- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Choose Titanium Seamless Tube for Critical Applications?

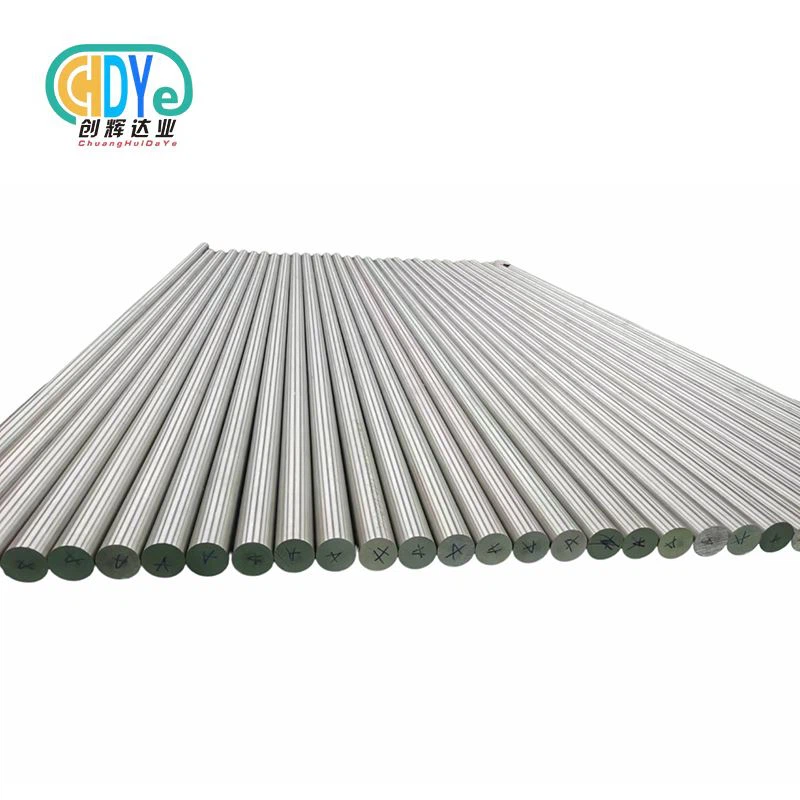

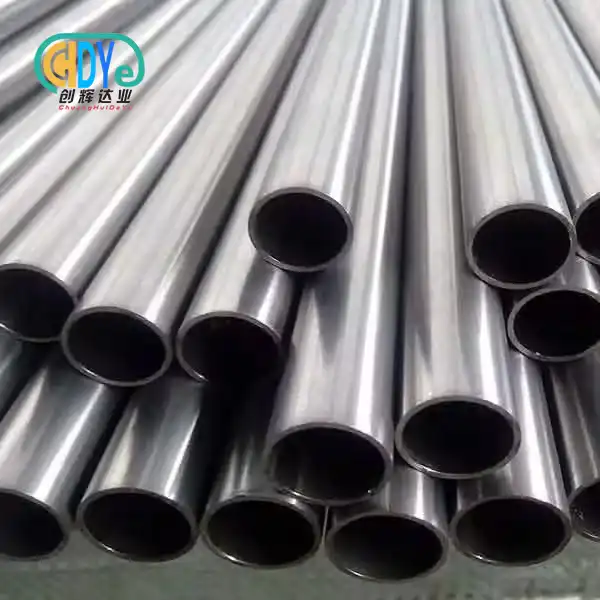

When it comes to materials for mission-critical frameworks, titanium seamless tube is the best choice for areas that require the best execution conceivable. Compared to other sorts of channels, consistent titanium tubing has a much higher strength-to-weight proportion, is more safe to rust, and works dependably in unforgiving situations. From chemical preparing hardware to pressure driven frameworks in shuttle, these tubes donate imperative employments the quality and solidness they require. This makes them an fundamental portion for engineers who can't bear for materials to come up short.

