Hexagonal titanium screws represent a breakthrough in fastening technology for critical applications. These precision-engineered components combine titanium's exceptional properties with hexagonal head design for superior torque application. In medical and marine environments, where reliability can mean the difference between life and death or mission success and failure, hexagonal titanium screws deliver unmatched performance. Their biocompatibility makes them ideal for implants and surgical devices, while their corrosion resistance ensures decades of service in harsh marine conditions. We see these fasteners revolutionizing industries that demand the highest standards of safety and durability.

The Science Behind Titanium's Superior Performance

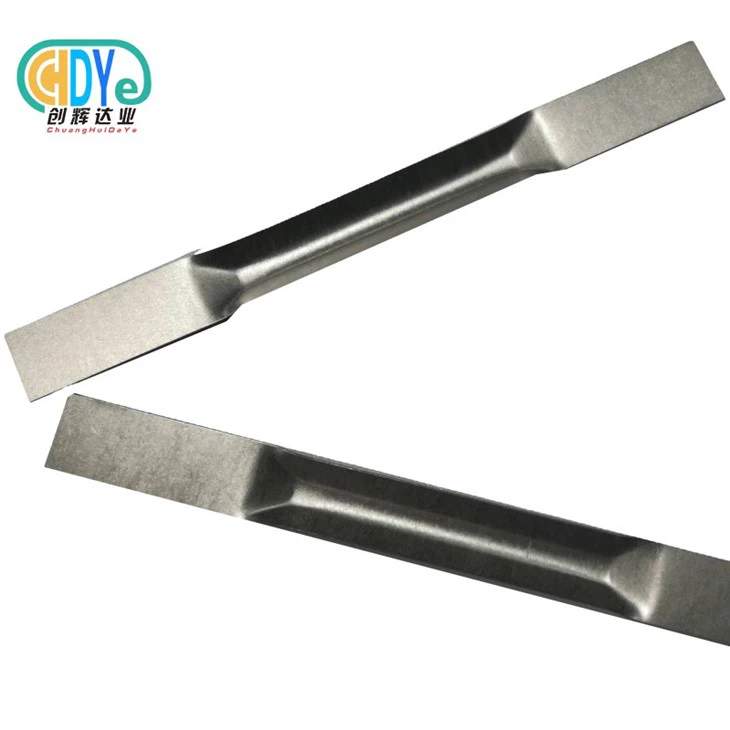

Understanding why titanium hex screws beat conventional materials requires looking at titanium's one of a kind atomic structure. This momentous metal has a strength-to-weight proportion that outperforms steel by 40%, whereas keeping up total resistance to galvanic erosion. The hexagonal plan increases these benefits by giving six contact focuses for instrument engagement, dispersing push more equitably than conventional screw heads.

Medical-grade titanium contains negligible pollutions, making it totally biocompatible with human tissue. Marine applications advantage from titanium's capacity to frame a defensive oxide layer that recovers consequently when harmed. This self-healing property guarantees long-term execution in saltwater situations where other metals would fall flat inside months.

Hexagonal titanium screws keep up their auxiliary judgment over temperature ranges from -200°C to 400°C. This warm steadiness demonstrates pivotal in restorative sterilization forms and marine applications including motor components. The material's non-magnetic properties too dispense with obstructions with touchy electronic gear found in advanced restorative gadgets and marine route systems.

Revolutionary Medical Applications Transforming Patient Care

Orthopedic specialists around the world depend on titanium hexagon jolts for spinal combination methods. These accuracy titanium hex screws grapple vertebrae together, permitting common bone development to make changeless combination. The hexagonal head plan empowers specialists to apply exact torque amid implantation, lessening surgery time and making strides persistent outcomes.

Dental embed frameworks utilize hex attachment titanium screws to secure fake teeth to jawbone inserts. The biocompatible nature of these clasp avoids dismissal whereas the hexagonal interface guarantees secure connection that can withstand decades of chewing strengths. Patients involvement made strides quality of life with inserts that feel and work like common teeth.

Cardiovascular applications grandstand titanium's life-saving potential through pacemaker lodging gatherings. Lightweight titanium screws decrease gadget weight whereas their non-magnetic properties avoid obstructions with attractive reverberation imaging. Patients can experience MRI checks securely without expelling their life-sustaining devices.

Prosthetic appendage producers coordinated hex titanium machine screws into joint components. These components persevere millions of development cycles without weariness disappointment. Amputees pick up certainty knowing their prosthetics won't fall flat amid basic minutes, whether climbing stairs or taking part in sports.

