- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

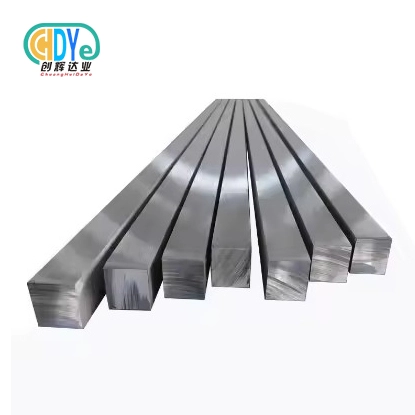

Grade 2 Titanium Square Bar – Corrosion Resistance Expert

For B2B obtainment pros all inclusive, Review 2 titanium square bar is the gold standard for corrosion-resistant mechanical applications. This commercially immaculate titanium fabric is fundamental in flying machine, chemical handling, and marine businesses due to its lightweight plan, strength, and chemical resistance. Companies looking for dependable, long-term fabric arrangements that deliver reliable comes about beneath challenging operational settings ought to contribute in Review 2 titanium square bar due to its demonstrated track record in serious situations and cost-effective life expectancy execution.

Understanding Grade 2 Titanium Square Bar and Its Unique Properties

Chemical Composition and Grade Comparison

Review 2 titanium is the most common commercially unadulterated titanium, with 99.2% immaculateness and controlled debasements of oxygen, nitrogen, carbon, hydrogen, and press. Its composition equalizations mechanical characteristics and formability way better than other titanium grades. Review 1 has somewhat superior ductility but lower quality, whereas Review 4 has higher quality but lower formability. Review 2 is perfect for direct quality and erosion resistance applications.

Grade 2 titanium has 0.18–0.25% oxygen concentration, which boosts its quality. This controlled oxygen level progresses weldability, machinability, and mechanical characteristics. Based on application needs and execution desires, obtainment directors can make taught choices by understanding compositional changes.

Mechanical Properties and Physical Characteristics

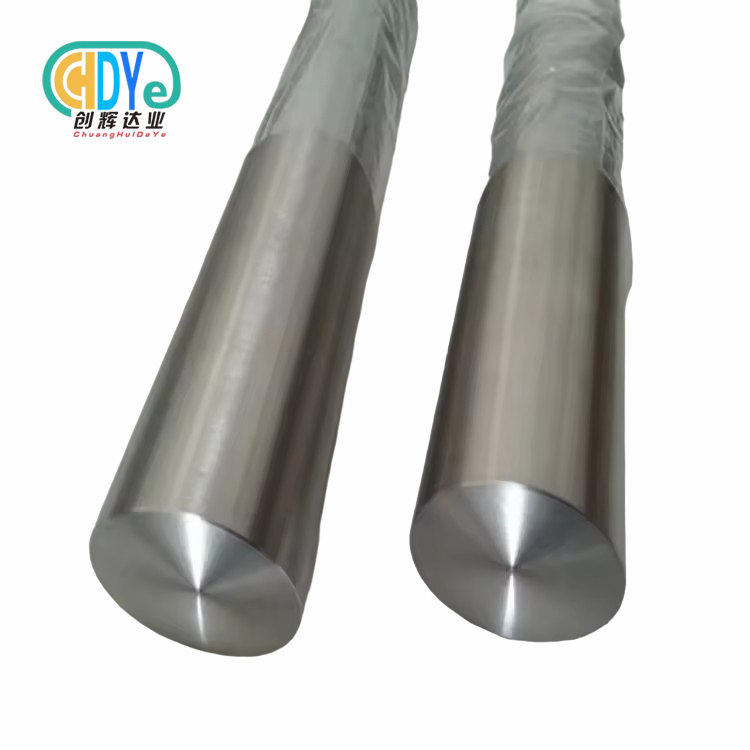

Review 2 titanium square bars have ductile quality of 345-483 MPa (50-70 ksi) and surrender quality of 275-414 MPa. Reasonable for shaping and auxiliary applications, the fabric has exceptional ductility and prolongation values over 20%. These mechanical properties are steady from cryogenic to 315°C (600°F).

Grade 2 titanium has a thickness of 4.51 g/cm³, making it 45% lighter than steel whereas keeping up quality. This tall strength-to-weight proportion benefits aeronautical, convenient, and weight-sensitive frameworks. The material's moo warm conductivity and modulus of versatility make it flexible in exact applications and warm cycling.

