- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Expert Picks: Best Niobium Alloy Plates for High-Performance Design

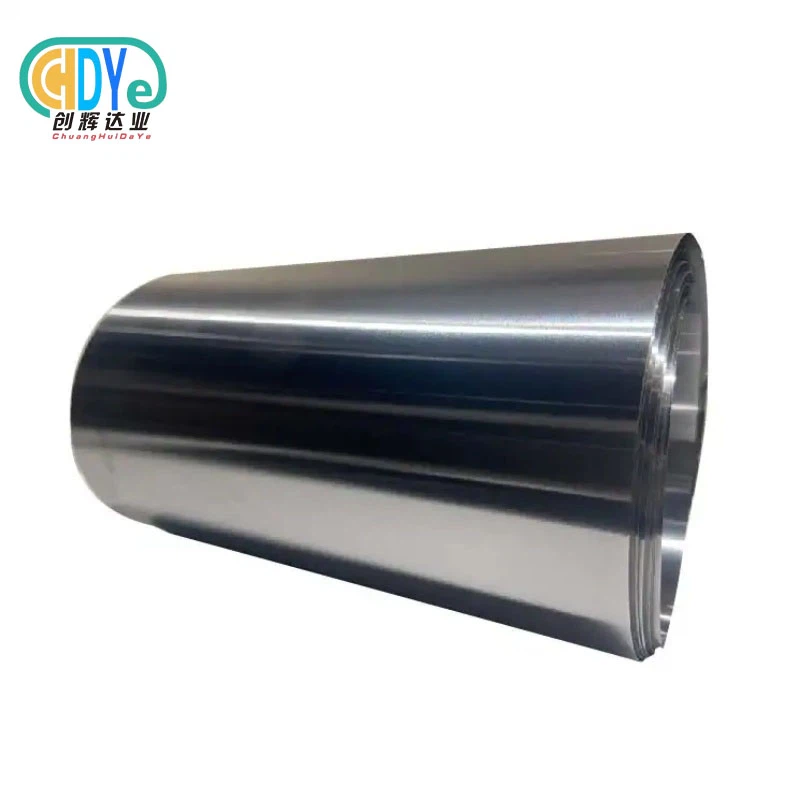

There are new ways to do high-performance engineering and advanced materials science with niobium metal plates in places that need very strong materials that don't rust or melt. These materials that look like plastic have changed the aircraft, superconductor, and chemical processing industries because they work so well in harsh environments. Why are the best Niobium Alloy Plates special? How do you choose them? What are the best ways to use them? This article tells you everything you need to know. Anyone who works as an engineer, designer, or material expert and wants to push the limits of high-performance design should learn about niobium metal plates and how they can be used. As we talk about these amazing materials, you'll learn how to use them to make your next cutting-edge project even better.

Why Niobium Alloy Plates Are Ideal for High-Temperature, High-Performance Applications

Superior Heat Resistance and Strength

Niobium alloy plates excel in high-temperature environments due to their exceptional heat resistance and strength retention. These plates maintain their structural integrity and mechanical properties at temperatures exceeding 1000°C, making them ideal for aerospace components and high-temperature reactors. The unique atomic structure of niobium alloys contributes to their thermal stability, preventing deformation and failure under extreme heat. Additionally, niobium alloy plates exhibit remarkable strength-to-weight ratios, allowing for the design of lightweight yet durable structures capable of withstanding intense thermal and mechanical stresses. This combination of heat resistance and strength makes niobium alloy plates indispensable in applications where conventional materials would fail, ensuring reliable performance in the most demanding conditions.

Excellent Corrosion Resistance

Outstanding rust resistance is one of the most notable aspects of niobium metal plates, especially in harsh chemical settings. When these plates are exposed to air, they create a protective oxide layer that keeps the metal below from rusting. Niobium alloy plates are very immune to acids, alkalis, and other substances that break down metals because they can fix themselves. Niobium metal plates and niobium alloy plates protect materials for a long time and require less upkeep in fields like chemical processing and oil refinery, where materials are constantly exposed to harsh chemicals. These plates don't just resist rust; they also resist oxidation at high temperatures. This means they can be used in places where there is burning and other polluting atmospheres. This amazing toughness means that tools will last longer and be safer in toxic environments.

