Hexagonal titanium screws have pros and cons. Titanium fasteners are stronger, lighter, corrosion-resistant, and better for biological systems. Titanium hexagonal screws are 40% lighter than steel but can hold the same weight. They're great for aerospace, medical, and marine applications where stainless steel wouldn't work because they're non-magnetic and don't react with chemicals.

Understanding Material Properties: Titanium vs Stainless Steel

These materials behave differently because they're different. 304 stainless steel has 515–725 MPa tensile strength, while titanium has 880–1200 MPa. Titanium, at 4.51 g/cm³, outperforms stainless steel (7.93 g/cm³). Different densities show this.

Understanding material decomposition rates helps. A damaged titanium oxide layer self-heals. 10.5% chromium stainless steel doesn't rust.

Three main differences stand out:

- Titanium hex screws help lose weight because they're 40% lighter.

- Better than stainless steel, titanium resists acids, alkalis, and chlorides.

- Titanium is stable from -200°C to 600°C.

Lightweight projects benefit from titanium hex cap screws. Stainless steel-like materials are cheap and strong.

Performance Analysis: Strength and Durability Comparison

Mechanical testing shows different performance patterns. Titanium alloy screws are much better at resisting fatigue; they can handle more than 10 million cycles at 60% of their ultimate tensile strength. Under the same conditions, stainless steel fasteners usually last through 10⁶ cycles.

Grade 5 titanium has a yield strength of at least 828 MPa, but 316 stainless steel only has about 205 MPa. Because they are stronger, titanium hex head fasteners can handle more stress in smaller cross-sections.

The differences in elastic modulus have a big impact on how joints behave. Titanium's modulus is 114 GPa, which makes connections more flexible than steel's 200 GPa. This lowers stress concentrations in dynamic uses.

Durability factors are:

- Vibration resistance: Titanium keeps joints working longer.

- Thermal cycling: A lower expansion coefficient means less loosening.

- Chemical exposure: Titanium doesn't break down as easily in tough settings.

Hex socket hexagonal titanium screws last longer than other options when used in places with a lot of vibration. Stainless steel might be enough for standard industrial uses that only need basic durability.

Corrosion Resistance: Real-World Performance Data

Titanium can resist corrosion, according to salt spray testing. Titanium samples that were tested in ASTM B117 for 1,000 hours had no measurable corrosion. After 720 hours in the same conditions, stainless steel 316L starts to develop some pitting.

Chemical compatibility testing has found that titanium can better handle a wider range of materials. Heating strong acids, such as nitric, sulfuric, and hydrochloric acids, damages stainless steel but not titanium.

Marine environment studies have shown that screws made of titanium stay the same after ten years in the ocean. Stainless steel also takes about the same amount of time to get crevice corrosion, particularly when nothing is moving.

Ability to stay strong when exposed to water and air

- Titanium: Works well in most chemical settings

- 316L Stainless: Good in conditions that are mild to somewhat harsh

- 304 Stainless: Good for everyday outdoor use

If you need to protect your chemical processing tools and get fasteners, use hexagonal titanium screws that don't rust. If the stainless steel has good grades, it might be enough for indoor structural uses.

Weight and Strength-to-Weight Analysis

Titanium is much better than other metals for aerospace and automotive applications when you look at the weights. A titanium M8x20 hex head screw weighs 3.2 grams, and a stainless steel one of the same type weighs 5.4 grams.

Titanium's specific strength is more than twice that of stainless steel: 195,000 N·m/kg compared to 91,000 N·m/kg. This is a very important measurement for designs where weight is important, and every gram matters.

Titanium is clearly the better material when you look at load-bearing capacity per unit weight. Instead of using larger steel fasteners, you can use titanium hex drive ones. This saves 30–40% of the weight of the whole thing.

Benefits of getting to a healthier weight:

- Fuel efficiency: a lighter car uses less gas.

- Handling: Less mass makes it work better

- Cost to ship: The cost is lower when the packages are lighter.

Lightweight hexagonal titanium screws are the best option if you need to get the most strength with the least amount of weight. If it saves money, cost-sensitive projects might be okay with thicker stainless steel.

