- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Specify Titanium Coil Tubes for Custom Projects?

When specifying a Titanium Coil Tube for custom applications, procurement professionals must carefully evaluate several critical parameters to ensure optimal performance and cost-effectiveness. The specification process requires thorough consideration of operating conditions, dimensional requirements, material grades, and manufacturing tolerances. Proper specification directly impacts heat transfer efficiency, corrosion resistance, and overall system reliability. Understanding these fundamental requirements enables engineers to select the most suitable titanium coil configuration while minimizing project risks and maximizing long-term value in demanding industrial environments.

Understanding Titanium Coil Tubes and Their Key Properties

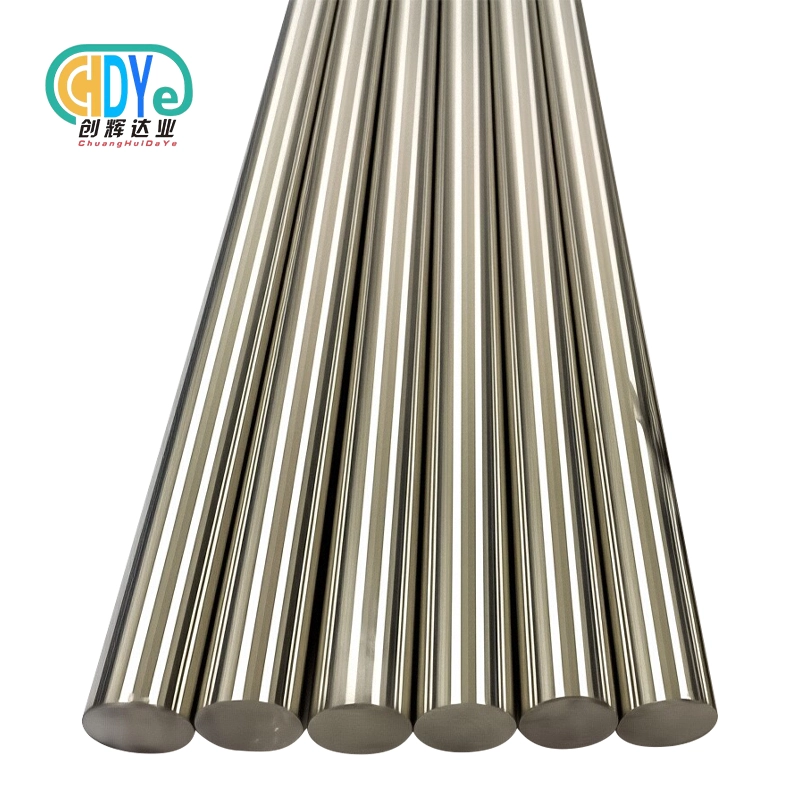

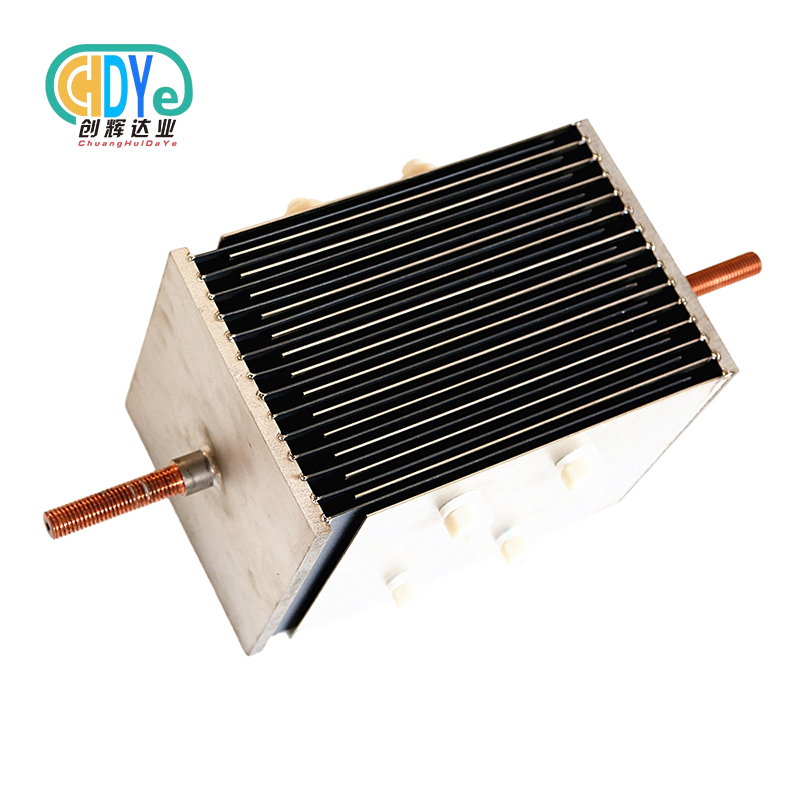

Titanium coil tubes represent precision-engineered components manufactured from high-quality titanium and titanium alloys through specialized coiling and annealing processes. These sophisticated heat exchange components are designed specifically for continuous fluid circulation systems where exceptional performance characteristics are essential.

Manufacturing Methods and Industrial Grades

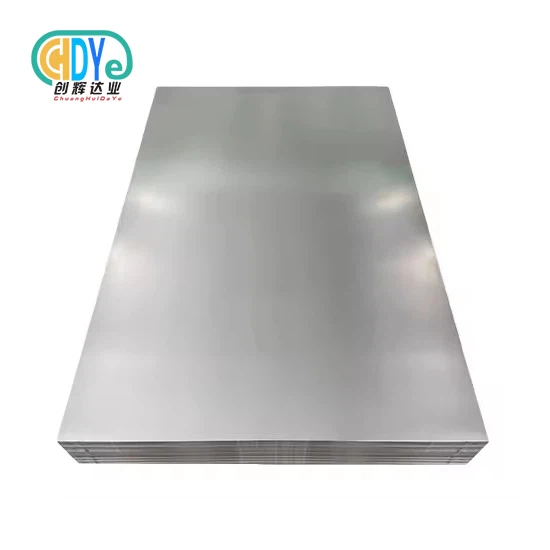

The fabricating handle starts with premium-grade titanium materials that experience exactness coiling to accomplish uniform ebb and flow and great roundness. Amid generation, controlled tempering methods guarantee ideal mechanical properties whereas keeping up tall weakness resistance. Common mechanical grades incorporate Review 1 and Review 2 commercially pure titanium, which offer amazing erosion resistance and formability. Review 2 titanium gives improved quality characteristics, while keeping up prevalent ductility for complex coil configurations.

Advanced fabricating strategies guarantee steady divider thickness and surface wrap-up quality throughout the coiling hprocess The tempering treatment disposes of remaining stresses that might compromise execution beneath cyclic loading conditions. Quality control measures amid generation confirm dimensional exactness, surface judgment, and mechanical properties according to universal standards.