Standardized Dimensions and Manufacturing Specifications

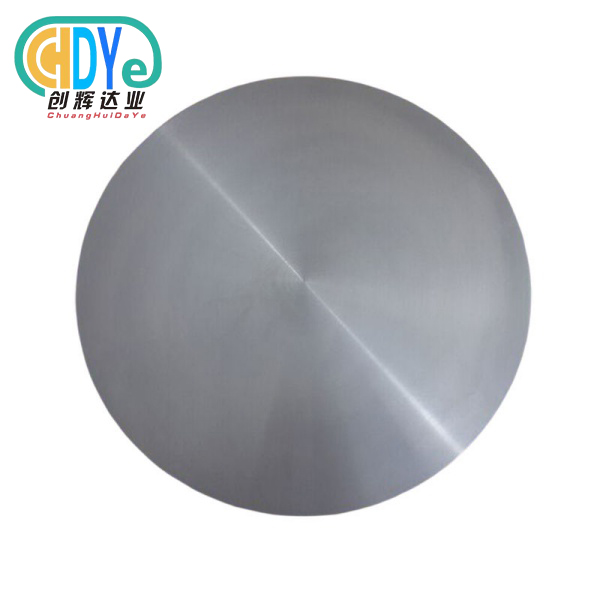

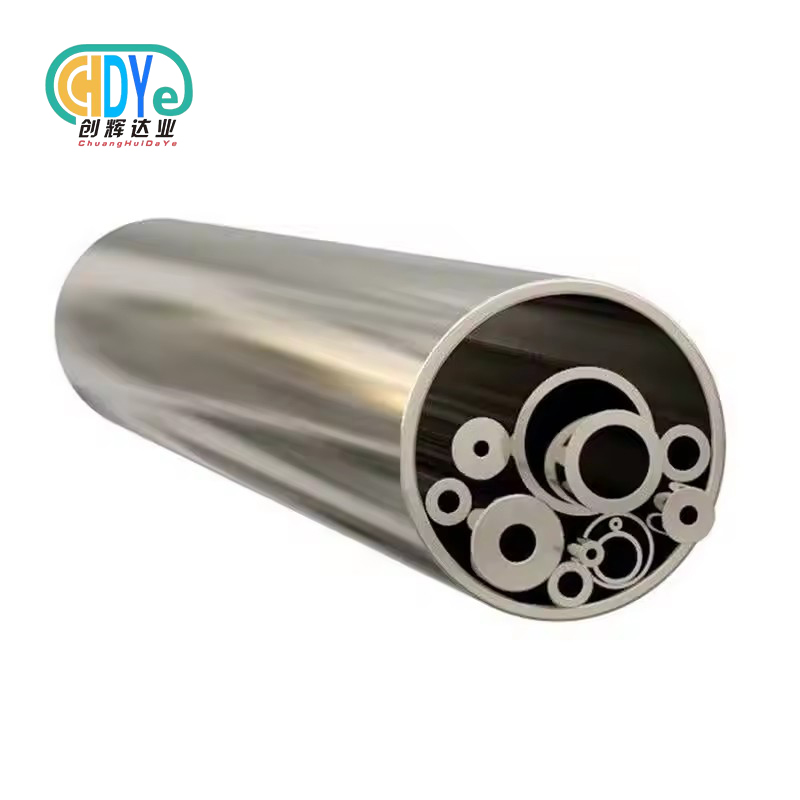

We fabricate titanium square bars to ASTM B348, AMS 4928, and ISO 5832 benchmarks to meet worldwide standards and quality benchmarks. Standard square estimations are 8x8 to 200x200 mm, with bespoke sizes catering to extraordinary venture requests. In spite of the fact that bigger lengths can be obliged, length parameters regularly shift up to 6000 mm.

Advanced manufacturing and warm treatment guarantee homogenous grain structure and mechanical qualities over the cross-section of each bar. Strengthened surfaces are ideal for machinability and formability, though shinning, cleaned, and machined wraps up suit diverse applications and aesthetics.