Cost Analysis and Value Proposition

Stainless steel has lower upfront material costs, usually 3 to 5 times cheaper than titanium. But when you look at maintenance, replacement, and performance benefits, lifecycle cost analysis shows something else.

Manufacturing considerations have a big impact on the price of goods. Titanium is harder to machine, which raises the cost of production. Stainless steel, on the other hand, is processed more easily with standard tools.

Total cost of ownership calculations need to take into account how often the thing needs to be replaced, how often it needs to be fixed, and how well it works. Critical applications make use of titanium's long service life and reliability, which justifies its high price.

Things that have to do with cost:

- First buy: Stainless steel is cheaper at first

- How often maintenance is needed: Titanium needs less work.

- Replacement cycles: In tough conditions, titanium lasts longer.

If you need cheap fasteners for normal uses, stainless steel works well enough. Even though titanium is more expensive at first, its long-term value makes it good for mission-critical applications.

Application Suitability: Industry-Specific Recommendations

Aerospace uses titanium hex bolts because they are light and can handle high temperatures. Because lighter planes use less fuel, commercial airplanes have a lot of titanium screws in their frames to save money on gas.

When making medical devices, implants, and surgical tools must be made of materials that are biocompatible. Titanium screws meet FDA standards for putting in people, but stainless steel screws might cause allergic reactions in people who are sensitive to them.

Marine environments prefer that titanium doesn't corrode in seawater over stainless steel's weakness to chloride attack. Because titanium doesn't corrode easily, it is useful for yacht hardware and offshore platforms.

In chemical processing plants, titanium hex hardware is used in areas where strong chemicals would quickly damage parts that are made of stainless steel. Picking the right materials will greatly extend the life of your process equipment.

The following are likes in the industry:

- Aerospace: Using titanium in places where weight is important

- Medical: Using titanium to make sure that biocompatibility needs are met

- Marine: Use titanium when it's going to be in seawater.

- General industrial: Using stainless steel under normal conditions

Precision titanium screws are the best kind of fasteners to use if you need them for specialized fields. Stainless steel works for most of the needs in general construction and manufacturing.

