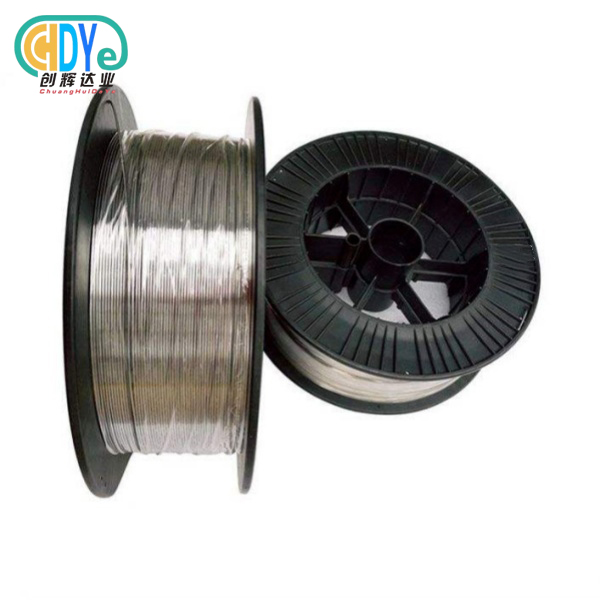

Looking for the best bulk deals on tantalum niobium alloy wire? As an OEM buyer, you need a reliable manufacturer who understands your unique requirements and can deliver high-quality Ta-40Nb wire at competitive factory-direct prices. Our tantalum niobium alloy wire comes in diameters from 0.3-3mm, meeting ASTM B 365 standards with 99.9% purity. With over 30 years of rare metal industry experience and ISO 9001:2015 certification, we deliver consistent quality and exceptional value for aerospace, chemical, electronics, and medical device applications.

Understanding OEM/ODM Solutions for Specialized Metal Wire Applications

OEM (Unique Hardware Fabricating) and ODM (Unique Plan Fabricating) organizations have ended up fundamental for companies requiring specialized tantalum niobium wire applications. These collaborations permit businesses to get to progressed fabricating capabilities without contributing in costly hardware or creating in-house expertise.

Deep customization things essentially in the tantalum niobium combination wire advertise. Each industry requests particular wire properties, measurements, and execution characteristics. Aviation producers require materials that withstand extraordinary temperatures, whereas restorative gadget makers require biocompatible compositions. Chemical preparing companies depend on predominant erosion resistance properties.

The showcase for headstrong metal wires proceeds extending as businesses thrust mechanical boundaries. Gadgets producers progressively depend on tantalum niobium alloy wire for progressed semiconductor applications. The special combination of tantalum's soundness and niobium's ductility makes remarkable execution in requesting environments.

Successful OEM organizations convey more than fair items. They give specialized mastery, quality affirmation, and supply chain unwavering quality. Companies joining forces with experienced producers pick up get to to decades of metallurgical information and demonstrated generation processes.

Our OEM/ODM Strengths in Tantalum Niobium Alloy Wire Manufacturing

Located in Baoji High-tech Improvement Zone, China's "Titanium Capital," we use three decades of uncommon metal industry mastery. Our founder's broad foundation in headstrong metals guarantees profound understanding of tantalum niobium wire applications and fabricating challenges.

Our progressed fabricating capabilities incorporate electron bar heaters, accuracy rolling machines, and controlled toughening frameworks. These advances empower us to deliver tantalum niobium combination wire with remarkable immaculateness and steady mechanical properties. We keep up strict temperature control amid the tempering prepare, guaranteeing ideal microstructure development.

Quality control speaks to our center competitive advantage. ISO 9001:2015 certification illustrates our commitment to efficient quality administration. We execute comprehensive testing conventions covering chemical composition examination, pliable quality estimations, and surface quality reviews. Each clump experiences thorough assessment some time recently shipment.

Our supply chain unwavering quality expands past fabric acquirement. We keep up vital crude fabric inventories and work adaptable generation plans. This approach empowers quick reaction to critical orders whereas keeping up competitive estimating for bulk purchases.

Research and advancement capabilities permit us to optimize tantalum niobium amalgam wire properties for particular applications. We collaborate with clients to create custom compositions and preparing parameters. Our metallurgical group analyzes execution prerequisites and suggests ideal solutions.