Key Material Properties and Performance Characteristics

Titanium coil tubes display exceptional erosion resistance over assorted chemical situations, empowering dependable operation in seawater, chlorinated arrangements, and aggressive cleaning liquids. This remarkable erosion resistance permits producers to indicate more slender divider areas, subsequently moving forward warm exchange coefficients, while reducing fabric costs and system weight.

The smooth inside surface characteristics of titanium coils essentially decrease fouling propensities compared to elective materials. This inalienable cleanliness figure keeps up reliable warm execution over amplified working period, while minimizing maintenance requirements. The tall strength-to-weight proportion of titanium empowers compact framework plans without compromising auxiliary judgment beneath weight and temperature cycling.

Applications Across Critical Industries

Aerospace and defense applications use titanium coil tubes in natural control frameworks, water-powered circuits, and specialized warm exchangers where weight reduction and reliability are paramount. The material's capacity to withstand extraordinary temperature variations and destructive climates makes it irreplaceable for airplane and military equipment.

Chemical preparation offices utilize titanium coiled tubing in reactors, condensers, and evaporators, taking care of destructive media that would quickly degrade ordinary materials. The pharmaceutical andfood preparationg businesses depend on titanium's non-toxic properties and ease of sterilization for keeping up item quality standards.

Criteria for Specifying Titanium Coil Tubes in Custom Projects

Successful specification of titanium coil tubes requires systematic evaluation of project-specific operating conditions and performance requirements. Engineers must analyze the complete operating envelope to select appropriate materials and configurations.

