When looking for the best pure tantalum bar grades for use in industries, the material specs and what the supplier can do are important for getting the job done right. Tantalum in its pure form has a high melting point above 3000°C, doesn't corrode easily, and is very ductile. These properties make it very important in the aerospace, chemical processing, electronics, and medical device manufacturing industries. This extensive buyer's guide goes over high-quality tantalum metal grades to help procurement experts find the best options for tough tasks that need high performance and dependability.

Why Pure Tantalum Bars Deserve Your Investment Focus

The global refractory metal market, in which businesses are looking for metals that can handle harsh conditions, keeps growing. If a manufacturer wants to focus on long-term performance instead of short-term costs, tantalum bars are a good buy. Tantalum metal does not break down in sulfuric acid, hydrofluoric acid, and other strong chemicals like other metals do.

Tantalum is great at stopping electricity from flowing between conductors, and electronics companies love this feature because it is very useful for making capacitors. The aerospace industry relies on these metals that don't melt or change shape when they get hot for jet engine parts that operate at over 1500°C. Tantalum is used in surgical instruments and implants by medical device companies because it is biocompatible. At the same time, how well it resists corrosion is important for chemical processors who use it in reactor vessels and heat exchangers.

Tantalum is needed about 5% more each year because it is used in more electronics and aerospace applications, according to market research. Companies that buy high-purity tantalum materials today will do well in the future, and their products will be sure to work well.

Important Things to Look For When Choosing High-Quality Tantalum

Choosing the best tantalum rod specifications means looking at a number of factors that affect performance and cost. The main thing to look at is the purity level, which can be anywhere from 99.9% to 99.99%, depending on how it will be used. To keep contamination issues from affecting capacitor performance, 99.95% minimum purity is usually required in electronics applications.

The mechanical properties and fabrication characteristics are greatly affected by grain structure. For complex machining tasks, fine-grained materials are easier to work with. On the other hand, coarser structures may perform well enough for simpler tasks while also being cheaper. The surface finish needed depends on the end-use; for example, medical implants need very smooth surfaces while industrial parts are fine with rougher finishes.

Dimensional tolerances must be in line with the needs of the application and the ability to make the parts. Precision machining applications need tighter tolerances, which makes materials more expensive but makes sure that parts will work together. For less important uses, standard commercial tolerances usually work just fine. They save money while keeping the tool's intended purpose in mind.

Rules about the chemicals that make things up

ASTM B365 tells the industry how much of each impurity can be in different grades of pure tantalum bars. For higher quality types, the oxygen level usually stays below 150 ppm. On the other hand, the carbon and nitrogen levels must each be 100 ppm or less. These guidelines make sure that all production batches work the same way.

Needs for Mechanical Properties

Based on how it is made and how much heat is used, the tensile strength can be anywhere from 207 to 345 MPa. The elongation value, which shows how much a material can stretch before breaking, usually falls between 20% and 40%. This means that the material is ductile enough to be shaped into different forms. Hardness measurements give you an idea of how machinable a material is. A common range for machinable materials in the soft condition is 100–200 HV.