Understanding Titanium Seamless Tubes: Essential Properties and Benefits

It is vital to note that titanium seamless tubes are made utilizing exact metallurgical strategies that guarantee indeed quality without weld creases. This is what makes them really diverse from welded choices. The consistent plan gets freed of the frail spots that can happen in welded joints, making a structure that is uniform and solid sufficient to handle tall temperatures and weights. Hot expulsion or cold drawing are utilized in this strategy of making to keep the material's astuteness along the entire length of the tube.

Superior Mechanical Properties

Titanium tubing is fundamental in numerous requesting businesses since of its special mechanical properties. The ductile quality of these tubes is astounding, extending from 240 MPa for Review 2 to over 900 MPa for Review 9. They too have a mass that is approximately 40% lower than steel. The edge in strength-to-weight proportion is particularly valuable in aviation, where each gram checks for fuel proficiency and payload capacity.

Advanced Corrosion Resistance

The characteristic oxide layer on titanium ensures it exceptionally well from numerous destructive conditions. When this detached film gets broken, it mends itself consequently. This secures against seawater, chlorides, acids, and soluble bases for a long time. This highlight is exceptionally valuable for chemical preparing plants since titanium tubes do not break down rapidly when they are uncovered to cruel chemicals that would rapidly break down stainless steel or carbon steel options.

Temperature Stability and Performance

Titanium consistent tubes can be utilized in temperatures extending from outright zero to 600°C, and their mechanical qualities remain the same at all of these temperatures. This warm soundness is exceptionally vital in places like fly motors, where parts go through quick changes in temperature, and chemical reactors that work at tall temperatures.

Titanium Seamless Tubes vs Alternative Materials: Making the Right Choice

When choosing a material, it's important to look at its performance, its prices over its lifetime, and its operational needs. When compared to other materials, titanium seamless tubes are much better at resisting rust and performing mechanically. However, they may seem more expensive at first.

Performance Comparison with Stainless Steel

Stainless steel tubes are cheap at first, but they don't work well in places where there is a lot of corrosion or when the temperature is very high. Titanium works better than 316L stainless steel in chloride settings because it doesn't rust even after being exposed for a long time. This benefit is especially useful for marine uses, since seawater causes pitting and crevice rust in stainless steel within months, but titanium's surface stays solid for decades.

Economic Considerations and Lifecycle Value

When comparing materials, procurement teams should look at the total cost of ownership instead of the price of the original purchase. Titanium usually leads to lower total costs because it lasts longer, needs less maintenance, and doesn't need to be replaced as often. Chemical companies that use titanium heat exchanger tubes say that they don't have to replace them every year and that they last 15 to 20 years, which saves them a lot of money.

Weight Advantages in Critical Applications

In aerospace and military applications, reducing weight without affecting the strength of the structure is very important. When compared to steel alternatives, titanium tubes are much lighter while still meeting or exceeding strength standards. When titanium parts are used in hydraulic and pneumatic systems, commercial aircraft makers say that fuel efficiency goes up by 2 to 3 percent.

Critical Applications Across Industries: Why Titanium Seamless Tubes Excel

In industries like aircraft, chemical processing, marine, medicine, and energy, where performance and safety standards are very high, titanium seamless tubes are used all the time. Titanium is used in different ways by different industries to deal with different operational problems and legal needs.

Aerospace and Defense Applications

Ttanium seamless tubes made for aerospace applications make sure that all of an airplane's systems are strong and light. When compared to steel options, hydraulic lines made from Grade 9 titanium are 35% lighter and can handle pressures higher than 5,000 psi. Titanium is useful for military airplanes because it is not magnetic, which is important for stealth applications and electronic warfare systems. When it comes to fuel systems, engine makers use titanium tubing, which has to meet the highest standards for corrosion protection and fire safety.

Chemical Processing and Petrochemical Industries

Titanium's high resistance to harsh media makes it ideal for use in heat exchangers, reactor parts, and transfer lines in chemical processing plants. In chlor-alkali plants, titanium tubes are used in electrolytic cells because regular materials break down after a few months of being exposed to chlorine. Titanium is used in seawater cooling systems on offshore oil platforms to get rid of biofouling problems and cut down on maintenance needs in remote areas where getting help is still hard and costs a lot.

