- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

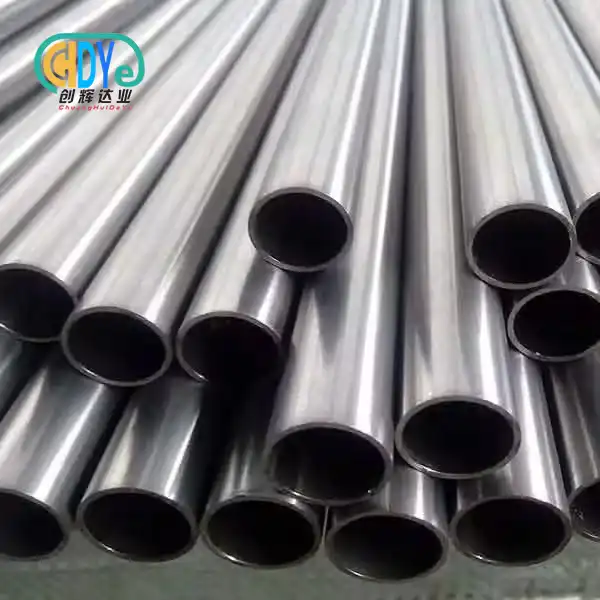

Titanium Seamless Tube for Medical & Surgical Devices

When it comes to biocompatibility, erosion resistance, and mechanical quality, titanium seamless tubes are the best that can be utilized to make restorative and surgery gadgets. These precision-engineered parts have changed the restorative field by making it less demanding to utilize solid, light arrangements for imperative assignments like making surgical instruments and implantable contraptions. Titanium consistent tubes have special qualities that make them fundamental for companies that make restorative hardware that needs materials that can withstand sterilization forms and keep their auxiliary astuteness over time.

Understanding Titanium Seamless Tubes in Medical Applications

Titanium consistent tubes are empty tubes that are accurately made utilizing progressed consistent handling strategies that get freed of welded joints. This gives the tubes way better consistency and basic keenness, which is vital for making restorative gadgets. Since there are no weld creases, there are no powerless spots that seem influence the execution of the gadget or the security of the understanding. This makes these tubes particularly valuable in troublesome surgical settings where steadfastness is exceptionally imperative.

Exceptional Material Properties for Medical Use

The standout properties of medical-grade titanium tubes consolidate unprecedented disintegration resistance that remains unfaltering in genuine fluids, uncommon biocompatibility that dodges unfavorable tissue reactions, and an idealize strength-to-weight extent that diminishes contraption weight without giving up quality. These characteristics make titanium tubes particularly well-suited for applications requiring long-term implantation or repeated sterilization cycles.

Common Grades and Their Medical Applications

Restorative applications commonly utilize particular titanium grades, with Review 2 (Gr2) and Review 5 (Gr5/Gr9) being the most predominant choices. Review 2 titanium is prized for its great erosion resistance and prevalent biocompatibility, making it perfect for surgical disobedient and brief inserts. Review 5 offers improved quality properties, guaranteeing ideal execution in load-bearing inserts and auxiliary surgical components. Extra grades like Gr1, Gr7, and Gr12 serve specialized restorative applications where particular mechanical properties or improved erosion resistance are required.

Manufacturing and Quality Standards of Titanium Seamless Tubes for Medical Use

Titanium seamless tubes are made in a strict, multi-step process that starts with choosing the right raw materials and continues with using advanced manufacturing methods. The process of making a seamless tube starts with extruding high-purity titanium billets. This is followed by hot rolling and precise cold drawing to get the exact dimensions and high mechanical properties needed for medical uses.

Advanced Manufacturing Process Controls

Heat treatment steps are very important for improving the quality of tubes. Carefully controlled annealing processes make sure that the grain structure and mechanical properties are the same all the way through the thickness of the tube wall. Multiple quality checks are built into the manufacturing process, such as measuring to make sure the parts are the right size, checking the finish on the outside, and testing the mechanical properties to make sure they meet strict medical-grade standards.

Compliance with International Medical Standards

Medical-grade titanium tubes have to meet strict international standards like ASTM B338, ASTM B337, ASTM B861, and ASTM B862. These standards say what the tubes are made of chemically, mechanically, and in terms of their sizes. ISO 9001:2015 approval makes sure that quality is managed throughout the whole production process, and FDA compliance verification makes sure that the product is safe for use in medical devices. These standards call for a lot of tests, like checking for rust resistance, making sure the tubes' mechanical properties are correct, and making sure they are biocompatible, to make sure they work well in medical settings.

Comparing Titanium Seamless Tubes with Other Materials in Medical Manufacturing

Before choosing parts for their products, companies that make medical devices often look at more than one material choice. Titanium seamless tubes always work better than other options like stainless steel, copper alloys, and welded titanium tubes because they have a unique set of features that make them great for medical uses.

Advantages Over Stainless Steel Components

Titanium is much better at being biocompatible than stainless steel options. There is a much lower chance of allergic reactions or tissue irritation during long-term implantation. Because titanium is less dense than stainless steel, it makes medical devices about 40% lighter than the same-sized stainless steel parts. This makes patients more comfortable and keeps surgeons from getting tired during long treatments. Titanium is also very resistant to corrosion, so devices stay intact even in harsh biological settings.

Superior Performance Compared to Welded Alternatives

When compared to welded tubes, seamless titanium tubes have much better structural integrity and reliability because there are no weak spots at the weld joints. Through seamless manufacturing, the wall thickness is always the same, and the mechanical qualities stay the same. This makes sure that the device works the same way throughout its lifecycle. Seamless tubes may cost more than welded ones, but they are more reliable and less likely to break, which makes them the best choice for critical surgical and implant uses where patient safety is very important.

