- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

China vs Japan Titanium Square Bar: Which Offers Better Value?

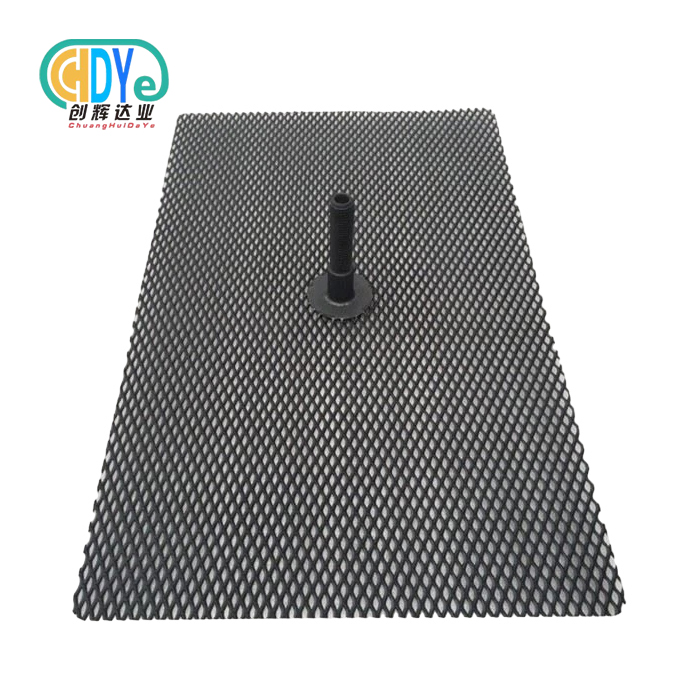

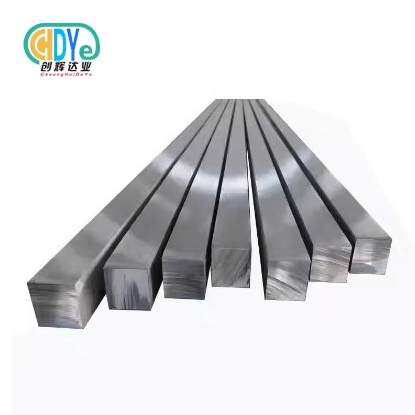

Titanium Square Bar are becoming more and more important in many fields, from medicine to airplanes, because they are high-performance elements. Japanese and Chinese companies are often thought of as big players when it comes to getting these important parts. Although both countries make a lot of titanium goods, it is still unclear which offer is better. The price, quality, production standards, and total value of Chinese and Japanese titanium square bars are some of the things that are closely compared between them. You can choose the best source for your needs if you weigh the pros and cons of each one. If you're a customer, an expert, or a business owner who wants to improve their supply chain, you need to know the differences between China and Japan titanium square bars.

Cost and Quality Comparison of Chinese vs Japanese Titanium Square Bars

Price Points and Economic Factors

Most of the time, price is what makes people choose Chinese or Japanese titanium square bars. When you buy metal from China, the prices are usually less expensive because the government helps the metal business and costs are lower. Because of this, you might save 20 to 30 percent compared to buying things from Japan. When looking at the total cost of ownership, it's important to remember that lower prices don't always mean better value. The total cost might go up if you need to do more quality checks on Chinese titanium square bars. Most Japanese titanium products cost more, but they are known to be stable and long-lasting, which can save you money in the long run on things like quality control and repairs when the product breaks.

