- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to test the quality of Tantalum Alloy Bar?

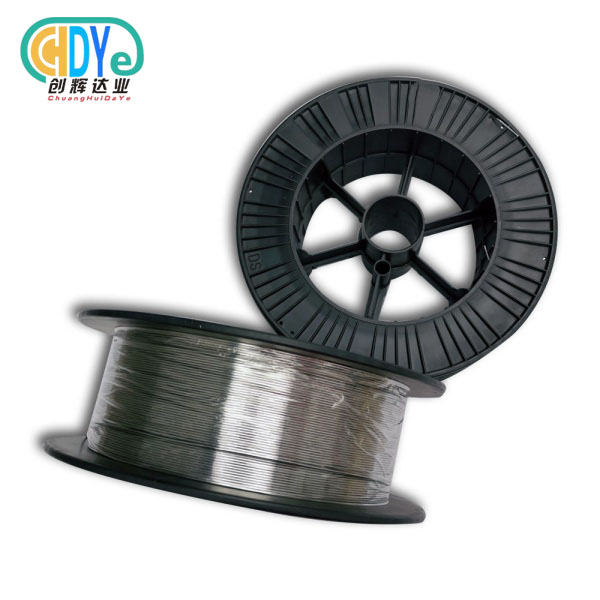

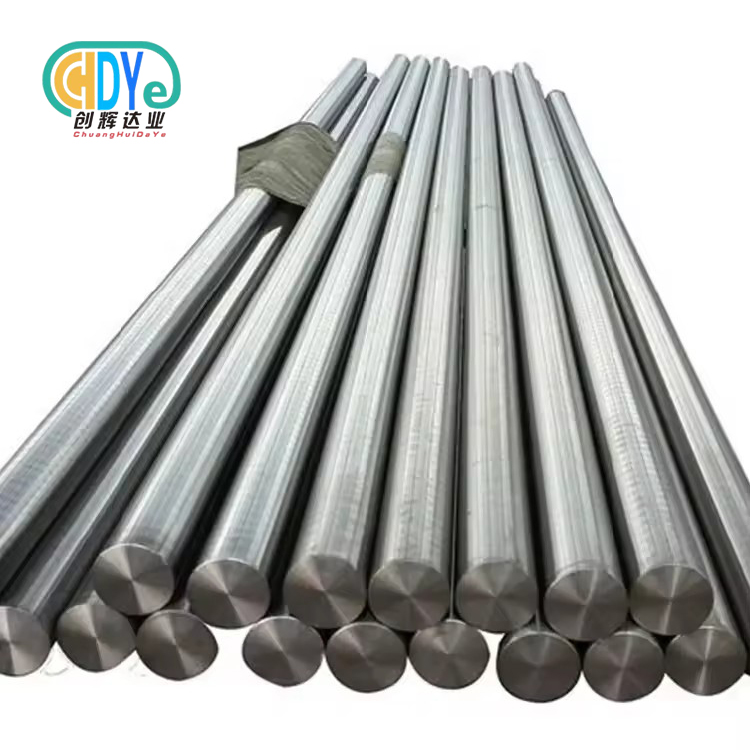

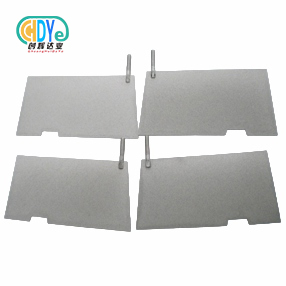

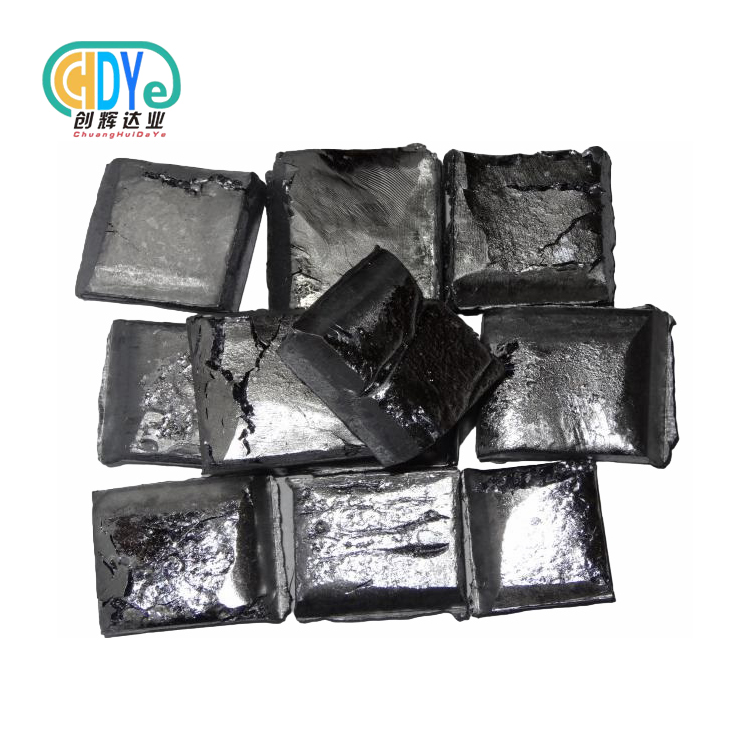

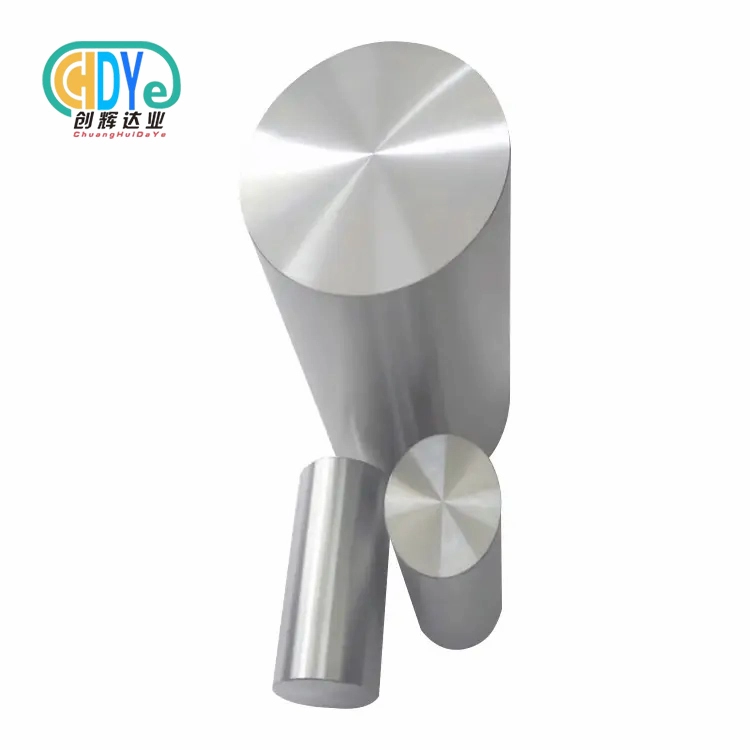

As a seasoned supplier of Tantalum Alloy Bars, I understand the critical importance of ensuring the quality of our products. Tantalum alloy bars are widely used in various industries, including aerospace, electronics, and chemical processing, due to their excellent corrosion resistance, high melting point, and good ductility. In this blog post, I will share some effective methods to test the quality of Tantalum Alloy Bars.

1. Visual Inspection

The first step in testing the quality of Tantalum Alloy Bars is a thorough visual inspection. This can reveal obvious defects such as cracks, scratches, pits, or surface irregularities. Using a magnifying glass or a microscope can help to detect smaller flaws that might not be visible to the naked eye.

Surface Finish: A smooth and uniform surface finish is an indication of high - quality Tantalum Alloy Bars. Rough or uneven surfaces may suggest problems during the manufacturing process, such as improper rolling or heat treatment.

Color and Luster: The color and luster of the tantalum alloy bar can also provide clues about its quality. A consistent color without any signs of oxidation or discoloration is desirable. Oxidation can occur due to improper storage or exposure to high - temperature and high - humidity environments, which may affect the mechanical properties of the bar.

2. Dimensional Measurement

Accurate dimensional measurement is crucial to ensure that the Tantalum Alloy Bars meet the required specifications. The following dimensions are typically measured:

Diameter and Thickness: For Tantalum Round Bar, the diameter should be measured at multiple points along the length of the bar to ensure uniformity. Any significant variation in diameter can affect the bar's performance in applications where precise fitting is required. For rectangular or square bars, the thickness and width are measured in a similar manner.

Length: The length of the bar should be measured to ensure it meets the specified requirements. Deviations in length can cause problems during installation or assembly.

Precision measuring tools such as calipers, micrometers, and length gauges are commonly used for these measurements. The measured values should be compared with the design specifications, and any deviations beyond the acceptable tolerance range may indicate a quality issue.