Environmental and Mechanical Demand Assessment

Operating temperature ranges altogether impact fabric determination and coil plan parameters. High-temperature applications may require particular titanium grades with improved crawl resistance, whereas cryogenic conditions require materials with demonstrated low-temperature sturdiness. Weight cycling recurrence influences weariness life calculations and impacts the divider thickness specifications.

Chemical compatibility evaluation includes analyzing all prepared liquids, cleaning operators, and potential contaminants that might contact the titanium surface. Whereas titanium illustrates great common erosion resistance, particular situations may require specialized amalgam compositions or surface treatments to guarantee long-term reliability.

Titanium Grade Comparison and Selection

Grade 1 commercially immaculate titanium offers the greatest erosion resistance and formability, making it perfect for complex coil geometries in moderate-strength applications. Its amazing ductility empowers tight twist radii without compromising basic keenness. Review 2 titanium gives higher quality characteristics, while keeping up great formability, reasonable for applications requiring improved mechanical properties.

Titanium amalgams such as Ti-6Al-4V may be indicated for high-strength applications requiring prevalent mechanical properties. Be that as it may, these combinations ordinarily show diminished erosion resistance compared to commercially immaculate grades and require cautious assessment of natural compatibility.

Dimensional Considerations and Tolerance Requirements

Coil breadth determinations must suit framework format limitations while optimizing warm exchange execution. Bigger coil distances across, by and large, give superior warm trade proficiency but require more establishment space. The number of coil turns influences both warm exchange surface range and weight drop characteristics.

Tube breadth determinationequalizess warm exchange execution against stream resistance and fabric costs. Littler tube breadths increase warm exchange coefficients but maresult inigher weight drops and potential fouling concerns. Divider thickness details must fulfill weight necessities while considering erosion allowances and manufacturing tolerances.

Comparing Titanium Coil Tubes with Alternative Materials

Material selection decisions require a comprehensive evaluation of performance characteristics, cost implications, and long-term reliability factors. Understanding the comparative advantages helps justify titanium selection for specific applications.

Performance Benchmarking Against Conventional Materials

Stainless steel coil tubes offer lower starting costs but regularly require more noteworthy divider thickness due to second-rate erosion resistance in forceful situations. The expanded divider thickness diminishes thermal exchange effectiveness and increases framework weight. Support costs frequently surpass initial investment funds due to corrosion-related disappointments and replacement requirements.

Copper coil tubes give fabulous warm conductivity but endure fast ccorrosionin seawater and chlorinated situations. The predominant erosion resistance of titanium eliminates the requirement for defensive coatings or cathodic protection systems required with copper establishments. This advantage becomes especially noteworthy in marine applications and water treatment systems.

Cost-Benefit Analysis and Life-Cycle Considerations

While titanium coil tubes command a premium estimate compared to ordinary materials, the added value of ownership regularly favors titanium determination. Expanded benefit life, diminished support requirements, and the end of defensive frameworks contribute to favorable long-term economics.

The lightweight characteristics of titanium diminish auxiliary back psupport requirementsand transportation costs. Establishment time reserve funds result from the disposal of complex back structures required for heavier routine materials. These variables contribute altogether to the general venture financial mattersbeyondt basic fabric comparisons.

Application-Specific Advantages

Marine situations exhibit titanium's remarkable esteem suggestion through for all intents and purposes boundless benefit in seawater applications. The material's resistance to microbiologically impacted erosion eliminates the necessity for biocide treatment and related natural concerns.

High-purity applications in pharmaceutical and semiconductor fabrication benefit from titanium's non-contaminating characteristics and ease of cleaning approval. The material's capacity to withstand forceful cleaning chemicals without corrosion guarantees steady item quality standards.

Procurement Considerations for Titanium Coil Tubes

Successful procurement of titanium coil tubes requires understanding market dynamics, supplier capabilities, and quality assurance requirements. Strategic sourcing approaches can significantly impact project success and cost optimization.

Pricing Dynamics and Market Factors

Titanium estimating reflects worldwide supply-demand adjustment with crude fabric costs representing the biggest component. Arranging volume essentially impacts unit estimating, with bigger amounts empowering way better economies of scale. Customization necessities, dimensional complexity, and resilience determinations influence manufacturing costs and delivery schedules.

