- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the advantages of using Niobium Titanium Alloy Wire?

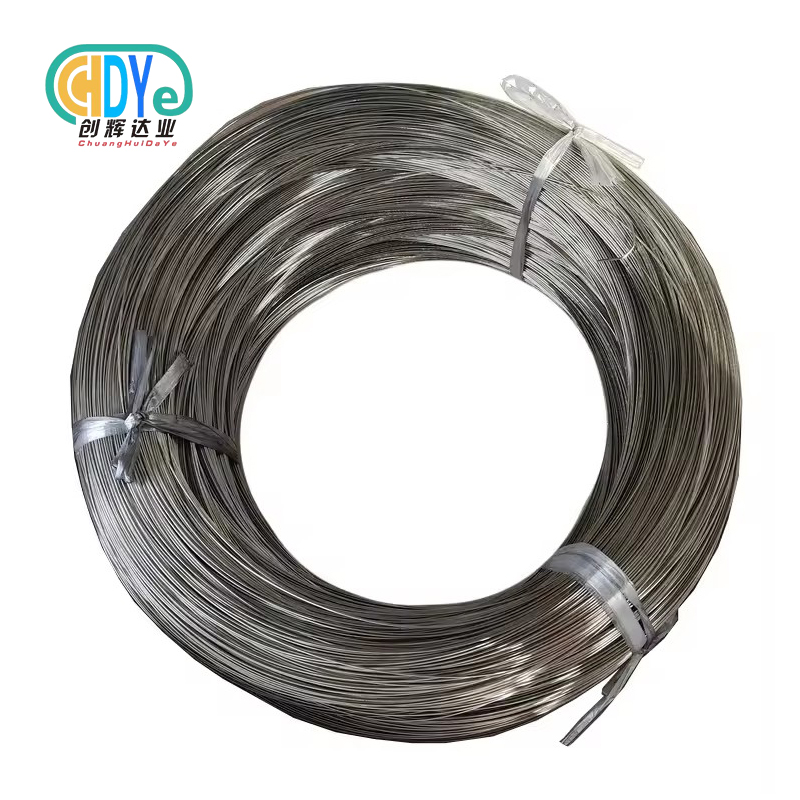

In the realm of advanced materials, Niobium Titanium Alloy Wire stands out as a remarkable innovation with a multitude of advantages that make it an ideal choice for various industries. As a leading supplier of Niobium Titanium Alloy Wire, I am excited to delve into the numerous benefits that this exceptional material offers.

Exceptional Superconductivity

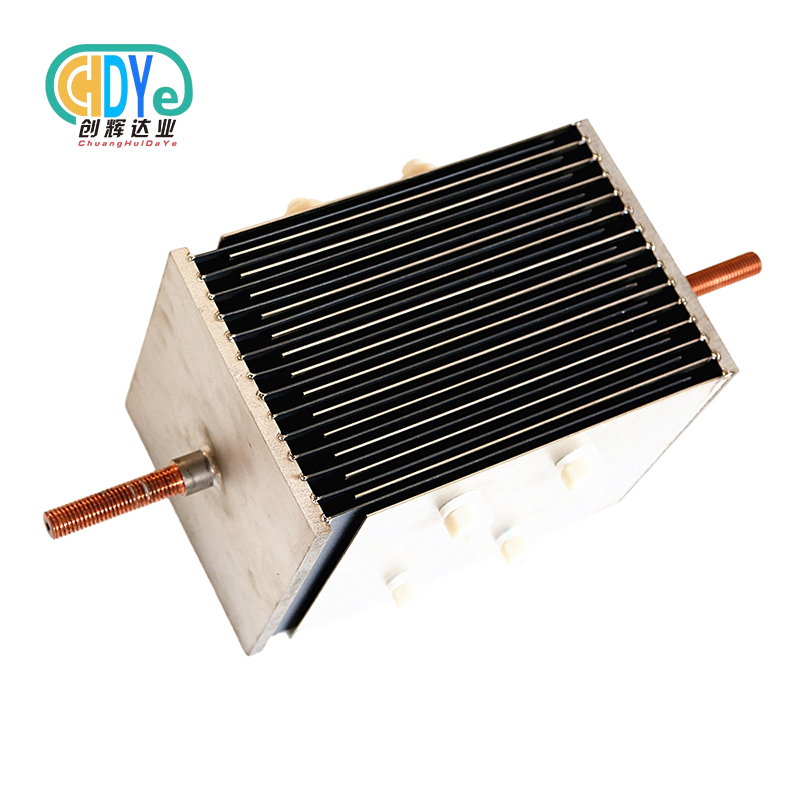

One of the most significant advantages of Niobium Titanium Alloy Wire is its outstanding superconducting properties. At low temperatures, typically below 9.2 Kelvin, this alloy exhibits zero electrical resistance. This phenomenon allows for the efficient transmission of electrical current without any energy loss due to resistance. In practical applications, this means that superconducting magnets made from Niobium Titanium Alloy Wire can generate extremely strong magnetic fields with minimal power consumption.

Superconducting magnets are widely used in medical imaging devices such as Magnetic Resonance Imaging (MRI) machines. The high - strength magnetic fields produced by these magnets are crucial for obtaining clear and detailed images of the human body. By using Niobium Titanium Alloy Wire, MRI manufacturers can create more powerful and energy - efficient magnets, leading to better diagnostic capabilities and reduced operating costs.

Another area where superconducting magnets find application is in particle accelerators. These large - scale scientific instruments are used to study the fundamental particles of matter. The ability of Niobium Titanium Alloy Wire to generate strong and stable magnetic fields is essential for guiding and accelerating particles at high speeds. Without this alloy, the development of modern particle physics research would be severely hampered.

