- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Grade 5 Titanium Alloy Sheet for Chemical Processing

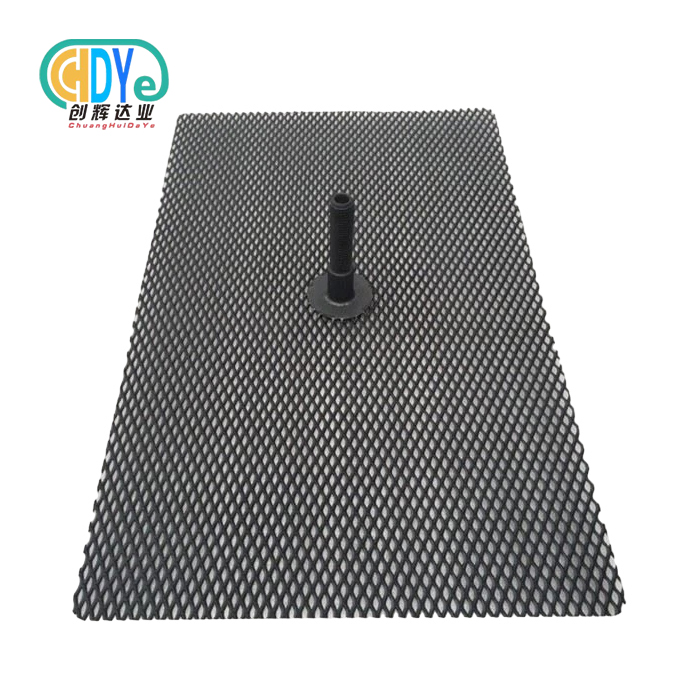

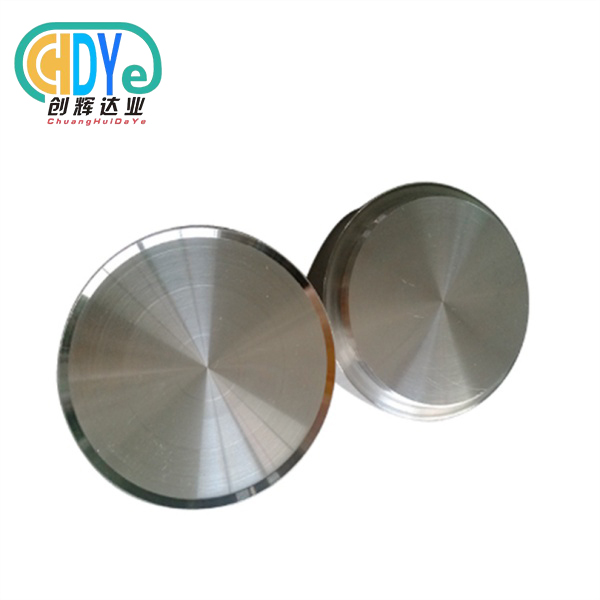

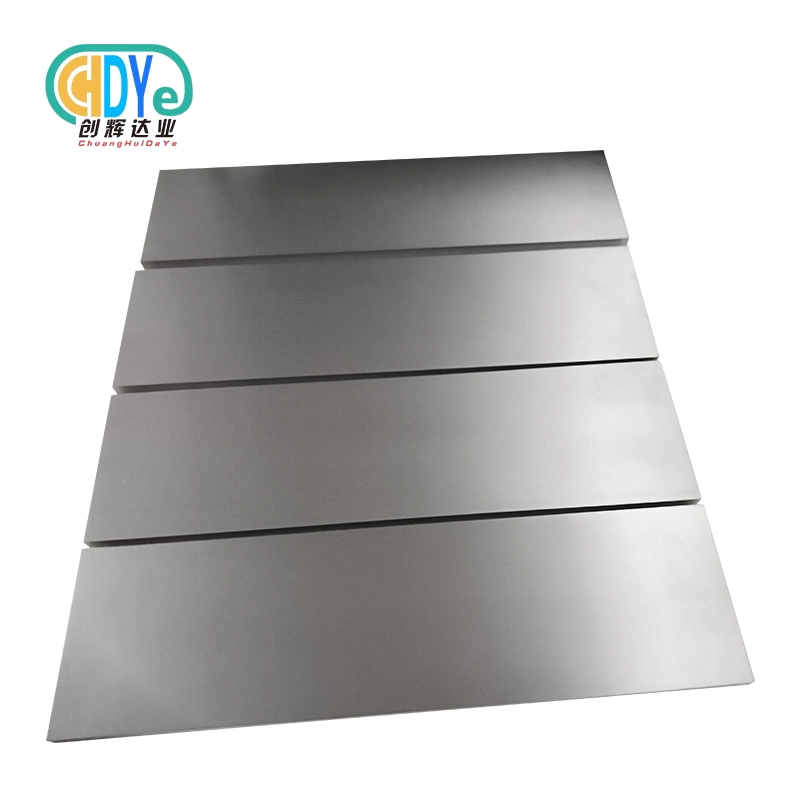

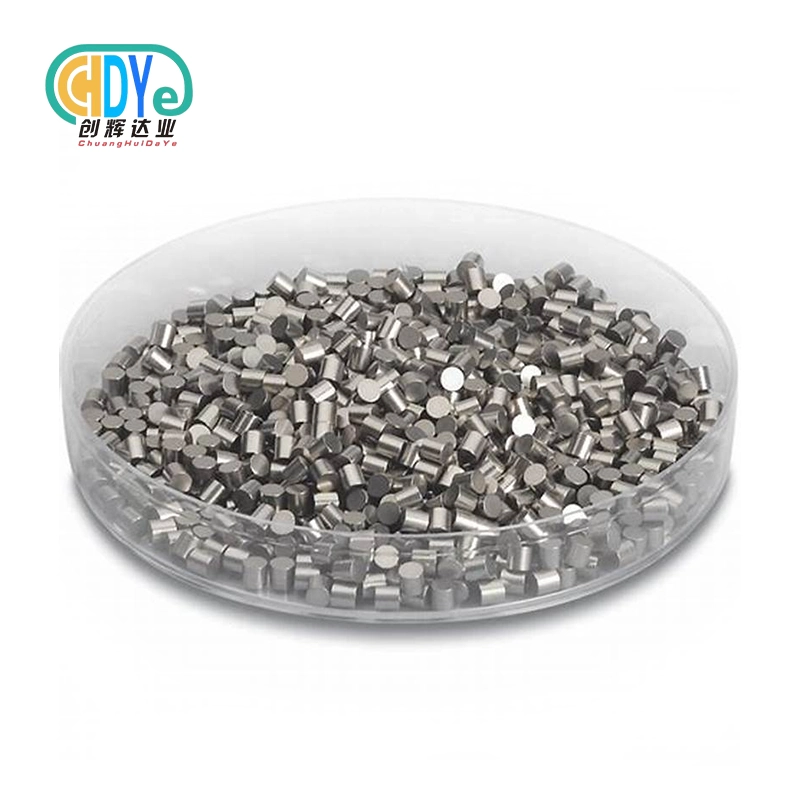

Grade 5 titanium alloy sheet, too known as Ti-6Al-4V, speaks to the gold standard for chemical handling applications requiring extraordinary erosion resistance and mechanical quality. This high-performance fabric combines 6% aluminum and 4% vanadium with titanium to make an combination that withstands forceful chemical situations whereas keeping up basic astuteness. Chemical handling offices around the world depend on these sheets for basic gear counting warm exchangers, response vessels, and channeling frameworks where routine materials come up short beneath extraordinary conditions.

Understanding Grade 5 Titanium Alloy Sheets in Chemical Processing

The unusual microstructure of Ti-6Al-4V performs well in demanding industrial conditions because to its chemical makeup. Aluminum strengthens and decreases density, while vanadium hardens and resists fatigue. Ti-6Al-4V sheets are useful in chemical processing, where equipment is constantly exposed to corrosives, high temperatures, and mechanical stress.

Superior Chemical Resistance Properties

Chemical preparing situations request materials that stand up to corruption from acids, soluble bases, and natural solvents. Ti-6Al-4V sheets illustrate extraordinary resistance to chlorine compounds, sulfuric corrosive arrangements, and hydrochloric corrosive concentrations that quickly fall apart stainless steel options. The detached oxide layer that actually shapes on the surface gives nonstop assurance against chemical assault, guaranteeing hardware life span and diminishing support costs.