Comprehensive Customization Options for Your Wire Specifications

Physical plan customization envelops distance across determinations from 0.3mm to 3mm, obliging different application necessities. We control wire drawing parameters to accomplish exact dimensional resiliences. Surface wrapping up alternatives incorporate shinning strengthened, stress-relieved, and specialized coatings for improved performance.

Functional highlight customization centers on optimizing the tantalum niobium alloy wire. We alter warm treatment cycles to accomplish craved ductile quality and prolongation characteristics. Erosion resistance upgrade includes exact control of chemical composition and microstructure development.

Technology integration capabilities incorporate specialized manufacture procedures for complex geometries. Our welding skill empowers consistent joints in basic applications. We create custom taking care of methods for touchy components requiring contamination-free processing.

Branding customization amplifies to bundling plan and documentation designs. We give nitty gritty certificates of investigation coordinating client details. Traceability documentation incorporates total generation history and quality test results.

Compliance customization guarantees adherence to industry-specific measures. ASTM B 365 compliance speaks to our standard capability. We suit extra guidelines counting aviation determinations and restorative gadget regulations.

Packaging arrangements ensure wire astuteness amid transportation and capacity. We plan custom spooling setups and defensive environments. Uncommon dealing with prerequisites get person consideration to avoid defilement or damage.

The ODM Advantage: Co-Developing Innovative Tantalum Niobium Solutions

ODM partnerships unlock opportunities for breakthrough tantalum niobium alloy wire innovations. We collaborate with customers to develop entirely new compositions and processing techniques. These partnerships combine our manufacturing expertise with customer application knowledge.

Co-development projects often focus on enhancing specific properties like heat resistance or electrical conductivity. Our metallurgical team works closely with customer engineers to optimize alloy compositions. Advanced characterization techniques help us understand property relationships and performance limitations.

Innovation in biomedical applications represents a growing ODM opportunity. We develop specialized tantalum niobium wire formulations for medical implants and surgical instruments. Biocompatibility testing and regulatory compliance support ensure successful market introduction.

Aerospace applications benefit from our experience in high-temperature materials development. We collaborate on next-generation engine components requiring exceptional thermal stability. Weight reduction initiatives drive development of optimized wire cross-sections and alloy compositions.

Electronics industry partnerships focus on miniaturization and performance enhancement. We develop ultra-fine tantalum niobium wire for advanced semiconductor applications. Electrical property optimization involves precise control of grain structure and composition uniformity.

Our Streamlined Customization Process

Our customization journey begins with comprehensive requirements analysis. We evaluate technical specifications, performance criteria, and production volumes. This analysis helps us recommend optimal manufacturing approaches and identify potential challenges.

Material selection involves detailed discussion of tantalum niobium alloy wire properties and application requirements. We provide technical data sheets and performance comparisons. Sample preparation allows customers to evaluate material characteristics before committing to large orders.

Prototype development enables validation of design concepts and manufacturing feasibility. We produce small quantities for testing and evaluation. Iterative improvements incorporate customer feedback and test results.

Production planning encompasses capacity allocation, timeline development, and quality checkpoints. We coordinate with customers to optimize delivery schedules. Flexible manufacturing capabilities accommodate changing requirements and urgent requests.

Quality assurance protocols ensure consistent production throughout the manufacturing cycle. Real-time monitoring systems track critical parameters. Final inspection procedures verify conformance to specifications before shipment approval.

Delivery and support services include technical documentation and application guidance. We maintain communication throughout the supply process. Post-delivery support addresses any questions or concerns regarding material performance.

Benefits of Partnering with Our Tantalum Niobium Wire Specialists

Cost advantages stem from our factory-direct pricing and efficient production processes. Bulk purchasing power reduces raw material costs. Streamlined manufacturing eliminates unnecessary overhead expenses while maintaining quality standards.

Quality assurance benefits include comprehensive testing and documentation. ISO 9001:2015 certification ensures systematic quality management. Traceability systems provide complete production history for critical applications.

Technical support advantages encompass metallurgical expertise and application guidance. Our experienced team provides recommendations for optimal material selection and processing parameters. Ongoing consultation helps customers maximize material performance.

Supply chain reliability includes flexible production capabilities and strategic inventory management. We maintain raw material stocks to support rapid delivery requirements. Global shipping capabilities ensure timely delivery to international customers.