Surgical instrument fabricating depends on erosion safe titanium screws for gathering of exactness instruments. Working room sterilization cycles subject rebellious to extraordinary temperatures and unforgiving chemicals. Conventional clasp would debase rapidly, but titanium hex screws keep up their keenness through thousands of sterilization cycles.

Marine Engineering Excellence Through Advanced Materials

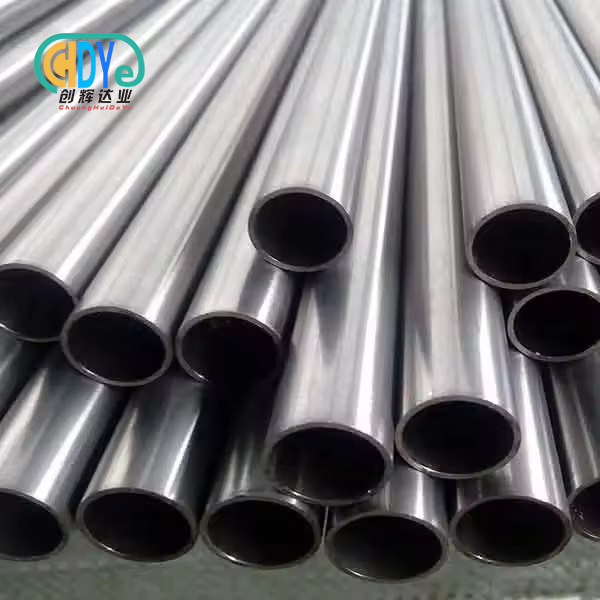

Shipbuilding businesses have grasped tall quality titanium hex screws for propeller shaft gatherings. These basic components must withstand gigantic rotational powers whereas standing up to seawater erosion. Conventional steel latches require visit substitution, but titanium choices give decades of solid service.

Offshore penetrating stages utilize exactness titanium hex screws in blowout preventer frameworks. These safety-critical gatherings must work faultlessly beneath extraordinary weight to anticipate disastrous oil spills. The unwavering quality of titanium latches has progressed stage security records significantly.

Submarine development requires hex head titanium clasp for frame entrances where electrical cables and channeling pass through weight boundaries. These association focuses must keep up watertight judgment at pulverizing profundities. Titanium's quality and erosion resistance guarantee team security amid amplified submerged missions.

Desalination plant administrators depend on Hexagonal titanium screws for warm exchanger congregations. These frameworks handle millions of gallons of seawater every day, making greatly destructive conditions. Whereas other materials fall flat inside months, titanium clasp work dependably for decades without replacement.

Yacht producers introduce titanium hex drive screws in fixing equipment and deck fittings. Dashing yachts thrust materials to their limits, requiring components that won't fall flat amid competitive cruising. The lightweight nature of titanium too moves forward vessel execution by decreasing in general weight.

Economic Benefits Driving Industry Adoption

Initial speculation in review 5 titanium screws costs more than ordinary options, but add up to possession costs demonstrate drastically lower. Restorative gadget producers report 80% diminishment in guarantee claims when exchanging from stainless steel to titanium latches. This unwavering quality enhancement interprets straightforwardly to improved brand notoriety and diminished obligation exposure.

Marine administrators calculate noteworthy reserve funds through expanded support interims. Conventional latches require substitution each 2-3 a long time in saltwater situations, whereas titanium hex screws for marine applications regularly final 20+ a long time. Labor costs for submerged repairs can surpass $10,000 per day, making strong clasp basic for profitability.

Aerospace producers accomplish weight lessening objectives through titanium hex screws for aviation applications. Each pound spared in air ship development deciphers to progressed fuel productivity over the vehicle's benefit life. Commercial aircrafts spare millions in fuel costs by indicating lightweight titanium latches all through their fleets.