Research conducted by the Titanium Improvement Affiliation illustrates that Ti-6Al-4V keeps up basic keenness in chemical situations where Review 316 stainless steel encounters critical erosion inside months. This execution advantage deciphers straightforwardly into decreased downtime and lower add up to taken a toll of proprietorship for chemical handling offices.

Mechanical Performance Under Extreme Conditions

Chemical reactors and heat exchange applications benefit from Ti-6Al-4V sheets' stable mechanical properties at high temperatures. Without degradation, these sheets withstand internal pressure and heat cycling with tensile strength above 895 MPa and yield strength about 828 MPa. The material's fatigue resistance ensures chemical processing equipment's reliable functioning under variable loads.

Heat treatment improves mechanical properties for specific applications. Solution treatment and aging increase hardness and ductility, allowing fabricators to customize characteristics for chemical processing. Custom solutions for complex equipment designs where standard materials fail performance are possible with this flexibility.

Real-World Applications in Chemical Processing

Chemical processing companies make chlorine production equipment, pharmaceutical reaction vessels, and petrochemical distillation columns from Ti-6Al-4V sheets. A big Texas chlor-alkali facility replaced nickel-based heat exchanger tubes with Ti-6Al-4V sheets, increasing service life by 300% and lowering maintenance costs.

Since the aerospace sector uses Ti-6Al-4V extensively, production procedures have improved, improving quality control and material characteristics for chemical processing applications. These advancements guarantee chemical processing sheets with predictable performance for critical equipment applications.

Grade 5 Titanium Alloy Sheet vs Competitors: Making the Right Choice

Performance, lifespan costs, and operational needs must be considered while choosing chemical processing equipment materials. Ti-6Al-4V sheets outperform Grade 2 titanium, austenitic stainless steels, and specialty nickel alloys in chemical processing.

Performance Comparison with Alternative Materials

Ti-6Al-4V sheets have roughly twice the tensile strength of grade 5 titanium alloy sheet and equal corrosion resistance. This strength advantage allows thinner wall sections, decreasing material costs and equipment weight without sacrificing safety. The improved mechanical qualities enable for smaller equipment designs, improving facility layout and lowering installation costs.

Grade 316L stainless steel is cheaper but needs regular repair in severe chemical conditions. In situations where 316L stainless steel pits within six months, NACE International found that Ti-6Al-4V sheets remain structurally intact. Excellent corrosion resistance reduces the need for protective coatings and frequent component replacement.

Nickel-based alloys like Hastelloy C-276 are chemically resistant but expensive. These superalloys excel in high-temperature applications, whereas Ti-6Al-4V sheets perform similarly at lower cost for most chemical processing applications below 400°C. Due of its weight, titanium decreases structural support and installation complexity.

Lifecycle Cost Analysis

Beyond initial material costs, Ti-6Al-4V sheets save money over time through decreased maintenance, increased service life, and operational reliability. When replacing stainless steel with Ti-6Al-4V, chemical processing industries save 40-60% on maintenance. These savings add up quickly in high-throughput operations where downtime costs might surpass $100,000 per day.

Ti-6Al-4V sheets resist fatigue and crack propagation under cyclic loading conditions, unlike other materials. This reliability decreases catastrophic failure and safety problems, adding benefit beyond cost savings. Titanium alloy equipment facilities frequently have lower insurance premiums due to their better safety.

Ti-6Al-4V sheets' lightweight nature decreases structural loads and allows more efficient equipment designs, improving lifespan value. Grade 5 titanium alloy sheet's thermal characteristics boost heat transfer efficiency and energy consumption.

Procurement Guide: Acquiring Grade 5 Titanium Alloy Sheets for Chemical Processing

Effective obtainment of Ti-6Al-4V sheets requires understanding advertise flow, provider capabilities, and quality prerequisites particular to chemical handling applications. Vital buyers use showcase information and provider connections to secure ideal estimating whereas guaranteeing fabric quality and conveyance unwavering quality.

Supplier Certification and Quality Standards

Supplier certification is crucial for chemical processing applications, which require high-quality materials. ISO 9001:2015 certificate ensures quality, while ASME and ASTM certifications cover pressure vessel and chemical processing standards. From raw material sources to final product delivery, suppliers should provide mill test certifications showing chemical composition and mechanical qualities.

Advanced titanium processors have vacuum melting and controlled environment heat treatment technologies. These facilities assure constant material qualities and eliminate contaminants that could affect chemical processing performance. Procurement professionals should assess supplier manufacturing capabilities during qualification to ensure application compatibility.