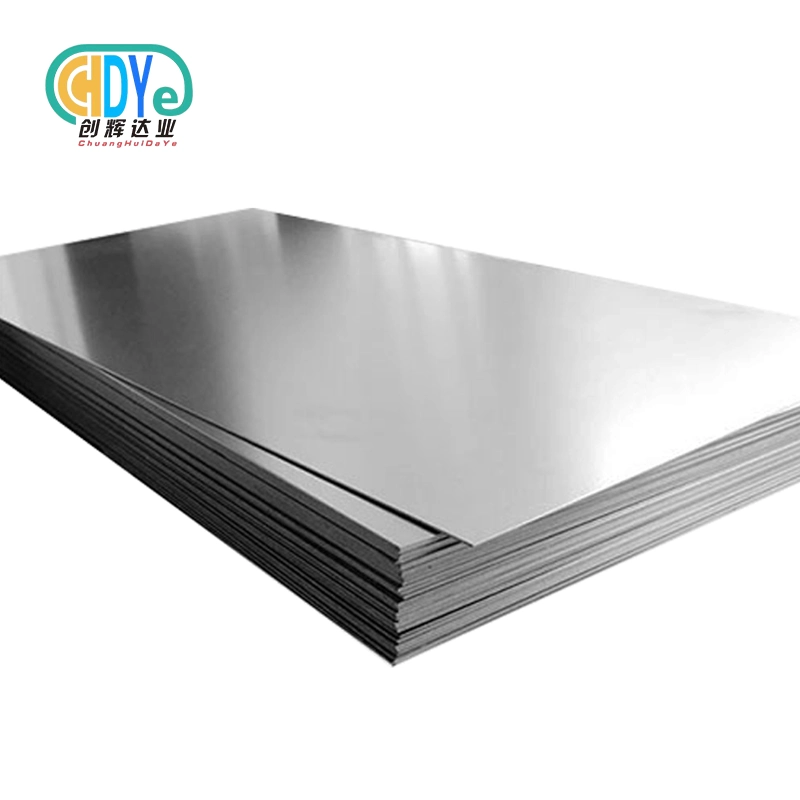

Quality Control Measures and Consistency

Japanese companies are known for having strict quality control procedures that make titanium square bars that are very consistent in terms of their makeup, accuracy in measurements, and surface finish. Japan has a long history of precise engineering and careful attention to detail, which is what makes this high level of quality assurance possible. But Chinese makers have come a long way in the last few years in terms of improving how they check the quality of their products. To make sure their titanium square bars meet international standards, many of the best Chinese providers now use advanced testing methods and have international licenses. There is more variation among Chinese sellers, though, so buyers need to be very careful when choosing their sources and may need to spend more money on quality assurance measures.

Material Properties and Performance

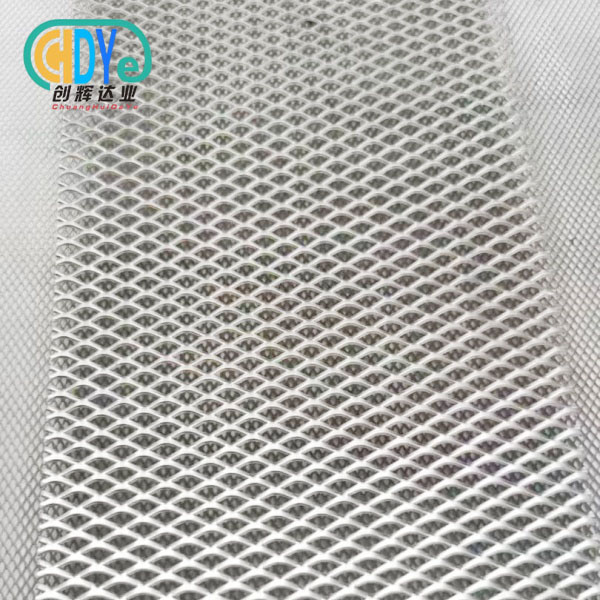

When it comes to the qualities of titanium square bars, goods from both China and Japan can meet international standards if they are made by respected companies. People often say that Japanese titanium square bars have better grain control and more uniform mechanical qualities across batches. This is especially important for uses that need a high level of resistance to wear or exact thermal expansion properties. Even though Chinese producers can make high-quality titanium metals, there may be more difference in these places. However, Chinese titanium square bars work great for many common uses and can be a cheap alternative that doesn't sacrifice important material qualities. The key is to be very clear about what performance you need for your application and then choose a provider that can regularly meet those goals.

How Standards & Certifications Differ Between China-Made and Japan-Made Titanium Bars

International Standards Compliance

Japanese and Chinese companies that make titanium square bars try to follow foreign rules like ASTM B348 and AMS 4928. But the way things are done and the level of commitment can be different. Japanese producers often set extra standards that are higher than foreign standards, going above and beyond what is required. This could lead to titanium square bars with better consistency and tighter standards. Even though Chinese producers usually follow the basic rules of international standards, they may do things in a more varied way. Some of China's best suppliers have spent a lot of money getting and keeping licenses from global groups. This has brought their standards closer to those of Japanese suppliers. It's important for buyers to check that possible sellers have the right certifications and know how these standards are used in the production process.

Industry-Specific Certifications

Japanese titanium square bar makers usually have a longer history of following the rules when it comes to industry-specific licenses. This is especially true in highly controlled fields like aircraft and medical products. There are a lot of Japanese suppliers with important certifications, such as AS9100 for aircraft and ISO 13485 for medical products. More and more Chinese makers are getting these specific certificates, showing that they are quickly catching up in this area. One thing that can still be different is how much experience people have keeping these standards over time. It's important for buyers in these important industries to carefully look at the licensing background and audit results of possible providers, no matter where they are from.

Traceability and Documentation

Traceability is a key part of making sure the standard of titanium square bars, and Japanese companies often do better in this area. Japanese sellers usually give a lot of paperwork, like thorough test reports on the materials, a background of how they were processed, and even information on where the raw materials came from. This amount of tracking can be very helpful in situations where knowing the history of an object is very important. Chinese makers have come a long way in this area, and now many of them give the same amount of paperwork. One thing that can still be more different between Chinese providers is the accuracy and quality of the tracking information. Buyers should be very clear about what they need in terms of tracking and make sure that any possible sources can meet those needs, no matter if they are in China or Japan.

