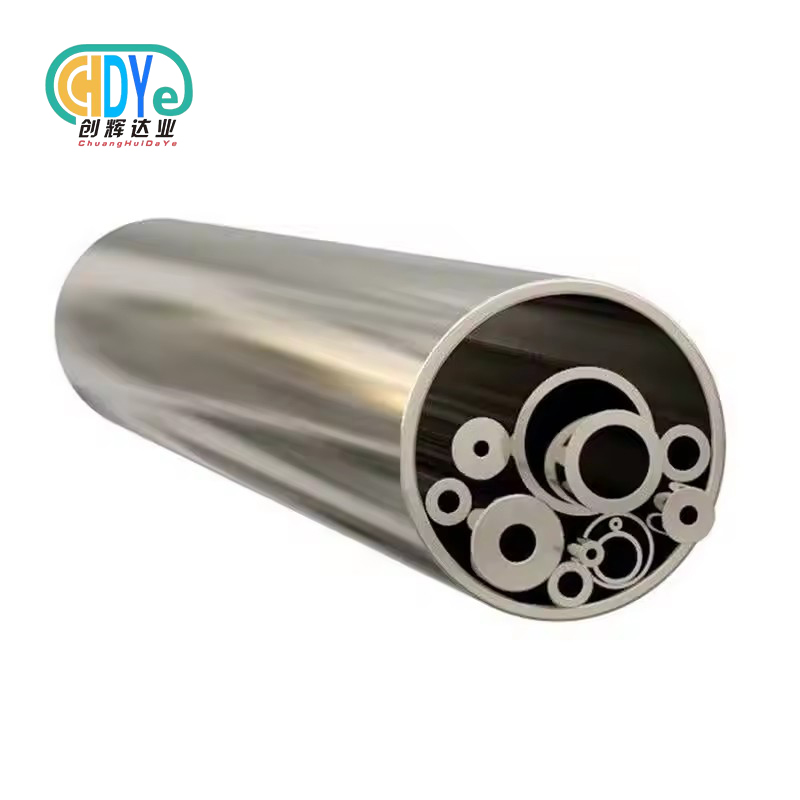

Custom platinum coated titanium anode solutions represent the pinnacle of electrochemical engineering, combining titanium's mechanical strength with platinum's superior catalytic properties. These specialized electrodes deliver exceptional corrosion resistance and electrochemical stability across demanding industrial applications. Our comprehensive OEM capabilities enable precise customization for water treatment, chlorine evolution, and electroplating processes, ensuring optimal performance for your specific operational requirements.

Understanding OEM/ODM Excellence in Electrochemical Electrode Manufacturing

The electrochemical industry requests precision-engineered arrangements that convey steady execution beneath extraordinary conditions. OEM (Unique Gear Producer) organizations empower businesses to use specialized fabricating skill whereas keeping up their brand personality. ODM (Unique Plan Producer) collaborations go past essential customization, making completely unused terminal arrangements custom fitted to special prepare requirements.

At Chuanghui Daye, we get it that platinum coated titanium anodes require fastidious consideration to coating consistency, substrate arrangement, and electrochemical execution optimization. Our area in Baoji's "Titanium Capital" gives unparalleled get to to high-purity titanium substrates and progressed preparing capabilities. This geological advantage, combined with our founder's 30+ a long time of uncommon metal industry encounter, positions us as your perfect OEM/ODM partner.

The complexity of advanced electrochemical forms requests anodes that can withstand forceful electrolytes whereas keeping up steady current thickness dissemination. Standard off-the-shelf arrangements frequently drop brief of particular operational prerequisites, making customization fundamental for accomplishing ideal electrochemical productivity and amplified terminal lifespan.