3. Chemical Composition Analysis

The chemical composition of Tantalum Alloy Bars plays a vital role in determining their properties and performance. There are several methods available for chemical composition analysis:

Spectroscopic Analysis: This method uses a spectrometer to analyze the elemental composition of the tantalum alloy bar. Spectroscopic techniques such as optical emission spectroscopy (OES) and X - ray fluorescence (XRF) can quickly and accurately identify the presence and concentration of various elements in the alloy. For example, OES can detect elements such as niobium, tungsten, and titanium, which are commonly added to tantalum to form alloys with improved properties.

Wet Chemical Analysis: Wet chemical analysis involves dissolving a sample of the tantalum alloy bar in appropriate reagents and then performing chemical reactions to determine the concentration of specific elements. This method is more time - consuming and labor - intensive than spectroscopic analysis but can provide highly accurate results, especially for trace elements.

The chemical composition of the tantalum alloy bar should match the specified requirements. Any deviation in the composition can affect the bar's mechanical, physical, and chemical properties, leading to potential performance issues in its intended applications.

4. Mechanical Property Testing

Mechanical property testing is essential to evaluate the strength, ductility, and toughness of Tantalum Alloy Bars. The following tests are commonly performed:

Tensile Testing: Tensile testing involves applying a gradually increasing tensile force to a sample of the tantalum alloy bar until it breaks. During the test, the stress and strain are measured, and the results are used to calculate the yield strength, ultimate tensile strength, and elongation of the bar. These properties are important for applications where the bar will be subjected to tensile loads, such as in structural components or fasteners.

Hardness Testing: Hardness testing measures the resistance of the tantalum alloy bar to indentation or scratching. Common hardness testing methods include the Brinell, Rockwell, and Vickers hardness tests. The hardness of the bar can provide information about its strength, wear resistance, and heat treatment history.

Impact Testing: Impact testing is used to evaluate the toughness of the tantalum alloy bar. A sample is subjected to a sudden impact load, and the energy absorbed during the impact is measured. This test is particularly important for applications where the bar may be exposed to dynamic or shock loads, such as in aerospace or automotive components.

5. Microstructural Analysis

Microstructural analysis can provide valuable information about the internal structure of Tantalum Alloy Bars, which can affect their mechanical and physical properties. The following techniques are commonly used:

Metallographic Examination: Metallographic examination involves preparing a polished cross - section of the tantalum alloy bar and then etching it to reveal the microstructure. A microscope is used to observe the grain size, shape, and distribution, as well as the presence of any phases or inclusions. A fine - grained microstructure generally indicates better mechanical properties, such as higher strength and ductility.

Electron Microscopy: Electron microscopy, such as scanning electron microscopy (SEM) and transmission electron microscopy (TEM), can provide higher - resolution images of the microstructure. These techniques can be used to study the detailed structure of the alloy, including the presence of nanoscale phases or defects.

6. Non - Destructive Testing

Non - destructive testing (NDT) methods are used to detect internal defects in Tantalum Alloy Bars without damaging the bar. The following NDT methods are commonly used:

Ultrasonic Testing: Ultrasonic testing uses high - frequency sound waves to detect internal defects such as cracks, voids, or inclusions. The sound waves are transmitted into the bar, and any reflections from defects are detected and analyzed. Ultrasonic testing is a sensitive method that can detect small defects deep within the bar.

X - ray Testing: X - ray testing uses X - rays to penetrate the tantalum alloy bar and create an image of its internal structure. This method can detect larger internal defects, such as porosity or foreign objects. X - ray testing is particularly useful for inspecting complex - shaped bars or bars with thick cross - sections.

Conclusion

Testing the quality of Tantalum Alloy Bars is a comprehensive process that involves multiple methods and techniques. By conducting visual inspections, dimensional measurements, chemical composition analysis, mechanical property testing, microstructural analysis, and non - destructive testing, we can ensure that our Tantalum Rods and Bars meet the highest quality standards.

As a supplier of Pure Tantalum Bar and other tantalum alloy products, we are committed to providing our customers with high - quality materials. If you are interested in purchasing Tantalum Alloy Bars or have any questions about our products, please feel free to contact us for a detailed discussion and to initiate a procurement negotiation. We look forward to serving you and meeting your specific requirements.

E-mail: info@chdymetal.com

what'app: 86-18049386902

References

ASM Handbook Volume 3: Alloy Phase Diagrams. ASM International.

ASTM Standards for Tantalum and Tantalum Alloys. ASTM International.

Callister, W. D., & Rethwisch, D. G. (2017). Materials Science and Engineering: An Introduction. Wiley.

Learn about our latest products and discounts through SMS or email