Comprehensive Corrosion Resistance Analysis for Grade 2 Titanium Square Bar

Natural Oxide Layer Protection Mechanism

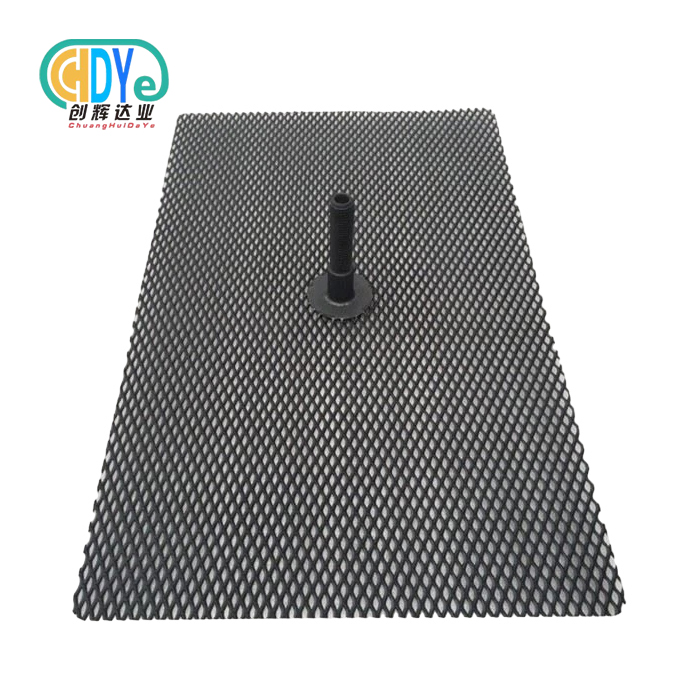

When exposed to oxygen, Grade 2 titanium forms a persistent, adherent oxide layer, which makes it corrosion-resistant. Although just 2-5 nanometers thick, this naturally occurring titanium dioxide (TiO₂) coating offers exceptional protection against several corrosive environments. When injured by mechanical or chemical means, the oxide layer self-heals.

This protective mechanism works in chlorides, organic acids, oxidizing acids, and seawater. Grade 2 titanium is suited for acidic and alkaline solutions because its oxide layer is stable from 2 to 12. This natural barrier lasts without maintenance and does not delaminate or wear away like conventional coatings.

Comparative Corrosion Performance Analysis

Grade 2 titanium outperforms stainless steel and aluminum in harsh conditions. Grade 2 titanium resists pitting corrosion in chloride-rich situations above 60°C, unlike 316L stainless steel. Despite their strong corrosion resistance, aluminum alloys are susceptible to galvanic corrosion when mixed with incompatible metals, unlike titanium.

Laboratory research shows that Grade 2 titanium corrodes below 0.0025 mm/year in seawater at ambient temperatures, compared to 0.025-0.05 for high-grade stainless steels. For important applications, this ten-fold corrosion resistance enhancement extends service life, lowers maintenance costs, and improves operational dependability.

Real-World Application Performance

Chemical processing, maritime engineering, and offshore applications confirm Grade 2 titanium square bars' high corrosion resistance. Titanium heat exchangers and reactor vessels in petrochemical operations last over 20 years without corrosion. Titanium components commonly outlast infrastructure in marine applications like desalination plants and offshore platforms.

Pharmaceutical manufacturing case studies reveal that Grade 2 titanium retains surface integrity and purity after prolonged washing and sterilization. Over long working durations, performance consistency maintains product quality and reduces contamination risks and equipment replacement costs.

Procurement Guide: How to Source the Best Grade 2 Titanium Square Bar?

Technical Specifications and Quality Requirements

Grade 2 titanium square bars must be purchased with caution due to technical standards and quality certifications. Dimensional tolerances, surface quality, mechanical properties, and chemical composition verification are important. ASTM B348 compliance assures material satisfies standards, however medical applications may require ISO 5832 certification.

Quality documentation should contain MTCs, ultrasonic inspection reports, and dimensional inspection records. These records trace and verify material qualities for regulated sectors and important structural components. Procurement specialists should set acceptance criteria and inspection methods to verify project materials fulfill specifications.

Cost Analysis and Budget Optimization

Grade 2 titanium square bars cost 3-5 times more than stainless steel items. However, lifespan cost analysis frequently shows favorable economics due to reduced maintenance, prolonged service life, and increased performance. Titanium investments often pay off in decreased downtime, lower replacement costs, and improved operational reliability.

Cost-effective procurement tactics include volume buying, strategic supplier partnerships, and flexible delivery schedules. Established suppliers with inventories help reduce lead times and project delays. Despite higher initial costs, custom size and precision machining often reduce subsequent processing and material waste.

Supplier Evaluation and Selection Criteria

The correct titanium square bar supplier affects project success and long-term satisfaction. Manufacturing, quality, technical assistance, and delivery should be assessed. ISO 9001:2015 accreditation shows quality management, but aerospace and medical applications may require industry-specific certifications.

Vacuum melting, precision forging, and sophisticated machining ensure product quality and accuracy. Technical help, such as material selection and application engineering, enhances procurement and product development. Reliable delivery and flexible order amounts meet project needs and timelines.

Why Choose Chuanghui Daye for Grade 2 Titanium Square Bar Supply?

Advanced Manufacturing Capabilities and Quality Systems

From China's "Titanium Capital" in Baoji High-tech Improvement Zone, Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. employments over 30 a long time of uncommon metal mechanical encounter. Vacuum dissolving heaters, hot manufacturing presses, exactness rolling plants, and CNC machines permit us to control the whole fabricating handle from crude fabric to completed item. This coordinates strategy evacuates multi-supplier fabricating chain unusualness and guarantees quality.

