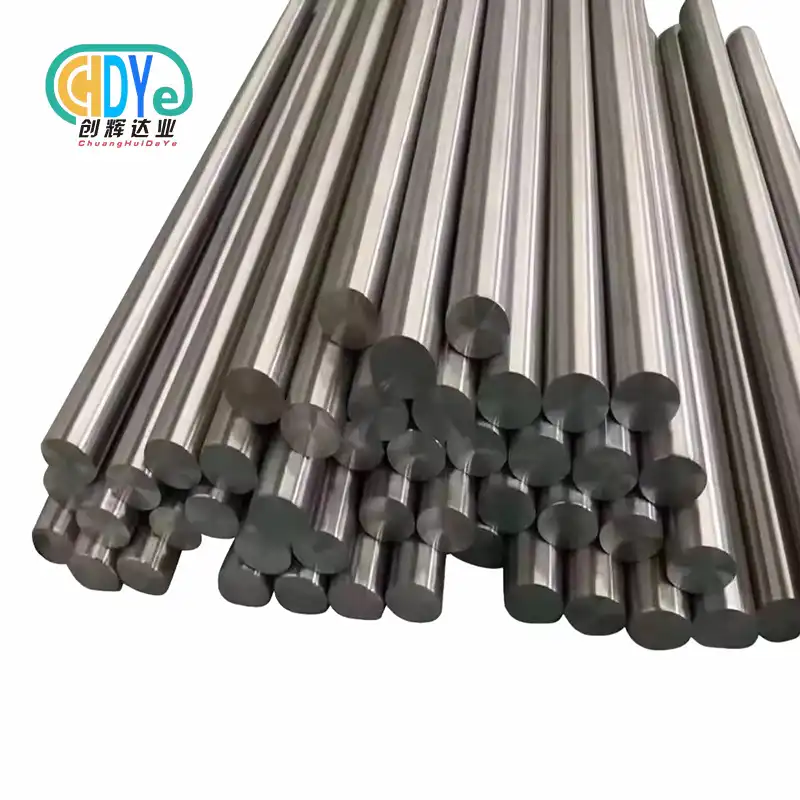

For chemical processing, the guide recommends pure tantalum bars. Acids preserve tantalum best. For piping, heat exchangers, and reaction vessels, global chemical plants need high-purity tantalum. Knowing what tantalum is used for and how to choose materials will make it last through harsh chemicals.