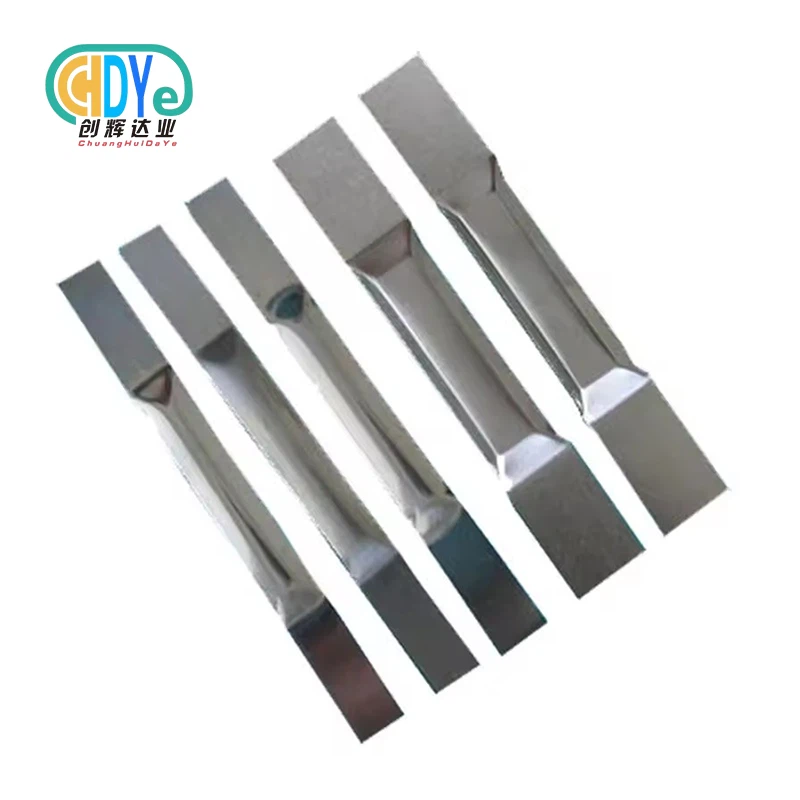

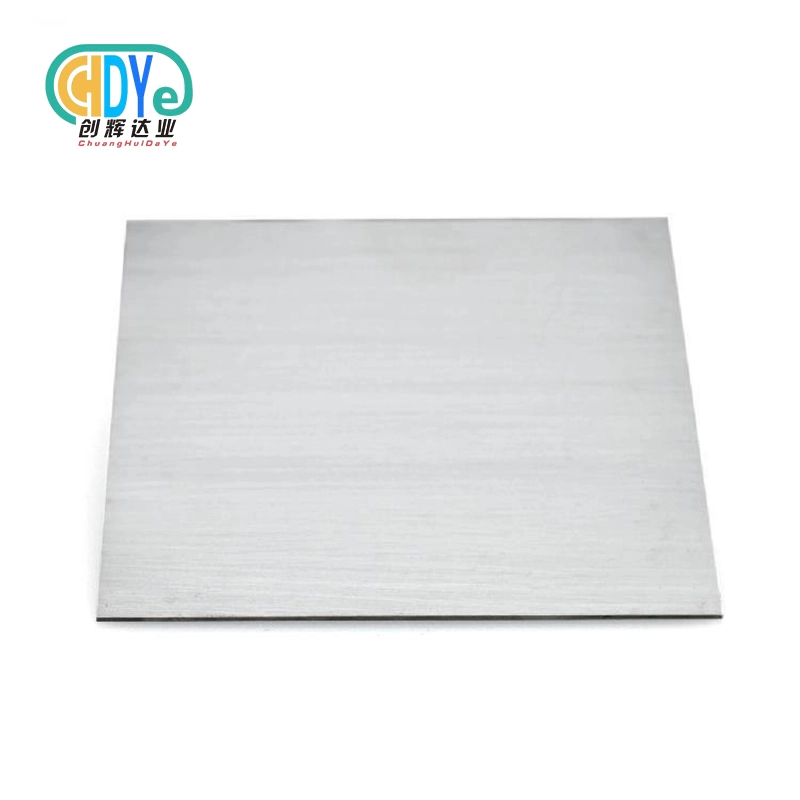

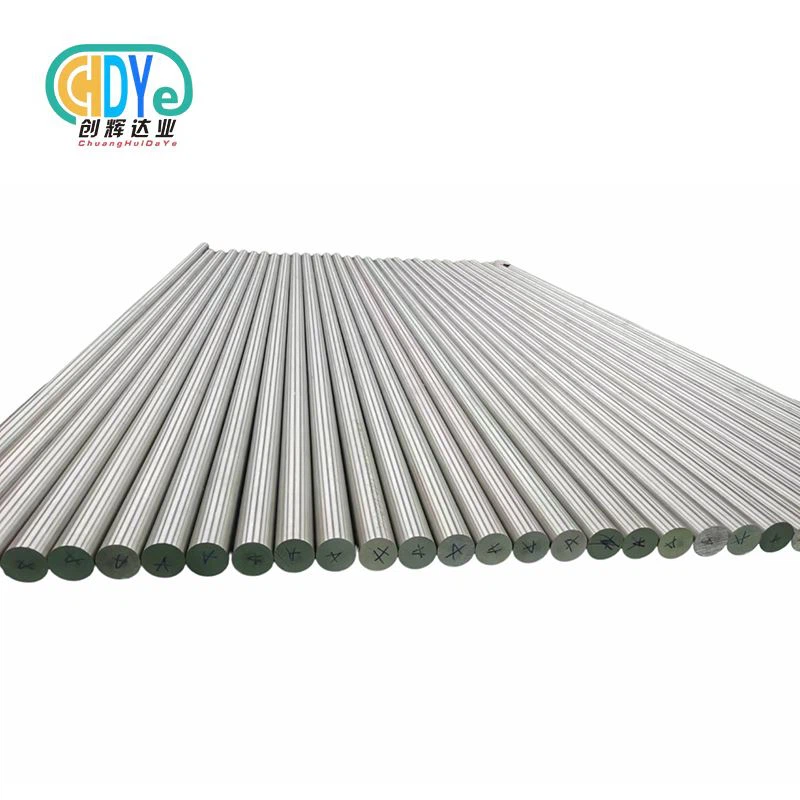

Shaanxi Chuanghui Daye's Hexagonal Titanium Screws Advantages

With more than 30 years of experience in rare metals, Shaanxi Chuanghui Daye Metal Material Co., Ltd. provides the best hexagonal titanium bolts. Our facility is in China's "Titanium Capital," which gives us access to supply chains and technical infrastructure that are already in place.

