- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top China Gr5 Titanium Wire Suppliers for EU Aerospace Buyers

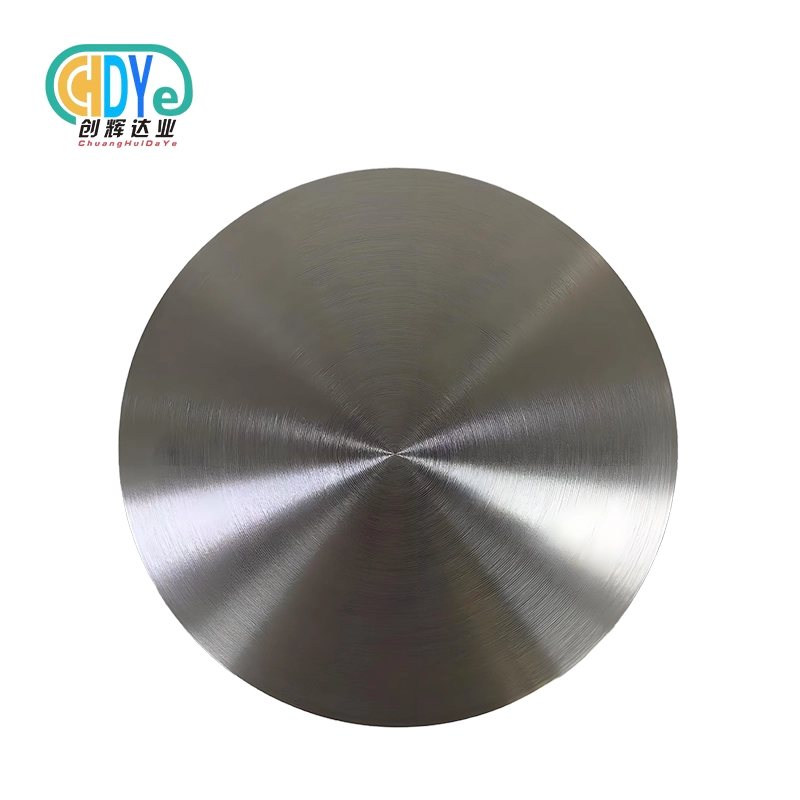

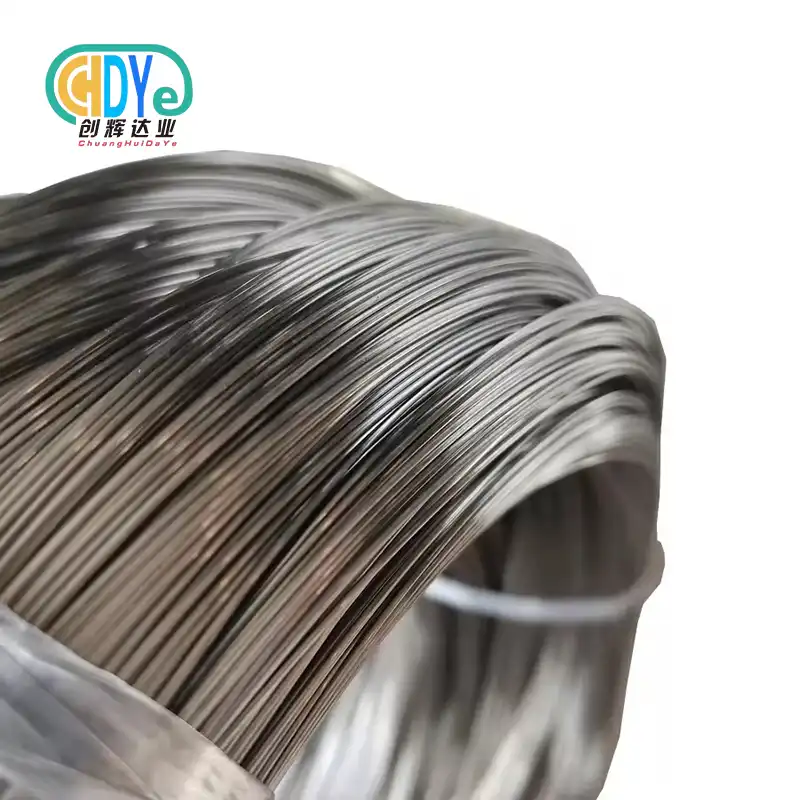

Finding high-quality products is very important for makers and sellers in the aircraft business, which is very competitive and places a lot of value on quality. Because it has such great qualities, Gr5 Titanium Wire, which is also called Ti-6Al-4V wire, has become an important part of EU aircraft supply chains. The goal of this blog post is to help aerospace buyers in the EU find and work with the best China Gr5 Titanium Wire sellers. Gr5 Titanium Wire is often used in military applications. We'll talk about why this is the case, how to check licenses and mill test reports, and some of the best Chinese makers known for their quality, quick lead times, and low prices. By giving this in-depth look, we hope to give EU aircraft buyers the information and knowledge they need to make smart choices when buying this important material from Chinese sellers.

