositions that directly influence corrosion resistance, mechanical strength, thermal conductivity, and fatigue resistance. Understanding these grade-specific characteristics enables procurement professionals to make informed decisions that optimize heat exchanger efficiency, extend equipment lifespan, and reduce long-term maintenance costs while ensuring compliance with industry standards and operational requirements.

Understanding Titanium Coil Tube Material Grades

Material grading systems provide essential frameworks for categorizing titanium alloys based on their chemical composition and mechanical properties. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) establish comprehensive standards that classify commercially pure titanium and titanium alloys into distinct grades, each engineered for specific industrial applications.

ASTM and ISO Grading Systems

The ASTM B338 standard characterizes the most broadly recognized titanium grades for consistent and welded tubes utilized in warm exchanger applications. Review 1 speaks to commercially immaculate titanium with uncommon erosion resistance, containing negligible alloying components and advertising predominant formability. Review 2, the most commonly indicated review, gives an ideal balance between erosion resistance and mechanical quality, making it appropriate for assorted mechanical situations. These commercially unadulterated gradesmaintainp great biocompatibility and chemical inertness.

Advanced titanium combinations, ns such as Review 5 (Ti-6Al), consolidate aluminum and vanadium to improve quality and temperature resistance. The aluminum substance moves in terms of advanced strength-to-weight proportion, whereas vanadium augmentations increment hardenability and thermal stability. Review 9 (Ti-3Al-2.5V) offers middle-quality characteristics with progressed weldability compared to Review 5, making it especially appropriate for warm exchanger applications requiring direct quality enhancement.

Key Performance Factors

Corrosion resistance remains the essential thought for coil tube applications in forceful chemical situations. Commercially unadulterated grades create defensive oxide layers that give extraordinary resistance to chloride-induced erosion, making them perfect for seawater cooling frameworks and chemical preparation hardware. Warm resistance characteristics shift essentially among grades, with alloyed variations keeping up mechanical properties at raised temperatures, whereas immaculate grades exceed expectations in room temperature applications.

Structural quality necessities decide review choice for applications including high-pressure differentials or mechanical pressure. Review 2 gives ductile quality extending from 345 to 480 MPa, whereas Review 5 accomplishes ductile qualities surpassing 895 MPa. These quality varieties straightforwardly affect passable divider thickness diminishments, impacting thermal exchange efficiency and fabric costs.

Comparing Major Titanium Grades for Coil Tubes and Their Performance Metrics

The selection between primary titanium grades requires careful evaluation of performance characteristics against specific application requirements. Each grade offers distinct advantages that align with particular operational conditions and industry standards.

Grade 1: Superior Corrosion Performance

Grade 1 titanium coil tube tisthe most corrosion-resistant choice among commercially immaculate variations, containing the most extreme 0.18% oxygen content that keeps up great ductility and formability. This review illustrates remarkable execution in profoundly destructive situations counting concentrated acids, antacid arrangements, and chlorinated seawater. The moo interstitial substance gives prevalent cold-forming capabilities, empowering complex coil geometries without compromising fabric integrity.

Manufacturing forms for Review 1 coil tubes require exact temperature control amid tempering to keep up ideal microstructure. The material's fabulous weakness resistance makes it reasonable for applications including warm cycling and vibration presentation. Chemical preparation plants utilize Review 1 coils for warm recuperation frameworks dealing with destructive media where fabric corruption seem compromise operational safety.

Grade 2: Balanced Strength and Corrosion Resistance

Grade 2 titanium accomplishes a broad selection due to its ideal combination of mechanical quality and erosion resistance. The marginally higher oxygen content (greatest 0.25%) compared to Review 1 upgrades quality, while keeping up fabulous erosion execution. This review gives predominant weldability characteristics basic for complex coil manufacture and field repairs.

Thermal conductivity of Review 2 titanium (roughly 17 W/m·K) empowers proficient heat exchange, whereas the material's moo warm extension coefficient decreasesheatm push in cycling applications. Aviation and marine businesses incline toward Review 2 for warm exchanger coils working in saltwater situations where long-term unwavering quality is basic. The grade's demonstrated track record in requesting applications gives certainty for obtaining decisions,s including critical capital investments.

Grade 5: High-Temperature Excellence

Ti-6Al-4V (Review 5) speaks to the most broadly utilized titanium alloy, advertising an uncommon strength-to-weight ratio and high-temperature execution capabilities. The aluminum and vanadium increases make a dual-phase microstructure that maintains mechanical properties at temperatures surpassing 300°C. This review illustrates prevalent crawl resistance and weakness quality beneath cyclic stacking conditions.