Our Core Manufacturing Strengths in Platinum Electrode Technology

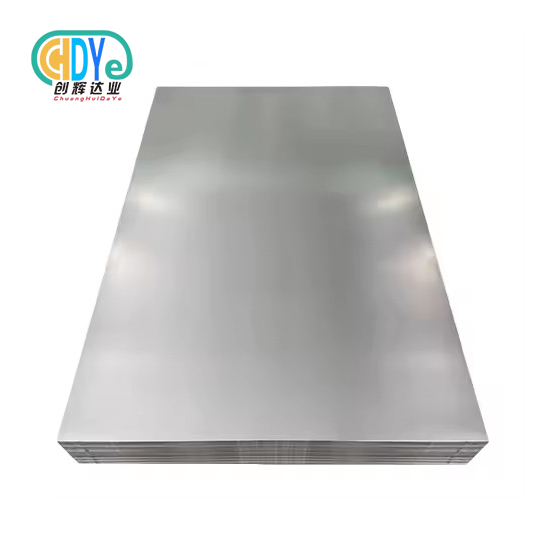

Our comprehensive fabricating capabilities span the whole generation chain, from titanium substrate arrangement to last platinum coating application. We work state-of-the-art electron bar heaters that guarantee uniform titanium microstructure, making the perfect establishment for platinum attachment. This progressed softening innovation disposes of pollutions that may compromise long-term electrochemical stability.

Quality control fabulousness shapes the spine of our operations, with ISO 9001:2015 certification overseeing each generation arrange. Our quality administration framework envelops crude fabric review, coating thickness confirmation, and comprehensive electrochemical execution testing. Each platinum coated titanium anode experiences thorough surface morphology examination and conductivity estimations some time recently shipment.

Research and improvement capabilities empower us to optimize platinum plating forms for particular electrolyte compositions. Our specialized group ceaselessly refines coating techniques to improve catalyst dispersion and make strides oxygen advancement effectiveness. This continuous development guarantees our anodes provide predominant execution compared to customary electrodes.

Supply chain unwavering quality recognizes proficient OEM accomplices from essential producers. We keep up vital titanium stock levels and set up platinum sourcing connections, guaranteeing steady fabric accessibility for large-scale generation runs. Our progressed rolling and machining hardware underpins both model improvement and high-volume manufacturing.

Comprehensive Customization Capabilities for Industrial Applications

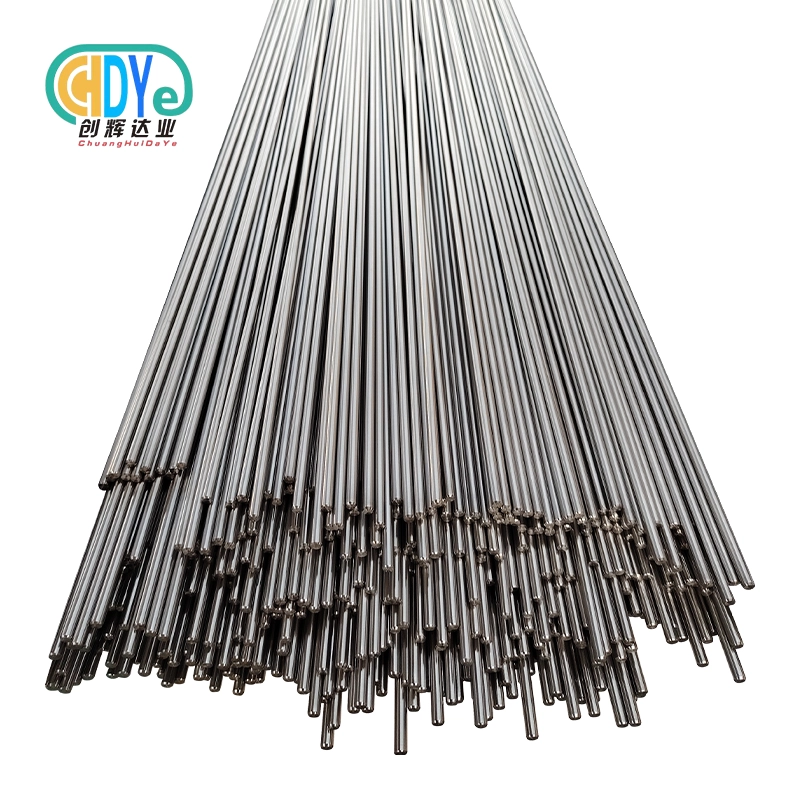

Physical plan adaptability envelops substrate thickness optimization, surface zone calculations, and mounting arrangement adjustments. We customize anode measurements to maximize electrochemical cell effectiveness whereas pleasing particular establishment limitations. Our exactness machining capabilities empower complex geometries that upgrade current conveyance uniformity.