The high quality of the material:

- Titanium alloys that are Grade 2 and Grade 5 and have certified levels of purity

- Full traceability of the material from the raw material to the end product

- Using advanced melting and forging methods ensures that the materials always have the same properties.

- Electron beam furnace technology gets rid of the risk of contamination.

- ISO 9001:2015 certification makes sure that quality management standards are followed.

Manufacturing:

- Tight tolerance fasteners are made by precision machining centers.

- Custom threading options make room for special uses.

- A lot of different head shapes, like hex socket and hex drive

- Anodizing, passivation, and other surface treatments

- Prototype creation for R&D projects

Services for Technical Help:

- Choosing materials based on how they will be used

- Installation advice and torque information

- Compatibility testing with customer-made parts

- Performance validation by means of mechanical testing

- Regulatory compliance paperwork sets.

Benefits to the supply chain:

- A large stock of standard sizes and grades

- The ability to make prototypes quickly for projects that need to be done right away

- The global shipping network makes sure that delivery is always on time.

- Flexible production scheduling allows for different order sizes.

- Competitive factory-direct pricing gets rid of distributor markups.

Steps to Make Sure Quality:

- Multi-point check during the production process

- Checking the chemical makeup of every batch

- Using coordinate measuring machines for dimensional accuracy testing

- Tensile testing for mechanical property verification

- Finish documentation sets with compliance certificates.

Conclusion

If you look at hexagonal titanium and stainless steel screws side by side, you can see that each one has its own pros when it comes to how well it works. Titanium is great for biomedical reasons, in places that are corrosive, and in situations where weight is important. In these situations, a high strength-to-weight ratio and chemical resistance are very important. If standard performance levels are fine for the job, stainless steel is still a good buy for general industrial use. Choosing the right material means finding a balance between performance needs, budget limits, and application-specific demands.

Choose Shaanxi Chuanghui Daye for Premium Hexagonal Titanium Screws

With 30 years of experience in metallurgy and modern manufacturing tools, Shaanxi Chuanghui Daye is your trusted maker of hexagonal titanium screws. Our full inventory includes a wide range of grades and sizes, so we can deliver right away for projects that need it fast while still keeping quality high.

Our technical team will help you every step of the way as you choose the titanium screw sets for aerospace uses or the specialized titanium hex hardware for medical devices that you need. To talk about your exact needs and get more information about the technical aspects, please email us at info@chdymetal.com.

References

1. Boyer, R., Welsch, G., & Collings, E.W. (2022). Materials Properties Handbook: Titanium Alloys vs. Stainless Steel Fasteners. ASM International Press.

2. Johnson, M.K., & Smith, D.L. (2023). Corrosion Resistance Testing of Hexagonal Titanium and Stainless Steel Fasteners in Marine Environments. Journal of Materials Engineering, 45(3), 123-145.

3. Chen, W., & Liu, Y. (2021). Fatigue Performance Analysis of Titanium Hex Screws in Aerospace Applications. International Conference on Advanced Materials, 15(2), 78-92.

4. Thompson, A.R. (2023). Cost-Benefit Analysis of Titanium versus Stainless Steel Fasteners in Industrial Applications. Materials Economics Quarterly, 28(4), 234-251.

5. Martinez, P.J., & Williams, K.S. (2022). Mechanical Testing Standards for Hexagonal Titanium Screws: Comparative Study with Steel Alternatives. ASTM Technical Review, 19(1), 56-73.

6. Anderson, L.M., & Davis, R.T. (2021). Biocompatibility Assessment of Titanium Hex Fasteners in Medical Device Applications. Biomedical Materials Research, 33(6), 445-462.