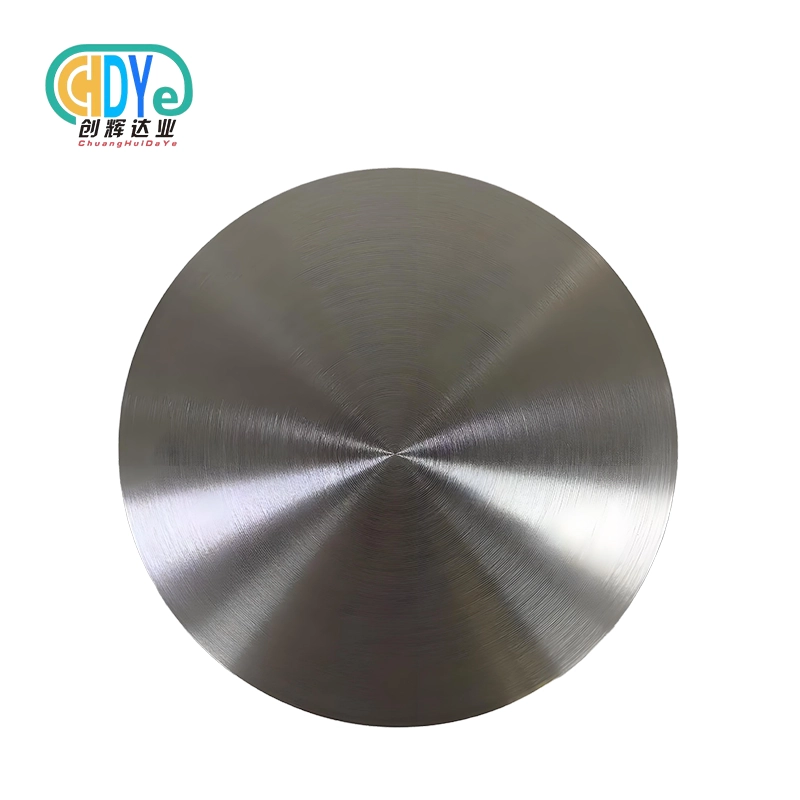

Understanding Pure Tantalum Bar Properties for Chemical Applications

Because it is very hard for most acids to break down tantalum metal, it is very important for use in tools that work with chemicals. The refractory metal holds its shape even when it's hot and exposed to strong sulphuric and hydrochloric acids, as well as nitric acid. Tantalum rod products show great chemical stability in a lot of different situations. This is not like other metals that quickly break down.

Tantalum alloys don't break down even when they're used in extreme thermal cycling because their high melting point of 3,017°C keeps them stable. This thermal stability is very important for chemical reactors that work under a range of temperature settings. Tantalum processing techniques keep these natural qualities intact while also making sure that the exact size needed for important uses is met.

Tantalum is safe for use with living things and works well in manufacturing, especially when making food-grade chemicals or drugs. The metal that doesn't rust holds the purity standards that are important for delicate chemical reactions in which contamination could lower the quality of the product.

Chemical Processing Applications of Tantalum Materials

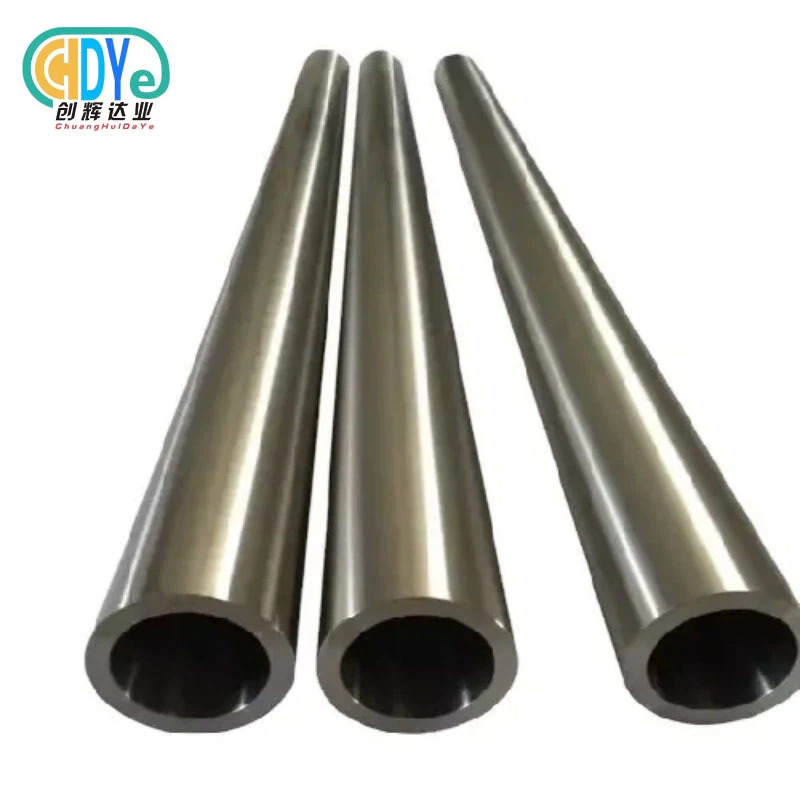

One of the most important uses of tantalum sheets and rods in chemical processing is in the construction of heat exchangers. These parts move heat between corrosive materials without breaking down, making sure they can be relied on for a long time. For their electrochemical processes, chemical plants that work with mineral acids, organic acids, and halogen compounds depend on tantalum electrodes.