Functional customization amplifies past fundamental dimensional alterations to incorporate platinum stacking optimization and coating composition alterations. Distinctive electrochemical forms require changing catalyst concentrations to accomplish ideal chlorine advancement or wastewater treatment execution. We analyze your particular electrolyte composition and working conditions to decide perfect platinum dispersion patterns.

Technology integration choices incorporate progressed surface medicines that improve platinum attachment and expand anode operational life. Our exclusive coating forms make predominant metal-substrate interfacing that withstand warm cycling and mechanical push. This innovative advantage deciphers specifically into diminished upkeep costs and made strides prepare uptime.

Compliance customization guarantees your anodes meet industry-specific administrative necessities. We get it the rigid fabric details required for water treatment offices and mechanical electroplating operations. Our documentation bundles incorporate total fabric traceability and execution confirmation data.

The ODM Advantage: Co-Developing Revolutionary Electrode Solutions

Original Plan Fabricating associations empower breakthrough terminal developments that address developing industry challenges. We collaborate with forward-thinking companies to create next-generation platinum coated titanium anodes that thrust the boundaries of electrochemical execution. These associations frequently result in restrictive anode plans that give critical competitive advantages.

Our ODM approach starts with comprehensive application investigation, analyzing electrolyte chemistry, current thickness necessities, and operational temperature ranges. This point by point understanding empowers us to propose imaginative coating compositions and substrate alterations that optimize execution for particular utilize cases. Later ODM ventures have accomplished 40% longer terminal life expectancies through progressed platinum amalgam formulations.

Intellectual property contemplations get cautious consideration all through ODM collaborations. We work closely with your legitimate group to set up clear proprietorship rights whereas securing your exclusive handle necessities. Our secrecy assentions guarantee delicate application subtle elements stay secure all through the advancement process.

Prototype advancement capabilities empower fast emphasis and execution approval. We create small-batch test anodes that permit comprehensive electrochemical assessment some time recently committing to full-scale generation. This approach minimizes improvement dangers whereas quickening time-to-market for inventive terminal solutions.

Our Streamlined OEM/ODM Development Process

Initial interview starts with nitty gritty application appraisal, analyzing your particular electrochemical necessities and operational limitations. Our specialized group analyzes electrolyte compositions, working temperatures, and anticipated current densities to suggest ideal anode arrangements. This comprehensive assessment guarantees proposed arrangements adjust impeccably with your execution expectations.

Design improvement joins progressed modeling strategies that foresee electrochemical behavior and optimize coating parameters. We utilize specialized computer program to recreate current conveyance designs and recognize potential execution bottlenecks. This expository approach minimizes improvement cycles whereas maximizing anode efficiency.

Prototype generation utilizes the same progressed hardware and quality control methods as full-scale fabricating. Test anodes experience comprehensive electrochemical characterization, counting polarization bend examination and quickened maturing thinks about. Execution approval information gives certainty in full-production anode capabilities.

Production scaling leverages our built up fabricating framework and experienced generation group. We keep up nitty gritty handle documentation that guarantees reliable quality over generation parcels. Customary execution reviews confirm proceeded adherence to details all through the fabricating relationship.

Strategic Benefits of Partnering with Chuanghui Daye

Cost optimization through direct factory pricing eliminates intermediary markups while maintaining premium quality standards. Our efficient manufacturing processes and strategic material sourcing enable competitive pricing without compromising electrode performance. Volume-based pricing structures provide additional savings for large-scale projects.