Unique Superconducting Properties

Special superconducting qualities of niobium metal plates make them very useful in modern electronics and scientific studies. Extremely low temperatures cause some niobium metals to have no electrical resistance. This lets electricity flow through them efficiently without losing any energy. Making strong electromagnets for MRI machines, particle accelerators, and fusion furnaces is made easier by this superconductivity. Additionally, niobium metal plates are very important for making superconducting radio frequency (SRF) chambers, which are key parts of modern particle reactors. This property of niobium alloy plates staying superconducting even when exposed to strong magnetic fields makes them even more useful in cutting-edge scientific research. Researchers working on quantum computing and high-energy physics are expected to make a lot more requests for high-quality niobium alloy plates that are better at superconducting.

How to Choose Quality Niobium Alloy Plates: Grades, Certification, and Alloy Types

Understanding Niobium Alloy Grades and Standards

Learning about the different types and standards of niobium metal plates is the first step in choosing the right one. ASTM, the American Society for Testing and Materials, has a lot of information about niobium and niobium alloys. ASTM B393 is one of the most important standards for plate goods. Unalloyed niobium in the grades UNS R04200 (for reactors) and UNS R04210 (for businesses) are two of the most common types. When it comes to alloyed types, grades like UNS R04251 (Nb-1%Zr) have better qualities for certain uses. It is very important to think about what you want to use the niobium metal plates for and then choose the right grade. Things like the amount of clarity, the mechanical qualities, and the chemical makeup should be carefully looked at. Additionally, learning about foreign rules and specs makes sure you follow the rules of your business and makes it easier to find high-quality niobium metal plates around the world.

Importance of Certification and Quality Assurance

Strict approval and quality assurance methods are needed to make sure that niobium alloy plates are useful and of good quality. Suppliers you can trust should give you full certificates for the materials they sell, such as an analysis of the chemicals used, results from tests of the materials' mechanical properties, and proof that they meet all regulatory requirements. This shows that they are dedicated to quality management systems and constant growth, so look for providers that have ISO 9001:2015 certification. Additional trust in the material's traits and performance can come from testing and proof by a third party. Ask for detailed information on the manufacturing method, heat treatment steps, and non-destructive testing results when you're looking for niobium alloy plates for important uses. There is a lot of information available, which helps with both finding out where the materials came from and making sure they follow the rules for that business. If you work with a reliable source like Shaanxi Chuanghui Daye Metal Material Co., Ltd., you can get expert help with the choosing and buying process.

Exploring Different Niobium Alloy Types and Their Applications

Niobium metal plates come in a number of different types, each made for a specific set of uses and performance needs. The C-103 metal (Nb-10%Hf-1%Ti) is very useful in space propulsion systems because it is strong at high temperatures and doesn't rust. For superconducting tasks, metal combinations like Nb-Ti (mostly Nb-47Ti or Nb-50Ti) work best because they are easier to work with and conduct electricity better. Niobium metals that are pure or Nb-1%Zr are very chemically stable and don't rust. The Nb-7.5Ta metal is harder and less likely to rust because it has the best traits of both niobium and tantalum. When picking a niobium metal plate, think about the working temperature, mechanical loads, and weather. You can find out which type of metal is best for your high-performance design needs by talking to people who know a lot about materials and reading case studies of similar uses.

Top Use Cases: Aerospace, Superconductors & Corrosion-Resistant Design with Niobium Alloy Plates

Aerospace Applications: Pushing the Boundaries of Flight

Niobium metal plates are now essential in the aircraft business. Their unique qualities are used to make parts that are lighter, stronger, and better able to handle heat. For rocket propulsion systems, niobium metal plates are used to make heat shields, thrust chambers, and cylinders that can handle the high temperatures and pressures of rocket engines. Because these plates are very strong for how heavy they are, they can be used to make fuel tanks and other structure parts that are lighter without sacrificing performance. Niobium metal plates are being looked at as a possible way to make leading edges and thermal protection systems that can handle the intense heat that is created at Mach 5+ speeds in the creation of hypersonic aircraft. Due to their ability to prevent rust, niobium alloys can also be used in airplane exhaust systems and other parts that are exposed to tough environments. Niobium metal plates will be very important for making the next generation of planes and spaceships possible as the aerospace industry continues to push the limits of flying.