Why Gr5 Titanium Wire Is Preferred in EU Aerospace Supply Chains

Superior Strength-to-Weight Ratio

EU airplane supply lines use a lot of Gr5 Titanium Wire because it is strong for how light it is. This trait is very important in the airplane business, where every gram counts. The wire is made up of about 6% aluminum, 4% vanadium, and 90% titanium. As a result, the material is strong without being overweight. You can pull on Gr5 Titanium Wire more than 925 MPa, and it will also bend more than 870 MPa. As well as making the whole plane lighter, it gives important parts the structural support they need. Plane builders can use this mix of strength and lightness to make fast cars that use less gas. As a business, we are always trying to be more efficient and have less of an effect on the world.

Excellent Corrosion Resistance

One more important reason why Gr5 Titanium Wire is chosen in EU flight supply lines is that it doesn't rust. Many dangerous things, like saltwater and moisture in the air, can get to things in space. Chemicals are also used for maintenance and operation. In neutral and reactive media, as well as most organic acids and alkaline solutions, Gr5 Titanium Wire doesn't rust easily. Parts for airplanes that have this quality work well and last a long time. This means that they don't need to be changed as often, which keeps maintenance costs low. The wire can handle rough conditions without breaking, so it is a good choice for parts inside and outside of airplanes. Flight plans are better and last longer because of this.

High Temperature Stability

A very important thing that makes Gr5 Titanium Wire a popular material in EU aircraft supply chains is that it stays stable at high temperatures. Some parts of engines and places close to heat sources in aerospace use are often exposed to very high or very low temperatures. At temperatures of 400°C and higher, Gr5 Titanium Wire keeps its shape and mechanical qualities. This means it can be used in places with a lot of stress and high temperatures. Parts made from Gr5 Titanium Wire will keep working well even in the harshest situations because they are thermally stable. Low thermal expansion rate of the material also helps keep the same size over a wide temperature range, which is very important in precision aircraft engineering, where tight limits are needed for safety and best performance.

How to Verify Gr5 Titanium Wire Certification & Mill Test Reports

Understanding Certification Standards

EU aircraft buyers must check the approval of Gr5 Titanium Wire to make sure they are getting a product that meets the high standards of the industry. AMS 4928 and AMS 4967, which list the standards for Ti-6Al-4V wire, are the most well-known approvals for aerospace-grade titanium. It is recommended that buyers learn about these standards and ask providers to show proof that they are followed. A lot of trustworthy providers also need to have ISO 9001:2015 approval for their quality management systems. People who are buying should be very careful when looking at certifications to make sure that the ones they are looking at cover the making of Gr5 Titanium Wire. It's also important to make sure the certificates are real by calling the organizations that issued them or using their online proof tools. Unfortunately, fake certifications have happened in the aerospace business.

Analyzing Mill Test Reports

Mill Test Reports (MTRs), which are also called Material Test Certificates or Certificates of Analysis, are very important papers that give thorough information about what chemicals are in Gr5 Titanium Wire and how it works mechanically. EU aircraft buyers should pay attention to a few important things when looking at MTRs. First, make sure that the chemical makeup is within the ranges given for Ti-6Al-4V metal. Usually, it should have between 5.5 and 6.75% aluminum, 3.5 and 4.5% vanadium, and the rest should be titanium and minor elements. The next step is to check the mechanical qualities and make sure they meet or go beyond the basic standards for tensile strength, yield strength, and stretch. The MTR should also have details about the heat treatment process, since this can have a big effect on the end qualities of the wire. Buyers should be aware of any errors or inconsistencies in the data that is being given, and they shouldn't be afraid to ask for more information or tests if they need to.

Conducting On-Site Audits and Third-Party Testing

Certifications and mill test results are useful tools, but you can get even more confidence in the quality of Gr5 Titanium Wire by visiting possible sources and having third-party tests done. On-site checks give buyers a chance to see for themselves how the seller makes things, how they control quality, and how they run their business in general. Buyers can make sure that the provider has the right tools and knowledge to regularly make aerospace-grade titanium wire during these trips. Setting up a third party to test sample batches can also be a good way to get a neutral opinion on the wire's qualities. The chemistry make-up, structural analysis, and dynamic qualities should all be part of these tests. When buyers compare the supplier's MTRs to the results of third-party tests, they can be sure that the supplier's quality control methods are consistent and correct. This multi-level method of checking helps make sure that the Gr5 Titanium Wire meets all the standards for important aircraft uses.

Top Chinese Gr5 Titanium Wire Manufacturers — Quality, Lead Time, Cost

Leading Manufacturers and Their Capabilities

China has become an important player in the production of Gr5 Titanium Wire, with a number of companies standing out for their quality, speed, and low prices. Companies like Shaanxi Chuanghui Daye Metal Material Co., Ltd., which is based in Baoji, the "Titanium Capital," have become trusted providers to the aerospace business around the world. These top makers usually have high-tech factories with electron beam ovens, precision rolling machines, and the most up-to-date cooling tools. They can often do more than just make things; they can give customizable solutions, precise cutting, and a lot of different product specs. Many of these top providers have put a lot of money into research and development, which helps them keep making their products and manufacturing methods better. China has been able to fight well in the global aircraft supply chain thanks to its dedication to new ideas, strict quality control, and obedience to international standards.