Procurement Guide: How to Source High-Quality Titanium Seamless Tubes for Medical Devices?

To successfully buy medical-grade titanium tubes, you need to carefully consider a number of things that have a direct effect on how well the tubes are made and how well they work. When buying from businesses, people who want to make things must think about things like minimum order amounts, lead times, and the ability to customize so that the supply chain can meet the needs of production while keeping costs low.

Key Procurement Considerations

Medical-grade titanium tubes have exceptionally distinctive costs depending on the review of the tube, its measurements, and the number of tubes that are requested. More often than not, requesting more tubes will get superior costs. Lead times for ordinary sizes can be a few weeks, whereas lead times for custom sizes can be a few months. This implies that exact request estimating is vital to keep generation plans. Since medical-grade materials are so specialized, providers ordinarily request least arrange sums that appear they can handle the strict quality controls and printed material that are required for therapeutic employments.

Supplier Selection Criteria

Choosing providers with the right certifications is a exceptionally imperative buying choice that has a coordinate impact on the quality of the item and compliance with directions. As a provider, you require to have ISO 9001:2015 certification for quality administration, the right certifications for making restorative gadgets, and confirmation that you have worked in the restorative gadget trade some time recently. Set up providers appear their commitment to quality by having careful quality affirmation programs, full printed material for fabric traceability, and a history of reliably conveying medical-grade items on time.

About Chuanghui Daye and Our Titanium Seamless Tube Solutions

Shaanxi Chuanghui Daye Metal Material Co., Ltd. has been making medical devices for more than 30 years and is an expert in making things out of titanium and rare metals. Because our company is in Baoji High-tech Development Zone, which is also known as China's "Titanium Capital," we can use the area's great infrastructure and knowledge to make high-quality titanium tubes that are perfect for medical and surgical uses.

Comprehensive Product Range and Capabilities

Our medical-grade titanium seamless tubes come in a number of types, such as Gr1, Gr2, Gr7, Gr9, and Gr12. They are made to strict ASTM B338, B337, B861, and B862 standards. The outside diameters can be between 10 and 300 mm, the wall thicknesses between 0.5 and 10 mm, and the lengths can be up to 18,000 mm, so they can fit a wide range of medical gadget needs. Each tube goes through strict quality control steps using high-tech production tools like electron beam furnaces, precision machining centers, and full testing facilities.

Quality Assurance and Customer Support

Our ISO 9001:2015 certification shows that we are dedicated to upholding the highest quality standards at all stages of production, from inspecting the raw materials to delivering and packing them up at the end. We offer full material traceability paperwork, detailed quality certificates, and technical support to make sure that our customers can easily add our products to their manufacturing processes. Because they care about quality and customer service, they have built long-term relationships with companies that make medical devices. These companies depend on consistent, high-performance titanium tube options for their most important uses.

Conclusion

Modern medical and surgical devices can't be made without titanium seamless tubes, which offer the best combinations of biocompatibility, corrosion protection, and mechanical performance. The seamless manufacturing method gets rid of any possible weak spots and makes sure that the quality is always the same, meeting the strict needs of medical applications. As medical technology keeps getting better, titanium seamless tubes will be the first choice for makers looking for durable, high-performance materials that make patients safer and devices last longer.

FAQ

Q: Why are titanium seamless tubes preferred over other metals for medical applications?

A: Titanium seamless tubes offer exceptional biocompatibility that minimizes adverse tissue reactions, superior corrosion resistance that maintains integrity in biological environments, and an optimal strength-to-weight ratio that reduces device weight while maintaining structural performance. The seamless construction eliminates potential failure points present in welded alternatives.

Q: How does titanium grade selection impact surgical instrument performance?

A: Different titanium grades offer varying mechanical properties and corrosion resistance levels. Grade 2 provides excellent biocompatibility for general surgical instruments, while Grade 5 offers enhanced strength for load-bearing applications. Proper grade selection ensures optimal performance characteristics for specific medical device requirements.

Q: What are typical lead times and minimum order quantities for medical-grade titanium tubes?

A: Lead times typically range from 4-8 weeks for standard dimensions and 8-12 weeks for custom specifications, depending on complexity and current production schedules. Minimum order quantities vary based on tube specifications but generally reflect the specialized quality controls required for medical-grade materials.

Partner with Chuanghui Daye for Premium Medical-Grade Titanium Solutions

Medical device manufacturers seeking reliable titanium seamless tube suppliers can leverage Chuanghui Daye's three decades of specialized manufacturing expertise and comprehensive quality assurance programs. Our precision-engineered tubes meet the most demanding medical application requirements while providing competitive factory-direct pricing and flexible customization options. Contact our technical team at info@chdymetal.com to discuss your specific requirements, request detailed specifications, or explore how our titanium seamless tubes can enhance your medical device manufacturing processes with superior performance and reliability.

References

1. American Society for Testing and Materials. "Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASTM International, 2021.

2. International Organization for Standardization. "Implants for Surgery - Metallic Materials - Part 2: Unalloyed Titanium." ISO Standards Catalogue, 2020.

3. Williams, David F. "Titanium for Medical Applications: Principles and Applications." Woodhead Publishing Series in Biomaterials, 2019.

4. Food and Drug Administration. "Guidance Document for Testing of Metallic Medical Devices." Center for Devices and Radiological Health, 2022.

5. Brunette, Donald M. "Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications." Springer Medical Publishing, 2018.

6. European Medicines Agency. "Guidelines on the Use of Titanium and Titanium Alloys in Medical Device Manufacturing." Committee for Medicinal Products for Human Use, 2021.

Learn about our latest products and discounts through SMS or email

_1760924447399.jpg)