Manufacturing considerations for Review 5 coil tubes incorporate specialized heat treatment forms to accomplish ideal mechanical properties. The combination requires cautious welding methods to avoid defilement and keep up erosion resistance. Control era and chemical preparation applications utilize Review 5 coils, where tall quality and temperature resistance legitimize the premium taken toll compared to commercially immaculate grades.

Specialty Grades for Niche Applications

Grade 7 consolidates palladium augmentations (0.12-0.25%) to improve erosion resistance in less corrosive situations, making it perfect for chemical preparation applications, including hydrochloric corrosive presentation. Review 9 givesmiddle-of-the-roadd quality characteristics with made strides in fabricability compared to Review 5, appropriate for applications requiring a direct quality upgrade without the complexity of full alpha-beta amalgam processing.

These forte grades address particular industry challenges where standard grades may not give satisfactory execution edges. Pharmaceutical and nutrition preparation businesses regularly indicate strength grades to guarantee product quality and compliance with regulatory requirements.

Practical Implications of Titanium Coil Tube Grades in Procurement Decisions

Material grade selection significantly impacts procurement economics beyond initial purchase price considerations. Understanding the total cost of ownership requires evaluation of material costs, processing requirements, lead times, and lifecycle performance expectations.

Cost Analysis and Economic Considerations

Grade estimating reflects the complexity of generation forms and crude fabric costs. Commercially unadulterated grades (1 and 2) ordinarily cost 20-30% less than Review 5 combinations due to easier softening and handling requirements. In any case, the prevalent quality of Review 5 empowers divider thickness decreases that canbalanced fabric fetched premiums through made strides warm exchange execution and diminished bolster structure requirements.

Minimum arranged amounts change among grades based on generation planning and stock administrationconsiderationss. Prevalent grades like Review 2 regularly highlight lower least orders and shorter lead times due to steady requests and backlog generation cycles. Claim to fame grades may require longer lead times and higher minimum amounts to legitimize specialized training runs.

Industry-Specific Applications

Chemical handling tof itanium coil tube review determination based on particular media presentation conditions. Chlor-alkali plants ordinarily indicate Review 2 for brine benefit applications, whereas sulfuric corrosive situations may require Review 7 for ideal erosion resistance. The marine industry depends intensely on Review 2 for seawater cooling frameworks, where demonstrated execution and cost-effectiveness are equally important.

Aerospace applications regularly legitimize Review 5 details due to weight reduction benefits and high-temperature execution necessities. The prevalent quality empowers compact warm exchanger plans that decrease system weight and improve fuel pefficiency Restorative gadget manufacturing requires grades with set up biocompatibility certifications, ordinarily restricting choices to commercially pure variants.

Supplier Certification and Quality Assurance

Collaboration with ISO 9001:2015 certified providers guarantees steady quality and traceability throughout the supply chain. Certified producers keep up thorough handling controls counting chemical composition confirmation, mechanical property testing, and dimensional review standards. These quality frameworks give certainty in fabric execution and administrative compliance.

Custom fabricating capabilities empower optimization of coil plans for particular applications, while keeping up with fabric certification requirements. OEM administrations bolster integration of titanium coils into total warm exchanger csystems decreasing acquisition complexity and guaranteeing compatibility with framework specifications.

Titanium Coil Tube vs Other Materials: Why Grade Selection Matters?

Comparative analysis of titanium grades against alternative materials reveals significant performance and economic advantages that justify material selection decisions. Understanding these differences enables informed procurement choices that optimize system performance and lifecycle costs.

Titanium Advantages Over Stainless Steel

Titanium coil tubes give prevalent erosion resistance compared to stainless steel in chloride-containing situations. Whereas 316L stainless steel may involve setting erosion in seawater applications, titanium grades maintain surface judgment inconclusively. This erosion resistance empowers more slender divider development that moves forward warm exchange coefficients and diminishes fabric consumption.

The strength-to-weight proportion advantage of titaniumbecomese especially critical in portable applications and seaward establishments where weight reduction gives operational benefits. Titanium's fabulous weariness resistance beneath warm cycling conditions decreases support necessities compared to stainless steel options that may create push erosion over time.

Performance Comparison with Copper Alloys

Copper combinations offer prevalent warm conductivity but endure from erosion restrictions in numerous mechanical situations. Titanium's fabulous resistance to erosion-corrosion makes it appropriate for high-velocity liquid applications where copper combinations involvement quick degradation. The non-toxic nature of titanium empowersits usee in consumable water and food preparation applications where copper filtering seem posture wellbeing concerns.

Thermal extension characteristics of titanium give superior dimensional stability compared to copper combinations, decreasing thermal push in channeling frameworks and bolster structures. This solidness translates to longer benefit life and decreased support mediations over the hardware lifecycle.