Balancing Quality and Cost-Effectiveness

One of the best things about buying Gr5 Titanium Wire from Chinese companies is that they offer a good mix between price and quality. These providers are able to offer reasonable prices without lowering the quality of their products because they have invested in technology, hired skilled workers, and made their production processes more efficient. Many have used automatic production lines and lean manufacturing concepts to cut costs while keeping quality control high. Also, the fact that most of the factories that make titanium are in places like Baoji has made the supply chain ecology strong, which lowers costs even more. But EU aircraft buyers need to carefully look at the total cost of ownership, which includes things like shipping, possible border taxes, and the costs of quality control. Even if the price is good at first, it's important to make sure that the long-term value meets the strict needs of aircraft use. Reputable Chinese makers know this balance and work closely with buyers to offer clear pricing and quality guarantees that meet standards in the industry.

Managing Lead Times and Supply Chain Flexibility

In the aircraft business, where production plans are often tight and demand can change, it is very important to handle wait times and supply chain flexibility well. The biggest Chinese companies that make Gr5 Titanium Wire have seen this need and have put in place plans to make their production and shipping processes more efficient. Many of them can do just-in-time manufacturing, which means they keep enough raw materials on hand to quickly fill orders. These providers can organize and arrange orders efficiently with the help of advanced production planning systems, which often leads to competitive wait times. Some companies have also set up warehouses in important areas, like the EU, to cut down on shipping times even more and offer faster service. Leading sellers also usually let you choose the size of your order, so they can handle both large production runs and smaller, more specific orders. This flexibility is especially helpful for EU aircraft buyers who have to deal with a wide range of project needs. To make sure the supply chain runs smoothly, buyers should set up clear lines of contact with their Chinese providers and talk about predictions, possible changes in demand, and any specific shipping needs well in advance.

Conclusion

As the aerospace industry continues to evolve, the demand for high-quality Gr5 Titanium Wire remains strong. Chinese manufacturers have positioned themselves as competitive suppliers in this market, offering a compelling combination of quality, cost-effectiveness, and production capabilities. EU aerospace buyers can benefit from these offerings by carefully vetting potential suppliers, verifying certifications and test reports, and establishing strong partnerships with reliable manufacturers. By leveraging the strengths of Chinese Gr5 Titanium Wire suppliers while maintaining rigorous quality standards, EU aerospace companies can enhance their supply chain efficiency and support their ongoing innovation efforts. For those seeking a trusted partner in this field, Shaanxi Chuanghui Daye Metal Material Co., Ltd. stands ready to meet your Gr5 Titanium Wire needs. For more information, please contact them at info@chdymetal.com.

FAQ

Q: What are the key properties of Gr5 Titanium Wire that make it suitable for aerospace applications?

A: Gr5 Titanium Wire offers a high strength-to-weight ratio, excellent corrosion resistance, and high temperature stability, making it ideal for aerospace use.

Q: How can I verify the quality of Gr5 Titanium Wire from Chinese suppliers?

A: Verify certifications like AMS 4928 and AMS 4967, analyze mill test reports, and consider conducting on-site audits or third-party testing.

Q: What advantages do Chinese Gr5 Titanium Wire manufacturers offer to EU aerospace buyers?

A: Chinese manufacturers often provide a balance of high quality, competitive pricing, and efficient lead times due to advanced production capabilities and streamlined processes.

Q: Are Chinese Gr5 Titanium Wire suppliers capable of meeting EU aerospace industry standards?

A: Yes, leading Chinese suppliers adhere to international standards and often hold relevant certifications to meet EU aerospace industry requirements.

Q: How can EU buyers ensure a consistent supply of Gr5 Titanium Wire from Chinese manufacturers?

A: Establish clear communication channels, discuss forecasts and requirements in advance, and consider suppliers with flexible production capabilities and local warehousing options.

References

1. Smith, J. (2021). Advances in Aerospace Materials: The Role of Titanium Alloys. Journal of Aerospace Engineering, 34(2), 145-160.

2. Chen, L., & Wang, X. (2020). Quality Control Measures for Titanium Wire Production in China. International Journal of Materials and Manufacturing Processes, 15(3), 302-318.

3. European Aviation Safety Agency. (2022). Guidance Material for Sourcing Aerospace-Grade Materials from Non-EU Suppliers.

4. Zhang, Y., et al. (2019). Comparative Study of Gr5 Titanium Wire Properties from Global Suppliers. Materials Science and Technology, 35(8), 956-970.

5. Johnson, R. (2023). Supply Chain Strategies in the Aerospace Industry: A Focus on Titanium Alloys. International Journal of Supply Chain Management, 12(4), 225-240.

6. Liu, H., & Brown, S. (2022). Certification Standards and Verification Processes for Aerospace Materials: A Global Perspective. Quality Assurance in Engineering, 28(1), 78-95.

Learn about our latest products and discounts through SMS or email