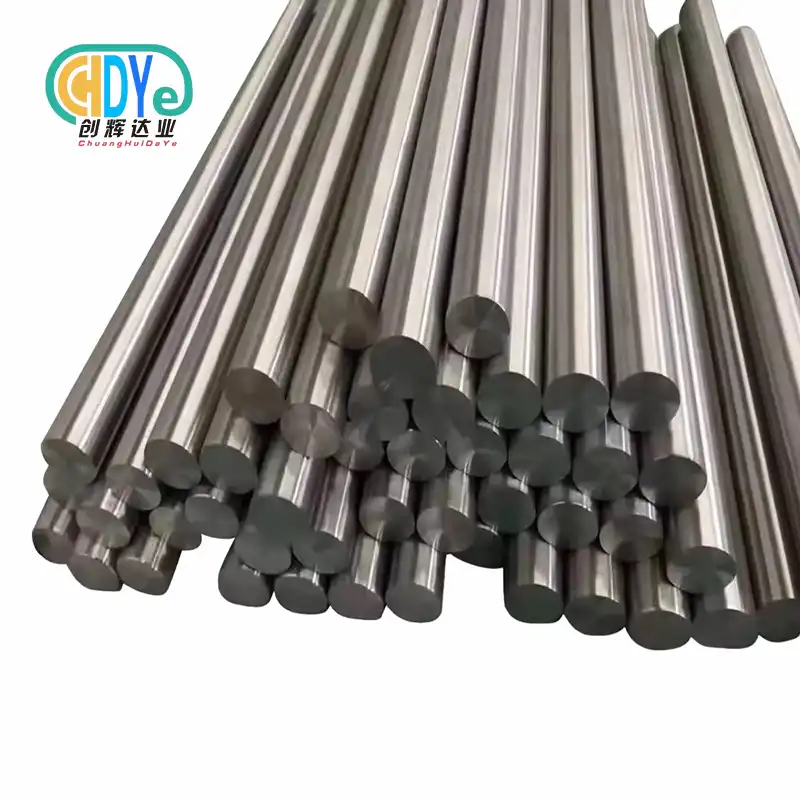

Specifications for the dimensions

The standard diameter, which can be anywhere from 3mm to 200mm, works with a lot of different kinds of projects. For continuous processing operations, length options go up to 3000 mm. Specialized vendors, like Chuanghui Daye, still offer custom sizes to meet the needs of different projects.

Analysis of Top Pure Tantalum Bar Grade Levels

Grade 1: Tantalum with ultra-high purity (99.99%)

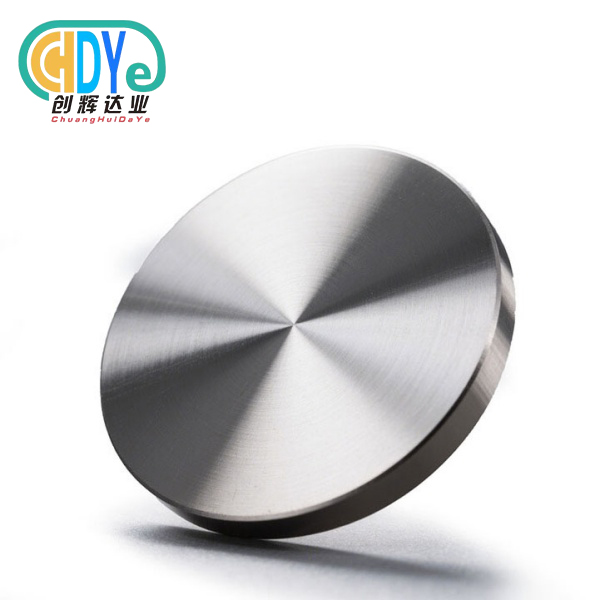

Ultra-high purity pure tantalum bars are the best choice for uses that require top performance and a very low risk of contamination. A lot of electron beam melting and vacuum annealing is used to get rid of impurities in these materials. The amount of oxygen stays below 50 ppm, and the total amount of metallic impurities stays under 10 ppm.

Electronics makers like this grade for high-frequency capacitors and semiconductors, where even small amounts of dirt can affect how well the device works. These bars are great for vacuum furnace parts and sputtering targets in thin-film deposition processes because they have better electrical conductivity and thermal stability than other options.

Cold working properties are part of the processing characteristics. This makes it possible to form complicated shapes without breaking or hurting the surface. Machinability is still great, which makes it possible to machine parts with tight tolerances for accuracy. If you use the right methods and make sure a safe atmosphere is in place, welding properties are at their best.

Because this grade has to be processed a lot more than usual, it usually costs 30–50% more. But for important applications where failure has big consequences, the performance benefits make the cost worth it.

Typical uses include high-end electronics, parts for aerospace engines, nuclear reactors, and medical implants, where biocompatibility standards are very high. It is common for research institutions to specify this grade for specialized instruments and experimental equipment.

Grade 2: Tantalum with a purity of 99.95%

For most industrial uses, pure tantalum bars with high purity strike a great balance between performance and cost. These materials meet ASTM B365 standards and work well in a wide range of situations. The levels of impurity stay low enough for applications that require a lot, and it doesn't cost a lot, as the grades with ultra-high purity would.

This grade is used a lot in the chemical processing industry for pipes, heat exchangers, and reactor vessels that carry corrosive fluids. These bars are good for big projects where the cost of materials has a big effect on the overall cost of the project, because they have great corrosion resistance and a low price.