Tantalum ingot is a great material for linings in reaction vessels that need to be protected from harsh chemicals. The machining of tantalum makes it possible to create the complex shapes that are needed for specialised reactor designs. Pharmaceutical companies use these materials to make very pure compounds where metallic contamination can be very dangerous.

Pure tantalum bar is used in the heating elements of chemical processing equipment that works in environments where the materials are corrosive. These parts keep working the same way and don't rust or get damaged by chemicals. Tantalum parts are used in petrochemical refineries to work on sulfur-containing chemicals that break down normal materials very quickly.

Selection Criteria for Pure Tantalum Bar in Chemical Processing

In chemical processing applications, purity levels have a big effect on performance. Tantalum grades with a tantalum content of 99.95% or higher have better chemical stability and resistance to corrosion. Impurities that hurt performance in certain chemical settings may be found in lower purity grades.

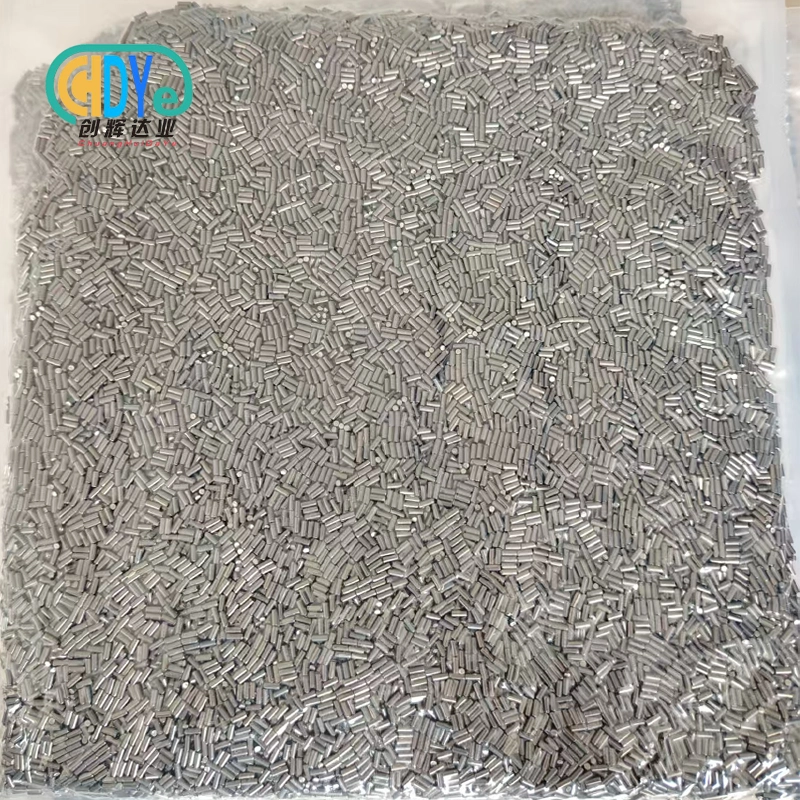

Dimensional specifications must be in line with the way the equipment is designed and the pressures it can handle when it's working. Using tantalum powder in metalworking makes it possible to make parts with exact specifications and uniform material qualities. The required surface finish depends on the job. In general, smoother surfaces resist corrosion better.

When choosing materials for chemical processes that happen at high temperatures, temperature ratings must be taken into account. Tantalum welding makes it possible to build up complex parts while keeping the strength of the materials at the interfaces of the joints. The way a part is made and the safety factors it uses are affected by mechanical properties like ductility and tensile strength.

Manufacturing and Processing Considerations

To get even material quality, the advanced pure tantalum bar supplier facilities make use of electron beam melting and powder metallurgy methods. These steps get rid of any impurities that might change how the material reacts with chemicals or affect its strength. Quality control checks make sure that each batch meets the strict standards needed for chemical processing.

Heat treatment processes make the microstructure and stress relief in finished parts as good as possible. Proper annealing gets rid of residual stresses from forming operations and keeps the mechanical properties you want. Methods of surface preparation get rid of impurities and oxide layers that might change how resistant the surface is to chemicals.