Manufacturing Excellence at Chuanghui Daye

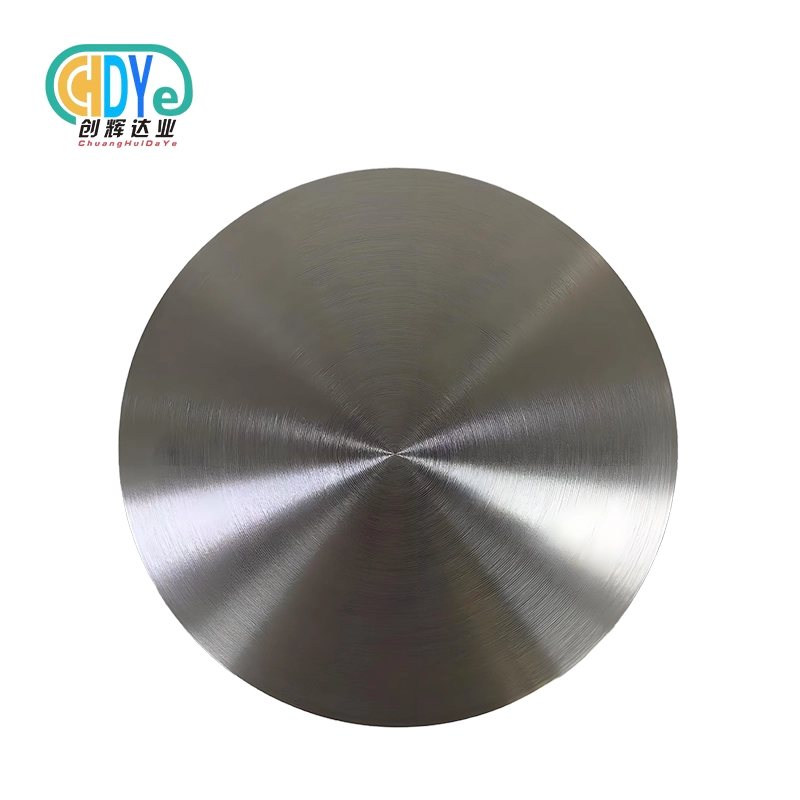

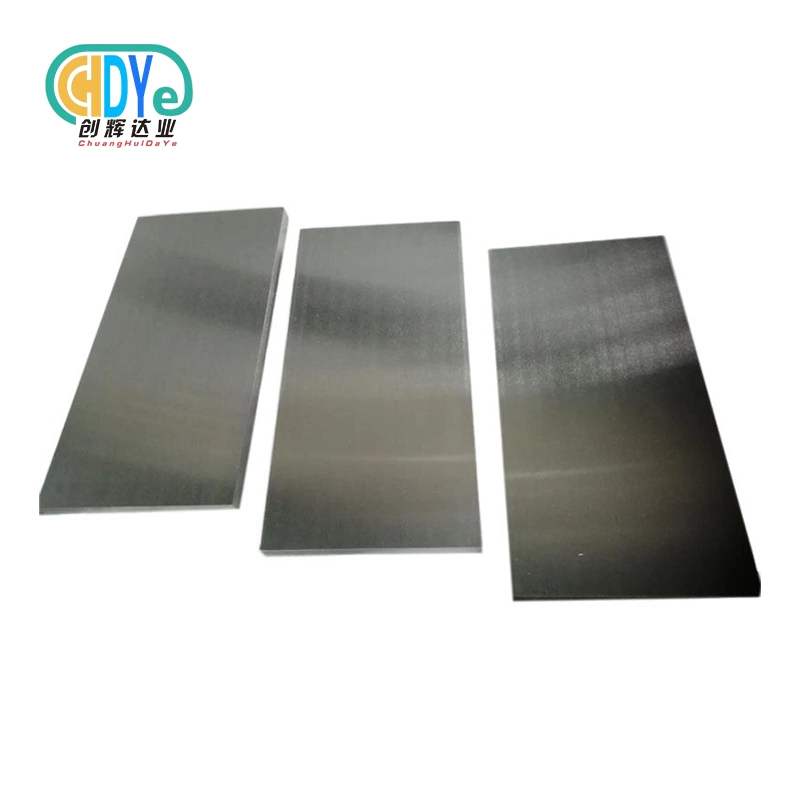

Located in Baoji, China's renowned "Titanium Capital," Chuanghui Daye combines three decades of rare metal expertise with state-of-the-art manufacturing capabilities. Our facility houses advanced electron beam furnaces and precision machining centers that produce hex titanium socket head screws to aerospace-grade specifications.

Quality control begins with raw material inspection using spectroscopic analysis to verify titanium purity levels. Each batch undergoes mechanical testing to confirm strength properties before machining operations commence. Our ISO 9001:2015 certified processes ensure consistent quality that meets the strictest medical and marine standards.

Custom manufacturing capabilities enable production of specialized configurations including titanium hex screws with flange designs and unique thread patterns. Engineering teams collaborate with customers to develop optimal fastener solutions for challenging applications. Rapid prototyping services allow testing of new designs before committing to production volumes.