Market timing can affect estimating due to titanium's specialized supply chain characteristics. Long-term supply understandings may give cost stability for recurring necessities, while empowering providers to optimize production planning. Understanding these advertising flows makes a difference for experts who create compelling sourcing strategies.

Supplier Evaluation and Selection Criteria

Supplier specialized capabilities must adjust to venture requirements, including fabricating hardware, quality fsystems and building back. ISO 9001:2015 certification gives affirmation of steady quality administration practices. Extra certifications, such as AS9100 for aviation applications, may be required for particular industries.

Geographic contemplations influence conveyance plansoperationsns costs, and communication viability. Providers with worldwide reach can give neighborhood bolster whereas keeping up steady quality guidelines. Supply chain adaptability gets to be basic for overseeing unforeseen request changes or critical delivery requirements.

Quality Assurance and Documentation Requirements

Comprehensive fabric traceability documentation guarantees compliance with industry guidelines and administrative necessities. Chemical composition certificates, mechanical property confirmation, and dimensional assessment reports give basic quality approval. Non-destructive testing capabilities may be required for basic applications.

Manufacturing prepares documentationthat illustrates provider quality control viability and empowers persistent advancement activities. Normal provider reviews confirm continuous compliance with quality guidelines and distinguish potential advancement opportunities.

Case Studies and Practical Examples

Real-world applications demonstrate the practical benefits of proper titanium coil tube specification and highlight common challenges encountered during implementation.

Aerospace Environmental Control System

A major flying machine producer required lightweight warm exchanger coils for cabin natural control frameworks working over extraordinary temperature ranges. The detailed handling included assessing Review 2 titanium coils with particular dimensional resiliences to fit inside the restricted establishment space.

The chosen arrangement given 40% weight reduction compared to stainless steel options, while maintaining prevalent corrosion resistance against air moisture and cleaning chemicals. Exact details of coil geometry empowered ideal warm exchange execution inside strict weight impediments. Theextentd accomplished certification compliance, while diminishing working costs, made strides in fuel efficiency.

Chemical Processing Heat Recovery System

A petrochemical office required corrosion-resistant coil tubes for a warm recuperation framework dealing with high-pressure streams. The determination prepared assessed different titanium grades against particular chemical compatibility necessities and working conditions.

Grade 1 titanium coils were chosen based on prevalent erosion resistance and formability characteristics. The lean divider plan empowered improved warm recuperation productivity, while giving 20-year benefit life projections. Legitimate detail killed the rrequirementfor costly defensive coatings and diminished upkeep downtime significantly.

Marine Desalination Application

A seawater desalination plant required dependable warm exchanger coils capable of withstanding nonstop seawater presentation. The determination is centered on long-term unwavering quality and upkeep, taking into account optimization.

Titanium coil tubes killed the galvanic erosion issues experienced with past materials, while giving predominant thermal exchange execution. The detail included particular surface wrap-up necessities to minimize fouling and optimize cleaning adequacy. The establishment accomplished its plan life desires while decreasing working costs through killed substitution cycles.

Shaanxi Chuanghui Daye Metal Material Co., Ltd.: Your Trusted Titanium Coil Tube Partner

Shaanxi Chuanghui Daye Metal Material Co., Ltd. brings over three decades of specialized expertise in titanium coil tube manufacturing and supply. Located in Baoji High-tech Development Zone, known as China's "Titanium Capital," our company leverages advanced manufacturing capabilities and comprehensive quality systems to serve global industrial clients.

Comprehensive Product Portfolio and Customization Capabilities

Our titanium coil tube product line encompasses various grades, including commercially pure titanium and specialized alloys suitable for diverse industrial applications. Manufacturing capabilities include precision coiling, controlled annealing, and custom forming to meet specific project requirements. Available configurations range from simple helical coils to complex serpentine designs with tight dimensional tolerances.

Customization services extend beyond standard dimensional modifications to include specialized surface treatments, non-standard alloy compositions, and unique coil geometries. Our engineering team collaborates with clients to optimize coil designs for specific operating conditions while maintaining cost-effectiveness and manufacturability.