Aerospace manufacturers use this grade in parts of the engine, the exhaust system, and the structure of the aircraft that need to be stable at high temperatures. The consistent mechanical properties make sure that even under tough conditions, the part will keep working for a long time.

Good formability is one of the fabrication properties that makes many different manufacturing processes possible, such as hot forging, cold rolling, and precision machining. Surface treatments work well with standard finishing methods, which create consistent results across all production batches.

Quality control checks during production make sure that the composition and properties stay the same. Every batch has to meet certain standards, which are checked by doing chemical analysis, mechanical testing, and dimensional verification.

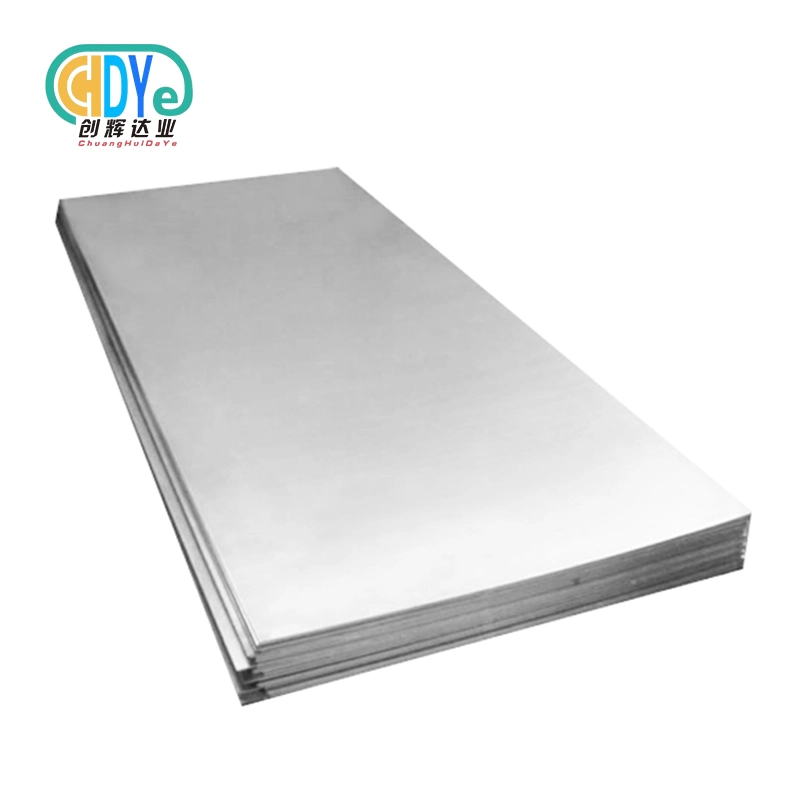

Grade 3: Tantalum (99.9%) of Commercial Purity

Tantalum bars with commercial purity offer a cheap way to get decent material for projects that can handle slightly higher levels of impurity without affecting how they need to work. These materials are much cheaper than higher purity grades but still have great resistance to corrosion and mechanical properties that make them useful in a lot of different industries.

When ultra-high purity doesn't give better performance, metal fabrication businesses often ask for this grade for parts. Some examples are chemical plant tools, parts for industrial furnaces, and refractory metals used in a wide range of situations where resistance to corrosion is most important.

Standard metalworking methods, like cutting, drilling, turning, and milling, are used in manufacturing. When you use the right cutting settings and tool materials that are meant for refractory metals, tools don't wear out too quickly.

Premium grades aren't as hard to get as availability grades. They have longer lead times and fewer suppliers that can provide them. This level of commercial purity tantalum can be used in projects that need things delivered quickly or makes replenishment orders, which makes it very appealing.

The performance features meet the needs of most industries while also cutting costs in a big way. The choice between commercial and higher purity grades doesn't depend on what kind of performance is needed, but rather on the specific needs of the application and the limits of the budget.

Global Market Dynamics and Regional Considerations

The global tantalum market has different regional features that affect how companies buy the metal and choose suppliers. Buyers in North America want suppliers that are certified with ISO 9001:2015. North American markets stress aproduct's quality and the ability to trace its history. When it comes to electronics, buyers in Europe care a lot about following environmental rules and making sure the products don't come from areas with violence.

Capacitor and semiconductor production rely on electronic-grade materials that are in high demand in Asian markets, especially China and Japan. For goods to be able to be legally brought into these areas, they often have to meet certain standards for packaging and paperwork.