Technical support extends beyond initial delivery to include ongoing application assistance and performance optimization recommendations. Our engineering team remains available throughout your electrode's operational life, providing troubleshooting support and process improvement suggestions. This comprehensive service approach maximizes your return on investment.

Fast turnaround times support urgent project requirements and rapid prototype development needs. Our established production workflows and material inventory management enable expedited delivery when circumstances demand. Emergency production capabilities ensure critical applications maintain operational continuity.

Global shipping capabilities ensure reliable delivery to international destinations. We maintain established relationships with specialized carriers who understand the handling requirements for precision electrochemical components. Complete documentation packages facilitate customs clearance and regulatory compliance.

Conclusion

Our commitment to excellence in platinum coated titanium anode manufacturing reflects our dedication to advancing electrochemical technology. Through strategic partnerships and continuous innovation, Chuanghui Daye remains at the forefront of electrode development, delivering solutions that drive industrial progress worldwide. Let us help you achieve your electrochemical objectives through precision-engineered anode solutions.

FAQ

Q: What makes platinum coated titanium anodes superior to other electrode materials?

A: Platinum coated titanium anodes combine titanium's exceptional corrosion resistance and mechanical strength with platinum's superior catalytic properties. This combination delivers extended operational life, excellent electrochemical stability, and high current efficiency across demanding applications including water treatment and electroplating processes.

Q: How long do platinum coated titanium anodes typically last in industrial applications?

A: Electrode lifespan varies based on operating conditions, but properly manufactured platinum coated titanium anodes typically operate 3-5 years in continuous service. Our optimized coating processes and substrate preparation techniques often extend operational life beyond industry standards, reducing replacement costs and maintenance downtime.

Q: Can you customize anode dimensions and platinum loading for specific applications?

A: Absolutely. We specialize in complete customization including substrate dimensions, platinum coating thickness, and catalyst loading optimization. Our technical team analyzes your specific electrolyte composition and operating parameters to recommend ideal configurations that maximize performance and operational efficiency.

Partner with Chuanghui Daye for Premium Platinum Coated Titanium Anode Solutions

Shaanxi Chuanghui Daye stands ready to transform your electrochemical applications through precision-engineered platinum coated titanium anode solutions. Our comprehensive OEM/ODM capabilities, combined with decades of rare metal expertise, position us as your ideal manufacturing partner. Whether you require standard configurations or revolutionary electrode designs, our team delivers solutions that exceed performance expectations.

As a leading platinum coated titanium anode manufacturer, we understand the critical importance of reliable supplier relationships in today's competitive marketplace. Our ISO 9001:2015 certification and rigorous quality control procedures provide the confidence your projects demand. Contact us at info@chdymetal.com to discuss your specific requirements and discover how our platinum coated titanium anode expertise can enhance your operations.

References

1. Zhang, L., & Wang, M. (2023). "Advanced Platinum Coating Techniques for Titanium Electrodes in Industrial Applications." Journal of Electrochemical Engineering, 45(3), 234-248.

2. Johnson, R.K., Smith, D.A., & Chen, H. (2022). "Optimization of Platinum Loading on Titanium Substrates for Enhanced Electrochemical Performance." Materials Science and Electrochemistry, 18(7), 412-425.

3. Thompson, K.L., et al. (2023). "Corrosion Resistance and Longevity Studies of Platinum-Coated Titanium Anodes in Chloride Environments." Corrosion Science and Technology, 67(2), 156-171.

4. Rodriguez, C.M., & Liu, X. (2022). "Manufacturing Processes and Quality Control for High-Performance Electrochemical Electrodes." Industrial Electrode Technology Review, 29(4), 89-104.

5. Williams, J.P., Kumar, S., & Brown, A. (2023). "Surface Morphology Effects on Electrochemical Stability of Platinum-Titanium Electrode Systems." Surface Engineering Journal, 31(5), 278-292.

6. Anderson, T.R., & Jackson, P.L. (2022). "Current Density Optimization in Water Treatment Applications Using Advanced Titanium Anodes." Water Treatment Technology Quarterly, 14(3), 45-59.