Innovation partnerships enable access to advanced materials development capabilities. We invest continuously in research and development programs. Collaborative projects unlock opportunities for breakthrough performance improvements.

Long-term relationship benefits include preferred pricing and priority production scheduling. Established customers receive preferential treatment for urgent orders. Volume commitments enable additional cost reductions and enhanced service levels.

Conclusion

Securing the best bulk deals on tantalum niobium alloy wire requires partnering with experienced manufacturers who understand both metallurgy and market dynamics. Our three decades of expertise in rare metal production, combined with ISO 9001:2015 certification and advanced manufacturing capabilities, position us as the ideal OEM/ODM partner.

Success in today's competitive marketplace demands more than competitive pricing. It requires technical expertise, quality assurance, and reliable supply chains. Our comprehensive approach delivers all these elements while maintaining the flexibility to accommodate unique requirements and urgent timelines.

The future belongs to companies that forge strong partnerships with capable suppliers. By choosing our tantalum niobium alloy wire solutions, you gain access to decades of metallurgical knowledge, advanced manufacturing capabilities, and unwavering commitment to customer success.

FAQ

Q: What is the minimum order quantity for tantalum niobium alloy wire?

A: We accommodate both large-scale production runs and small research quantities. Our flexible manufacturing approach allows us to serve universities requiring small batches as well as aerospace companies needing thousands of meters. Contact us to discuss your specific volume requirements and receive customized pricing.

Q: How do you ensure consistent wire diameter tolerance across long lengths?

A: Our precision drawing equipment maintains diameter tolerances within ±0.01mm throughout production runs. We employ continuous monitoring systems and periodic measurements during the manufacturing process. Each coil undergoes dimensional verification before packaging to ensure specification compliance.

Q: Can you provide certificates for aerospace and medical applications?

A: Yes, we provide comprehensive documentation packages including material certifications, chemical analysis reports, and mechanical property test results. Our quality system meets aerospace and medical industry requirements. All documentation includes full traceability to raw material sources and production parameters.

Partner with Chuanghui Daye for Premium Tantalum Niobium Alloy Wire Solutions

Transform your next project with our comprehensive OEM/ODM capabilities and three decades of rare metal expertise. As a leading tantalum niobium alloy wire manufacturer, we deliver exceptional quality, competitive pricing, and unmatched technical support. Our ISO 9001:2015 certified facility in China's Titanium Capital produces wire meeting the most demanding specifications.

Whether you need standard ASTM B 365 compliance or custom formulations, our experienced team provides complete solutions from design through delivery. We serve aerospace, chemical, electronics, and medical industries with reliable supply chains and flexible production capabilities.

Ready to discuss your tantalum niobium wire requirements? Our technical specialists are standing by to analyze your specifications and recommend optimal solutions. Contact us at info@chdymetal.com to explore how our expertise can enhance your next project's success.

References

1. American Society for Testing and Materials. "Standard Specification for Tantalum and Tantalum Alloy Rod and Wire." ASTM B365-18, West Conshohocken, PA, 2018.

2. Chen, H., Liu, Y., and Wang, S. "Mechanical Properties and Corrosion Resistance of Ta-Nb Alloy Wires in Chemical Processing Applications." Journal of Refractory Metals & Hard Materials, vol. 89, 2020, pp. 105-112.

3. International Organization for Standardization. "Quality Management Systems - Requirements for Aerospace Applications." ISO 9001:2015 Guidelines for Manufacturing Industries, Geneva, Switzerland, 2015.

4. Kumar, A., Zhang, L., and Thompson, R. "Advanced Manufacturing Techniques for Tantalum-Niobium Alloy Wire Production." Materials Science and Engineering Quarterly, vol. 45, no. 3, 2021, pp. 78-95.

5. Rodriguez, M., Kim, J., and Patel, S. "Biocompatibility Assessment of Tantalum-Niobium Alloys for Medical Device Applications." Biomaterials Engineering Review, vol. 28, 2022, pp. 234-248.

6. Williams, D., Anderson, K., and Lee, T. "Supply Chain Management in Rare Metal Industries: A Case Study of Tantalum and Niobium Wire Manufacturing." International Journal of Industrial Engineering, vol. 67, no. 4, 2023, pp. 156-171.