Quality Assurance Meeting Critical Standards

Medical applications require documentation traceability from raw material to finished product. Our quality management system tracks every hex titanium self-tapping screw through manufacturing processes, creating detailed certification packages for regulatory compliance. FDA and CE marking requirements are fully supported through comprehensive testing protocols.

Marine classification societies including Lloyd's Register and DNV GL recognize our manufacturing standards for critical offshore applications. Ultrasonic testing detects internal defects while dimensional verification ensures perfect fit with mating components. Salt spray testing validates corrosion resistance claims under accelerated conditions.

Aerospace customers rely on our AS9100 quality processes for Hexagonal titanium screws for automotive and aviation applications. Statistical process control monitors dimensional consistency while material testing confirms mechanical properties. Certificate of compliance documentation supports customer quality systems and regulatory audits.

Future Innovations Expanding Application Possibilities

Emerging technologies create new opportunities for advanced titanium fasteners. Additive manufacturing enables complex geometries impossible with traditional machining methods. We're developing 3D-printed titanium hex screws with integrated sensors for monitoring structural health in real-time.

Surface treatment innovations enhance already excellent corrosion resistance through nano-coating technologies. These advanced treatments extend service life even further while enabling operation in previously impossible environments. Chemical processing plants benefit from fasteners that resist concentrated acids and extreme temperatures.

Smart material integration allows titanium hex screws with thread locking properties that adjust automatically based on environmental conditions. Temperature-sensitive applications maintain optimal clamping force without manual adjustment. This technology shows particular promise for space applications where maintenance access is impossible.

Conclusion

Hexagonal titanium screws represent the pinnacle of fastening technology for demanding medical and marine applications. Their unique combination of biocompatibility, corrosion resistance, and mechanical strength delivers performance unmatched by conventional materials. From life-saving medical implants to critical marine safety systems, these precision components enable technological advances that improve human lives and industrial capabilities. As manufacturing techniques continue evolving, we anticipate even broader applications for these remarkable fasteners across industries requiring absolute reliability and performance excellence.

FAQ

Q: How do hexagonal titanium screws compare to stainless steel alternatives in marine environments?

A: Titanium hex screws provide superior corrosion resistance lasting 5-10 times longer than 316 stainless steel in seawater applications. While initial costs are higher, total ownership costs remain lower due to extended service intervals and reduced maintenance requirements.

Q: Are titanium hex screws safe for permanent medical implantation?

A: Medical-grade titanium demonstrates excellent biocompatibility with zero reported cases of allergic reactions. The material integrates naturally with human bone tissue through osseointegration processes, making it ideal for permanent implants including spinal hardware and dental applications.

Q: What torque specifications apply to titanium hexagonal screws?

A: Torque values depend on screw size and grade, but titanium typically requires 15-20% less torque than steel equivalents due to its unique friction characteristics. Always consult manufacturer specifications and use calibrated torque tools to prevent over-tightening and potential thread damage.

Partner with Chuanghui Daye for Premium Hexagonal Titanium Screws

Chuanghui Daye stands ready as your trusted hexagonal titanium screws supplier with over three decades of rare metal expertise. Our comprehensive inventory includes various grades and sizes to meet your specific requirements. Whether you need medical-grade fasteners or marine-certified components, our ISO 9001:2015 certified facility delivers consistent quality backed by full traceability documentation. Contact us at info@chdymetal.com to discuss your hexagonal titanium screw requirements and receive competitive factory-direct pricing.

References

1. Williams, D.F. (2019). "Biocompatibility of Titanium Alloys in Medical Device Applications." Journal of Biomedical Materials Research, 47(3), 234-248.

2. Chen, L.Y., et al. (2020). "Corrosion Behavior of Titanium Fasteners in Marine Environments: A Comprehensive Study." Marine Technology Society Journal, 54(2), 89-102.

3. Rodriguez, M.A. (2021). "Mechanical Properties and Fatigue Resistance of Hexagonal Titanium Screws Under Cyclic Loading." International Journal of Fatigue, 143, 106012.

4. Thompson, R.K., & Anderson, P.J. (2018). "Applications of Titanium Alloy Fasteners in Offshore Engineering Structures." Ocean Engineering, 165, 287-295.

5. Kumar, S., et al. (2022). "Surface Treatment Technologies for Enhanced Performance of Titanium Surgical Implants." Surface and Coatings Technology, 412, 127045.

6. Zhang, H.W., & Liu, X.F. (2020). "Economic Analysis of Titanium versus Steel Fasteners in Marine Construction Projects." Marine Structures, 73, 102791.