Critical applications benefit from third-party testing and certification. Independent labs can validate material qualities and chemical composition, while specialized testing services can assess corrosion resistance under process circumstances. This extra inspection justifies premium cost for mission-critical applications where material failure could disrupt operations.

Market Pricing and Negotiation Strategies

Raw material costs, manufacturing complexity, and market demand affect Ti-6Al-4V sheet pricing. Market variations alter titanium sponge prices quarterly, affecting final product costs. Strategic purchasers track titanium commodity prices to buy when markets are favourable and establish long-term supply agreements during price stability.

Volume purchasing offers cost savings due to suppliers' tiered pricing depending on annual consumption. Chemical processing plants might use maintenance schedules and expansion projects to combine purchases and get volume discounts. Smaller factories might boost their buying power with industry partnerships.

Contracts should cover chemical processing-specific price adjustments, delivery timeframes, and quality criteria. Suppliers like steady demand and may provide better prices for multi-year volume commitments. Strong financial purchasers can negotiate payment terms and inventory management to their advantage.

Regulatory Compliance and Documentation Requirements

Chemical processing may need compliance with ASME Boiler and Pressure Vessel Code, FDA pharmaceutical regulations, and environmental emissions control equipment standards. To ensure supplier compliance, procurement specifications must explicitly describe standards and certifications.

Material traceability, heat treatment, and dimensional inspection reports are required in addition to mill test certificates. Electronic documentation technologies speed compliance verification and regulatory response. Supplier quality records should be complete and accessible during compliance audits.

Export, customs, and currency rules complicate international procurement. Expert suppliers facilitate international transactions with customs clearance and export control documentation. Services like this justify supplier selection based on capability, not price.

Trusted Suppliers and Brands of Grade 5 Titanium Alloy Sheets

Chemical processing plants that need consistent material quality and delivery must choose reputable suppliers. Leading suppliers support long-term chemical processor partnerships with technical understanding, manufacturing capabilities, and customer service quality.

Key Supplier Evaluation Criteria

Assessment of manufacturing competence should include production capacity, quality control, and technical assistance. Leading providers oversee the manufacturing process from raw material melting to final inspection and packaging in integrated facilities. Vertical integration guarantees quality and speeds client service.

Technical support distinguishes premium from commodity vendors. Expert technical teams advise on material selection, fabrication, and quality. This expertise is especially useful for complex chemical processing applications where standard specifications must be modified to meet unique operating conditions.

Sustainable supply chains are ensured by financial stability and business continuity planning. Chemical processing companies invest heavily in supplier qualification and desire stable, growing partners. Financial study of titanium suppliers should assess creditworthiness, operational efficiency, and strategic positioning.

Leading Industry Suppliers

Large integrated titanium producers and chemical processing fabricators exist. VSMPO-AVISMA and Carpenter Technology have extensive product lines and global distribution. Large-volume customers benefit from these providers' production capacity, technological capabilities, and financial stability.

Specialized vendors offer better customer service and chemical processing application expertise. Grade 5 titanium alloy sheet Industries and Continental Steel & Tube Company offer customized solutions and stock large quantities for fast delivery. These suppliers specialize in complicated application bespoke processing and technical assistance.

Regional suppliers can offer better delivery, customer service, and pricing in specialized markets. Shaanxi Chuanghui Daye Metal Material Co., Ltd. uses their location in China's "Titanium Capital" to offer high-quality Ti-6Al-4V sheets at low prices and consistent delivery. ISO 9001:2015 certification and extensive quality control provide constant chemical processing material qualities.

Partnership Development Strategies

Clear requirements, regular performance evaluation, and collaborative problem-solving are essential for supplier partnerships. Annual company reviews should cover quality, delivery, and process improvement. Structured interactions foster mutual understanding and constant progress.

Buyers and sellers profit from long-term agreements' stable demand and pricing. Chemical processing facilities can use maintenance schedules and expansion plans to build volume commitments for preferential pricing and priority allocation during supply restrictions. Suppliers respect these ties and typically improve service and technical support.

The advanced technology collaboration model involves vendors providing engineering skills for equipment design and optimization. Through material specification optimization, fabrication process advancements, and lifecycle cost savings, this partnership can be valuable. Leading suppliers invest in these partnerships to differentiate themselves.