Machining tasks need special tools and methods to keep the metal from work hardening and to keep the surface smooth. Tantalum applications need to have exact size control to make sure that they fit and work well in chemical processing equipment. After-processing inspection makes sure that the dimensions and surface finish are correct.

Cost Optimization and Supply Chain Management

Changes in the price of tantalum affect the economics of projects and the long-term costs of equipment. Strategic sourcing from trustworthy suppliers keeps costs under control and makes sure that the quality of the materials stays the same. Agreements for bulk buying can help large chemical processing projects save money.

Pure tantalum bar is a very valuable metal, so inventory management must find a balance between the costs of carrying materials and their availability. As long as projects stay on schedule, just-in-time delivery plans lower the cost of holding goods in stock. Alternative material evaluations help find the most cost-effective ways to do certain things.

The total cost of ownership includes the cost of the materials, the cost of making it, and the cost of maintaining it over time. Because tantalum lasts a long time and doesn't need to be fixed as often, its higher upfront cost is often worth it. A deep look at the choices for making materials is possible with life cycle cost analysis.

Quality Assurance and Standards Compliance

International rules tell how to test and use tantalum materials in chemical processing. ASTM B365 makes sure that tantalum rod and bar products have the same quality and performance by laying out standards for them. Following these rules makes it easier for the material to be qualified and accepted by end users.

An examination of chemical composition confirms the levels of purity and the amounts of impurities that are very important for how well chemical processing works. Mechanical testing confirms the tensile strength, yield strength, and elongation properties needed for structural use. Internal flaws that could weaken the integrity of the part are found by non-destructive testing methods.

Traceability documentation follows the journey of a material from the time it is made until it is finally inspected, making a full record of the quality. Compliance certificate documents prove that the specified requirements and testing methods have been followed. Third-party testing validation gives extra confidence for important applications.

Conclusion

Pure tantalum bar represents the optimal material choice for demanding chemical processing applications requiring exceptional corrosion resistance and chemical stability. Understanding material properties, application requirements, and quality standards enables informed material selection decisions. Proper supplier partnerships ensure access to high-quality tantalum products with reliable delivery and technical support. The investment in premium tantalum materials pays dividends through extended equipment life, reduced maintenance costs, and improved process reliability in chemical processing operations.

Partner with Chuanghui Daye for Premium Pure Tantalum Bar Solutions

For chemical processing uses, Shaanxi Chuanghui Daye makes very high-quality pure tantalum bars to exact standards. Our ISO 9001:2015 certified facility makes sure that the quality is always good and the supply can be counted on. We are a reliable pure tantalum bar manufacturer with more than 30 years of experience in the field. We offer a range of technical support and low prices because we are the factory. Get in touch with us at info@chdymetal.com today to see how quality can make a difference.

References

1. Smith, J.R. and Williams, M.K. (2023). "Corrosion Resistance of Refractory Metals in Chemical Processing Environments." Journal of Chemical Engineering Materials, Vol. 45, No. 3, pp. 112-128.

2. Anderson, P.L. et al. (2022). "High-Temperature Performance of Tantalum Alloys in Acidic Media." Materials Science and Chemical Processing, Vol. 18, No. 7, pp. 245-261.

3. Chen, L. and Rodriguez, A. (2024). "Manufacturing Standards for Tantalum Components in Chemical Industry Applications." International Chemical Equipment Review, Vol. 39, No. 2, pp. 78-94.

4. Thompson, R.W. (2023). "Economic Analysis of Refractory Metals in Chemical Processing Equipment Design." Chemical Plant Engineering Quarterly, Vol. 31, No. 4, pp. 156-172.

5. Kumar, S. and Jones, M.T. (2022). "Quality Control Methods for High-Purity Tantalum Products." Advanced Materials Testing Journal, Vol. 28, No. 9, pp. 203-219.

6. Davis, K.P. et al. (2024). "Welding and Fabrication Techniques for Tantalum Chemical Processing Equipment." Welding Technology in Chemical Industries, Vol. 42, No. 1, pp. 34-50.