Medical Device Manufacturing

Titanium is used in medical devices because it is biocompatible and can be precisely machined to make implantable devices and surgical tools. Because human bone has the same elastic modulus as titanium tubes, orthopedic implant makers use them for hollow bone screws and spine rods. The material is radiolucent, which means that X-rays can be seen clearly after insertion, and it is also resistant to corrosion, so it will stay biocompatible in the body for a long time.

Procurement Insights: How to Source Quality Titanium Seamless Tubes

To do effective procurement, you need to do a lot of research on your suppliers, like checking all of their certifications and carefully looking over their manufacturing methods. For success, you need to know the technical requirements, quality standards, and supply chain skills that set reliable suppliers apart from others that aren't up to par.

Essential Quality Certifications and Standards

Teams in charge of buying things must make sure that suppliers follow industry standards like ASTM B338, B337, B861, and B862 rules. Having ISO 9001:2015 certification makes sure that quality control is consistent throughout the whole production process. For example, AS9100 certification is needed for aerospace applications, while ISO 13485 compliance is needed for medical purposes. For each batch, suppliers should give full material traceability paperwork, such as mill test records and chemical composition reports.

Customization Capabilities and Technical Support

Reliable providers offer a wide range of customization options, such as precise size tolerances, surface finishes, and changes to the mechanical properties of the product. When making specifications, being able to provide technical help is very important because experienced suppliers can give useful advice on choosing materials, making sure dimensions are correct, and finding cost-effective ways to make things. Getting help from engineers during the planning phase can often keep changes during production from being too expensive.

Supply Chain Reliability and Lead Time Management

Disruptions in the global supply chain show how important it is for suppliers to be able to keep their finances in order and handle their stock well. Established suppliers keep strategic stock levels of popular grades and sizes, which lets them respond quickly to urgent needs. Clear information about lead times lets you plan your project perfectly, and minimum order numbers that are easy to change can meet the needs of both prototypes and large-scale production.

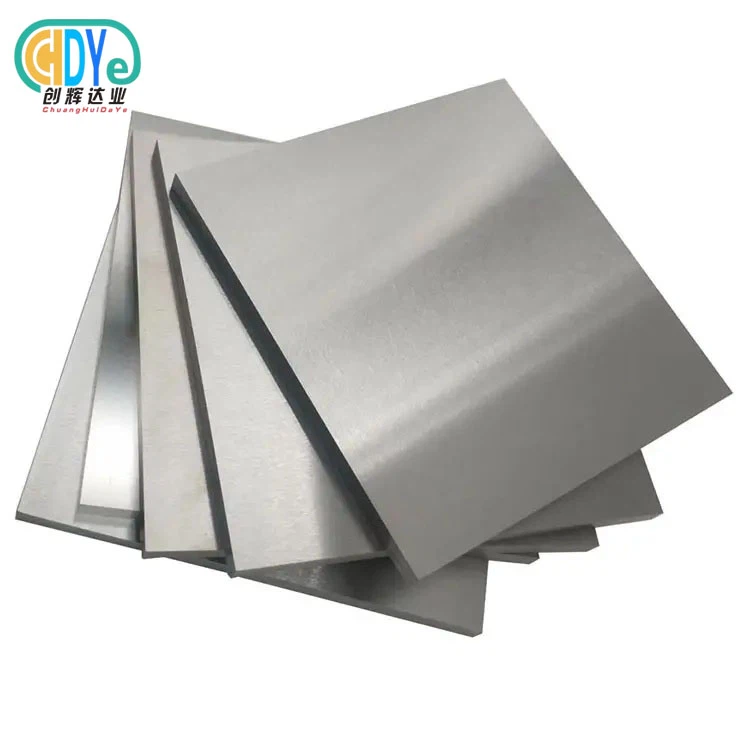

Company Introduction and Product & Service Information

Shaanxi Chuanghui Daye Metal Fabric Co., Ltd. is one of the greatest companies in the world that offers consistent titanium tubes. They center on high-quality titanium materials like Gr1, Gr2, Gr7, Gr9, and Gr12 for a wide extend of commercial employments. Since our company is in the Baoji High-tech Advancement Zone, which is too known as China's "Titanium Capital," it has simple get to to transportation and a well-established industry foundation that makes a difference with generation and distribution.