Quality Assurance and Manufacturing Excellence

ISO 9001:2015 certification demonstrates our commitment to consistent quality management throughout the production process. Advanced manufacturing equipment, including electron beam furnaces, precision rolling mills, and CNC machining centers, ensures dimensional accuracy and surface finish quality. Comprehensive testing capabilities verify material properties, dimensional compliance, and surface integrity for every shipment.

Quality control procedures encompass raw material inspection, in-process monitoring, and final inspection protocols. Complete traceability documentation accompanies every order, providing essential compliance verification for regulated industries. Our quality systems support continuous improvement initiatives and maintain customer confidence in product reliability.

Global Supply Chain and Technical Support

International supply chain capabilities enable reliable delivery to global markets while maintaining competitive pricing and consistent quality standards. Technical support services include application engineering, material selection guidance, and installation consulting to optimize project outcomes. Our experienced team assists with specification development, ensuring proper material selection for specific operating environments.

Customer service excellence includes responsive communication, flexible delivery scheduling, and comprehensive after-sales support. Long-term partnership relationships enable continuous collaboration on evolving requirements and new application development. These capabilities position Chuanghui Daye as a trusted partner for critical titanium coil tube applications across diverse industries.

Conclusion

Specifying titanium coil tubes for custom projects requires careful consideration of operating conditions, material properties, and supplier capabilities. Proper specification directly impacts system performance, reliability, and long-term cost-effectiveness. Understanding titanium's unique advantages enables informed decision-making that optimizes project outcomes while justifying premium material costs through enhanced performance and extended service life. The specification process demands collaboration between procurement professionals, engineers, and experienced suppliers to achieve optimal results in demanding industrial applications.

FAQ

Q: What titanium grade provides the best corrosion resistance for seawater applications?

A: Grade 1 commercially pure titanium offers exceptional corrosion resistance in seawater environments due to its minimal alloying content and natural oxide formation. Grade 2 titanium also performs excellently in marine applications while providing higher strength characteristics when mechanical requirements demand enhanced properties.

Q: How do manufacturing processes affect titanium coil tube performance?

A: Precision coiling and controlled annealing processes significantly impact mechanical properties and dimensional accuracy. Proper annealing eliminates residual stresses that could cause premature failure under cyclic loading. Surface finish quality affects heat transfer efficiency and fouling resistance, making manufacturing process control critical for optimal performance.

Q: What are typical lead times for custom titanium coil tube orders?

A: Standard configurations typically require 1-2 weeks for production and delivery, while complex custom designs may require 2-3 weeks, depending on specification complexity and current production schedules. Rush orders can often be accommodated with expedited processing for urgent project requirements.

Q: How do coil dimensions affect heat transfer performance?

A: Coil diameter and tube spacing directly influence heat transfer coefficients and pressure drop characteristics. Smaller coil diameters increase turbulence and heat transfer rates but create higher pressure drops. Optimal design balances these factors based on specific application requirements and system constraints.

Partner with Chuanghui Daye for Superior Titanium Coil Tube Solutions

Shaanxi Chuanghui Daye combines decades of titanium expertise with advanced manufacturing capabilities to deliver exceptional titanium coil tube solutions for your custom projects. Our ISO 9001:2015 certified facility in China's Titanium Capital ensures consistent quality and competitive pricing for global markets. Contact our technical specialists at info@chdymetal.com to discuss your specific requirements and receive expert guidance on titanium coil tube specifications. As a leading titanium coil tube manufacturer, we provide comprehensive customization services, reliable delivery schedules, and ongoing technical support to optimize your project outcomes.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate." ASTM B265-20, 2020.

2. Boyer, R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Park, Ohio, 1994.

3. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio, 2000.

4. Lutjering, Gerd and Williams, James C. "Titanium: Engineering Materials and Processes, 2nd Edition." Springer-Verlag Berlin Heidelberg, 2007.

5. Schutz, R.W. and Thomas, D.E. "Corrosion of Titanium and Titanium Alloys." ASM Handbook Volume 13B: Corrosion Materials, ASM International, 2005.

6. Tubular Exchanger Manufacturers Association. "Standards of the Tubular Exchanger Manufacturers Association, 10th Edition." TEMA Inc., Tarrytown, New York, 2019.

Learn about our latest products and discounts through SMS or email