Our ISO 9001:2015 certification appears quality administration and persistent advancement. Each generation group is tried for inner issues utilizing chemical composition examination, mechanical property confirmation, and ultrasonic assessment. For administrative and shopper compliance, fabric test reports, review certifications, and dimensional records give total traceability.

Comprehensive Product Range and Customization Services

Our titanium grades span from economically pure (Gr1, Gr2, Gr4) to high-strength alloys (Gr5, Gr9, Gr23), meeting different application needs. Standard inventory comprises square bar sizes with bespoke measurements for special projects. Bright, polished, and machined finishes suit varied applications and tastes.

Beyond dimensional specifications, customisation includes heat treatments, precision machining, and value-added processing. Our technical team helps customers improve material selection and processing for specific applications. The consulting approach optimizes performance while reducing costs and lead times.

Global Supply Chain and Technical Support

Our interesting area in China's titanium generation center gives us get to to quality crude materials and specialized fabricating information at sensible costs. Built up calculated assentions permit dependable worldwide conveyance with numerous shipping choices, counting discuss cargo for critical needs. Our supply chain administration frameworks meet client conveyance desires by guaranteeing stock accessibility and generation scheduling.

Technical offer assistance incorporates fabric determination, application building, and execution optimization. Our master group exhorts from starting request to item conveyance and application help. Long-term organizations and titanium fabric application victory are accomplished with this full benefit approach.

Conclusion

Grade 2 titanium square bars are ideal for applications requiring corrosion resistance, lightweight design, and durability. Its mechanical qualities and chemical resistance make it essential in aircraft, marine engineering, chemical processing, and medical devices. Successful procurement demands careful attention to technical specifications, supplier capabilities, and lifecycle cost considerations that include operating and performance benefits beyond initial material prices. Strategic partnerships with skilled vendors who offer technical support and quality assurance optimize essential application results.

FAQ

Q: What are the standard dimensions available for Grade 2 titanium square bars?

A: Standard dimensions range from 8×8 mm to 200×200 mm with lengths up to 6000 mm. Custom dimensions are available to meet specific project requirements, with precision tolerances maintained throughout the size range.

Q: How does Grade 2 titanium compare to stainless steel in corrosion resistance?

A: Grade 2 titanium exhibits superior corrosion resistance compared to stainless steel, particularly in chloride-rich environments. Corrosion rates are typically 10 times lower than high-grade stainless steels in seawater applications.

Q: What surface finishes are available for titanium square bars?

A: Available surface finishes include bright (mirror-like), polished (enhanced corrosion resistance), and machined (tight dimensional tolerance) conditions. Each finish option serves specific application requirements and aesthetic preferences.

Q: Can Grade 2 titanium square bars be welded?

A: Yes, Grade 2 titanium demonstrates excellent weldability using TIG welding methods in inert gas environments. Proper welding procedures maintain corrosion resistance and mechanical properties in welded joints.

Q: What quality certifications are provided with titanium square bars?

A: Material test certificates (MTC), ultrasonic inspection reports, and dimensional inspection records are provided with each shipment. ISO 9001:2015 certification ensures quality management compliance throughout production.

Contact Chuanghui Daye for Premium Titanium Square Bar Supply Today

Ready to experience the superior performance of Grade 2 titanium square bars?Shaanxi Chuanghui Daye combines three decades of rare metal expertise with advanced manufacturing capabilities to deliver exceptional materials for your critical applications. Our ISO 9001:2015 certified facility produces premium titanium square bars meeting international standards while providing competitive factory-direct pricing and flexible customization options. Contact our technical team at info@chdymetal.com for detailed specifications, custom quotes, and expert consultation on your titanium square bar manufacturer requirements. We're committed to supporting your project success with reliable materials, comprehensive documentation, and responsive service that exceeds expectations.

References

1. American Society for Testing and Materials. "Standard Specification for Titanium and Titanium Alloy Bars and Billets." ASTM B348-19, 2019.

2. Boyer, R., Welsch, G., and Collings, E.W. "Materials Properties Handbook: Titanium Alloys." ASM International, Materials Park, Ohio, 1994.

3. Schutz, R.W. and Thomas, D.E. "Corrosion of Titanium and Titanium Alloys." ASM Handbook Volume 13B: Corrosion Materials, ASM International, 2005.

4. Titanium Development Association. "Guidelines for Designers and Manufacturers Using Titanium." Technical Report TDA-H-8, 2018.

5. Lütjering, G. and Williams, J.C. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, Second Edition, 2007.

6. International Organization for Standardization. "Implants for Surgery - Metallic Materials - Wrought Titanium 6-Aluminum 4-Vanadium Alloy." ISO 5832-3:2016, 2016.

Learn about our latest products and discounts through SMS or email