We've been making things with uncommon metals for more than 30 a long time, so we can provide you precision-engineered consistent tubes that work dependably in extreme conditions. We take after strict quality control methods that are in line with universal benchmarks like ISO 9001:2015, ASTM B338, ASTM B337, B861, and B862. Our generation abilities cover sizes from OD10 to 300 mm, WT0.5 to 10 mm, and L100 to 18000 mm, so we can meet a wide run of needs, from prototyping to large-scale production.

Advanced production lines have electron pillar heaters, accuracy machining centers, and specialized testing instruments that make beyond any doubt the standard of the items is continuously the same. From reviewing the crude materials to the last pressing, our quality administration framework keeps an eye on each step of the generation handle and makes beyond any doubt that all the printed material required to track each shipment is legitimately completed. Specialized bolster administrations offer assistance clients select the right materials, make the best utilize of determinations, and discover arrangements that are particular to their needs.

Conclusion

Choosing titanium seamless tube for important uses is an investment in long-term performance, dependability, and operating efficiency. Titanium is the best material for aerospace, chemical processing, medical, and marine uses because it has great mechanical properties, very low corrosion, and has been used successfully in harsh conditions. Even though the original costs may be higher than other options, the overall cost of ownership benefits from longer service life, less maintenance, and better safety make the investment worth it for important systems that can't fail.

FAQ

Q: What distinguishes seamless tubes from welded titanium tubes?

A: Seamless tubes are manufactured through extrusion or drawing processes without welded joints, eliminating potential weak points and ensuring uniform strength throughout the tube length. Welded tubes contain heat-affected zones that may exhibit different mechanical properties compared to the base material, potentially creating stress concentration points under extreme conditions.

Q: How do I select the appropriate titanium grade for my application?

A: Grade selection depends on specific application requirements including corrosion resistance, strength, and operating temperature. Grade 2 offers excellent general corrosion resistance, Grade 7 provides enhanced resistance to reducing acids, while Grade 9 delivers higher strength for structural applications. Consulting with experienced suppliers ensures optimal grade selection for specific operating conditions.

Q: What are typical lead times for custom titanium tube orders?

A: Lead times vary based on specifications, quantities, and current production schedules. Standard sizes typically ship within 2-4 weeks, while custom dimensions may require 6-8 weeks for manufacturing. Urgent requirements can often be accommodated through expedited processing, though premium pricing may apply for accelerated delivery schedules.

Partner with Chuanghui Daye for Superior Titanium Seamless Tube Solutions

Shaanxi Chuanghui Daye combines three decades of metallurgical expertise with advanced manufacturing capabilities to deliver exceptional titanium seamless tube solutions for your critical applications. Our ISO 9001:2015 certified facility produces tubes meeting stringent ASTM standards while providing comprehensive technical support throughout your procurement process. Contact our engineering team at info@chdymetal.com to discuss your specific requirements and discover why leading manufacturers choose Chuanghui Daye as their trusted titanium seamless tube supplier for mission-critical applications.

References

1. American Society for Testing and Materials. "Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers." ASTM B338-18, 2018.

2. Boyer, Rodney, et al. "Materials Properties Handbook: Titanium Alloys." ASM International Materials Park, Ohio, 1994.

3. Donachie, Matthew J. "Titanium: A Technical Guide, 2nd Edition." ASM International, Materials Park, Ohio, 2000.

4. Lutjering, Gerd and James C. Williams. "Titanium: Engineering Materials and Processes." Springer-Verlag Berlin Heidelberg, 2007.

5. Peters, Manfred, et al. "Titanium Alloys for Aerospace Applications." Advanced Engineering Materials, Volume 5, Issue 6, 2003.

6. Schutz, R.W. and D.E. Thomas. "Corrosion of Titanium and Titanium Alloys." ASM Handbook Volume 13A: Corrosion: Fundamentals, Testing, and Protection, 2003.

Learn about our latest products and discounts through SMS or email