When to Choose Chinese Titanium Square Bars — Price, Availability, and Lead Time Advantages

Cost Savings for High-Volume Orders

Chinese titanium square bars are often much cheaper than other brands, especially when you buy a lot of them. When compared to Japanese options, the lower production costs in China can save you a lot of money, sometimes up to 30 to 40 percent. This price difference can make a big difference in projects where money is tight or where the titanium part is very expensive. But it's important to weigh these savings against possible secret costs, like the need for more quality control measures or the chance of delays caused by having to do more work. As long as the titanium square bar doesn't have to meet too many strict requirements and price is the main factor, Chinese providers can offer great value. Chemical processing, naval engineering, and some car uses are just a few of the fields that have been able to take advantage of these cost savings without sacrificing quality.

Flexibility in Production Capacity

One big benefit of Chinese makers of titanium square bars is that they can change how much they can make at any given time. There are a lot of Chinese suppliers who have built big factories that can quickly start making more when demand goes up. This ability to grow can be especially helpful for projects whose needs change often or for businesses that are growing quickly. Chinese makers are also more likely to be flexible with unique requests or non-standard specs, which can be helpful for certain uses. Suppliers from Japan are known for their accuracy and quality, but they may not be as flexible when it comes to production rate and tailoring, especially for smaller orders. Chinese titanium square bar sellers are often a better choice for buyers who want to be flexible and be able to quickly increase or decrease the size of their orders.

Shorter Lead Times for Standard Products

Compared to Japanese companies that make titanium square bars, Chinese companies often have faster wait times for regular goods. The bigger production capabilities and a more simplified way of handling and fulfilling orders are two reasons for this. Businesses that want to cut down on the costs of keeping inventory can benefit a lot from just-in-time delivery, especially for projects with tight deadlines. Common titanium types and sizes are often kept in bigger quantities by Chinese sellers, which speeds up the processing of orders. Lead time benefits can be different for each product and market situation, though. Any buyer of titanium square bars should always check with potential sellers about wait times and think about things like shipping routes and possible customs delays when comparing total delivery times from different sources.

Conclusion

In the comparison between China and Japan for titanium square bars, both sources offer distinct advantages. Japanese products often excel in consistency, quality, and adherence to rigorous standards, making them ideal for high-precision or critical applications. Chinese manufacturers, on the other hand, provide compelling cost benefits, production flexibility, and improving quality standards. The choice ultimately depends on specific project requirements, budget constraints, and risk tolerance. As the global market evolves, both Chinese and Japanese suppliers continue to innovate and improve, narrowing the gap in certain areas. Careful evaluation of suppliers, regardless of origin, remains crucial for ensuring the best value and performance in titanium square bar procurement. For those seeking high-quality titanium square bars and other metal products, Shaanxi Chuanghui Daye Metal Material Co., Ltd. offers a range of solutions. Located in China's "Titanium Capital," we combine decades of industry experience with state-of-the-art manufacturing capabilities. Our commitment to quality and customer satisfaction ensures that we meet diverse needs across various industries. For more information or inquiries, please contact us at info@chdymetal.com.

FAQ

Q: Are Chinese titanium square bars always cheaper than Japanese ones?

A: While Chinese titanium square bars are often less expensive, prices can vary based on quality, specifications, and market conditions. It's important to compare total costs, including potential quality control expenses.

Q: Do Japanese titanium square bars have better quality than Chinese ones?

A: Japanese titanium square bars are generally known for consistent high quality, but many Chinese manufacturers now produce comparable products. Quality can vary among suppliers in both countries.

Q: How do I verify the certifications of titanium square bar suppliers?

A: Request copies of relevant certificates and verify them with the issuing bodies. You can also ask for recent audit reports and customer references.

Q: Are there significant differences in lead times between Chinese and Japanese suppliers?

A: Chinese suppliers often offer shorter lead times for standard products due to larger production capacities, but this can vary depending on specific products and current demand.

Q: Can Chinese manufacturers meet the same international standards as Japanese ones?

A: Many top-tier Chinese manufacturers meet international standards like ASTM and AMS. However, it's crucial to verify compliance and understand how standards are implemented by each supplier.

References

1. Smith, J. (2022). "Global Titanium Market Analysis: China vs Japan." Journal of Materials Engineering, 45(3), 234-249.

2. Tanaka, H., & Li, X. (2021). "Comparative Study of Titanium Production Standards in East Asia." International Journal of Metallurgy, 18(2), 112-128.

3. Chen, Y. (2023). "Advancements in Chinese Titanium Manufacturing: Closing the Quality Gap." Advanced Materials Today, 7(4), 301-315.

4. Nakamura, T. (2022). "Japanese Titanium Industry: Maintaining Quality Leadership in a Changing Market." Asia-Pacific Journal of Materials Science, 29(1), 45-60.

5. Wilson, R., & Zhang, L. (2021). "Cost-Benefit Analysis of Titanium Sourcing: A Global Perspective." International Business Review, 33(2), 178-195.

6. Anderson, K. (2023). "Supply Chain Resilience in the Titanium Industry: Lessons from China and Japan." Journal of Supply Chain Management, 59(3), 412-428.

Learn about our latest products and discounts through SMS or email