High Strength and Ductility

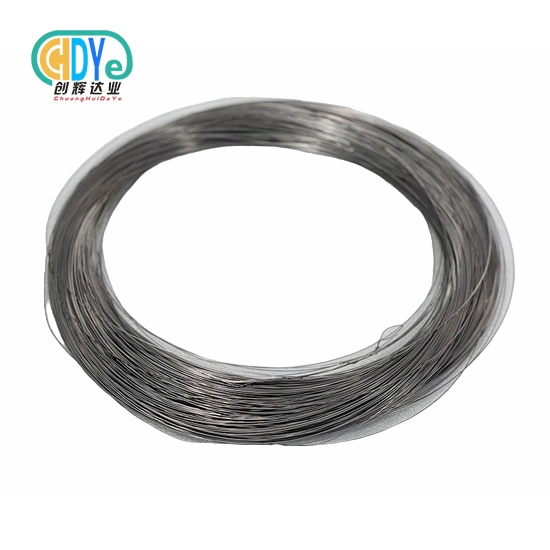

Niobium Titanium Alloy Wire combines high strength with excellent ductility. This unique combination of properties makes it suitable for a wide range of mechanical applications. The high strength of the alloy ensures that it can withstand significant mechanical stresses without breaking or deforming. At the same time, its ductility allows it to be easily formed into various shapes, such as coils, springs, and wires of different diameters.

In the aerospace industry, Niobium Titanium Alloy Wire is used in the construction of aircraft components. For example, it can be used to make high - strength cables and wires that are used in the control systems of airplanes. The alloy's ability to maintain its mechanical properties under extreme conditions, such as high temperatures and high pressures, makes it an ideal material for aerospace applications.

In the automotive industry, Niobium Titanium Alloy Wire can be used in the manufacturing of high - performance engine components. The high strength and ductility of the alloy allow for the production of lightweight yet strong parts, which can improve the fuel efficiency and performance of vehicles. For instance, it can be used to make engine valves and connecting rods, which need to withstand high - speed vibrations and mechanical loads.

Corrosion Resistance

Niobium Titanium Alloy Wire has excellent corrosion resistance, which makes it suitable for use in harsh environments. The alloy forms a passive oxide layer on its surface when exposed to oxygen, which protects it from further corrosion. This property is particularly important in applications where the wire is in contact with corrosive substances, such as chemicals, seawater, or acids.

In the chemical industry, Niobium Titanium Alloy Wire can be used in the construction of chemical reactors and pipelines. The corrosion resistance of the alloy ensures that it can withstand the corrosive effects of various chemicals, preventing leaks and ensuring the safety and reliability of the chemical processing equipment.

In the marine industry, Niobium Titanium Alloy Wire is used in the construction of ships and offshore platforms. The alloy's resistance to seawater corrosion makes it an ideal material for components such as cables, ropes, and fasteners that are exposed to the harsh marine environment. This helps to extend the service life of these components and reduce maintenance costs.

Compatibility with Other Materials

Niobium Titanium Alloy Wire has good compatibility with other materials, which allows it to be easily integrated into various systems. It can be welded, brazed, or soldered to other metals, such as copper, aluminum, and stainless steel. This compatibility makes it possible to combine the unique properties of Niobium Titanium Alloy Wire with those of other materials to create composite structures with enhanced performance.

In the electronics industry, Niobium Titanium Alloy Wire can be used in the production of electronic components. For example, it can be used as a conductor in printed circuit boards (PCBs). The compatibility of the alloy with other metals used in PCBs, such as copper, allows for the efficient transfer of electrical signals and the reliable operation of electronic devices.

Availability and Customization

As a supplier of Niobium Titanium Alloy Wire, we offer a wide range of products to meet the diverse needs of our customers. We can provide wires with different diameters, lengths, and compositions to suit specific applications. Whether you need a small quantity of wire for a research project or a large - scale supply for industrial production, we can meet your requirements.

We also offer high - quality High Purity Niobium Wire and Pure Niobium Wire for customers who have specific purity requirements. Our team of experts can work with you to understand your needs and provide customized solutions.

If you are interested in our Niobium Titanium Alloy Wire products, we encourage you to contact us for a detailed discussion about your procurement needs. Our dedicated sales team is ready to assist you in finding the right products and providing competitive pricing.

Conclusion

In conclusion, Niobium Titanium Alloy Wire offers a wide range of advantages, including exceptional superconductivity, high strength and ductility, corrosion resistance, compatibility with other materials, and availability in customized forms. These properties make it an ideal material for various industries, such as medical, aerospace, automotive, chemical, and electronics. As a supplier, we are committed to providing high - quality Niobium Titanium Alloy Wire products and excellent customer service. If you are looking for a reliable source of Niobium Titanium Alloy Wire, please do not hesitate to contact us to start a procurement discussion.

Ready to buy Niobium Titanium Alloy Wire? Contact us to talk about your particular prerequisites and get point by point citations. We're committed to building long-term associations based on quality fabulousness and client victory. Reach out to us nowadays and contact us at info@chdymetal.com for quick help with your obtainment needs.

References

"Superconductivity: Principles and Applications" by David J. Van Harlingen

"Materials Science and Engineering: An Introduction" by William D. Callister Jr. and David G. Rethwisch

"Corrosion Resistance of Metals and Alloys" by Pierre Marcus and Jean - Marie Cherin

Learn about our latest products and discounts through SMS or email