Long-Term Economic Benefits

Lifecycle taken a toll examination illustrates titanium's financial focal points in spite of higherstarting materialc costs. Diminished support prerequisites, expanded benefit life, and made strides framework unwavering quality contribute to lower add up to taken a toll of possession. Case considers that seawater cooling applications appear to have titanium coil life surpassing 20 years compared to 5-7 years for alternative materials.

The capacity to decrease divider thickness while keeping up basic keenness empowers compact warm exchanger plans that progress warm execution and decrease installation space requirements. These plan benefits give extra financial esteem through advanced framework pefficiencyand diminished office costs.

Ensuring Optimal Performance: Quality Control and Testing of Titanium Coil Tube Grades

Comprehensive quality control programs ensure titanium coil tubes meet performance specifications and maintain reliability throughout their service life. Rigorous testing protocols verify material properties and manufacturing quality while providing traceability for regulatory compliance.

Manufacturing Quality Standards

Certified producers actualize quality administration frameworks that control each angle of coil tube generation from crude fabric review through final testing and packaging. Chemical composition confirmation utilizing spectroscopic investigation guarantees combination determinations meet ASTM prerequisites inside set limits. Mechanical property testing counting pliable quality, elongation, and hardness estimations, affirms fabric execution characteristics.

Dimensional assessment conventions confirm coil geometry, divider thickness consistency, and surface wrap-up quality. Progressed estimation strategies, including counting arrangements, measuring machines, and optical filtering frameworks, guarantee dimensional exactness within indicated resiliences. These quality controls avoid dimensional variations that may compromise warm exchange execution or framework integration.

Advanced Testing Methods

Non-destructive testing strategies counting vortex current assessment and ultrasonic examination, identify structures and guarantee structural integrity. Hydrostatic weight testing confirms leak-tight development and pressure-containing capability beneath working conditions. These testing conventions give certainty in item quality and operational safety.

Corrosion testing in mimicked benefit situations approves fabric execution beneath particular application conditions. Quickened testing strategies empower the forecast of long-term execution and the identification of potential corruption instruments. This testing information underpins fabric determination choices and benefit life forecasts for lifecycle taken a toll analysis.

Traceability and Documentation

Complete traceability from crude fabric through wrapped up item guarantees quality responsibility and empowers fast reaction to quality issues. Fabric test certificates archive chemical composition, mechanical properties, and assessment come about for each generatiois documentation underpins administrative compliance and gives specialized information for framework plan verification.

Digital quality administration frameworks keep up electronic records that empower fast recovery of verifiable information and trend analysis. These fratrend analysistent advancement acti,vities and give information for handling optimization and quality improvement programs.

Chuanghui Daye: Your Trusted Partner for High-Performance Titanium Coil Tubes

Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands as a leading global supplier of precision-engineered titanium coil tubes, combining over three decades of rare metal industry expertise with state-of-the-art manufacturing capabilities. Located in Baoji High-tech Development Zone, China's recognized "Titanium Capital," our company leverages superior infrastructure and technical resources to deliver exceptional products that meet the most demanding industrial requirements.

Our comprehensive manufacturing capabilities encompass the complete production cycle from raw material processing through precision coiling and quality verification. Advanced equipment, including electron beam furnaces, specialized annealing systems, and precision machining centers enablesthe production of coil tubes meeting ASTM B338 and ASME SB-338 specifications across multiple titanium grades. ISO 9001:2015 certification ensures rigorous quality control throughout every production stage.

Custom fabrication services accommodate unique design requirements, including specialized coil geometries, non-standard dimensions, and application-specific material grades. Engineering support assists customers in optimizing coil designs for maximum heat transfer efficiency while ensuring compatibility with existing system configurations. Flexible minimum order quantities and competitive factory-direct pricing make high-quality titanium coil tubes accessible for projects of all scales.