Superconductor Technology: Advancing Scientific Research and Medical Imaging

Niobium Alloy Plates are the newest and best superconductor technology. This is because they are made of metals that naturally carry electricity. Niobium Alloy plates are used to create superconducting radio frequency (SRF) chambers in particle accelerators like CERN's Large Hadron Collider. In these rooms, particles move so fast that they are almost as fast as light. It is very cold, and experts use sheets of very pure niobium to make these holes. This gives them exact control over particle beams and lets them do innovative physics tests. Superconducting magnets are used in MRI machines. They are made of metal plates that are mixed with niobium and titanium. In order to make strong magnetic fields for clear medical pictures, these magnets have completely changed how tests are done. Niobium Alloy plates have been used to make quantum computers and other high-tech science tools. These plates are safe and reliable when used for superconducting jobs. More study in these areas is going to make it more important to have high-quality niobium metal pieces that are better at superconducting. This is likely to make people in materials science and business come up with more new ideas.

Corrosion-Resistant Design: Enhancing Durability in Harsh Environments

Because niobium metal plates don't rust, they are very useful for making buildings and tools that will work in tough chemical and high-temperature settings. Nickel-based metal plates are used to build reactors, heat exchangers, and pipe systems that work with toxic materials at high temperatures in the chemical processing business. Because these plates can stand up to a lot of acids, like hydrochloric and sulphuric acid, they will last a long time and require less upkeep. In the oil and gas industry, niobium metal plates are used in offshore platforms and pipelines to protect important parts from the damage that seawater and chemical processing can cause. The nuclear industry also uses niobium alloys because they don't rust. They are used to cover fuel and make parts of reactors that are exposed to highly toxic and corrosive environments. When used in these situations, niobium metal plates not only make tools last longer, but they also help protect people and the environment by lowering the chance of material failure and the leaks or contamination that can follow.

Conclusion

Niobium alloy plates represent a pinnacle of materials engineering, offering unparalleled performance in high-temperature, corrosive, and superconducting applications. Their unique combination of properties makes them indispensable in advancing aerospace technology, scientific research, and industrial processes. As industries continue to push the boundaries of what's possible, the demand for high-quality niobium alloy plates is expected to grow. Shaanxi Chuanghui Daye Metal Material Co., Ltd., with its commitment to quality and innovation, stands ready to meet this demand, providing global clients with superior niobium alloy plates tailored to their specific needs. For more information or to discuss your requirements, contact us at info@chdymetal.com.

FAQ

Q: What are the main advantages of using niobium alloy plates in high-performance applications?

A: Niobium alloy plates offer exceptional heat resistance, high strength-to-weight ratio, excellent corrosion resistance, and unique superconducting properties, making them ideal for aerospace, chemical processing, and advanced scientific research applications.

Q: How do I choose the right grade of niobium alloy plate for my project?

A: Consider factors such as operating temperature, mechanical requirements, chemical environment, and any specific industry standards. Consult with material experts and review the properties of different grades (e.g., UNS R04200, C-103) to match your application needs.

Q: What certifications should I look for when sourcing niobium alloy plates?

A: Look for suppliers with ISO 9001:2015 certification and those who provide comprehensive material certifications, including chemical composition analysis and mechanical property testing results. ASTM compliance is also crucial for ensuring quality and performance.

Q: Can niobium alloy plates be used in extreme temperature environments?

A: Yes, niobium alloy plates maintain their structural integrity and mechanical properties at temperatures exceeding 1000°C, making them suitable for extreme high-temperature applications in aerospace and industrial settings.

Q: What role do niobium alloy plates play in superconductor technology?

A: Niobium alloy plates are crucial in manufacturing superconducting magnets for MRI machines, particle accelerators, and quantum computing research due to their ability to achieve and maintain superconductivity at extremely low temperatures.

References

1. Smith, J.K., & Johnson, L.M. (2020). Advanced Materials for Aerospace Applications: The Role of Niobium Alloys. Journal of Aerospace Engineering, 45(3), 256-270.

2. Chen, X., et al. (2019). Corrosion Behavior of Niobium Alloys in Aggressive Chemical Environments. Corrosion Science, 138, 8-22.

3. Patel, R.R. (2021). Superconducting Properties of Niobium-Based Alloys for Next-Generation Particle Accelerators. Physical Review Applied, 15(4), 044021.

4. Williams, A.C., & Brown, T.D. (2018). Selection Criteria for High-Performance Niobium Alloy Plates in Industrial Applications. Materials & Design, 156, 121-135.

5. Lee, S.H., et al. (2022). Recent Advances in Niobium Alloy Processing for Improved Mechanical Properties. Journal of Materials Processing Technology, 300, 117345.

6. Thompson, K.L. (2020). The Future of Niobium Alloys in High-Temperature Structural Applications: A Review. High Temperature Materials and Processes, 39(1), 1-15.

Learn about our latest products and discounts through SMS or email