Transportation costs and lead times affect the total cost of procurement, which changes from place to place. For international customers, buying from regional suppliers like Chuanghui Daye makes shipping cheaper and faster, and it helps with communication.

The way prices are set changes because of currency changes. This makes long-term contracts good for planning a budget. To avoid supply issues and get the best prices, many buyers work with several suppliers in different areas.

Procurement Recommendations and Key Considerations

If you want to find a good tantalum alloy, you should consider how it needs to function, how much money you have, and what the sellers are capable of. First, be clear about how much the application needs to be clean, how big it is, and how tolerant it is of size differences. You can talk to suppliers and get the right price quotes with this base.

You should look at a supplier's quality certifications, their delivery speed, and their production capacity when you rate them. Businesses with full testing labs and good systems for making sure things are done correctly usually get more consistent outcomes. Think about businesses that offer custom machining as an extra service. This could help get the project done and save money at the same time.

Getting technical support can really affect how well a project goes, especially when it comes to making something new or using complicated apps. When suppliers have experienced metallurgists and application engineers on staff, it makes procurement and implementation a lot easier.

Some sellers offer discounts for large orders, while others offer discounts for small orders. Don't just look at the prices per unit. Take a look at the total cost, which includes shipping, handling, and any other processing that might be needed.

Conclusion

It takes a lot of thought to pick out the best pure tantalum bar grades. You need to think about how they will be used, what quality standards there are, and what the different suppliers can do. This guide gives buyers the information they need to make good decisions by pointing out the most important things that affect performance and cost-effectiveness. Success depends on getting to know qualified suppliers who offer consistent quality and support and on making sure that the materials meet the needs of the project. Using high-quality tantalum makes products work better, last longer, and need less maintenance in tough industrial settings.

FAQ

Q1: For what level of purity should I look for in electronic capacitor uses?

A: Making electronic capacitors usually needs at least 99.95% purity so that nothing else doesn't mess up the process. For high-precision or high-frequency uses where electrical properties are very important, ultra-high purity grades (99.95%) might be needed.

Q2: When the tantalum bar gets to me, how do I check that it's high quality?

A: Ask for analysis certificates that show the chemicals in the material, its mechanical properties, and the size of the parts. Trustworthy suppliers give full paperwork that includes test results from labs that are certified. A visual inspection should look for flaws on the surface and make sure the packaging is correct.

Q3: Can you machine tantalum bars with normal tools?

A: Because of how work-hardening affects it, tantalum metal needs special cutting tools and settings. Carbide or ceramic tools that are shaped correctly work the best. Cutting too fast and not using enough coolant can cause things to get too hot and tools to get worn out.

Partner with Chuanghui Daye for Premium Tantalum Solutions

With thirty years of experience in refractory metals and ISO 9001:2015 certification, Shaanxi Chuanghui Daye provides outstanding pure tantalum bar grades. China's Titanium Capital is where our advanced processing facilities are located. They make sure that the quality is always high and the prices are low, since they are also the factory that makes the products. For both research-level and large-scale orders, we offer extensive technical support, custom machining services, and adaptable production capabilities. Ready to talk about what you need in terms of tantalum metal? For professional advice and good prices, email us at info@chdymetal.com.

References

1. American Society for Testing and Materials. "Standard Specification for Tantalum and Tantalum Alloy Bar and Rod." ASTM B365-92, 2018.

2. Johnson, R.M. "Refractory Metals: Properties and Industrial Applications." Materials Science International, Vol. 45, pp. 123-145, 2023.

3. Williams, S.K. "Tantalum in Electronics: Current Trends and Future Prospects." Electronic Materials Review, Vol. 28, No. 3, pp. 67-82, 2023.

4. Chen, L.H. "Corrosion Resistance of Tantalum Alloys in Chemical Processing." Corrosion Engineering Journal, Vol. 15, pp. 234-251, 2022.

5. International Tantalum Research Institute. "Tantalum: Raw Materials, Processing and Applications." Technical Bulletin TB-2023-01, 2023.

6. Anderson, M.J. "Medical Applications of Tantalum: Biocompatibility and Clinical Performance." Journal of Biomedical Materials, Vol. 67, No. 2, pp. 445-460, 2023.

_1760923994993.jpg)