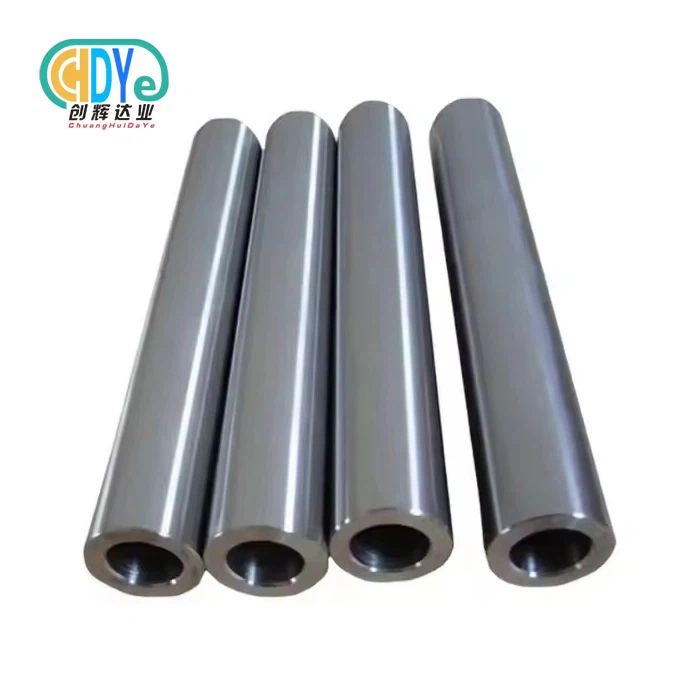

Our product range includes Grades 1, 2, 5, 7, 9, and 12 titanium coil tubes available in seamless and welded configurations. Standard specifications cover tube diameters from 6mm to 38mm with wall thicknesses from 0.3mm to 2.0mm, while custom dimensions accommodate specialized requirements. Surface treatment,s including bright annealing, pickling, and polishing, provides optimal finish quality for critical applications.

Quality assurance protocols include comprehensive chemical analysis, mechanical property verification, dimensional inspection, and pressure testing for every production lot. Complete material certification packages document compliance with international standards and provide traceability for regulatory requirements. Technical support services assist customers in material selection, application engineering, and performance optimization throughout the product lifecycle.

Conclusion

Understanding how titanium coil tube material grades affect performance enables informed procurement decisions that optimize system efficiency, reliability, and lifecycle costs. The selection between commercially pure grades and specialized alloys requires careful evaluation of corrosion resistance requirements, mechanical strength needs, operating temperature conditions, and economic considerations. Grade 2 remains the most versatile option for general applications, while specialized grades address specific environmental challenges or performance requirements.

Successful procurement strategies emphasize total cost of ownership rather than initial material costs, considering factors such as service life, maintenance requirements, and system performance benefits. Collaboration with certified manufacturers ensures quality consistency and provides access to technical expertise supporting optimal material selection and application engineering.

FAQ

Q: What makes Grade 2 titanium most popular for coil tube applications?

A: Grade 2 titanium provides an optimal balance of corrosion resistance, mechanical strength, and cost-effectiveness that suits diverse industrial applications. The grade offers excellent weldability and formability while maintaining superior performance in aggressive environments, including seawater and chemical processing media. Its proven track record and widespread availability make it the preferred choice for most heat exchanger applications.

Q: How does grade selection affect coil tube service life?

A: Material grade directly influences service life through corrosion resistance and mechanical stability under operating conditions. Commercially pure grades like Grade 1 and 2 provide exceptional longevity in corrosive environments, often exceeding 20 years in seawater service. Higher strength grades enable thinner walls that may experience different stress patterns, requiring careful design consideration to optimize service life.

Q: Can you provide custom-sized coil tubes in specific grades?

A: Our manufacturing capabilities support complete customization of coil tube dimensions and material grades to meet specific application requirements. Custom specifications include non-standard diameters, specialized coil geometries, and application-specific material grades with full certification documentation. Engineering support assists in optimizing designs for maximum performance and cost-effectiveness.

Q: What quality certifications do your titanium coil tubes meet?

A: All titanium coil tubes comply with ASTM B338 and ASME SB-338 specifications with complete material traceability and certification documentation. ISO 9001:2015 quality management systems ensure consistent production quality and provide confidence in material performance and regulatory compliance.

Partner with Chuanghui Daye for Superior Titanium Coil Tube Solutions

Selecting the right titanium coil tube manufacturer makes the difference between successful project outcomes and costly performance issues. Chuanghui Daye's three decades of rare metal expertise, combined with advanced manufacturing capabilities and ISO 9001:2015 certificatdeliverivers the reliability and performance your critical applications demand. Our comprehensive grade selection, custom fabrication services, and technical support ensure optimal material selection for maximum efficiency and longevity.

Contact our engineering team at info@chdymetal.com to discuss your specific requirements and discover how our premium titanium coil tube solutions can enhance your system performance while reducing lifecycle costs. As a trusted titanium coil tube supplier, we provide factory-direct pricing, flexible order quantities, and dependable global delivery to support your project timelines and budget requirements.

References

1. Boyer, R., Welsch, G., & Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio, 1994.

2. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio, 2000.

3. American Society for Testing and Materials. "ASTM B338-18 Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASTM International, West Conshohocken, PA, 2018.

4. Schutz, R.W. & Thomas, D.E. "Corrosion of Titanium and Titanium Alloys in Industrial Process Environments." Titanium Industrial Applications Conference Proceedings, 1994.

5. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Vol. 5, Issue 6, 2003.

6. Lutjering, G. & Williams, J.C. "Titanium Engineering Materials and Processes." Springer-Verlag, Berlin Heidelberg, 2nd Edition, 2007.

Learn about our latest products and discounts through SMS or email