Conclusion

For chemical processing applications that require corrosion resistance, mechanical strength, and operational reliability, Ti-6Al-4V sheets are ideal. These sheets' decreased maintenance costs, extended service life, and better safety justify their higher cost. Successful procurement needs strategic supplier selection, quality verification, and long-term partnerships to maximize value and supply chain reliability. Chemical processing facilities investing in Ti-6Al-4V sheets get reliable material, industry-leading supplier capabilities, and extensive technical support.

FAQ

Q: What makes Ti-6Al-4V sheets superior to Grade 2 titanium for chemical processing?

A: Ti-6Al-4V sheets provide nearly double the tensile strength of Grade 2 titanium while maintaining equivalent corrosion resistance. This strength advantage enables thinner wall sections, reducing material costs and equipment weight. The enhanced mechanical properties also allow for more compact equipment designs and improved fatigue resistance under cyclic loading conditions common in chemical processing applications.

Q: How does the corrosion resistance of Ti-6Al-4V compare to stainless steel in chemical environments?

A: Independent testing demonstrates that Ti-6Al-4V maintains structural integrity in environments where Grade 316L stainless steel experiences significant corrosion within months. The passive oxide layer naturally forming on titanium provides superior protection against chlorine compounds, acids, and organic solvents commonly used in chemical processing. This performance translates to extended equipment life and reduced maintenance costs.

Q: What quality certifications should I require when purchasing Ti-6Al-4V sheets for chemical processing?

A: Essential certifications include ISO 9001:2015 for quality management, ASTM specifications for material properties, and ASME certifications for pressure vessel applications. Suppliers should provide complete mill test certificates documenting chemical composition and mechanical properties. Additional third-party testing may be required for critical applications where material failure could result in significant operational disruption.

Q: Can Ti-6Al-4V sheets be welded and fabricated using standard equipment?

A: Ti-6Al-4V sheets can be welded using TIG and plasma arc welding processes with proper shielding gas protection. Fabrication operations including cutting, forming, and machining require specific techniques to prevent contamination and work hardening. Experienced fabricators utilize specialized tooling and controlled atmospheres to maintain material properties during processing operations.

Q: What factors influence Ti-6Al-4V sheet pricing in the market?

A: Pricing reflects titanium sponge raw material costs, manufacturing complexity, and market demand dynamics. Titanium commodity prices fluctuate quarterly, affecting final product costs. Volume purchasing provides substantial discounts, while custom specifications and accelerated delivery requirements command premium pricing. Long-term supply agreements can provide price stability and preferential allocation during market constraints.

Partner with Chuanghui Daye for Premium Ti-6Al-4V Sheets

Shaanxi Chuanghui Daye delivers exceptional Ti-6Al-4V sheets specifically engineered for demanding chemical processing applications. Our ISO 9001:2015 certified manufacturing facility in China's Titanium Capital ensures consistent quality through advanced vacuum melting, precision rolling, and comprehensive testing protocols. We provide complete mill test documentation, custom dimensions, and reliable global delivery for projects requiring superior corrosion resistance and mechanical performance. Contact our technical team at info@chdymetal.com to discuss your specific requirements and receive competitive pricing as a trusted grade 5 titanium alloy sheet manufacturer.

References

1. Davis, Joseph R. "Titanium and Titanium Alloys for Chemical Process Industries." ASM International Handbook of Materials Selection, 2019.

2. Peters, M. and Leyens, C. "Titanium Alloys in Chemical Processing Equipment: Performance and Economic Considerations." Materials Science and Engineering Review, Vol. 45, 2020.

3. NACE International. "Corrosion Performance of Titanium Alloys in Chemical Processing Environments." Technical Publication SP0169, 2021.

4. Titanium Development Association. "Guidelines for Titanium Alloy Selection in Process Industries." Technical Bulletin TDA-105, 2019.

5. American Society of Mechanical Engineers. "Materials and Specifications for Pressure Vessels: Titanium Alloy Applications." ASME Section II, Part D, 2022.

6. Lütjering, Gerd and Williams, James C. "Engineering Properties of Ti-6Al-4V for Industrial Applications." Springer Materials Engineering Handbook, 2018.

Learn about our latest products and discounts through SMS or email